Sylvester Obinna Osuji, Ebuka Nwankwo

Department of Civil Engineering, University of Benin, Nigeria

Correspondence to: Ebuka Nwankwo, Department of Civil Engineering, University of Benin, Nigeria.

| Email: |  |

Copyright © 2017 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Abstract

An experimental study of the structural and mechanical properties of some selected tropical timber species available locally in Nigeria was carried out. The fundamental aim of this paper is to establish the properties of timbers currently used in Benin City, since manufacturing and preservation processes affect the properties of timber. Four chosen species, Albizia (Albizia ferruginea), Dahoma or Ekhimi (Piptadeniastrum africanum), Ekki (Lophira Alata) and Opepe (Nauclea diderichii), were obtained, and tests for their mechanical properties (compressive strength, modulus of rupture and modulus of elasticity) and physical properties (moisture content and density) were conducted. The mechanical properties of these species were compared to data published by international organisations. It was observed that woods from Benin City had lower strength values, compared to average values published for these species. From the results, Albizia showed much lower strength properties than Ekhimi and Opepe. Ekki exhibited very high values of all mechanical properties, at 12% moisture content. It also had a very high density. Albizia had a low density and moisture content at its basic state, while Ekhimi and Opepe had medium moisture contents and densities at their basic states, respectively. From these results, their suitability as structural members was inferred, after having compared their mechanical properties.

Keywords:

Tensile test, Strength, Moisture content, Density, Elastic

Cite this paper: Sylvester Obinna Osuji, Ebuka Nwankwo, Investigation into the Physical and Mechanical Properties of Structural Wood Commonly Used in Nigeria: A Case Study of Benin City, Journal of Civil Engineering Research, Vol. 7 No. 5, 2017, pp. 131-136. doi: 10.5923/j.jce.20170705.01.

1. Introduction

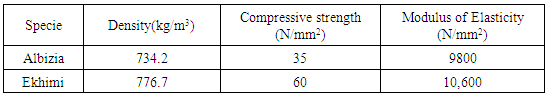

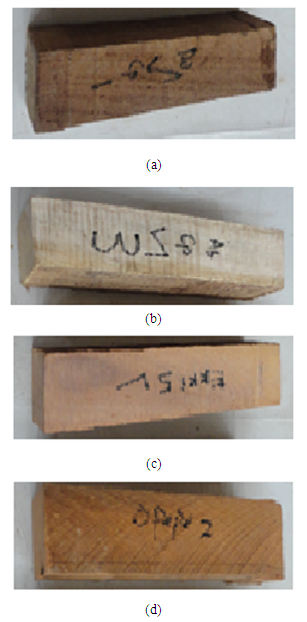

Timber is a major construction material that can be used in almost every facet of construction [1]. Timber in its simplest form can be said to be the hard, tough substance that forms the trunks of trees [2]. The Nigerian code of practice, NCP2 1973, defines timber as wood in a form suitable for construction of carpentry, joinery, or for manufacturing purposes [1, 2]. Basically, timber is a biological and organic material often used in its natural state; anisotropic and hydroscopic, with widely varying properties depending on species, geographical area where the tree grows, the growth conditions, size of the tree at harvest, sawing and any other manufacturing processes [3].As a structural element, timber is usually used in areas in a structure where load-bearing is at the minimum or virtually non-existent, to maximize the workability, and minimise cost [4]. However, in some countries where timber is the major construction material for most structures, design of these structures is done with regard to timber, and special treatment is given to the wood before or after construction [5]. Also, particular species are used in construction, depending on the property required. Some species possess high resistance to bending and compression stresses, chemical or insect attack, or resistance to fire than others, which makes them desirable when these properties are needed [6].In the tropics, timber abounds, and is one of the cheapest and highly available materials. In Nigeria, a wide range of species of timber are available, and selection of the appropriate species for a particular use is of utmost importance [7-9]. Significant reduction in compressive and static bending strength of these species could be attributed to many factors, among which are premature felling of the trees before they reach maturity; presence of defects in the wood; improper drying (seasoning) of the wood, and improper timber conversion processes; poor growth conditions (e.g. poor soil and nutrients for tree growth, etc.); position along the tree trunk from which the specimen was obtained (strength properties are usually greater towards the bottom of the trunk, and reduce as one travels upwards); discrepancies in the moisture content and density of the samples, which in turn, due to swelling and shrinkage, have a great influence on the moduli of elasticity of the samples; and the different locations of origin of the wood from which the different specimens used to undergo these tests were obtained [9-12]. Thus, this work intends to address the possible variation in properties of timber as a result of current manufacturing and production process in Nigeria. Thus, complementing the work of other researchers [9, 14, 15]. Table 1 to 3 show the mechanical properties of timber, which are not from Benin, published in literature.The aim of this research is to ascertain the inherent physical and mechanical characteristics/properties of some selected species of tropical timber available in Nigeria, using Benin City, Edo State. It has been shown that the location, climate, planting technique and specie could have significant impact on the physical and mechanical properties of timber [12-14]. Table 1. Properties for selected group of species [9]

|

| |

|

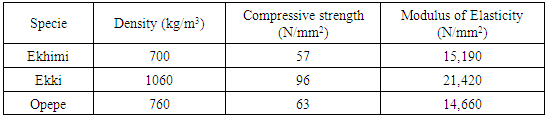

Table 2. Properties for selected group of species [14]

|

| |

|

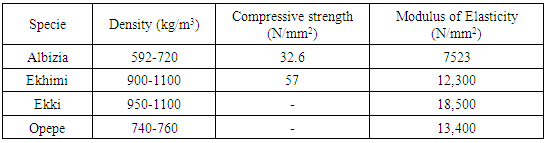

Table 3. Properties for selected group of species [15]

|

| |

|

2. Materials and Methods

All the samples were sawn and/or planed to the sizes required for each test, as required by BS 373: 1957 [16], and the diagrams of each sample shape and dimensions are shown along with the tests. However, there were slight variations in dimensions, due to poor machining operations by the operators, non-uniformity of the wood sold, the thickness of the blade used in cutting and the calibration of the Universal Testing Machine (UTM) used, calibrated in kN, which only reflects failure readings of sections of more than 5mm thickness. Regardless, all these variations in the dimensions were within the permissible variations stated in Clause 13 of BS 373: 1957.

2.1. Moisture Content Determination

In determining the moisture content of a timber specimen, several methods abound. However, the oven-drying method was chosen for use in this study due to its ease of conduction and relatively moderately high accuracy. The test was conducted according to Clause 2 of BS 373: 1957, and calculations made according to Appendix A of the same code. The test specimen was prepared as shown in Figure 1. | Figure 1. (a) Albizia (b) Opepe (c) Ekki (d) Ekhimi |

2.2. Compressive Strength Determination

The compressive strengths of the different species studied, in parallel and perpendicular direction to the timber grains, were obtained from test procedures according to Clauses 8a and 8b of BS 373: 1957. The shapes and sizes, as shown in Figure 2 were prepared according to the 2-inch standard for both tests stated in the code. Afterwards, each sample in turn, was placed under the compression chamber of an Avery-Denison Universal Testing Machine (as shown in Figure 3), and load was applied at a rate of 0.01cm/s. The failure load (in KN) of each sample was observed, read off the dial gauge and recorded. | Figure 2. (a) Ekhimi (b) Albizia (c) Ekki (d) Opepe |

| Figure 3. Arrangement of sample for compression test |

2.3. Tensile Strength Determination

The tensile strength parallel to the grain was determined for each specie, according to clause 12 of the BS 373: 1957 code. Each sample was mounted in the tension chamber of an Avery-Denison Universal Testing Machine shown in Figure 4. The tensile load was applied at a constant head speed of 0.02cm/s, and the failure loads of the samples were recorded. The tensile strength of each sample was obtained by dividing the cross-sectional area of the gauge length under test by the maximum load. | Figure 4. Avery-Denison Universal Testing Machine |

2.4. Bending Strength Test

Figure 5 shows the test specimen shape and size employed in the determination of the static bending strength (i.e. determination of the modulus of elasticity of a small clear specimen of timber). The sample size was obtained and tests were carried out according to the provisions of Clause 6 and Appendix A of the BS 373: 1957 code, using the 2 cm standard and the central loading method. | Figure 5. Static bending test specimen shapes and sizes (a) Albizia (b) Ekhimi (c) Ekki (d) Opepe |

The samples were cut to 20 mm x 6 mm x 500 mm, and finished for straight edges. The apparatus for the test, including a spirit level (to check for horizontality), clamps for holding down the specimen, a dial gauge to measure the deflection, and a hanger and weights for applying load at mid-span of each specimen.

3. Results

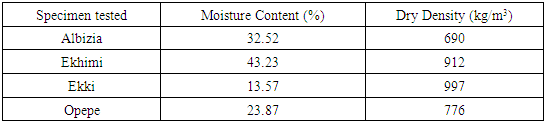

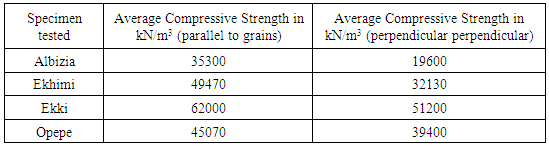

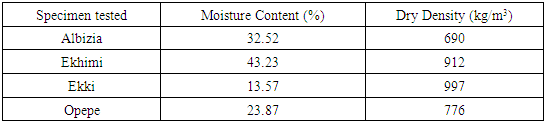

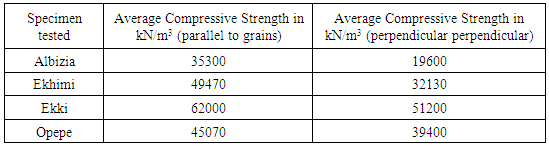

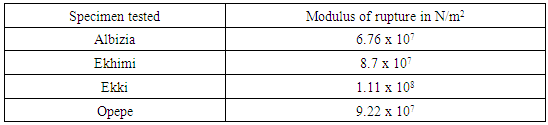

The moisture contents and dry densities results are presented in Table 4. Table 5 shows the compressive strength of studied timbers with respect to the direction of grain (i.e. parallel and perpendicular strength computations were obtained), while Table 6 shows the tensile strength of these timbers.Table 4

|

| |

|

Table 5. Compressive Strength

|

| |

|

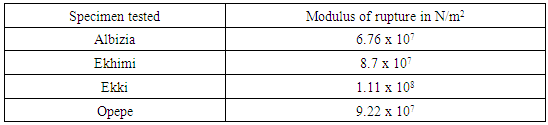

Table 6. Modulus of rupture

|

| |

|

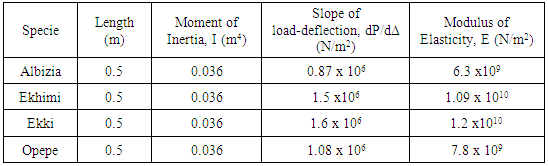

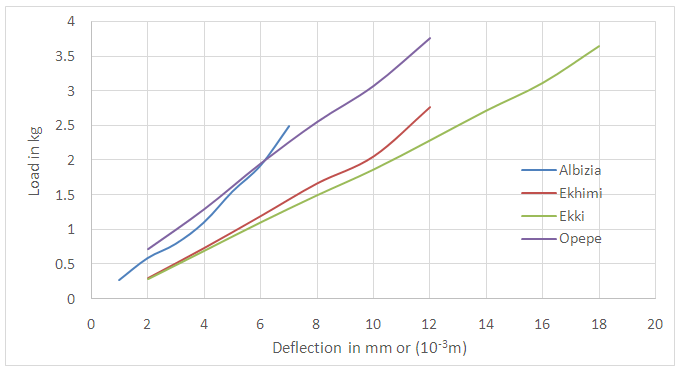

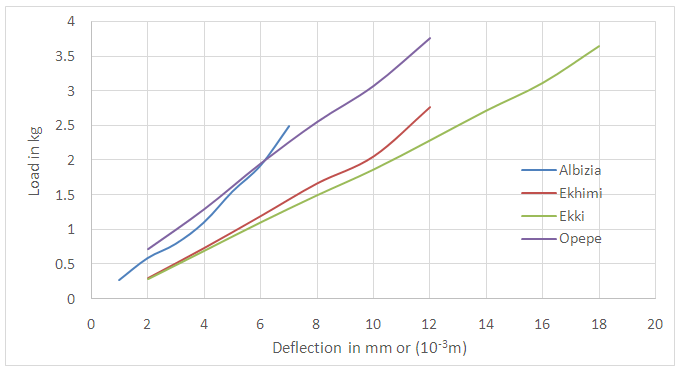

Applying a point load at mid-span to the specific timber beams, load-displacement curves were obtained as shown in Figure 6. Subsequently, the Young’s modulus of the selected timbers were obtained as shown in Table 7.  | Figure 6. Load deflection curves |

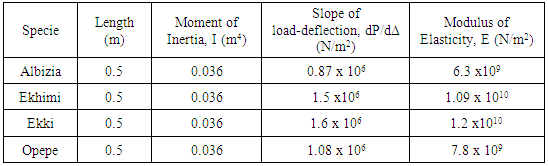

Table 7. Modulus of Elasticity Results

|

| |

|

4. Discussion of Results

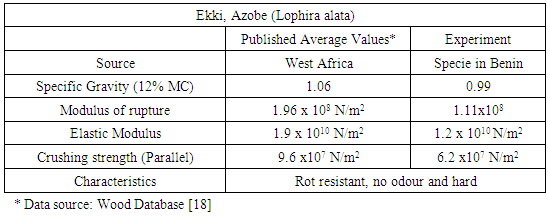

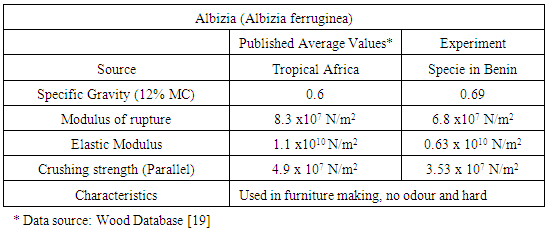

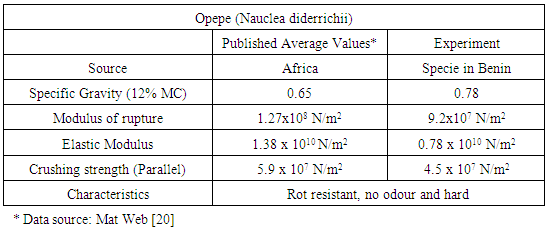

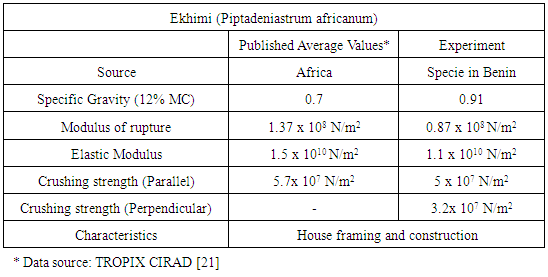

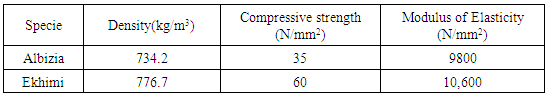

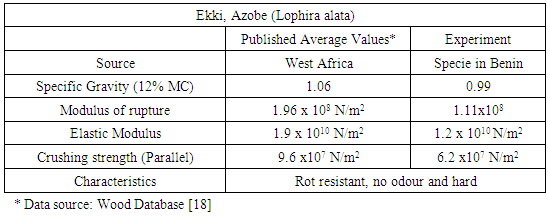

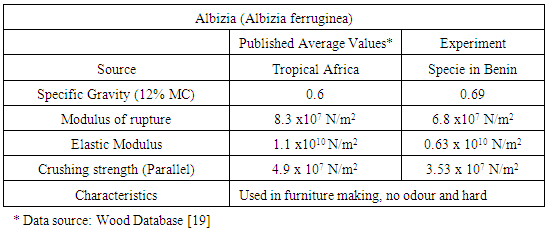

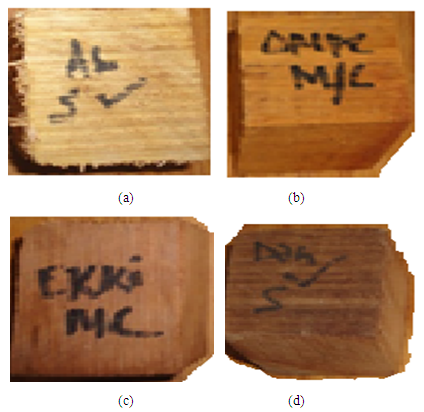

Comparing the results obtained from the tests to those presented in previous researches, it was observed that properties varied slightly, and sometimes, greatly. (Compare Tables 1, 2 and 3 to Tables 4-7)Changes in mechanical properties, as observed in the results, can be attributed to site specific factors in Benin City. The average annual precipitation of 2025mm and average tempetature of 27.5°C can be inferred to have significant effect on the properties of timber sourced from Benin City. Other research have shown that the property of latewood, for example, has a strong correlation with climatic variables. In fact, it was observed that specific months of intense precipitation and temperature have significant correlation with properties of latewood. Rainfalls in the month of May and August were found to be very important [17]. Thus, the substantial rainfall between the months April to September, in Benin City, could have significant effect on the varied properties observed. Thus, in this regard, the results from this work for timbers in Benin complements the results obtained from other studies. Also, comparing the compressive strength and modulus of elasticity values to those presented in other reports [15, 16], it was observed that the obtained compressive strength of Ekhimi was a bit lower than values presented in other works, and the same was the case with Ekki and Opepe. Albizia was within the same range. However, in the modulus of elasticity values, all the obtained results differed greatly, the obtained results being substantially less than those presented in the reports (this can be seen from comparing Tables 3 to 7).Fundamentally, the mechanical properties of woods tested falls below international values of published properties. In all cases, the specific gravities at 12% moisture content were higher in all samples tested in Benin City, compared to internally published values.The average values for the modulus of rupture (MOR) for Ekki, Albizia, and Ekhimi and Opepe species, at 12% moisture content, grown in Benin City were below average values, which have been published internationally. This shows that species in Benin City can sustain less bending strains and stresses before rupture. Thus, in designing for such local specie, care needs to be taken to apply a conservative factor of safety to account for the reduced bending strength.An average of 50% reduction in the elastic modulus (Young’s modulus) of species found in Edo State was also observed as shown in Tables 8-11. This implies that stiffness’s are lower for species found in Edo State. In comparison to other species, locally and international, the Ekki wood gave the highest elastic modulus. This values makes it a material of choice, internationally. Table 8. Comparison between experimental and published mechanical properties of Ekki

|

| |

|

Table 9. Comparison between experimental and published mechanical properties of Albizia

|

| |

|

Table 10. Comparison between experimental and published mechanical properties of Opepe

|

| |

|

Table 11. Comparison between experimental and published mechanical properties of Ekhimi

|

| |

|

Ekki also gave the highest value of crushing strengths. Though the values obtained for Ekki wood found in Benin City was lower than average values which have been published internationally, it was found to be the hardest wood in terms of compressive strength in Benin City.The relatively high values of compression and tensile strengths of Ekki wood found in Benin City, compared to other species from Benin City, makes it a material of choice in the construction of footbridges, piles and decks in Nigeria.The specific gravities of woods found in Benin City correlated well with averaged values that have been published. Also, Ekki was found to have the highest value of specific gravity, i.e. most dense.The significant reduction in compressive, static bending strength and Young’s Modulus of these species found in Benin City when compared to similar species elsewhere could be attributed to many factors, among which are premature felling of the trees before they reach maturity; presence of defects in the wood; improper drying (seasoning) of the wood, and improper timber conversion processes; poor growth conditions.Values obtained for the mechanical properties of locally sourced Ekki are similar to those of the Red woods, which are commonly found in the U.S. For example, the Red Oak has a modulus of rupture of 9.9 x 107 N/m2 compared to 1.11 x 108 N/m2 obtained for locally sourced Ekki. Red Oak has an average elastic modulus of 1.2 x 1010 N/m2 while locally sourced Ekki has a value of 1.16 x 1010 N/m2. However, Ekki from Benin City had much higher crushing strengths of 6.2 x 107 N/m2 when compared to Red Oak’s 4.7 x 107 N/m2 [22].

5. Conclusions

The following conclusions can be drawn from this work:1. This research shows that Ekki, being of high strength, can be used for major structural work. Ekki showed superior properties in terms of modulus of elasticity, crushing strength and modulus of rupture.2. The mechanical properties of timber can vary significantly depending on its manufacturing process and the climate of the location from which it is obtained.3. It was found that the mechanical properties of woods obtained from Benin City, at 12% moisture content, fell below the average values that have been published for similar species, internationally.4. Ekhimi from Benin City can be used but must be properly seasoned and protected against absorbing moisture due it its highly hygroscopic nature.5. Opepe from Benin City can also be used in structural works, but only for moderately-loaded members.6. It is unadvisable to use Albizia for any sound load-bearing structural member. It should be restricted to light construction and bracing.

References

| [1] | Ezeagu, C.A. and Nwokoye, D.N. (2009). “Design in Structural Timber”. Mufti Books, Sapele, Delta State, Nigeria. |

| [2] | Briggs, D. (2006). “Forest Industry”. Microsoft Student 2007 [DVD]. Redmond, WA: Microsoft Corporation, 2006. |

| [3] | Fuwape, J.A. (2000). “Wood Utilization: From Cradle to the Grave”. 25th Inaugural Lecture of the Federal University of Technology, Akure. |

| [4] | Miller, R.B. (1999). “Structure of Wood”. From Forest Products Laboratory, 1999. Wood handbook—Wood as an engineering material. General Technical Report FPL–GTR–113. Madison, WI: U.S. Department of Agriculture, Forest Service, Forest Products Laboratory. |

| [5] | Record, S.J. (1914). “The Mechanical Properties of Wood – Part III: Timber Testing.” Retrieved on 2nd October, 2011 from http://www.basiccarpentrytechniques.com/ The Mechanical Properties of Wood/The Mechanical Properties of Wood3.htm. http://www.wood-database.com/albizia/. (last accessed 29 Oct. 2017). |

| [6] | Civil Engineering Materials Laboratory, CE 305L (2003). “Compression of Wood”. Civil Engineering Materials Laboratory, Civil Engineering Department, University of New Mexico, United States. |

| [7] | Ahmad, Z., Bon, Y.C., Abdul-Wahab, E.S (2010). “Tensile Strength Properties of Tropical hardwoods in Structural Size Testing.” International Journal of Basic & Applied Sciences IJBAS-IJENS Vol: 10, No: 03. |

| [8] | Enabulele, O.A. (2000). “Strength properties of Rubber Tree”. Department of Civil Engineering, University of Benin, Benin City, Edo State, Nigeria. CVE/PROJ/1098. |

| [9] | Ejike, E.A. (2010). “The Basic Engineering Characteristics of some selected species of timber in Nigeria (Case study, Benin City)”. Department of Civil Engineering, University of Benin, Benin City, Edo State, Nigeria. |

| [10] | TRADA Wood Information Sheet (2002). “Timbers – Their Properties and Uses.” TRADA Technology Limited, Wood Information Sheet; Section 2/3, Sheet 10; Subject: Timber- General. |

| [11] | Van Gelder, H.A., Poorter, L., Sterck, F.J. (2006). “Wood Mechanics, Allometry and Life-History Variation in a Tropical Rain-Forest Tree Community”. New Phytologist Journal Compilation (2006) 171: 367-378. |

| [12] | Case, J., Chilver, and Ross, C.T.F. (1999). “Strength of Materials and Structures”. 4th ed. Arnold, Hodder Headline Group, London. |

| [13] | Zziwa, A., Kaboggoza, J.R.S., Mwakali, J.A., Banana, A.Y., and Kyeyune, R.K. (2006). “Physical and Mechanical Properties of some Less Utilized Tropical Timber Tree Species Growing in Uganda”. Uganda Journal of Agricultural Sciences, 2006, 12(1): 29-37. |

| [14] | CIRAD (2009). “Tropix-African Woods”. Developed by the “Production and Processing of Tropical Woods” Research Unit of CIRAD-Forestry Department. Retrieved on 6th November, 2011 from http://tropix.cirad.fr/africa/africa.html. http://www.wood-database.com/albizia/. (last accessed 29 Oct. 2017). |

| [15] | Vernikos Lines of World Timber (2006). “Tropical Timber - African Timber”. Retrieved on 6th November, 2011 from http://www.vernikoslines.gr/pub/en/content.aspx?Page=64. |

| [16] | BS 373: 1957. “Methods of Testing Small Clear Specimens of Timber”. British Standard Institution (BSI), London, UK. BSI 07-1999. |

| [17] | Vihermaa, Leena (2010). Influence of site factors and climate on timber properties of Sitka spruce (Picea sitchensis (Bong.) Carr.). PhD Thesis. University of Glasgow. Unique ID: glathesis: 2010-2271. |

| [18] | Wood Database. Ekki, from http://www.wood-database.com/ekki/. (last accessed 29 Oct. 2017). |

| [19] | Wood Database. Albizia, from http://www.wood-database.com/albizia/. (last accessed 29 Oct. 2017). |

| [20] | Material Property Data. Opepe Tropical Wood, from http://www.matweb.com/search/datasheetText.aspx?bassnum=PTST160. (last accessed 29 Oct. 2017). |

| [21] | Tropix 7 CIRAD 1998 -2011.Dabema, from https://tropix.cirad.fr/FichiersComplementaires/EN/Africa/DABEMA.pdf. (last accessed 29 Oct. 2017). |

| [22] | Wood Database. Red Oak, from http://www.wood-database.com/red-oak/.(last accessed 29 Oct. 2017). |

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML