| [1] | Jahangiri, N., Köseoğlu, K., Cengizler H., 2017, Concrete with by-products and waste materials as aggregate or cement: an overview. Dicle University Institute of Natural and Applied Science Journal, 6 (1) 29-38. |

| [2] | Rashad, A., 2016, Cementitious materials and agricultural wastes as natural fine aggregate replacement in conventional mortar and concrete. J. Build. Eng., 5(2016) 119-141. |

| [3] | Dash, M. K., Patro, S. K., Rath A. K., 2016, Sustainable use of industrial-waste as partial replacement of fine aggregate for preparation of concrete – A review. International Journal of Sustainable Built Environment, 5 (2) 484-516. |

| [4] | Vignesh, K., Lemessa, K., 2017, Behavior of Concrete with Agro and Industry Waste as a Replacement for Constitutive Materials. American Journal of Engineering Research. 6 (3) 79-85. |

| [5] | Nik, P.a., Ibrahim N.N., Abdul Ghani M. H. A., Ali, A. Z., Arshad, M. F., 2017, Compressive Strength of Construction Materials Containing Agricultural Crop Wastes: A Review. ISCEE 2016, MATEC Web of Conferences 103, 01018 (2017). |

| [6] | Parande, A. K., Stalin K., Thangarajan R. K., and Karthikeyan M. S., 2011, Utilization of Agroresidual Waste in Effective Blending in Portland CementISRN Civil Engineering, (2011), Article ID 701862, 12 pages. |

| [7] | Kumar, T. S., Balaji, K.V.G.D., Rajasekhar, K., 2016, Assessment of Sorptivity and Water Absorption of Concrete with Partial Replacement of Cement by Sugarcane Bagasse Ash (SCBA) and Silica Fume. International Journal of Applied Engineering Research. 11 (3) 5747-5752. |

| [8] | Etxeberria, M., Pacheco C., Meneses, J.M., Berridi. I., 2010, Properties of concrete using metallurgical industrial by-products as aggregates. Constr. Build. Mater. 24 (2) 1594-1600. |

| [9] | Kim, H.K., Jang, J.G., Choi, Y.C., Lee, H.K., 2014, Improved chloride resistance of high-strength concrete amended with coal bottom ash for internal curing. Constr. Build. Mater. 71 (2014) 334-343. |

| [10] | Yin, S.., Tuladhar R., Shi F.., Combe M, Collister T., Sivakugan N., 2015, Use of macro plastic fibres in concrete: A review. Constr. Build. Mater., 93( 2015) 180–188. |

| [11] | Kuosa, H., 2012, Reuse of recycled aggregates and other C&D wastes. Research report VTT-R-05984-12. http://www.vtt.fi/inf/julkaisut/muut/2012/VTT-R-05984-12.pdf. |

| [12] | Silva, R.V., de Brito, J., Dhir, R.K., 2014, Properties and composition of recycled aggregates from construction and demolition waste suitable for concrete production. Constr. Build. Mater. 65 (2014) 201–217. |

| [13] | Petrella, A, Petrella, M., Boghetich G., Petruzzelli D., Calabrese D., Stefanizzi P., De Napoli D., and Guastamacchia M.., 2007, Recycled waste glass as aggregate for lightweight concrete. Proceedings of the Institution of Civil Engineers-Construction Materials, 160 (4) 165-170. |

| [14] | Júnior, E. J., Bezerra H., Politi F. S., Paiva, A. E., 2014, Increasing the Compressive Strength of Portland Cement Concrete Using Flat Glass Powder. Materials Research. 17 (Supl. 1) 45-50. |

| [15] | Mo, K. H., Alengaram, U. J., and Jumaat, M. Z., 2014, Review on the Use of Agriculture Waste Material as Lightweight Aggregate for Reinforced Concrete Structural Members. Advances in Materials Science and Engineering, Volume 2014 (2014), Article ID 365197, 9 pages. |

| [16] | Claudiu, A., Cobirzan, N., 2013, Use of Agricultural Products and Waste in the Building Materials Industry. Pro Environment 6 (2013) 472 – 478. |

| [17] | Shinde, L. M., Naktode, P. L., Saklecha, P. P., 2015, A Review on Consumption of Agricultural Waste Material (Coconut Shell) As Aggregate in Design Mix Concrete. International Journal of Computer Applications (0975– 887), International Conference on Quality Up-gradation in Engineering, Science and Technology (ICQUEST2015). http://research.ijcaonline.org/icquest2015/number6/icquest2850.pdf. |

| [18] | Prustya, I. K., Patrob, S. K, Basarkarc, S. S., 2016, Concrete using agro-waste as fine aggregate for sustainable built environment – A review. International Journal of Sustainable Built Environment, 5 (2) 312–333. |

| [19] | Shafigh, P., Jumaat, M. Z., Mahmud, H., 2010, Mix design and mechanical properties of oil palm shell lightweight aggregate concrete – a review. Int J Phys Sci. 5 (14) 2127–34. |

| [20] | Khankhaje, E., Salim, M. R., Mirza, J., Hussin M.W., Rafieizonooz M., 2016, Properties of sustainable lightweight pervious concrete containing oil palm kernel shell as coarse aggregate. Construction and Building Materials, 126 (2016) 1054-1065. |

| [21] | Kawade1, U.R, Rathi, V.R, Girge, V. D., 2013, Effect of use of Bagasse Ash on Strength of Concrete. International Journal of Innovative Research in Science, Engineering and Technology, 2(7) 2997-3000. |

| [22] | Jayminkumar, A. P., Raijiwala, D. B., 2015, Experimental Study on Use of Sugar Cane Bagasse Ash in Concrete by Partially Replacement with Cement. International Journal of Innovative Research in Science, Engineering and Technology. 4 (4) 2228-2232. |

| [23] | Tashima, M.M., Moraes, J.C.B., Melges, J.L.P., Monzo, J., Borrachero, M.V., Soriano, L. and Paya, J., 2015, Assessment of sugar cane straw ash (SCSA) as pozzolanic material in blended Portland cement: Microstructural characterization of pastes and mechanical strength of mortars, Constr. Build. Mater., 94 (2015) 670-677. |

| [24] | Modani, P. O., Vyawahare, M R., 2013, Utilization of Bagasse Ash as a Partial Replacement of Fine Aggregate in Concrete. Procedia Engineering. 51(2013) 25-29. |

| [25] | Nwofor, T.C., Sule, S., 2012, Stability of groundnut shell ash (GSA)/ordinary Portland cement (OPC) concrete in Nigeria. Pelagia Research Library. Advances in Applied Science Research, 3(4) 2283-2287. |

| [26] | Ndefo, O., 2013, Properties of cement - groundnut shell ash concrete. International Journal of Innovative Research in Engineering & Science, 8(2) 16-23. |

| [27] | Sadaa, B.H., Amarteyb, Y.D., Bako, S.., 2013, An Investigation Into The Use Of Groundnut Shell As Fine Aggregate Replacement. Nigerian Journal of Technology, 32 (1) 54-60. |

| [28] | Yang, E.-I., Kim, M.-Y., Park, H.-G., Yi S.-T., 2010, Effect of partial replacement of sand with dry oyster shell on the long-term performance of concrete. Constr. Build. Mater. 24 (2010) 758–765. |

| [29] | Osei, D. Y., Jackson, E. N., 2016, Compressive Strength of Concrete Using Sawdust as Aggregate. International Journal of Scientific & Engineering Research, 7(4) 1349-1353. |

| [30] | Oyedepo, O. J., Oluwajana, S. D., Akande, S. P., 2014, Investigation of Properties of Concrete Using Sawdust as Partial Replacement for Sand. Civil and Environmental Research, 6 (2), 35-42. |

| [31] | Tomas, U. G. Jr., 2014, Effect of Sawdust as Fine Aggregate in Concrete Mixture for Building Construction. International Journal of Advanced Science and Technology, 63 (2014) 73-82. |

| [32] | Ismail, Z.Z., Jaeel, A.J., 2014, A novel use of undesirable wild giant reed biomass to replace aggregate in concrete. Constr. Build. Mater., 67 Part A, 68-73. |

| [33] | Ramezanianpour, A.A., Khani, M.M., Ahmadibeni, G.H., 2009, The effect of rice husk ash on mechanical properties and durability of sustainable concretes. Int. J. Civil Eng., 7 (2) 83–91. |

| [34] | Rukzon, S. and Chindaprasirt, P., 2014, Use of Rice Husk-Bark Ash in Producing Self-Compacting Concrete. Advances in Civil Engineering, Volume 2014 (2014), Article ID 429727, 6 pages. |

| [35] | Zareei, S. A., Ameri, F, Dorostkar, F., Ahmadi, M., 2017, Rice husk ash as a partial replacement of cement in high strength concrete containing micro silica: Evaluating durability and mechanical properties. Case Studies in Construction Materials. (2017). In press, available online: http://www.sciencedirect.com/science/article/pii/S2214509516300924. |

| [36] | Aziz, M.A., Murphy, C.K., Ramaswamy, S. D., 1979, Lightweight concrete using cork granules. The International Journal of Lightweight Concrete, 2(1) 29-33. |

| [37] | Kawabata, C. Y., Junior, H.S., Sousa-Coutinho, J., 2012, Rice husk derived waste materials as partial cement replacement in lightweight concrete. Ciênc. agrotec. 36 (5). http://dx.doi.org/10.1590/S1413-70542012000500010. |

| [38] | Guerra, M. I., Juan, A., Morán, J. M., García, J., Rodríguez D., 2016, Testing concrete made with cork powder and steel fibres. Scientific Research and Essays, 7 (46) 3974-3982. |

| [39] | Panesar, D.K., Shindman, B., 2012, The mechanical, transport and thermal properties of mortar and concrete containing waste cork. Cem. Concr. Comp., 34 (2012) 982-992. |

| [40] | Shafigh, P., Bin Mahmud, H, Jumaat, M. Z., Zargar M., 2014, Agricultural wastes as aggregate in concrete mixtures – A review. Construction and Building Materials, 53 (2) 110-117. |

| [41] | Chowdhury, S., Mishra, M., Sugania, O., 2015, The incorporation of wood waste ash as a partial cement replacement material for making structural grade concrete: An overview. Ain Shams Engineering Journal, 6 (2) 429-437. |

| [42] | Sayali, B. S., Shubhangi, P. N., Anjali, G. Y., Rutuja, T. S., Rahane, A.B., 2017, Replacement Of Cement With Bagasse Ash: Review. International Journal Of Engineering Sciences & Management, 7(2017) 127-131. |

| [43] | Potter, D., Gao F., Baggett, S., McKenna, J. R, McGranahan, G.H., 2002, Defining the sources of Paradox: DNA sequence markers for North American walnut (Juglans L.) species and hybrids. Scientia Horticulturae, 94 (1-2) 157-170. |

| [44] | Fleming, D., Temyer, J., 2009, Surface preparation: Practices, equipment, and standards through 25 years. J. Prot. Coat. Linings, 2 (2009) 56–62. |

| [45] | Marcus, H., 2013, The Oregon City Bridge, Part II. Shotcrete (2013) 23-24. |

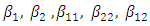

| [46] | Cheng, W., Liu, G., Chen, L., 2017, PET Fiber Reinforced Wet-Mix Shotcrete with Walnut Shell as Replaced Aggregate. Appl. Sci., 7, 345, 1-19. |

| [47] | Shimp, D.A., Bobo, W.S., 1969, Epoxy Resin-Walnut Shell Aggregate Wear Resistant Floor Toppings. U.S. Patent US3481257 A, 2, 1969. |

| [48] | Husain, M. S., Ahmad, A., Huda, S., Asim, M., 2017, Cost optimization of concrete by replacing fine aggregate with walnut shell powder. International Journal of Civil Engineering and Technology, 8 (3) 82–89. |

| [49] | Myers, R. H., Montgomery, D., Response Surface Methodology. John Wiley & Sons, Inc., New York, 2002. |

| [50] | Raymond, M. H., Douglas, C., M, Christine, M. A. C.. Response Surface Methodology: Process and Product Optimization Using Designed Experiments, 4th Edition, John Wiley & Sons, Inc., 2016. |

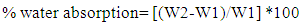

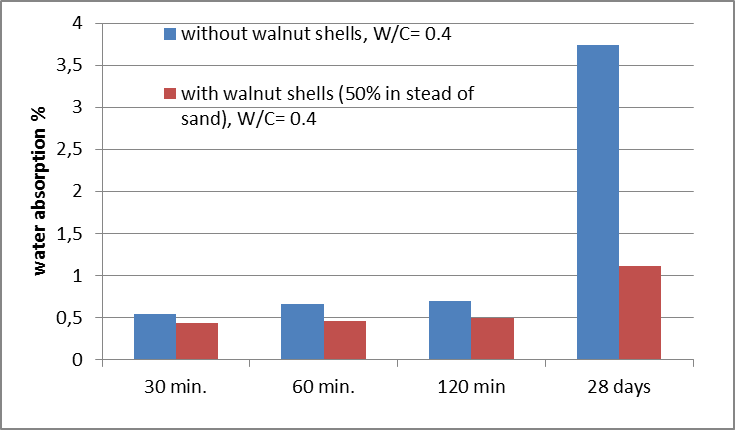

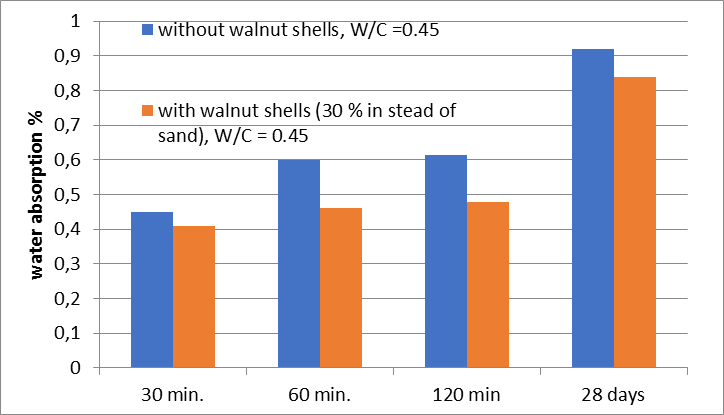

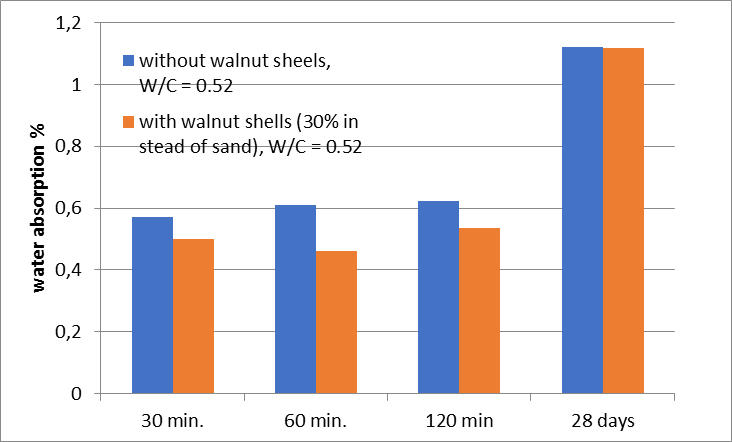

| [51] | Zhang, S., Zong, P. L., 2014, Evaluation of Relationship between Water Absorption and Durability of Concrete Materials. Advances in Materials Science and Engineering Volume 2014 (2014), Article ID 650373, 8 pages. |

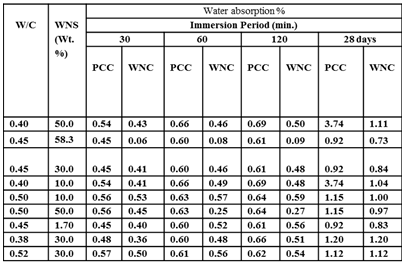

| [52] | Sisman, C. B., Gezer, E., Kocaman, I., 2011, Effects of organic waste (rice husk) on the concrete properties for farm buildings. Bulgarian Journal of Agricultural Science, 17 (1) 40-48. |

| [53] | Ealias, A. M., Rajeena, A. P., Sivadutt, S., John, L., Paul, A., 2014, Improvement of Strength of Concrete with Partial Replacement Of Course Aggregate With Coconut Shell and Coir Fibres. Journal of Mechanical and Civil Engineering. 11(2014) 16-24. |

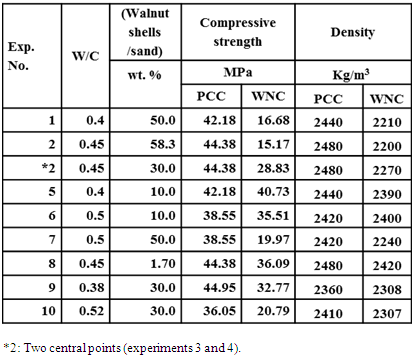

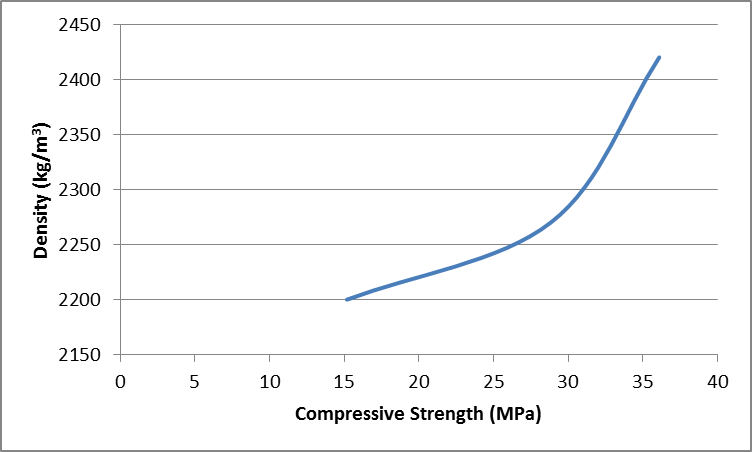

| [54] | Iffat, S., 2015, Relation between Density and Compressive Strength of Hardened Concrete. Concrete Research Letters, 6 (4) 182-189. |

| [55] | Agbenyeku, E., Muzenda, E., Msibi M., 2016, Transformation and Ulization of Agricultural Waste as Component of Green Concrete for Rural Housing and Development Schemes. 7th International Conference on Biology, Environment and Chemistry, IPCBEE 98(2016) 122-127. |

| [56] | Domke, P. V, 2012, Improvement In The Strength Of Concrete By Using Industrial And Agricultural Waste. IOSR Journal of Engineering, 2 (4), 755-759. |

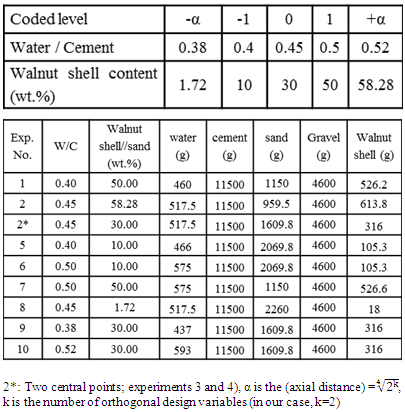

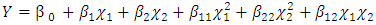

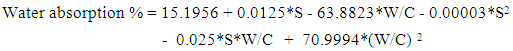

and

and  are the independent variables; and,

are the independent variables; and,  ,

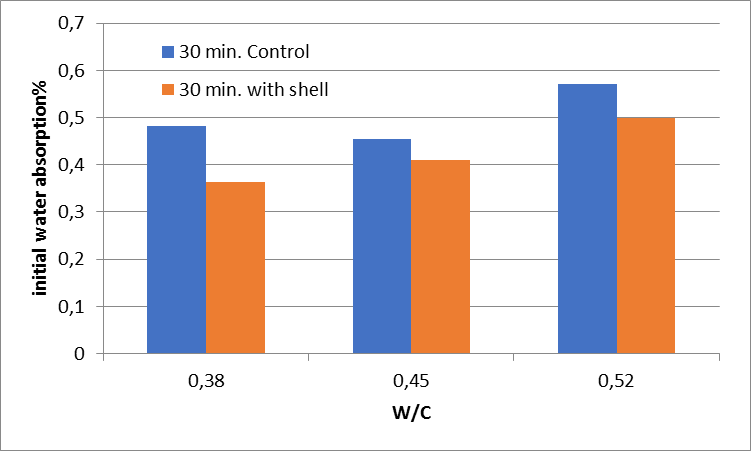

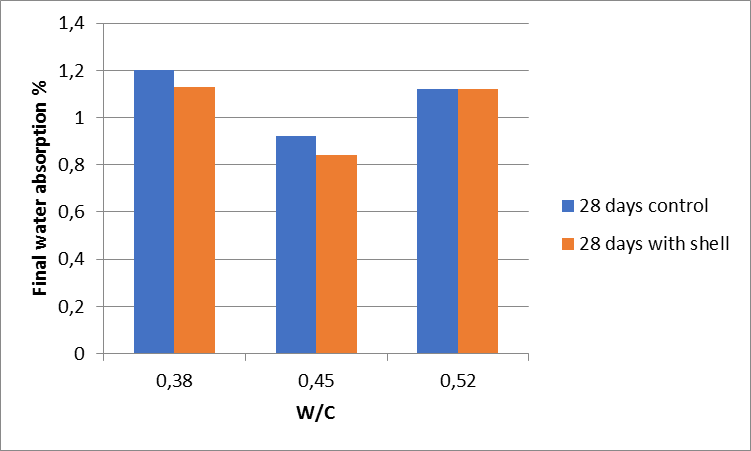

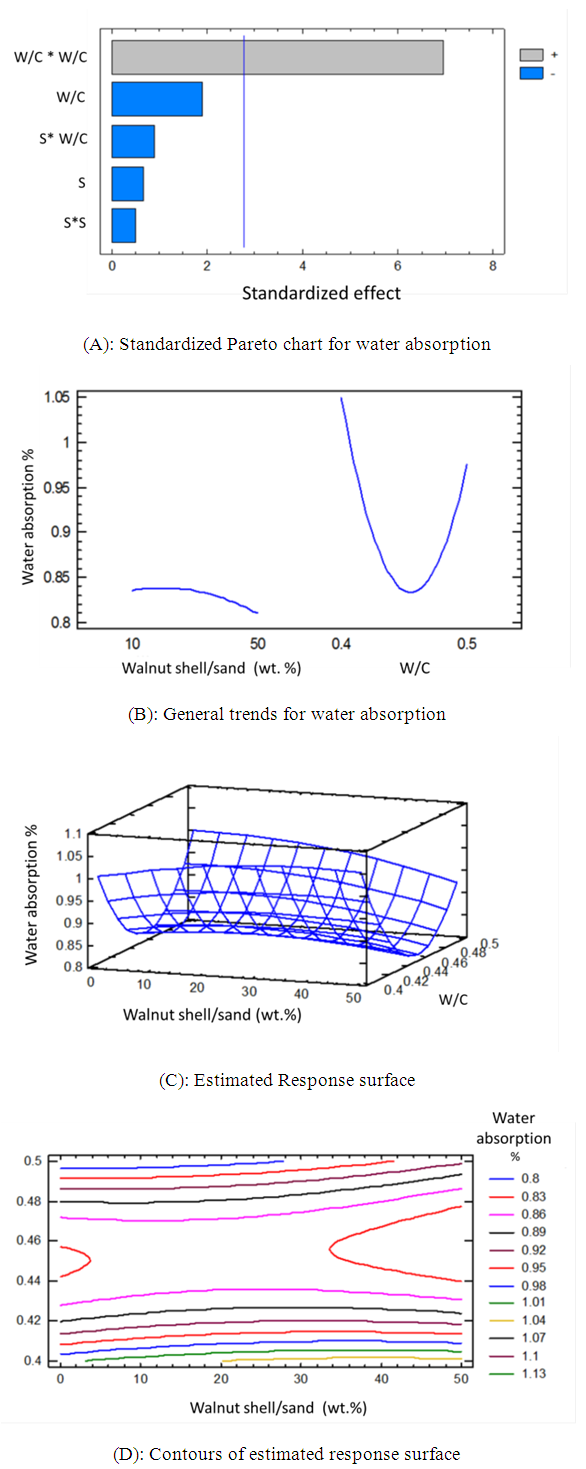

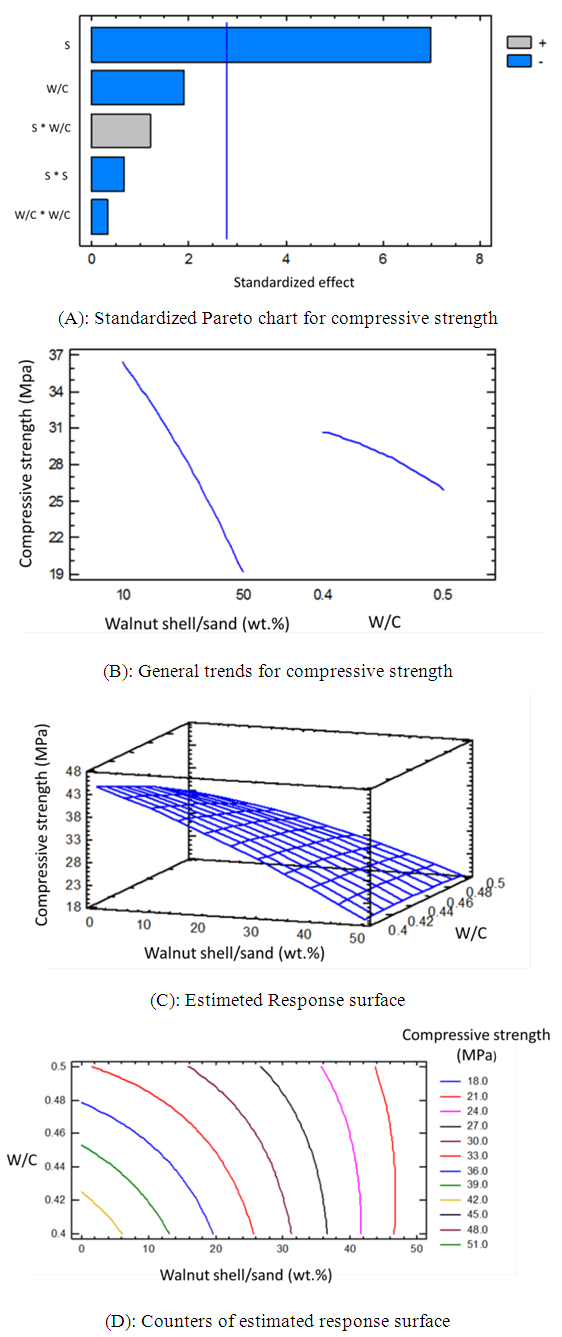

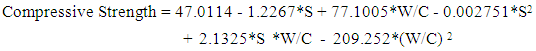

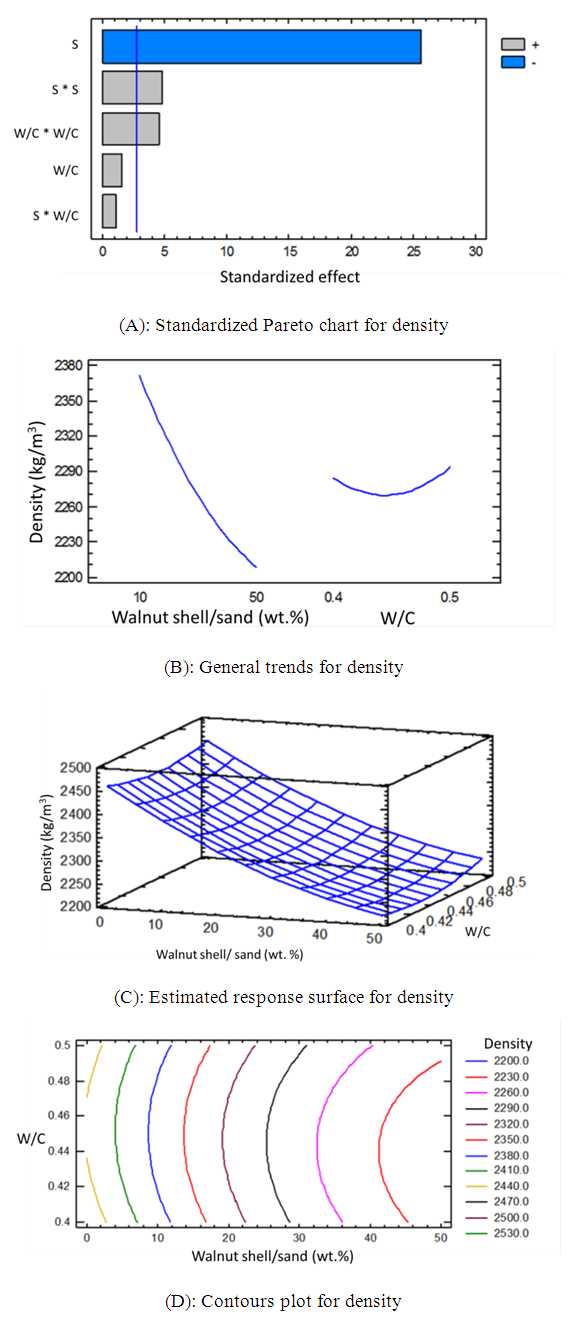

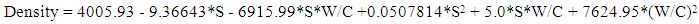

,  are the regression coefficients.The extensive application of RSM is in industry when several input variables significantly influence performance measures or quality characteristics of the product or process [50]. The analyses of variance (ANOVA) are used to determine significant differences between the effects of independent variables (p<0.05). Pareto chart is used to identify the impact level of the independent variables on each considered response. The vertical line (significant front) in Pareto chart determines the effects that are statistically significant at 95% as confidence level. Main trends, surface response, contour plots of the response surface as well as the empirical regression model can be used to optimize the dependent parameter (responses).

are the regression coefficients.The extensive application of RSM is in industry when several input variables significantly influence performance measures or quality characteristics of the product or process [50]. The analyses of variance (ANOVA) are used to determine significant differences between the effects of independent variables (p<0.05). Pareto chart is used to identify the impact level of the independent variables on each considered response. The vertical line (significant front) in Pareto chart determines the effects that are statistically significant at 95% as confidence level. Main trends, surface response, contour plots of the response surface as well as the empirical regression model can be used to optimize the dependent parameter (responses).

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML