-

Paper Information

- Next Paper

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Journal of Civil Engineering Research

p-ISSN: 2163-2316 e-ISSN: 2163-2340

2017; 7(3): 99-104

doi:10.5923/j.jce.20170703.02

Application of Rebound Hammer Method for Estimating Compressive Strength of Bricks

Md. Roknuzzaman, Md. Belal Hossain, Md. Ibrahim Mostazid, Md. Rashedul Haque

Department of Civil Engineering, Hajee Mohammad Danesh Science and Technology University, Dinajpur, Bangladesh

Correspondence to: Md. Roknuzzaman, Department of Civil Engineering, Hajee Mohammad Danesh Science and Technology University, Dinajpur, Bangladesh.

| Email: |  |

Copyright © 2017 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

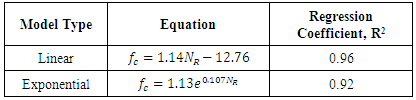

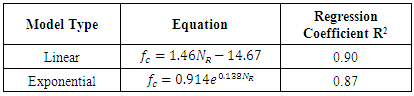

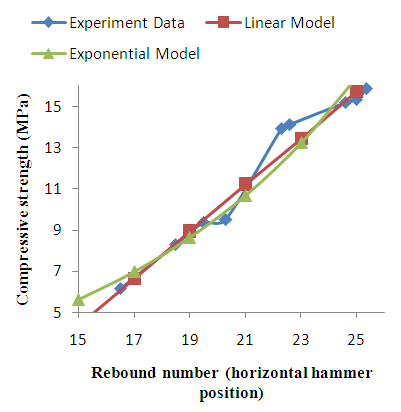

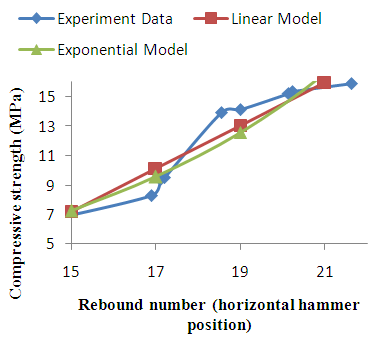

The Rebound Hammer strength test, being a non-destructive test, has its advantages of preserving integrity of sample. Besides, the test is relative simple, economical and versatile compared to conventional crushing tests. The method is widely used for testing concretes manufacturers of such rebound hammers usually provide calibrated curves showing the relation of compressive strength and rebound number concrete only. But these hammers can conveniently be used to test stones and bricks also. This paper presents some models for correlation between rebound number and compressive strength of bricks. 10 different samples of brick were collected from different manufacturers and rebound numbers was taken 20 times for each brick, 10 times for horizontal hammer position and 10 times for vertical. The samples were then tested in a universal testing machine to obtain their actual compressive strength. Linear and exponential correlations between average rebound number and compressive strength were established using least square parabola method. Regression coefficients for the proposed models were found to vary from 0.87 to 0.96. The proposed linear model for horizontal hammer position was found to be the better one with a regression coefficient of 0.96 which indicates the acceptability of this model for predicting compressive strength of bricks.

Keywords: Non-destructive test, Brick test, Rebound hammer

Cite this paper: Md. Roknuzzaman, Md. Belal Hossain, Md. Ibrahim Mostazid, Md. Rashedul Haque, Application of Rebound Hammer Method for Estimating Compressive Strength of Bricks, Journal of Civil Engineering Research, Vol. 7 No. 3, 2017, pp. 99-104. doi: 10.5923/j.jce.20170703.02.

Article Outline

1. Introduction

- Compressive strength of materials is usually determined by subjecting them to tests that eventually destroy the sample. Such tests are the direct ways of determining strength of materials but require various heavy and expensive equipment or machines. While they provide the actual strength of the materials, situations often require the estimation of strengths while preserving the specimen itself even if it means the estimated strength is empirical or approximate. In case of finished products like existing building structures, maintaining integrity becomes the first priority which cannot be attained by conventional destructive tests. Non-destructive tests (NDT) become necessary in such cases. They are desirable in several cases because of their relative simplicity, economy, versatility and preservation of the original samples. In fact the development of NDT has taken place to such an extent that it is now considered a powerful method of evaluating existing engineering structures like buildings, bridges, pavements or materials like metals, concrete or aggregates. Since the specimens are not loaded to failure in these tests, their strengths are estimated by measuring some other properties of the material. Therefore the results are estimations only and do not provide absolute values of strength. Non-destructive testing methods are used to the largest extent for assessment of concrete quality built in a structure. Such testing and assessment procedures are codified in technical standards, for example, ISO 1920-7, ASTM C805, ASTM 597, CSN EN 12504-2, nd CSN EN 12504-4 [1]. The rebound hammer test also known as Schmidt Hammer Test developed by Swiss engineer Ernst Schmidt in 1948 is one of the oldest, simplest and most popular non-destructive tests of concrete. The device used in the test known as Schmidt hammer or rebound hammer, uses a spring and measures the hardness of concrete surface using the rebound principle [2]. The rebound hammer test is codified in ASTM C805 [3] and CSN EN 12504-2 [4]. Acceptability of rebound hammer test is evaluated by different research works and studies. The research work carried by Sanchez and Tarranza revealed that in a quick strength and safety assessment of existing concrete structures, the Schmidt Hammer Test is fairly reliable [5]. Rubene and Vilnitis performed a series of laboratory tests and found that the average compressive strength of reinforced concrete wall obtained by crushing test and rebound hammer test (horizontal) was 44.29 MPa and 45.00 MPa respectively which shows a fair accuracy in estimation of strength [6]. Shariati et al. conducted Ultrasonic Pulse Velocity test and Schmidt Rebound Hammer tests of concrete and compared the results with corresponding crushing strength value. Their research revealed that a combined method for the two tests is an improvement in the concrete strength estimation [7]. However, studies have shown that rebound readings are sensitive to near-surface properties and influenced by surface smoothness, age of concrete, moisture content, carbonation, presence of aggregates, presence of air voids and steel reinforcement, temperature, and calibration of the rebound hammer [2]. An important precaution stated by American Concrete Institute is that, if the specimen is small, any movement under the impact will lower the rebound readings and in such cases the specimen has to be fixed or backed up by a heavy mass [8].As the rebound hammer test is intended primarily to test concrete, manufacturers of such rebound hammers supply the calibration curves correlating rebound number and compressive strength for concrete only. But many of the recent research works established that this method can be used to estimate compressive strength of building stones, bricks and other hard materials also by establishing correlations between rebound number and compressive strength of corresponding material. Rebound hammer test was performed on lime sand bricks and honeycomb bricks by Brozovsky to obtain correlation between rebound number and compressive strength and he concluded the test method to be usable in practice for lime sand bricks but in case of honeycomb bricks special considerations need to be taken into account [9]. Another attempt was made by the same researcher to assess compressive strength of calcium silicate bricks using a combination of the rebound hammer method and ultrasonic pulse method (SonReb) in which he stated that the combined non-destructive SonReb method was proved applicable for determination of compressive strength of calcium silicate bricks at checking tests in a production plant and for evaluation of bricks built in existing masonry structures [1]. Applicability of NDT method for masonry structure was also reviewed by McCann and Forde [10]. An exponential model for correlation between rebound number and strength of different types of stones and bricks proposed by Aliabdo and Elmoaty was found to have good regression coefficient of 0.9384. [11].Quality of masonry bricks is generally investigated in field by inspecting their colour, metallic sound by hammering, surface finishing and T-test [12]. None of these methods is fairly accurate and the inspection result may vary man to man. Moreover, none of these field tests provides an idea about numerical value of brick strength. Rebound hammer test, on the other hand, can give an estimated magnitude of compressive strength of brick if a fair correlation is established between rebound number and compressive strength of brick. Such correlations will be valid for that particular type of rebound hammer and it will as well be influenced by size, shape and characteristics of brick to be tested. The present study is focused on finding out a good correlation between rebound number and compressive strength of conventional bricks locally produced in Bangladesh. A standard N-type Schmidt hammer was used for this purpose. This study is aimed to establish a better alternative way for estimating compressive strength of brick that may be used as field test of brick before new construction as well as for inspecting existing masonry structure.

2. Materials and Methodologies

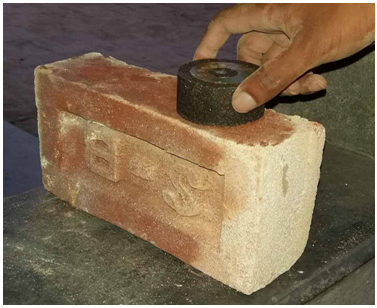

- Ten samples of local bricks (240 mm×115 mm×70 mm) were collected from three different brick fields located in the district of Dinajpur, Bangladesh. The bricks were manufactured form locally available plastic clay type soil. Study carried on similar soil revealed that this type of soil has an average specific gravity of 2.7 with moisture content 43.4% [13]. The samples were marked by numbering them 1 to 10. An N-type classic concrete hammer with impact energy of 2.207 N-m was used for non-destructive test of each brick (Figure 1).

| Figure 1. N-type rebound hammer |

| Figure 2. Surface smoothening with abrasive stone |

3. Results and Discussions

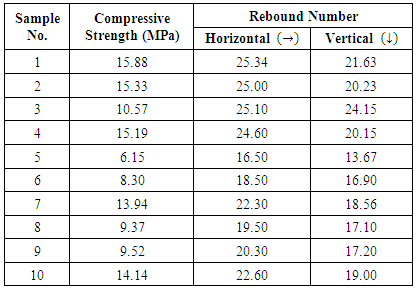

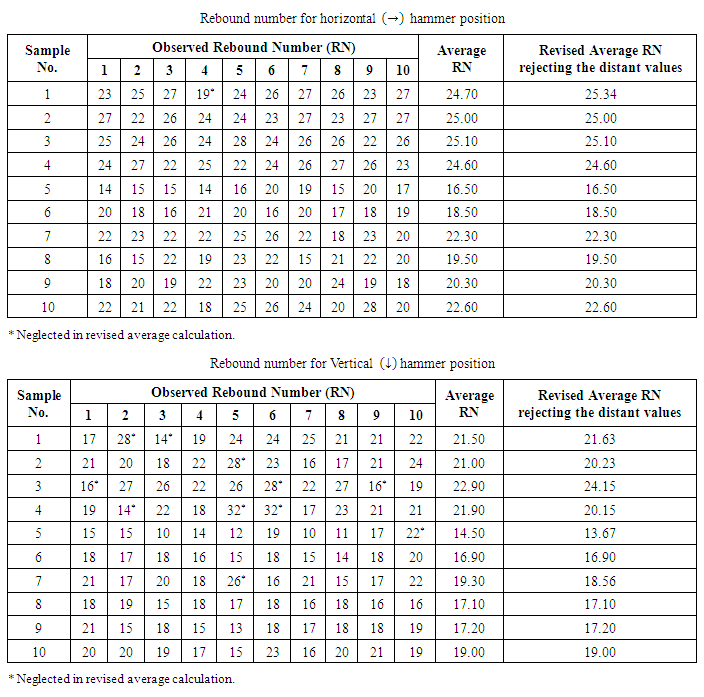

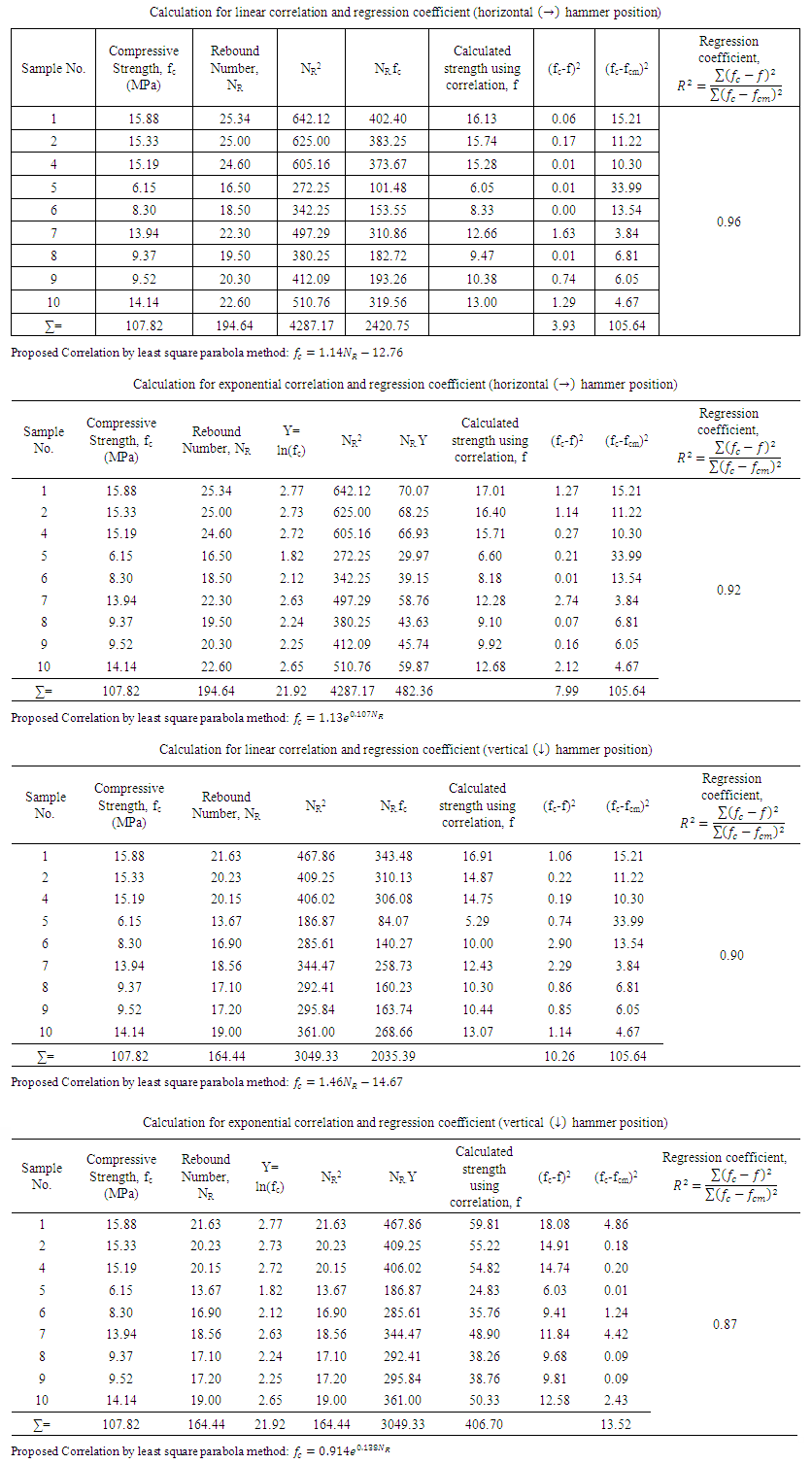

- Average rebound number is calculated and revised (if required) rejecting the values with a difference of 5 units or more from the average. Details of test data and calculation of average rebound number for both hammer position can be found in Appendix-A. Compressive strength for each of the sample was determined by crushing them in a universal testing machine. Average rebound number for two hammer positions and corresponding compressive strength is presented in Table 1. The table shows that compressive strength increases with increasing rebound number except for sample no. 3. For this particular sample rebound number was found to be high comparative to its low compressive strength. This was considered an experimental error and this sample was excluded in further calculations.

|

|

| Figure 3. Proposed model for horizontal hammer position |

|

| Figure 4. Proposed model for vertical hammer position |

4. Conclusions

- Rebound hammer is a handy and portable device and its operation is simple. Rebound hammer method, therefore, can be a suitable and convenient way for field identification of bricks and estimating their compressive strength. But this method does not give true value of strength and hence its application should be limited for inspection purpose only. The correlations presented in this paper are recommended for testing the conventional local bricks

manufactured in Bangladesh. For special bricks like perforated bricks, hollow bricks and other variants as well as for the bricks with different dimensions, similar study should be carried out to establish proper correlations.

manufactured in Bangladesh. For special bricks like perforated bricks, hollow bricks and other variants as well as for the bricks with different dimensions, similar study should be carried out to establish proper correlations.ACKNOWLEDGEMENTS

- The authors are grateful to their colleagues from the faculty of engineering, HSTU for their tremendous support and inspiration that greatly assisted the research. Authors would like to express their gratitude to the chairman and lab technicians of the Department of Agricultural and Industrial Engineering for their cooperation during the laboratory experiments.

| Appendix-A |

| Appendix-B |

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML