-

Paper Information

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Journal of Civil Engineering Research

p-ISSN: 2163-2316 e-ISSN: 2163-2340

2020; 10(2): 47-52

doi:10.5923/j.jce.20201002.03

Received: Aug. 19, 2020; Accepted: Sep. 11, 2020; Published: Sep. 26, 2020

Comparative Study on the Compressive Strength of C-25 Concrete Cured by Water Curing and Self-Curing Methods; A Case Study in Assosa, Ethiopia

Miskir Gebrehiwot, Robi Diriba

Department of Civil Engineering, Assosa University, Assosa, Ethiopia

Correspondence to: Miskir Gebrehiwot, Department of Civil Engineering, Assosa University, Assosa, Ethiopia.

| Email: |  |

Copyright © 2020 The Author(s). Published by Scientific & Academic Publishing.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Construction industry involves the application of different construction materials and equipment that makes the industry to consume big capital budget. Concrete is one of the construction materials which is the composition of cement, coarse aggregate, fine aggregate and water. Among the production processes of concrete, curing is a vital process to give the concrete it’s final strength. To attain the required final strength of concrete suitable amount and quality of water should be applied. Curing usually conducted by application of enough water on the casted structure for the required days of curing. But the application of the usual watering method for the areas like Assosa town is very difficult since there is a high scarcity of water in the town. The main objective of this study is to compare the compressive strength of C25 concrete cured by water curing and shrinkage reducing admixture (Polyethylene glycol 4000). And specifically to determine the physical properties of ingredients used in mix designing process, to determine compressive strength of C25 concrete cured by water immersion (CCWI), cured by water sprinkling (CCWS) and cured by self-curing admixture (Polyethylene glycol 4000) (CCS) and finally to compare the curing capacity of CCWI, CCWS and CCS, C25 concretes based on the determined compressive strength results. Based on the 28th day mean compressive strength results, CCWI, CCWS and CCS samples attained 33.53Mpa, 28.8Mpa and 34.37Mpa compressive strength results respectively. According to the observed change in compressive strength from the 7th to 14th to 28th days of curing CCS samples shows higher increment in compressive strength than both CCWI and CCWS samples which indicates better curing capacity.

Keywords: Compressive strength, Curing, Polyethylene glycol 4000, Properties of ingredients

Cite this paper: Miskir Gebrehiwot, Robi Diriba, Comparative Study on the Compressive Strength of C-25 Concrete Cured by Water Curing and Self-Curing Methods; A Case Study in Assosa, Ethiopia, Journal of Civil Engineering Research, Vol. 10 No. 2, 2020, pp. 47-52. doi: 10.5923/j.jce.20201002.03.

Article Outline

1. Introduction

- Curing is the name given to the process used for promoting the hydration of the cement. It controls temperature and moisture movement from and into the concrete. Curing allows continuous hydration and strength gain. Once curing stops strength gain of the concrete also stops. Proper moisture conditions are critical because the hydration of the cement virtually ceases when the relative humidity within the capillaries drops below 80% (ACI, 2009). If the water applied for curing is insufficient, the hydration in the cement paste will not proceed and the resulting concrete may not possess the desired strength and impermeability. Additionally, durability problem may arise due to the entrance of deleterious agents caused by the continuous pore structure formed on the near surface. More over due to early drying, micro-cracks or shrinkage cracks would develop on the surface of the concrete (C. Selvamony et al., 2010). Application of Unclean water for curing results quality problems on the concrete. Suitable Water for making concrete should also be used for curing purpose. Waters containing impurities that leading to stains is intolerable. When concrete is subjected to prolonged wetting, even a very low concentration of iron and organic matter may cause staining (S.K. Duggale, 2008).Since there is a higher scarcity of water in Assosa town, application of clean water for curing will be difficult. So to overcome this problem another alternative method of curing should be applied. These study focused on Self -curing concrete by the application of shrinkage reducing admixtures. Self –curing is very important from the point of view that saving of water is a necessity every day. One cubic meter of concrete requires 3m3 of water in construction and most of which is used for curing (Dayalan j and Buellah, 2014).The general objective of this study is to compare the compressive strength of C25 concrete by applying water curing and shrinkage reducing admixture (Polyethylene glycol 4000) curing. The specific objectives of this study are to determine the physical properties of concrete ingredients, to determine compressive strength of both watering and admixture cured C25 concretes and to compare curing capacity of both water cured and admixture cured C25 concretes at different ages of curing.

1.1. Curing of Concrete

- The rate and extent of moisture loss from concrete during cement hydration is controlled by curing. The hydration of cement take time, days, and even weeks rather than hours.There are two major methods of internal curing currently available. The first method uses saturated porous lightweight aggregate (LWA) in order to supply an internal source of water, which can replace the water consumed by chemical shrinkage during cement hydration. The second method uses poly-ethylene glycol (PEG) which reduces the evaporation of water from the surface of concrete and also helps in water retention. Self-Curing concrete is the newly emerging trend in the construction industry (Patel Manish Kumar, 2014). To achieve potential strength and durability requirements of the concrete, curing must be undertaken for a reasonable period of time. The cement hydration also controlled by curing. The curing period may depend on the properties of concrete, the purpose for which it is to be used, and the ambient conditions of the surrounding atmosphere. Curing is designed primarily to keep the concrete moist, by preventing the loss of moisture from the concrete during the period in which it is gaining strength. Curing may be applied in a number of ways and the most appropriate means of curing may be dictated by the site or the construction method (Bentiz D., 2002).One of the modern concrete type immerged is self-curing concrete. Self-curing concrete cures itself by retaining water (moisture). Self-curing or internal curing is technique that can be used to provide additional moisture in concrete for more effective hydration of cement and reduced self- dehydration (Patel Manish Kumar, 2014).Polyethylene glycol is a condensation polymer of ethylene oxide and water with general formula H(OCH2CH2)nOH where “n" is the average number of repeating Oxethylene groups typically from 4 to about 180. The abbreviation (PEG) is termed in combination with a numeric suffix which indicates the average molecular weights. One common feature of PEG appears to be the water-soluble nature. Polyethylene glycol is non-toxic, odourless, neutral, and lubricating (M.V. Jagannadha et al., 2012).Polyethylene glycols (PEGs) are family of water soluble linear polymers formed by the additional reaction of Ethylene oxide (EO) with Mono ethylene glycol (MEG) or Diethylene glycol. Though the increase in strengths were very small, it was observed that PEG involves complete internal curing of the concrete and helps to achieve a strength very nearer to the full strength of conventional reference mix (SR. Thiruchelve et al., 2017). Babitha Rani, et al., (2017) on their study on self-curing concrete with the addition of polyethylene glycol -4000, concluded that that PEG 4000 help in self-curing by giving strength on par with conventional curing. It was also found that 1% of PEG 4000 by weight of cement was optimum for M20 grade concretes for achieving maximum strength without compromising workability.The mechanism of self-curing can be explained that, the polymer added in the mix mainly form hydrogen bonds with water molecules and reduce the chemical potential of the molecules which in turn reduces the vapour pressure. This reduces the rate of evaporation from the surface. (N. Gowripalan et. al. 2001).

1.2. Types of Concrete Curing

1.2.1. Dry Air Curing

- Dry curing is a curing of concrete cubes by letting them to cure at room temperature in open air. Dry-air curing produced 15.2% in compressive strength, 6.59% in dynamic modulus of elasticity and 3.36% in ultrasonic pulse velocity reduction. This results early drying of concrete which virtually ceased hydration of the cement which resulted due to the relative humidity within capillaries dropped below 80%. Also, it caused 12.4% and 46.53% increase in initial surface absorption after 10 and 120 minutes respectively. This might be due to micro cracks or shrinkage cracks resulting from the early drying out of the concrete. Experimental results indicate that Dry-curing is not an efficient method to achieve good hardened properties of concrete (Fauzi, 1995).

1.2.2. Water Curing

- Water curing is carried out by supplying water to the surface of concrete to keep it moist. The water used for this purpose should not be more than about 5°C cooler than the concrete surface. Spraying warm concrete with cold water may give rise to ‘thermal shock’ that may cause or contribute to cracking. Alternate wetting and drying of the concrete must also be avoided as this causes volume changes that may also contribute to surface crazing and cracking (Nirav R., 2013).

1.2.3. Wet Coverings

- Wet coverings curing is done by Fabrics such as hessian, or materials such as sand, to maintain water on the surface of the concrete. On flat areas, fabrics may need to be weighed down. Wet coverings should be placed as soon as the concrete has hardened sufficiently to prevent surface damage. They should not be allowed to dry out as they can act as a wick and effectively draw water out of the concrete. Fabrics may be particularly useful on vertical surfaces since they help distribute water evenly over the surface and even where not in contact with it, will reduce the rate of surface evaporation (Md. Safuddin et al., 1991).

1.2.4. Membrane-Forming Curing Compounds

- These method of curing processed by retarding or reducing moisture from concrete by applying Liquid membrane forming -forming compounds consisting of waxes, resins, chlorinated rubber, and other materials. They are the most practical and most widely used method for curing not only freshly placed concrete but also for extending curing of concrete after removal of forms or after initial moist curing. Curing compounds should be able to maintain the relative humidity of the concrete surface above 80% for seven days to sustain cement hydration (NirR., 2013).

1.2.5. Internal Moist Curing

- Internal moist curing refers to methods of curing by providing moisture within the concrete as opposed to outside the concrete. This water should not affect the initial water to cement ratio of the fresh concrete. Lightweight (low-density) fine aggregate or absorbent polymer particles with an ability to retain a significant amount of water may provide additional moisture for concretes prone to self-desiccation. (Nirav R., 2013).Internal curing (IC) is a method to provide the water to hydrate all the cement, accomplishing what the mixing water alone cannot do. It Provides water to keep the relative humidity (RH) high, keeping self-desiccation from occurring. And also self-curing method eliminates largely autogenous shrinkage and Maintains the strengths of mortar/concrete at the early age (12 to 72 hrs.) above the level where internally & externally induced strains can cause cracking. It Can make up for some of the deficiencies of external curing, both human related (critical period when curing is required in the first 12 to 72 hours) and hydration. (M.V. Jagannadha et al., 2012).

2. Materials and Methods

2.1. Types of Concrete Curing

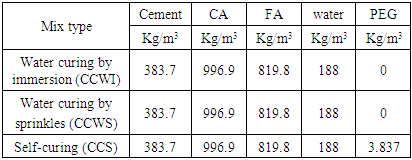

- The materials used in this study are cement, coarse aggregate, fine aggregate, water and self -curing Admixture (Polyethylene glycol 4000). The selection of self-curing admixture was based on its availability in the market. The sources of materials used in this study are; Ø Dangote OPC cement 42.5 -from marketØ Coarse aggregate- from Benshangul Gumuz region Ø Fine aggregate - from Benshangul Gumuz region Ø Water- from tap water system and Ø Self-curing admixture (polyethylene glycol 4000)- from market

2.2. Sampling Techniques and Sample Size

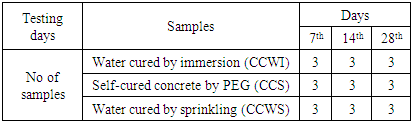

- Selection of samples for this study was purposive sample selection. For the determination of the properties of the ingredients, the amount of materials was taken as per the requirements of the test methods. For compressive strength test of C25 concrete 3 cubes for each testing days (7days, 14 days and 28 days) was casted for CCWI, CCWS and CCS concrete types as per the mix design determined before. CCWI stands for concrete cured by water immersion method for 7, 14 and 28 consecutive days. CCWS is concrete sample refers to concrete cured by water sprinkling for 7, 14 and 28 consecutive days. Method of curing applied for this sample were by using sprinkling of water twice a day. These method of curing is the usual method applied on different building constructions in the study area. CCS stands for concrete cured by PEG-4000.

|

|

2.3. Data Analysis

- Primary data for this study was collected form the results of laboratory experiments. Properties of ingredient that affect the mix design of the concrete were determined in BDU construction materials laboratory. The collected data was analysed by comparing the results with ASTM standard to insure the suitability of the materials. Compressive strength test results were also collected from laboratory. For the three (CCWI, CCWS and CCS) samples a total of 27 cubes were tested. The data obtained was analysed by comparing the average compressive strength result of each sample for 7th, 14th and 28th days of curing and the result is presented by charts and tables.

3. Result and Discussion

- The general objective of this study is to compare the compressive strength of C-25 concrete cured by water curing and self-curing methods. Specifically, this study was also aimed to determine the physical properties of concrete ingredients, to determine the compressive strength of water cured and self- cured C-25 concrete and finally to compare the curing capacity of both types of concretes.

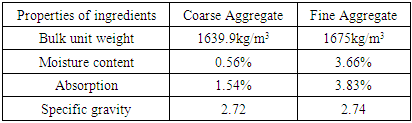

3.1. Properties of Ingredients

- The result of the physical properties of ingredients determined in this study were summarized on the Table 3 below.

|

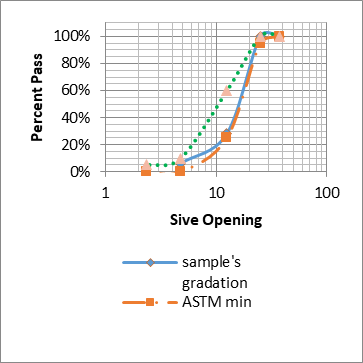

| Figure 1. Gradation curve for coarse aggregate |

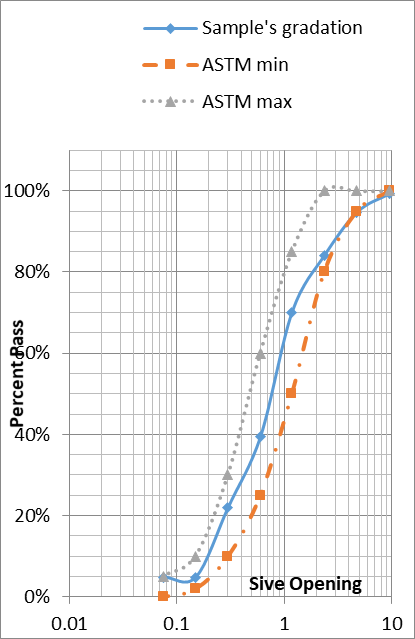

| Figure 2. Gradation curve for fine aggregate |

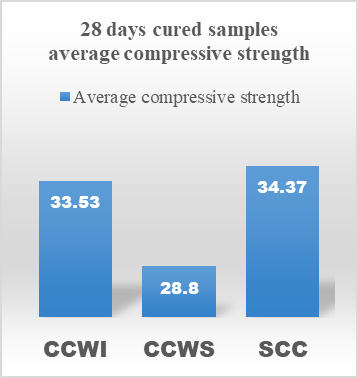

3.2. Compressive Strength Results

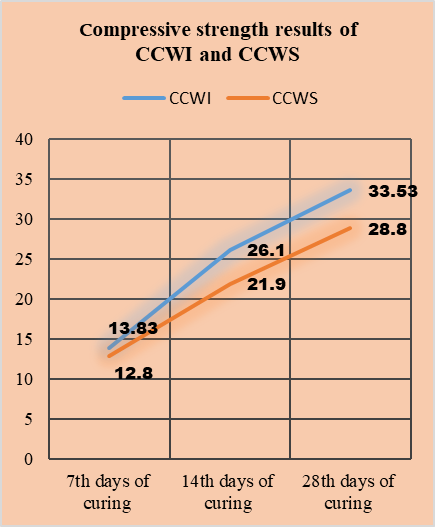

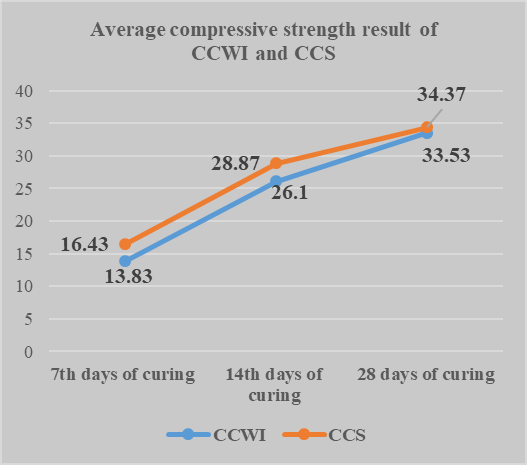

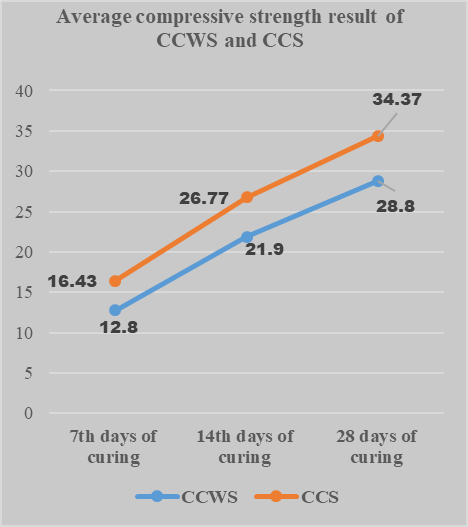

- The average compressive strength test results of CCWI at the 7th, 14th and 28th days of curing were 13.83Mpa, 26.1Mpa and 33.53Mpa respectively.The average compressive strength test results of CCWS at the 7th, 14th and 28th days of curing were 12.8Mpa, 21.9Mpa and 28.8Mpa respectively. The average compressive strength test results CCS at the 7th, 14th and 28th days of curing were 16.4Mpa, 28.87Mpa and 34.37Mpa respectively.

| Figure 3. Average 28th day compressive strength results |

3.3. Curing Capacity

- As it is illustrated on Figure 4. the compressive strength results of CCWI samples attained better compressive strength at all ages of curing than the CCWS concrete samples. This indicates that the conventional method of curing which is curing by immersion process is better for laboratory testing of samples. The average compressive strength value of CCWI increased by 12.27Mpa from the 7th days of curing to the 14th days of curing. Whereas the average compressive strength of CCWS sample increased by 9.1Mpa. This indicates that from the 7th to 14th days of curing days the concrete samples cured by immersion shows better curing capacity than the samples cured by water sprinkling method. The average compressive strength of CCWI concrete samples compressive strength value increased by 7.43Mpa from 14th to 28th days of curing. Whereas for the CCWS concrete samples it increased by 6.9Mpa. This also indicates that from the 14th to 28th days of curing the concrete samples cured by immersion shows better curing capacity than the samples cured by water sprinkling method.

| Figure 4. Average compressive strength results of CCWI and CCWS |

| Figure 5. Average compressive strength results of CCWI and CCS |

| Figure 6. Average compressive strength results of CCWS and CCS samples at different ages of curing |

4. Conclusions

- Ø The compressive strength of self-curing concrete samples cured by polyethylene glycol (PEG 4000) admixture (SCC) was better at all ages of curing than the concrete samples cured by water immersion (CCWI) and water sprinkling(CCWS) methods. Ø The compressive strength of concrete samples cured by water immersion method (CCWI) has attained better compressive strength than the samples cured by sprinkling method applied twice a day (CCWS). Ø The 28th day mean compressive strength results are 33.53Mpa, 28.8Mpa and 34.37Mpa for CCWI, CCWS and CCS concrete samples respectively. Ø According to the ACI mix design procedure the minimum 28th mean compressive strength required for C-25 concrete is 33.33Mpa. Therefore, CCS and CCWI concrete samples of this study has fulfil the minimum compressive strength requirement but the CCWS samples doesn’t attain minimum compressive strength requirement.Ø Based on the change in compressive strength from the 7th to 14th to 28th days of curing CCS samples shows higher increment of compressive strength than both CCWI and CCWS.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML