-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Journal of Civil Engineering Research

p-ISSN: 2163-2316 e-ISSN: 2163-2340

2020; 10(3): 72-76

doi:10.5923/j.jce.20201003.03

Received: Nov. 16, 2020; Accepted: Dec. 14, 2020; Published: Dec. 26, 2020

Pavement-Management Maintenance System (PMMS) Using Geographic Information Systems (GISs) for Asphalt Pavemnt Roads

Farag Khodary1, Hamdan Naggar2

1Qena Faculty of Engineering South Valley University, Qena, Egypt

2Department of Geography and Gis, Faculty of Arts, South Valley University, Qena, Egypt

Correspondence to: Farag Khodary, Qena Faculty of Engineering South Valley University, Qena, Egypt.

| Email: |  |

Copyright © 2020 The Author(s). Published by Scientific & Academic Publishing.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

This research aimed to identify how road networks can be managed and maintained using geographic information systems to find the most cost-effective solutions. We produced a database containing road information and analysed the data to produce a model for road-maintenance management. Maintenance can improve the condition of roads and prolong their life. Therefore, a model need to be created and adopts specialized information about the condition of roads, which can then be used to determine the road maintenance process. A pavement-management maintenance system collects and monitors information on the current condition of roads, in addition to determining maintenance priorities. Such a system can also be designed to create a set of procedures aimed at maintaining asphalt roads with an appropriate level of service. In this research, a 35-kilometre stretch of governorate roads was used as the basis for the model. The aim of this study was to use geographic information systems (GISs) to create a database of the structural condition of roads and defects, capable of evaluating the need for maintenance work. A GIS database and PMMS model could be achieved by evaluating pavement-maintenance needs through performing an inventory and condition survey for roads and determining the most cost-effective actions for the roads based on their condition. The roads in question were found to require different types of maintenance, which were described according to the severity and extent of the asphalt pavement distress. About 30% of the agricultural road from Qena to Qift was found to be in need of maintenance action in the form of reconstruction.

Keywords: Asphalt Pavement, Maintenance system, Geographic information systems

Cite this paper: Farag Khodary, Hamdan Naggar, Pavement-Management Maintenance System (PMMS) Using Geographic Information Systems (GISs) for Asphalt Pavemnt Roads, Journal of Civil Engineering Research, Vol. 10 No. 3, 2020, pp. 72-76. doi: 10.5923/j.jce.20201003.03.

Article Outline

1. Introduction

- Repair and maintenance of roads can be problematic if they have a heavy traffic load and if disruption for long periods is to be avoided. This calls for a well-thought-out plan to divert traffic away from some streets, resurface these quickly and then reopen them to traffic. All streets inevitably need to be resurfaced at some point to avoid road users having to endure poor road conditions and to minimize damage to utility works (water lines, sewage and telephones), which are affected by road-surface quality. The Roads Directorate does not have the ability to coordinate with other agencies before starting resurfacing operations (or has sufficient authority to stop any maintenance operations affecting city street facilities), and there is competition between the devices and agencies responsible for carrying out different kinds of road works, which can result in some streets being dug up again immediately after they have been resurfaced. Therefore, it was necessary to find a way of rectifying such problems associated with road maintenance. The designed system provides relevant decision-makers with all the information they need about the condition of roads and the level of maintenance required, as well as the estimated cost of this maintenance. The Arizona asphalt road-maintenance management system was designed to be the best maintenance method. Under this system, maintenance is based on a mathematical model that studies the potential need for maintenance of an asphalt road. This calculation is then modified by maintenance decisions, taking into consideration available budgets and engineering decisions [1]. Modelling of asphalt road degradation is an important engineering process which includes improving investment allocations to rehabilitate asphalt roads in the road network. An optimized repair procedure was found for every potential collocating condition according to dynamic programming, and a series of responses to a sample of asphalt road-condition files was created [2–3]. An important aspect of asphalt preservation is the use of road maintenance to improve road function and delay the rate of deterioration. Preventive maintenance is less expensive than rebuilding a road. Road surfaces can be preserved by adopting maintenance systems to identify and prioritize preventive maintenance needs [4]. Geographic information systems (GISs) and a PAVER system were used in this study for the purpose of flexible pavement-distress classification and maintenance prioritization. The processes in this research have three elements of distress severity level, type and options for repair. The technique is based on a Pavement Condition Index (PCI), which helps maintenance decision-makers choose the best maintenance programme [5]. Maintenance has an important and integral role in the life cycle of asphalt roads. The pavement-maintenance management system (PMMS) is a systematic method of examination and classification of the condition of roads in the studied area. The maintenance-management system classifies every section of the road and enters this into the database. The next step is to analyse the data and convert the data into recommendations for maintenance items. The best maintenance method is then chosen in terms of cost and available budget [6]. The aim of this study was to understand the relationship between road condition and the frequency of accidents in order to develop a road-surfacing system that works to reduce accidents. From our analysis of the results, it was found that road defects such as ditching must be taken into account, as this is considered to be a key safety factor in places where rain accumulates, as well as the sites where maintenance takes place [7].

2. Pavement-Management Maintenance System (PMMS)

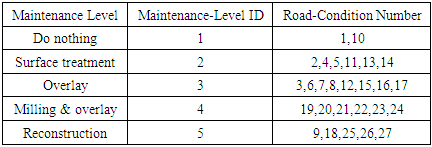

- There are three steps in this pavement-management system. The first one is inventory data, which are collected for each road segment, e.g., type, length, width, location, lane number and direction, in addition to maintenance history data, if available. Following the inventory survey, the condition of each segment should be rated using an automated survey procedure or using a visual inspection technique. Visual inspection is more popular and is widely used by many highway agencies. The condition rating for each segment is based on evaluation of the main distresses observed on the road, using three different condition levels (low, medium and high), considering both severity and extent. According to the Egyptian Code for Road Management, there are five levels of maintenance that can be applied, depending on the type and severity of defects in the roads in question: do nothing; surface treatment; overlay; milling and overlay; and reconstruction. There are three steps for building a pavement-management maintenance system (PMMS): conducting an inventory and condition survey, analysis and packing.

3. Inventory Data

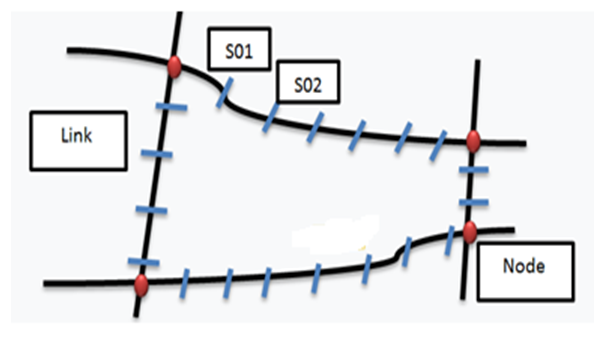

- In the inventory data and condition step, the longitudinal axis of roads is determined, and nodes are used to name the intersections of these axes. Nodes represent the geometric intersection point between two roads, and links are the portion between two successive nodes, as shown in Figure (1).

| Figure 1. Longitudinal axis of road links, nodes and segments |

4. Evaluation of Asphalt Concrete Pavement Distress (Condition Data)

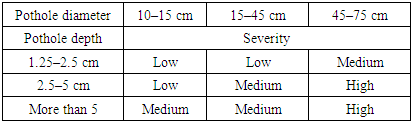

- Three main pavement distresses were evaluated in this research: fatigue cracks, rutting and potholes. Fatigue cracks occur in asphalt concrete as a result of repeated dynamic loads. These cracks begin under the asphalt surface where tensile stress and strain are high under the weight of tyres, and they then spread to the surface in the form of parallel longitudinal cracks. As a result of the effect of repeated movement loads, these cracks begin to spread in all directions in the form of sharp corners (similar to the skin of a crocodile); hence the name “crocodile cracks”. These cracks always occur in locations where the movement loads are frequent, especially in tyre tracks. Fatigue cracks reduce the life of roads and lead to collapse, making roads unusable. Among the factors affecting road efficiency are frequent loads and temperature changes [8–9]. The severity level of a crack, according to the Egyptian code for roads, can be classified as low (<1 cm), medium (1–2.5 cm) or high (<2.5 cm).Rutting is one of the main problems associated with roads, i.e., a drop in the longitudinal direction of the road and the formation of grooves. Rutting occurs as a result of increased loads, exceeding the design loads, an increase in the father’s ratio in the asphalt mix and lack of proper compaction of the soil. A rutting (permanent deformation) result from an increased volume of traffic and high tyre pressure and is one of the most common forms of distress in asphalt concrete roads [10]. The severity level of a crack, according to the Egyptian code for roads, can be Low (6–13 mm), medium (13–25 mm) or high (<25 mm). Potholes are a deformation of the road surface in the form of a basin, and they vary in depth, breadth and underlying cause. They are usually the result of water in the road soil structure and traffic passing over the affected area. Water affects the asphalt layer; traffic movement, in turn, affects the surface layer of the asphalt, and continuous traffic takes away all of the asphalt and road soil materials, creating a pit in the road that impedes traffic and may cause accidents. Identification of defects in asphalt roads is of great importance for determining the age of roads [11]. Table (1) presents evaluation values for potholes according to the Egyptian code for roads.

|

| Figure 2. Asphalt concrete pavement distress |

5. Road Condition (State)

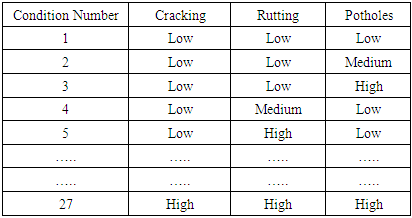

- In this study, we evaluated the condition of roads by analysing the three kinds of defects described earlier, as well as the extent of this distress (three levels, i.e., low, medium and high), so the road condition is 27 cases. Table (2) shows all expected cases of asphalt concrete pavement distress. Having ascertained the number indicating the condition of the road, this number can be linked with different maintenance levels.

|

|

6. Geographic Information Systems (GISs)

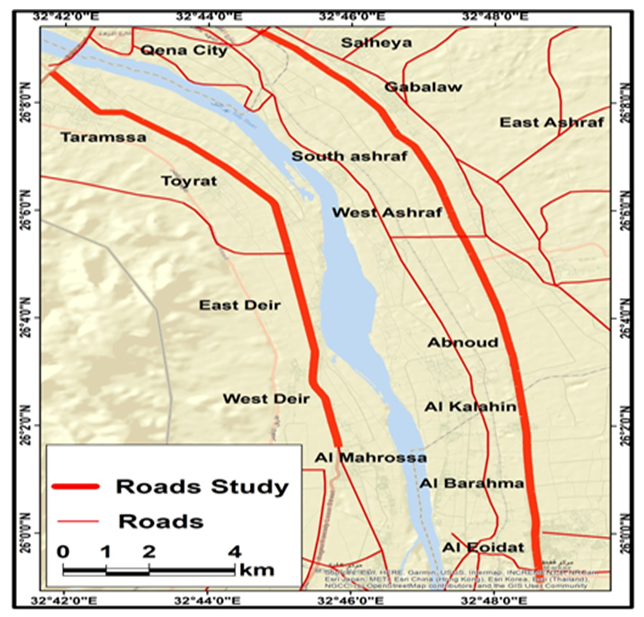

- Geographic information systems were used to help create an integrated system for maintenance. The study sample was located in the Arab Republic of Egypt, Qena Governorate, and it consisted of two roads, the first of which is the Qena to Qaft agricultural road east of the Nile, which extends between two circles of latitude 5″ 59-25°, 20″ 9-26° north, and between longitudes 38″ 48-32°, 42″ 44-32° east, extending from the south, from the Qaft–Qusayr road crossing point to the Al-Bayadiya crossing point in the north, for a distance of 21 km. The second of these two roads is the Qena to Al-Mahrousa agricultural road west of the Nile, which extends between two latitudes 36″ 1-26°, 33″ 8-26° N, and between longitudes 49-45 - 32°, 48″ 41-32° east, extending from the south, from the village of Mahrousa to the Dandara crossing point in the north, for a distance of 15.5 km. Figure (3) presents the roads in the studied area.

| Figure 3. Roads chosen for the study sample |

7. Results and Discussions

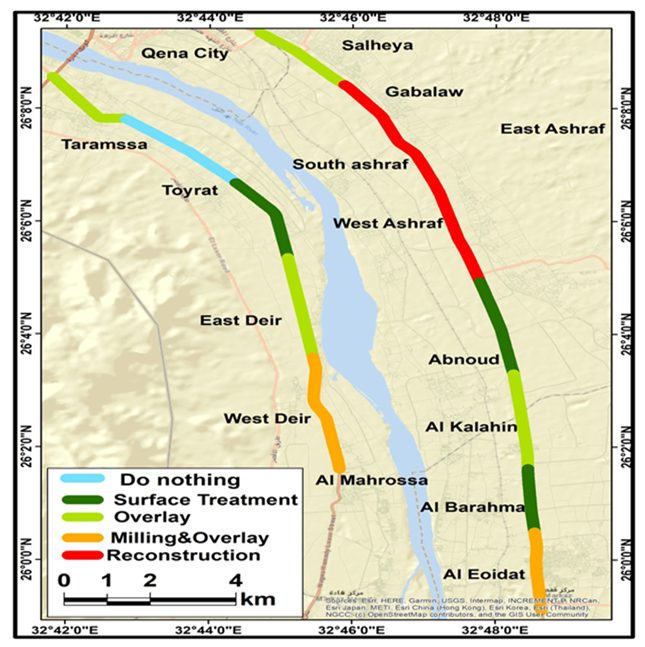

- Our data analysis revealed that the Qena–Qeft road needs five levels of maintenance, and the Qena–Al-Mahrousa road needs four levels of maintenance. Figure (4) presents the results of using GISs to present the final map and to determine the actual need for maintenance and the level of maintenance required. Having read this kind of map, decision-makers can determine the areas that need maintenance, and the extent of maintenance work required, and with the help of engineering maintenance experts, the costs of such maintenance can be calculated. Likewise, administrators can specify maintenance priorities, the appropriate methods to be used when immediate maintenance must be done, or cases that can be postponed.

| Figure 4. Final map and actual need for maintenance (and the level of maintenance required) |

8. Conclusions

- • The link established in this study between the road maintenance system and geographic information systems has enabled us to create a useful database that decision-makers can use when making recommendations about necessary action to be taken during selection of maintenance methods, based on the information obtained in this study.• Road owners need to update information on roads and road condition in order for decisions based on the results of the road maintenance system to yield accurate and efficient results and avoid unnecessary maintenance expenses.• Increased use of geographic information systems will help improve methods for managing owned assets such as public facilities and roads in particular.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML