Nahushananda Chakravarthy H. G.1, Sivakumar Naganathan2, Sivadass Thiruchelvam2, Kamal Nasharuddin Bin Mustapha2, Zakaria Che Muda2, Shivanand K. P.3

1School of civil Engineering, Linton University College, Malaysia

2Department of Civil Engineering, Universiti Tenaga Nasional, Malaysia

3Department of Civil Engineering, Siddaganga Institue of Technology, Tumkur, India

Correspondence to: Nahushananda Chakravarthy H. G., School of civil Engineering, Linton University College, Malaysia.

| Email: |  |

Copyright © 2016 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Abstract

This paper discuss the ultimate strength and design of cold formed built up steel sections by experimental and American (AISI-2007) standard method. For the experimental studies two cold formed steel channel members were connected back to back to form built up I sections and these channels are attached with screws. There were two sets of specimens were prepared such as plain and carbon fibre reinforced polymer (CFRP) strengthened built up columns. The prepared specimens tested for axial compression and results were noted. A series of parametric studies were also carried out by two different thickness and column length. The test results were compared with American (AISI-2007) Standards and proposed design equation using modular ratio concept method. The details of these investigation and the outcomes are presented in this paper.

Keywords:

Cold formed steel, Column, Built up, CFRP

Cite this paper: Nahushananda Chakravarthy H. G., Sivakumar Naganathan, Sivadass Thiruchelvam, Kamal Nasharuddin Bin Mustapha, Zakaria Che Muda, Shivanand K. P., Proposed Design Equations for the CFRP Strengthened Cold Formed Steel Built up I Sections, Journal of Civil Engineering Research, Vol. 6 No. 5, 2016, pp. 115-118. doi: 10.5923/j.jce.20160605.01.

1. Introduction

The use [1] of cold-formed steel structural members has increased in recent years, especially in light-weight steel construction, such as steel-framed housing, low-rise office buildings, factories, and warehouses. Cold-formed steel members are manufactured by either cold rolled or brake pressed into structural shapes. Cold-formed [2] steel light gauge members can be used efficiently in many structural applications. Similar to the heavy hot-rolled steel sections, cold-formed steel compression members can be used to carry a compressive load applied through the centroid of the cross section. Normally, [3, 4] three basic types of buckling, local, overall, and distortional, can occur in thin-walled steel sections. External fibre reinforcement will delay the buckling of the thin wall sections. More [5] recently, there has been a interest towards the use of externally applied composite fibre reinforcement in steel members which, combining the advantageous mechanical properties of different materials, leads to improved structural performance. FRP composites as a structural reinforcing material possess complementary material characteristics to concrete or steel, namely, higher strength-to weight ratio, ease of handling and high corrosion resistance, all of which transcend other considerations.The ultimate strength of plain and CFRP strengthened built up sections were tested experimentally in this study. The experimental results were compared with American (AISI 2007) standards. An equation is used to calculate the young’s modulus of CFRP strengthened composite sections and the results were validate with experimentally tested results.

2. Test Set up and Experimental Procedure

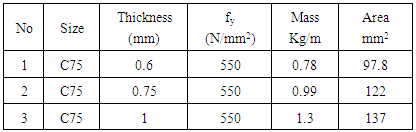

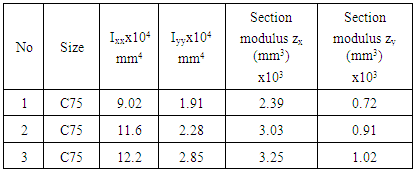

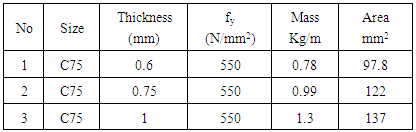

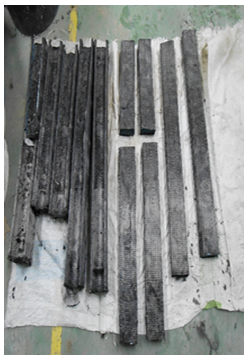

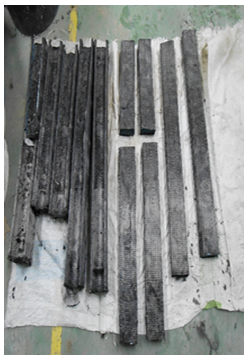

In this study cold formed lipped channel section were connected back to back with screws and strengthened with CFRP, a two phase experimental programme were conducted. In Phase 1, a total of 6 specimens of plain cold formed steel built up sections were tested. In Phase 2, a total of 6 specimens of CFRP strengthened cold formed sections were tested under concentric axial load. The sectional properties of single channel sections are as shown in Table 1 & 2. A pictorial view cfrp strengthened sections and the test setup is shown in Fig. 1 & 2. Two samples were used in each test and the average value was taken.Table 1. Sectional properties

|

| |

|

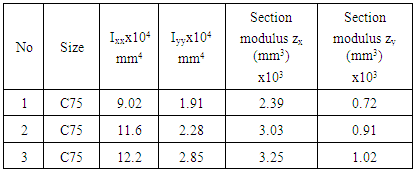

Table 2. Sectional properties

|

| |

|

| Figure 1. CFRP strengthened specimens |

| Figure 2. Experimental set up |

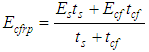

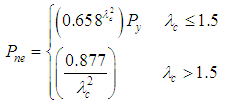

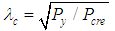

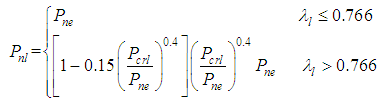

3. Calculation Based on AISI (2007) Standard

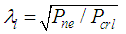

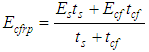

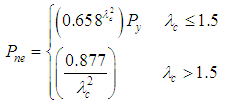

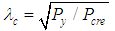

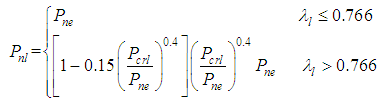

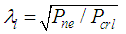

Design method for CFRP strengthened channel section proposed to axial compression based on AISI standards (AISI, 2007). To account CFRP, the Direct Strength Method (DSM) modified to estimate the ultimate strength of cold-formed steel columns experiencing flexural or flexural - torsional, local and distortional buckling. CFRP is assumed to play an important role in elastic buckling, slenderness ratio. The nominal axial strength Pn determined as minimum of (Pne, Pnl and Pnd) based on DSM method is in Eq. 3, 4 and 5, proposed by Schafer (2006). Total thickness of CFRP layered plate (tt) considered as CFRP thickness (tcf) + steel plate (ts) neglecting adhesive layer thickness (as this is week in strength and buckling) given by Eq. (1). The elastic modulus of the CFRP with steel is determined from the modular ratio concept and given by Eq. (2). This concept was checked before for CFRP strengthened channel section by Sreedhar kalavagunta (2013), same equations are used to validate the channel connected back to back as built up sections [7-9]. | (1) |

| (2) |

Flexural, Torsional, or Torsional-Flexural Buckling (Pne) | (3) |

where Pcre = Minimum of the critical elastic column buckling load in flexural, torsional, or torsional-flexural buckling.Local Buckling (Pnl):

Pcre = Minimum of the critical elastic column buckling load in flexural, torsional, or torsional-flexural buckling.Local Buckling (Pnl): | (4) |

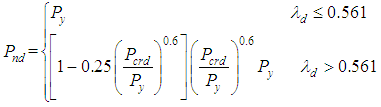

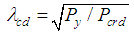

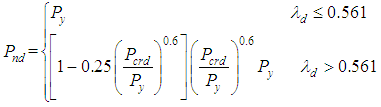

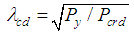

Pcrl = Critical elastic local column buckling load.Distortional Buckling (Pnd)

Pcrl = Critical elastic local column buckling load.Distortional Buckling (Pnd) | (5) |

where, Pcrd = Critical elastic distortional column buckling load.

Pcrd = Critical elastic distortional column buckling load.

4. Results and Discussions

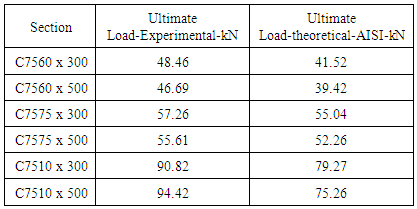

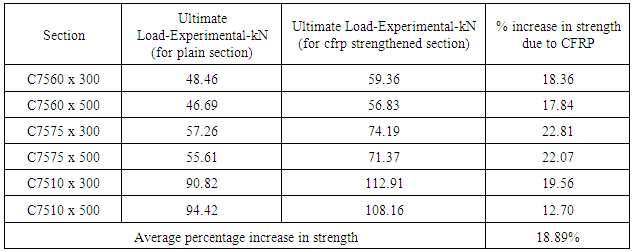

The experimental and design calculation results based on American standards (AISI 2007) of built columns are tabulated below. Table 3. Plain built up cold formed steel ultimate load: Experimental Vs theoretical

|

| |

|

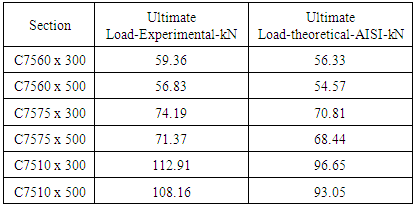

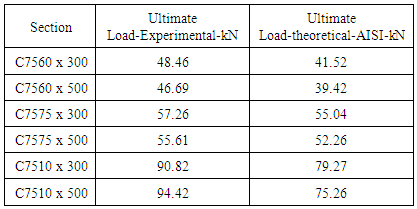

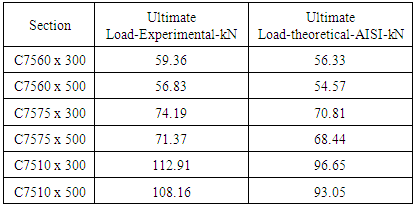

Table 4. CFRP strengthened cold formed steel-ultimate load: Experimental vs. theoretical

|

| |

|

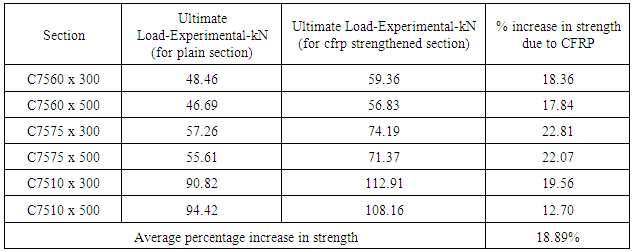

Table 5. Increase of strength due to CFRP strengthening

|

| |

|

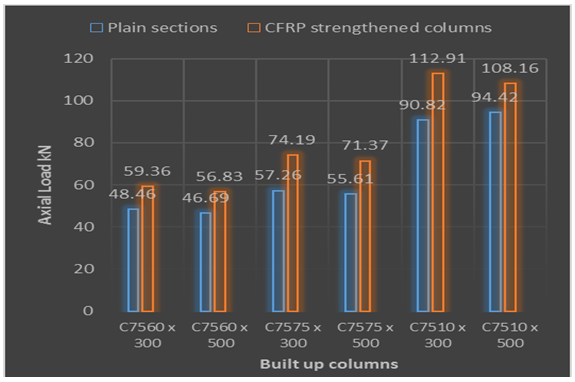

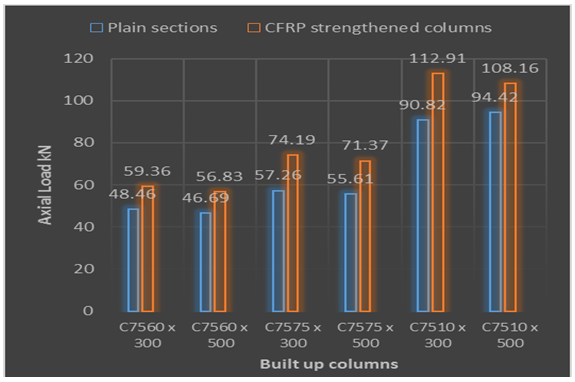

| Figure 3. Experimental results of plain and CFRP strengthened built up columns |

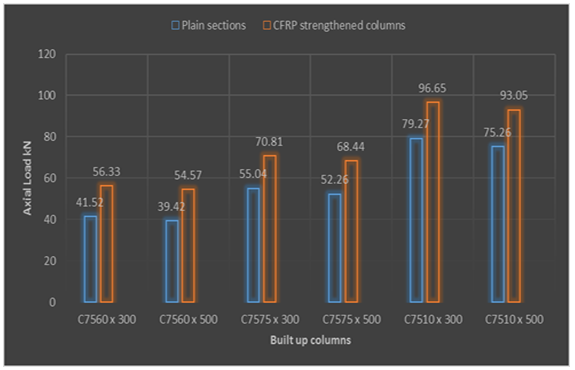

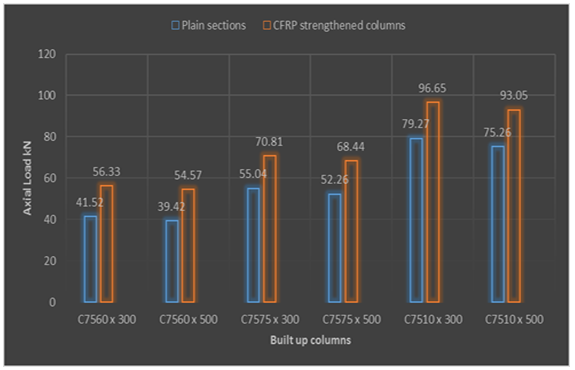

| Figure 4. Theoretical results of plain and CFRP strengthened built up columns as per AISI 2007 |

5. Conclusions

In this experimental study there were totally 12 built columns were tested. The ultimate strength of both plain and CFRP strengthened results were noted. As expected there is increase in strength of about 18.89% due to CFRP strengthening. The plain sections ultimate strength were calculated using direct strength method as specified in AISI standards and these results were closely matching with the experimental results. The proposed equations used for the calculations of CFRP strengthened built up columns using modular concept ratio method results also closely matching with the experimentally tested built up columns. There is chances of failure or pull out of screws will lead to reduction of ultimate strength of built up columns.

References

| [1] | Ben Young, M.ASCE; and Ju Chen, Design of Cold-Formed Steel Built-Up Closed Sections with Intermediate Stiffeners. 10.1061/(ASCE)0733-9445(2008)134:5(727). |

| [2] | Yu, W. W. Cold-formed steel design, 3rd Ed,Wiley, New York. |

| [3] | Demao Yang and Gregory J. Hancock, Compression Tests of High Strength Steel Channel Columns with Interaction between Local and Distortional Buckling. 10.1061/(ASCE)0733-9445(2004)130:12(1954). |

| [4] | Sreedhar Kalavagunta, Sivakumar Naganathan and Kamal Nasharuddin Bin Mustapha, Experimental Study on CFRP Strengthened Cold Formed Channel Columns, Research Journal of Applied Sciences, Engineering and Technology 6(21): 4058-4062, 2013. |

| [5] | Jimmy Haedir, Xiao-Ling Zhao, Design of short CFRP-reinforced steel tubular columns, Journal of constructional Steel Research 67 (2011) 497–509. |

| [6] | Sreedhar Kalavagunta, Sivakumar Naganathan and Kamal Nasharuddin Bin Mustapha, Proposal for design rules of axially loaded CFRP strengthened cold formed lipped channel steel sections, Thin-Walled structures 72(2013) 14–19. |

| [7] | AISI (American Iron and Steel Institute), 2007. North American Specification for the Design of Cold-Formed steel structural members. Iron and Steel Institute, Washington, DC. |

| [8] | N. Silvestre, D. Camotim and B. Young on the use of the EC3 and AISI specifications to estimate the ultimate load of cfrp-strengthened cold-formed steel lipped channel columns, Asia-Pacific Conference on FRP in Structures (APFIS 2007). |

| [9] | Schafer, B.W., 2006, Designing cold-formed steel using the direct strength method. Proceeding of the 18th International specialty Conference on Cold-Formed Steel Structures. Orlando, Florida, October 26-27. |

| [10] | Nuno, S., C. Dinar and Y. Ben, 2009 On the use of the EC3 and AISI specifications to estimate the ultimate load of CFRP-strengthened cold-formed steel lipped channel columns. Thin Wall. Struct., 47: 1102-1111. |

Pcre = Minimum of the critical elastic column buckling load in flexural, torsional, or torsional-flexural buckling.Local Buckling (Pnl):

Pcre = Minimum of the critical elastic column buckling load in flexural, torsional, or torsional-flexural buckling.Local Buckling (Pnl):

Pcrl = Critical elastic local column buckling load.Distortional Buckling (Pnd)

Pcrl = Critical elastic local column buckling load.Distortional Buckling (Pnd)

Pcrd = Critical elastic distortional column buckling load.

Pcrd = Critical elastic distortional column buckling load.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML