Hosiana Urio, Benson Rugalema Mwemezi

Department Civil Engineering, Ardhi University, Dar es Salaam, Tanzania

Correspondence to: Benson Rugalema Mwemezi, Department Civil Engineering, Ardhi University, Dar es Salaam, Tanzania.

| Email: |  |

Copyright © 2018 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Abstract

The study was undertaken to investigate the suitability of stabilized volcanic pumice from Mbalizi, Mbeya for construction of light-weight roads. Pumice in Mbeya region are found abundantly and they are not used as road construction material due to their low strength. Preliminary observations indicate that pumice has above average strength and bearing capacity characteristics when used as a wearing course for high traffic volume roads. Determining economical methods of improving the properties of pumice for use as a surface course for light-weight roads would be beneficial to Mbeya region. Test sample of 100Kg was selected purposively from Mbalizi, Mbeya region and sampled for laboratory testing. Laboratory test done included Moisture content test, Sieve analysis, Compact test, Atterbergs' limit test and Compressive strength test. All tests were done according to the laboratory specifications provided by laboratory testing manual and the results obtained were compared with the specifications provided by design manual. Pumice properties such as bulk density, dry density, optimum moisture content, fines modulus and gradation were determined. Thereafter Unconfined Compressive Strength (UCS) cubes of pumice with different percent of stabilizers were casted and tested after three days and seven days of curing. Stabilizers used in stabilizing pumice were cement and lime at different ratios as specified in laboratory testing manual. The first cubes prepared were of 2%, 4%, and 6% of cement stabilizer. The second cubes prepared were of 2%, 4% and 6% of lime stabilizer. The resulting concrete cubes were tested at three and seven days. All tested cubes of both cement and lime showed positive results in compressive strength aspects. Both three and seven days old cubes posted best compressive strength results for 2%, 4% and 6% of cement and lime stabilizer. From the results achieved from concrete cubes shows that the stabilized pumice is suitable to be used in construction of light-weight roads. The recommended mixture to be used in construction of light-weight roads should be of 2% - 4% Pozzolana cement, and 2.5% - 3% lime in the mixture with pumice. Pumice materials should be used for construction of road in order to save other material consumption to reduce land degradation in the view of the availability of pumice materials in Mbeya region.

Keywords:

Suitability, Stabilized Pumice, Light Weight Road Construction, Mbalizi, Tanzania

Cite this paper: Hosiana Urio, Benson Rugalema Mwemezi, Suitability of Stabilized Pumice for Light-Weight Road Construction: A Case of Mbalizi, Mbeya - Tanzania, Journal of Civil Engineering Research, Vol. 8 No. 2, 2018, pp. 21-26. doi: 10.5923/j.jce.20180802.01.

1. Introduction

Pozzolanas are materials which in presence of lime can produce cementations materials. They are obtained as a result of volcanic eruptions as hot ashes containing specific elements. This happens when they are thrown into the air and eventually cool and fall on the ground forming deep layer in loose form. Pozzolanas occur in three different forms; pozzolana ash, pozzolana pumice and pozzolana tuffs [1, 12].Pumice is a light-colored, light-weight igneous rock with cellular (porous) structure. When the erupted hot ashes are exposed to the process of rapid cooling while its mass is expanding under pressure of intensively evolving gases, the ashes turn into swollen lumps of magma forming a glassy porous rock which is known as pumice [2]. Pumice commonly has a rhyolitic (siliceous) composition but may have a rhyodacitic composition with increasing sodium content [3]. Pumice is the only rock that floats on water, although it will eventually become waterlogged and sink. It is usually light-colored, indicating that it is a volcanic rock high in silica content and low in iron and magnesium. Moreover, Pumice consists of fine grain or ash.Worldwide more than 50 countries produce pumice and related products Volcanic ash in large amount. Italy is the largest producer, and other major countries are Chile, Canada, Spain, Turkey, and the United states [1]. In Africa natural pozzolanas are present in 6 countries. These are, Burundi, Cape Verde, Ethiopia, Rwanda and Tanzania [4]. In Tanzania, accurate statistical data is hard to be found but information has indicated that there are many stones of pumice/volcanic ash/scoria of approximate 1 billion tons that are accessible in the country [1].In Tanzania pumice can be found in areas of previous volcanic eruptions such as Kilimanjaro region around Mount Kilimanjaro, Arusha region around mount Meru, Mbeya and Songwe regions around Rungwe mountains [1].A lightweight traffic road is considered as a road that has relatively low use (an Average Daily Traffic of less than 400 vehicles per day), low design speeds (typically less than 80kph), which is used by vehicles of less than 13 tons and corresponding geometry [5]. Most roads in rural areas are light weight roads. A well planned, located, designed, constructed, and maintained low-volume road system is essential for community development, flow of goods and services between communities, and resource management activities. However, roads, and particularly road construction, can create more soil erosion than most other activities that occur in rural areas.

1.1. Distributions of Pumices in Mbeya Region

According to [6, 7], Rungwe Pumice (RP) deposit from Rungwe Volcano in South-Western Tanzania is the first Plinian-style deposit from an African volcano to be closely documented focusing on its physical characterization. The RP is a mostly massive fall deposit with an inversely graded base. Empirical models suggest a maximum eruption column height HT of 30.5–35 km with an associated peak mass discharge rate of 2.8–4.8 × 108 kg/s. Analytical calculations result in HT values of 33 ± 4 km (inversion of TEPHRA2 model on grain size data) corresponding to mass discharge ranging from 2.3 to 6.0 × 108 kg/s. Lake-core data allow extrapolation of the deposit thinning trend far beyond on land exposures. Empirical fitting of thickness data yields volume estimates between 3.2 and 5.8 km3 (corresponding to an erupted mass of 1.1–2.0 × 1012 kg), whereas analytical derivation yields an erupted mass of 1.1 × 1012 kg. The plume corner is estimated to have been ca. 11–12 km from the vent. After an opening phase with gradually increasing intensity, a high discharge rate was maintained throughout the eruption, without fountain collapse as is evidenced by a lack of pyroclastic density current deposition in Mbeya region [6, 7].

1.2. Lightweight Traffic Roads

The lightweight traffic roads are considered as a road that has relatively low use (an Average Daily Traffic of less than 400 vehicles per day), low design speeds (typically less than 80kph), and corresponding geometry [8]. Most roads in rural areas are low-volume roads. A well planned, located, designed, constructed, and maintained low-volume road system is essential for community development, flow of goods and services between communities, and resource management activities. However, roads and particularly road construction, can create more soil erosion than most other activities that occur in rural areas. Proper planning and design of the road system normally minimize adverse impacts to the environment. Poorly planned road systems can have high maintenance and repair costs, contribute to excessive erosion, and fail to meet the needs of the users.

1.3. Pumice Stabilization

Modifying pumice or soil properties by adding another material to improve its durability is called soil stabilization. Soil stabilization has been used widely since the 1920s mainly for road construction. When a soil is successfully stabilized one or more of the following effects will be evident. Ÿ Strength and cohesion of the soil will increase, Ÿ Permeability of the soil will be reduced, Ÿ The soil will be made water repellent,Ÿ The durability of the soil will increaseŸ The soil will shrink and expand less in dry and wet conditions.

2. Rationale of the Study

There has been serious land degradation in Tanzania due to extensive exploitation of granite aggregates even in areas where there is plenty of natural lightweight aggregates (pumice). This is due to the fact that most consultants and contractors in Tanzania have resorted to use normal weight aggregates in construction because of the feeling that pumice are too week in construction project [9]. Mbeya is one of the regions where pumice materials are found abundantly and yet it is suffering from such problems. There is also a problem of suitable road construction materials in areas where pumice is found. Therefore, proper analysis and evaluation for the suitability of pumice materials for lightweight traffic road construction is required. The knowledge of pumice in Mbeya is inadequately disseminated and the existing specifications, test methods and pavement design are not always suitable for new unknown materials. Also existing test methods standardized for unbound road materials are indirect and test particles instead of the whole composite material. The methods are developed for conventional materials, such as gravel and crushed rock, and do not allow a fair comparison to be made between conventional materials and alternative materials, such as different kinds of pumices. Performance-based design needs methods that can evaluate the performance, both in advance and after construction. To reduce problems of land degradation and problem of suitable construction materials in Mbeya region it is necessary to find the proper analysis and evaluation for the suitability of pumice materials for light weight traffic road construction.

3. Methodology

3.1. Research and Sampling Designs

In this study, a case study method and experimental design were employed thorough out. Mbalizi area in Mbeya region was selected purposively. Site investigation involved observation of soils along the proposed sampling section. Sampling of the pumice materials from Mbalizi was done purposively. The excavation of twenty open pits for pumice sampling was done purposively, in each pit 5kg of pumice materials were taken totaling to 100kg sample [10].

3.2. Data Collection Methods

The research approaches for this study were both qualitative and quantitative approaches for collection of primary and secondary data. In this study, secondary data were collected through books, journal articles, periodicals, previous dissertations and professional report. While primary data were obtained from the laboratory tests of the pumice materials from Mbalizi. The laboratory tests conducted are as follows:-a) Moisture content TestMoisture content of the soil is assumed to be the amount of the water within the pore space between the soil grains which is removable by the oven drying at a temperature not exceeding 110°C [11]. The aim of this test in this study was to determine the amount of water present in pumice material.b) Compaction testCompaction tests aims at establishing the relationship between compacted dry density and soil moisture content [11]. It is also known as proctor tests divided in two parts namely; ο Heavy compaction which uses a 4.5kg rammer (modified proctor) and ο A light compaction which uses a 2.5kg rammer (standard proctor). In this research heavy compaction test (4.5kg rammer) was used. The aim of this test was to obtain maximum dry density of the pumice for light-weight road construction.c) Atterbergs’ limit testsThis is the general term for the tests which includes the following tests:ο Liquid limit (LL) this is the empirically established moisture content at which the soil passes from the liquid state to plastic state. It provides means of identifying fine grained cohesive soils and its variation of moisture content in a soil may have significant effects in its shear strength especially on fine grained soil. This was done at the laboratory by using cone penetrometer method.ο Plastic limit (PL) this is the empirically established moisture content at which the soil becomes too dry to be plastic. It is used together with liquid limit to determine plasticity index, which provides the means of classifying cohesive soils. The plasticity index was obtained from the difference between the liquid limit and plastic limit of the soil (PI = LL – PL).d) Grain / particle size distribution (Sieve analysis)It is basically for soil classification especially the course soils. It presents the relative portion of different sizes in the soils which provides the means of determining whether the soil consists of predominantly gravel, silt, sand or clay sizes and to a limited extent, which of these size ranges is likely to control the engineering properties of soils [11].e) Compression Strength test (UCS)In this method the unconfined compression strength of stabilize materials is determined by subjecting prepared specimens (mixed, compacted and cured) to an increased load until failure. The unconfined compressive strength (UCS) of a stabilized material is the load in KN/m2 (KPa) required to crush a cylindrical specimen of 127mm high and 152.4mm in diameter to total failure at a rate of application of load of 140KN/m2 per second (KPa/sec) [11]. This test was performed for the purpose of determining compressive strength of the pumice materials from Mbalizi.

3.3. Data Analysis

This is a process of examining data that has been collected in survey or experiment and making deduction or inference [10]. All field and laboratory determinations were done according to standard methods for the examination of pumice material. The focus of the analysis is on the findings of particle size analysis, physical characteristics, density measurement and compressive strength measurement of blended pumice with cement and lime to meet the standards specification in order to be used in light-weight road construction.

4. Results and Discussions

4.1. Material Preparation

Before conducting the material test, the pumice was first sieved to 20mm sieve and only the material passing on that sieve was used on carrying out material tests. Each sample to be used was prepared on its respective manner such as required mass on each test.

4.2. Sampling of Pumice

In order to accomplish the laboratory procedures, the excavation of open pit for sampling was done at mbalizi site. A total of 100kg of pumice sample was collected from Mbalizi site in Mbeya region. It was then transported to Dar es salaam via a bus.The pumice was then taken to the laboratory ready for testing. It was air-dried for 24 hours then sieved to remove materials retained on 20mm sieve for the preparation of laboratory tests. The pumice was spread into round shape and the divided into four quarters using a spade. Two opposite quarters were then selected to be used as sample. The aim was to obtain equal distribution of the pumice material.

4.3. Pumice Material Testing

4.3.1. Sieve Analysis

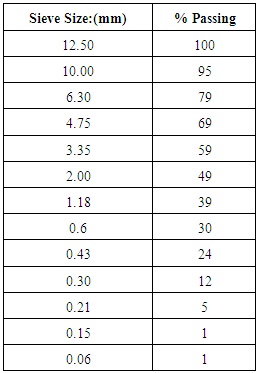

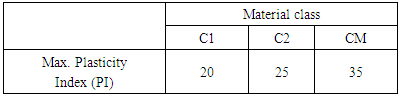

Before conducting test, the material was sieved so as to assess its particle size distribution. The standard sieves for aggregates were used. Standard sieves for aggregate used are 12.5mm, 10mm, 6.3mm, 4.75mm, 3.35mm, 2.0mm, 1.18mm, 0.6mm, 0.425mm, 0.3mm, 0.212mm, 0.150mm and 0.063mm.The sieves were arranged in ascending order with the largest at the top and the smallest at the bottom and kept to sieve shaker for some time. Then mass retained on each sieve was measured and the percentage passing material was then calculated.Table 1. Sieve analysis results -Source: Field work

|

| |

|

From Table 1 the results achieved shows that the particle size distribution of the pumice from Mbalizi possess little quantity of fines. Therefore, pumice from Mbalizi is classified as well graded sand (SW), classified as A-2-4. The classification is done as per AASHTO.

4.3.2. Moisture Content

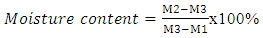

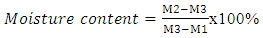

Moisture content of the soil is the amount of the water within the pore space between the soil grains [11]. To obtain the moisture content of the pumice the moisture content test was conducted. On this test the moisture content of blended sample was obtained by drying wet sample to an oven at a temperature of 110°C for 12 hours. The mass of the sample before drying and after drying was recorded. The following formula was used to calculate the moisture content of the sample; | (1) |

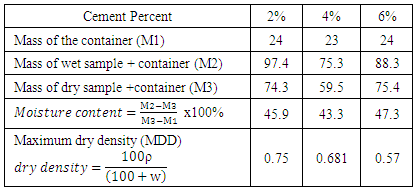

Where,M1=is the mass of empty container M2=is the mass of container and wet soil M3=is the mass of container and dry soilThe results for moisture content and dry density obtained are shown on the table 2 and 3.Table 2. Moisture Content and Dry Density Results for Cement stabilizer- Source: Field work: June, 2017

|

| |

|

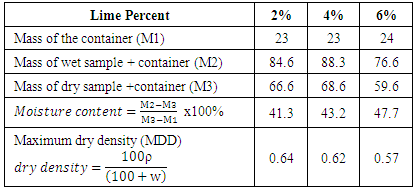

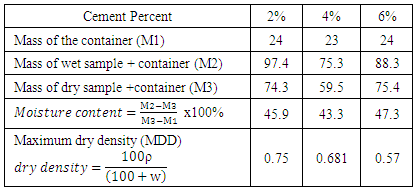

Table 3. Moisture Content and Dry Density Results for Lime stabilizer- Source: Field work: June, 2017

|

| |

|

Optimum moisture content and maximum dry density of stabilized pumice are satisfactory as compared from design manual.

4.3.3. Compaction Test

Compaction test was conducted which aims at establishing the relationship between compacted dry density and soil moisture content. It is also known as proctor tests divided in two parts namely, heavy compaction which uses a 4.5kg rammer (modified proctor) and light compaction which uses a 2.5kg rammer (standard proctor). In this project heavy compaction test (4.5kg rammer) was used. Test procedures. a) Six samples of 3kg each passing 20mm sieve was measured. Three sample was blended with cement (2%, 4% and 6%) and the other three samples was blended with lime (2%, 4%, 6%).b) Water was added to each blended sample then compacted with 4.5kg rammer in a proctor mould, compacting three layers with 27 blows on each layer.c) Mass of the mould and the sample was recorded until when the mass drop, taking moisture of each sample.The maximum dry density of the pumice for light-weight road construction are as shown in table 2-3 which are satisfactory.

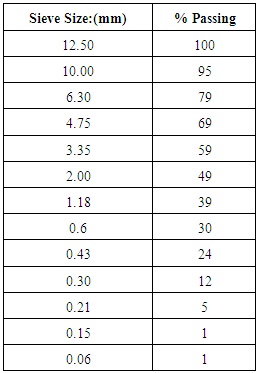

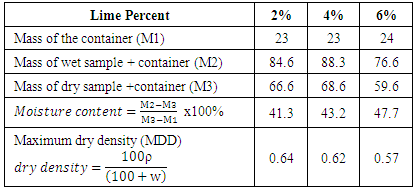

4.3.4. Atterbergs’ Limit

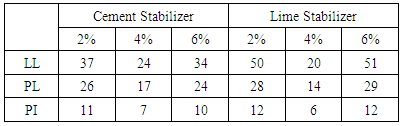

This is the general term for the tests which includes the following testsa) Liquid limit (LL) The soil passes from the liquid state to plastic state at this empirically established moisture content. This was done at the laboratory by using cone penetrometer method. Cone penetrometer test is the preferable method to the casagrande test as it is essentially static test depending on soil shear strength. This method covers the determination of a sample in its natural state or a sample from which materials retain on 425μm test sieves has been removed it is based on the measurement of penetration into the soil of a standardize cone. The liquid limit of the soil sample is the moisture content corresponding to the penetration of 20mm and was express to the nearly whole number.b) Plastic limit (PL)This is the empirically established moisture content at which the soil becomes too dry to be plastic. It is used together with liquid limit to determine plasticity index, which provides the means of classifying cohesive soils. Plasticity of the blended material was obtained by preparing pumice samples which having 140mm length and was dried to an oven for 24 hours then its new length was measured after shrinkage. c) Plasticity index (PI) Plasticity index was obtained by taking the difference between the liquid limit and plastic limit of the soil. It is the ranger of moisture content in which the soil is plastic where by the finer the soil the greater the plasticity index. Mathematically plasticity index can be obtained by using the following formula; PI = LL – PLWhere,PI-is the plasticity indexLL-is the liquid limitPL-is the plasticity limitTable 4. Plasticity Index Results after blending of pumice-Source; Field work: June, 2017

|

| |

|

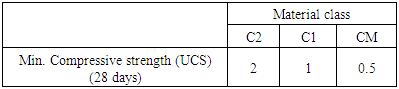

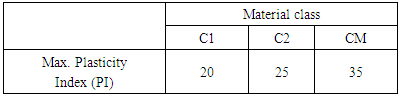

Table 5. Standard requirement of Plasticity Index- Source: [5]

|

| |

|

Table 4 shows the results of plasticity index obtained after blending with lime and cement, and table 5 shows the results extracted from [5], which recommends the required maximum plasticity index for each class. From comparison between the two tables above; it can be confidently stated that plasticity index of stabilized pumice is within the recommended results for all classes.

4.3.5. Compressive Strength Tests

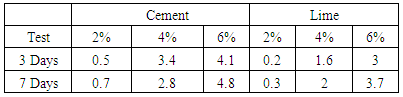

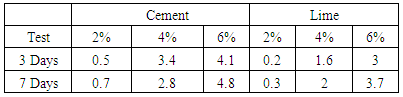

This was the key test on checking the suitability and strength of the Pumice material on pavement construction. The achieved results were positive compared with the one stated in the AASHTO standards and [5], BS 5628 PART I, 1978. For use of compressive strength, the strength obtained on 7days can be used to identify the strength expected to be obtained on 28 days, where by the strength on 7days are approximately to be 2/3 of the strength on 28 days. Now the results obtained from the findings some of them meet the requirement and few of them did not meet the requirements and this is due to poor workmanship and experience on preparation of cubes.Mortar cubes of size 100mm x 100mm x 100mm were casted and cured for 7 days and 3 days before crushing them. The curing method used was to immerse the cubes in the container of water. Curing of cubes made of individually appeared to fail and this is because the process of hydration takes place especially when lime reacts with water. Therefore, the remedial to that was to put the casted cubes into the plastic bags and then putting the bags into water container ensuring no water penetrated through the plastic bag.When crushing cubes, the failure plane and shape was considered to see if the material has been achieved the test. During the crushing of mortar cubes of different ratios, it appeared that most of the cubes have been achieved depending on their failure plane and the ones stated in [11]. Table 6. Compressive Results of blended pumice (MPa)- Source; Field work: June, 2017

|

| |

|

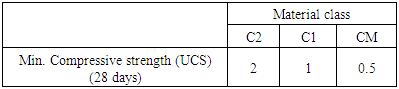

Table 7. Required Compressive Strength (MPa)- Source: [5]

|

| |

|

Table 6 shows the results of stabilized pumice with lime and cement, table shows the results obtained after stabilization of pumice, table 7 shows the required minimum strength as stated on [5].Therefore, it can be concluded that; stabilized pumice with lime mixture of (2%, 4% and 6%) are satisfactory as they attained the compressive strength of (0.5 – 1.0) MPa at seven days which is reasonable in sub-base layer for lightweight road, also stabilization of pumice with cement mixture of (2%, 4% and 6%) are also satisfactory as they attained the compressive strength of (0.7 – 2.3) MPa at seven days. The achieved compressive strength is satisfactory as they meet the required specification that the attained results of seven days should be 2/3 of the results to be obtained in 28 days.

5. Conclusions and Recommendations

5.1. Conclusions

The followings are conclusions that can be drawn from this study as follows.Regarding physical characteristics of pumice materials by particle size analysis and density measurement, the results achieved in table 1 shows that the particle size distribution of the pumice from Mbalizi possess little quantity of fines. Therefore, pumice from Mbalizi is classified as well graded sand (SW), classified as A-2-4.Concerning carrying out the trial mixture by modifying and stabilizing pumice materials with lime and cement. The results shows that stabilization of pumice with lime and cement meets the required specification as stated by AASHTO and Pavement Design Manual. The elements tested on this objective were, Plasticity of stabilized pumice on which the results obtained were satisfactory table 4, Optimum moisture content and maximum dry density of stabilized pumice table 2 and table 3 shows the results obtained which were satisfactory as stated from design manual.On the compressive strength of the mixed materials, the study shows that the obtained results of compressive strength of seven days casted cubes, table 6 are satisfactory as they meet specifications from design manual, table 7, as explained from the design manual that the compressive strength obtained in seven days casted cubes should be at least 2/3 of the results of 28 days casted cubes (BS 5628: Part I 1978).

5.2. Recommendations

The following recommendations are made based upon the findings and conclusion of the study.The recommended mixture to be used in construction of light-weight roads should be of 2% - 4% Pozzolana cement, and 2.5% - 3% lime in the mixture with pumice. Pumice materials should be used for construction of road in order to save other material consumption to reduce land degradation regarding the availability of these materials in Mbeya region.When using pumice materials, considering the factors such as good workmanship, experience in stabilized materials, the strength obtained on 7 days should be approximately 2/3 of the results obtained on 28days, (BS 5628: Part I 1978).

ACKNOWLEDGEMENTS

We would like to extend my profound gratitude to National Housing and Building Research Agency’s (NHBRA) for their involvement by allowing us to use their laboratory for this study.

References

| [1] | Makenya, A. R., and Malewo, V., (2018). The potential of using natural pozzolana for production of building materials; Case Study of Songwe area in Mbeya region, Tanzania. In Kiunzi R, Lukwale, S.R and Shemdoe, R.S (Eds) Informality in Housing and livelihood activities, building materials and Risk Management in Construction Industry in Tanzania. pp.177-193; Dar es Salaam, Tanzania: Ardhi University. |

| [2] | Mtui, A. L., and Kawiche, G. M., (1983). Portland Pozzolana Cement.Working Report No.31., Dar es Salaam: National Housing and Building Research Unit. |

| [3] | Bates, Robert Latimer & Jackson, Julia A., 1939- & American Geological Institute (1987), Glossary of geology, 3rd ed, American Geological Institute, Alexandria, Va. |

| [4] | Robert, L. Day., (1990). State of the Art Report prepared for the International Development Research Centre Ottawa, Canada: International Development Research Centre, University of Calgary. |

| [5] | United Republic of Tanzania, (1999). Pavement and Material Design Manual. Ministry of Works, Dar es Salaam. |

| [6] | Fontijn K, Delvaux D, Ernst GGJ, Mbede E, Jacobs P (2010a) Tectonic control over active volcanism at a range of scales: case of the Rungwe Volcanic Province, SW Tanzania; and hazard implications. J Afr Earth Sci 58: 764–777. |

| [7] | Fontijn K, Ernst GGJ, Elburg MA, Williamson D, Abdallah E, Kwelwa S, Mbede E, Jacobs P (2010b) Holocene explosive eruptions in the Rungwe Volcanic Province, Tanzania. J Volcanol Geotherm Res 196: 91–110. |

| [8] | Ministry of Works Tanzania, Central Materials Laboratory (CML) & Norwegian Public Roads Administration (NPRA), (June 2000). Standard Specifications For Road Works. Dar es salaam. |

| [9] | A. L. Mrema, and H. A. Mboya, (2013). Feasibility of light aggregate concrete for structural and non-structural works in Tanzania. Research and Applications in Structural Engineering, Mechanics and Computation pp.1769-1774, research Gate; DOI: 10.1201/b15963-318. |

| [10] | Kothari, C., 2004. Research Methodology Methods and Techniques. 2nd ed. New Delhi: New Age International LTD. |

| [11] | Central Materials Laboratory (CML), TANROADS & Norwegian Public Roads Administration (NPRAD), (2003). Field Testing Manual. Dar es salaam. |

| [12] | Ghassan K. Al-Chaar, Mouin Alkadi and Panagiotis G. Asteris, (2013). Natural Pozzolan as a Partial Substitute for Cement in Concrete. The Open Construction and Building Technology Journal, Vol. 7, pp.33-42. |

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML