-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Journal of Civil Engineering Research

p-ISSN: 2163-2316 e-ISSN: 2163-2340

2016; 6(4): 79-85

doi:10.5923/j.jce.20160604.01

Geotechnical Properties of Coconut Coir Fiber Soil Mixture

Gbenga Matthew Ayininuola, Peter Oluseyi Oladotun

Department of Civil Engineering, University of Ibadan, Ibadan, Nigeria

Correspondence to: Gbenga Matthew Ayininuola, Department of Civil Engineering, University of Ibadan, Ibadan, Nigeria.

| Email: |  |

Copyright © 2016 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

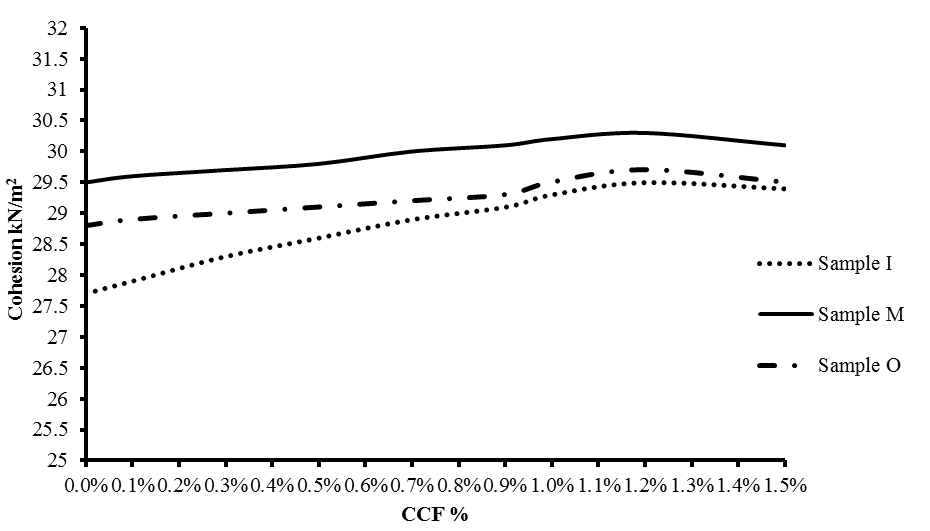

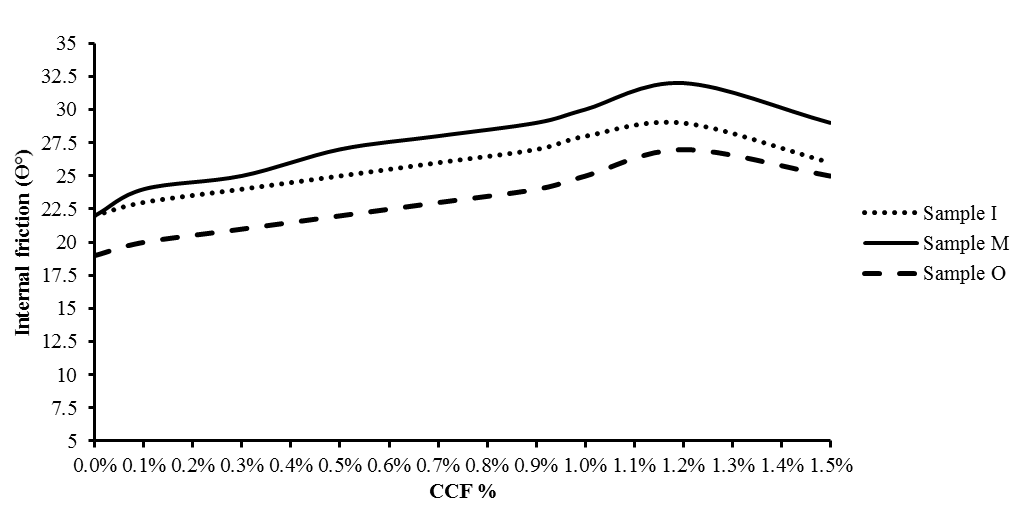

Soil encountered in many sites are either sound enough to withstand designed load from proposed structures to be erected upon them or there may be need to have the soil modified. One major method of enhancing soil strength capacity is to reinforce the soil with natural or artificial fibers. Coconut coir fiber was used as an additive material to improve the strength properties of soils such as the maximum dry density, the cohesion, angle of internal friction and the California bearing ratio CBR. Three different soil samples were sourced and mixed with different percentage proportions of coconut fiber (0.1%, 0.3%, 0.5%, 0.7%, 0.9%, 1.0%, 1.2% and 1.5%). Results of the experimental study revealed that all the soil parameters tested attained highest values at 1.2% coconut coir fiber addition. Addition of about 1.2% coconut fiber to the soil will enhance its strength.

Keywords: Coconut coir fiber, Soil reinforcement, Soil shear strength, Geotechnical properties

Cite this paper: Gbenga Matthew Ayininuola, Peter Oluseyi Oladotun, Geotechnical Properties of Coconut Coir Fiber Soil Mixture, Journal of Civil Engineering Research, Vol. 6 No. 4, 2016, pp. 79-85. doi: 10.5923/j.jce.20160604.01.

Article Outline

1. Introduction

- Stabilization is a process of improving subsoil engineering properties prior to construction. This can be accomplished in several ways such as preloading of the grounds involving application of high energy impacts, use of sand drains, prefabricated wick drains and chemical additives [1]. Reinforcement consists of incorporating certain materials with some desired properties within other material which lacks those properties [2]. Therefore, soil reinforcement is defined as a technique adopted to improve the engineering characteristics of soil in order to improve the soil properties such as shear strength, compressibility, density; and hydraulic conductivity [3]. Consequently, reinforced earth is a composite material consisting of alternating layers of compacted backfill and man-made reinforcing material [4]. The primary purpose of reinforcing soil mass is to improve its stability, increase its bearing capacity, and reduce settlements and lateral deformation [5].In ancient times, fiber was used for reinforcing soils. Early civilizations added straws and plant roots to soil bricks and cob wall to improve their properties although their mechanisms were not fully understood. However, modern geotechnical engineering has focused on the use of planar reinforcement. The reinforcing of soil with discrete fibers is still a relatively new technique in geotechnical projects [6].The concept of fiber-reinforcement in geotechnical projects originally involved the use of plant roots as reinforcement. Most researchers reported that plant roots increased the shear strength of the soil and the stability of natural slopes. With development of polymeric fiber since the late 1980s, triaxial compression tests, unconfined compression tests and direct shear tests have been conducted to study the effect of synthetic fiber-reinforcement on shear strength. Additionally, fiber-reinforcement previously was used to improve the road structure. Fiber reinforced subgrade (coir fiber and synthetic fiber) had notable influence on unconfined compression strength of silty sand [6]. Previous research has shown that fiber-reinforcement could increase the peak shear strength and limited post peak reductions in shear resistance and decreased the stiffness of the soil. Most of the experimental studies were conducted using granular soils. The mechanisms of fiber-reinforcement on dry sand reinforced with different types of fiber by using direct shear tests have been studied [7]. Fibers were placed at different specific orientations with respect to the shear plane. The fiber content, orientation of fibers, and modulus of fibers were found to influence the contribution of fibers to the shear strength development. The behavior of sand reinforced with discrete randomly oriented inclusions among other factors on particle shape and size of the sand has been investigated [8]. The effect of fiber-reinforcement was found to be more significant in fine sand with sub rounded particles than in medium grained sand with sub angular particles. The extensibility of the fibers was also found to influence the soil-fiber interaction. Fiber-reinforcement was reported to increase the shear strength of cohesive soils. The effect of two different forms of reinforcement such as coir mat and coir fiber as reinforcement in sand was explored [9]. Direct shear results with coir mat of different size openings and coir fiber of different lengths and at different percentages were added to determine the effect of their inclusion on shear strength of sand. It was found that the coir mat yielded higher value of angle of internal friction when compared with coir fiber. The use of waste fiber materials such as scrap tire rubber, polyethylene, and polypropylene fiber for the modification of clayey soils under unconfined compression, shear box, and resonant frequency tests was evaluated [10]. Waste fibers improved the strength properties and dynamic behaviour of clayey soils. Some researchers have studied the use of fibers to improve the ductility of cement-stabilized soils. Fiber-reinforcement increased the peak and residual shear strength of cement-treated soil, and changed their brittle behavior to ductile behavior was reported [11]. Behavior observed when using fibers with soils stabilized with cement or fly ash have been examined [12].The results of compaction tests on silty clay soil specimens reinforced with fibers were reported [13]. They concluded that the presence of fibers caused decrease in the density of soil. Unlike the case of sandy gravel, the test results showed that increment in the fiber content caused a modest increase in the maximum dry unit weight. The optimum moisture content was found to decrease with increasing in fiber content. The results of compaction test on palm fiber reinforced silty sand shown that the maximum dry density decreased and optimum moisture content increased with increasing in fiber content [14]. So far not much work has been reported on the use of coconut coir fiber. The present study is set out to investigate the behavior of coconut coir fiber in soil visa-vis its geotechnical properties.

2. Materials and Methodology

- Soil samples were collected from three different locations namely: Location I- Academy area, Iwo road with Latitude 7°24’19.316”N and Longitude 3°56’47.229”N, Location O- Olorunda Abaa area with Latitude 7°28’05.861”N and Longitude 3°58’42.888”N and Location M- Mokola area with Latitude 7°24'43.931"N and Longitude 3°53'28.361"E in Ibadan, Nigeria as shown in Figure 1. The soil samples were air dried and stock-piled for laboratory work. Coconut were bought from coconut vendor in Ibadan, processed so that the fibers were extracted manually and separated into strands of about 4cm long (Figure 2).

| Figure 1. Map showing the 3 samples locations I, M and O. Source: Google Earth |

| Figure 2. Weighing the fiber to be compacted with the soil |

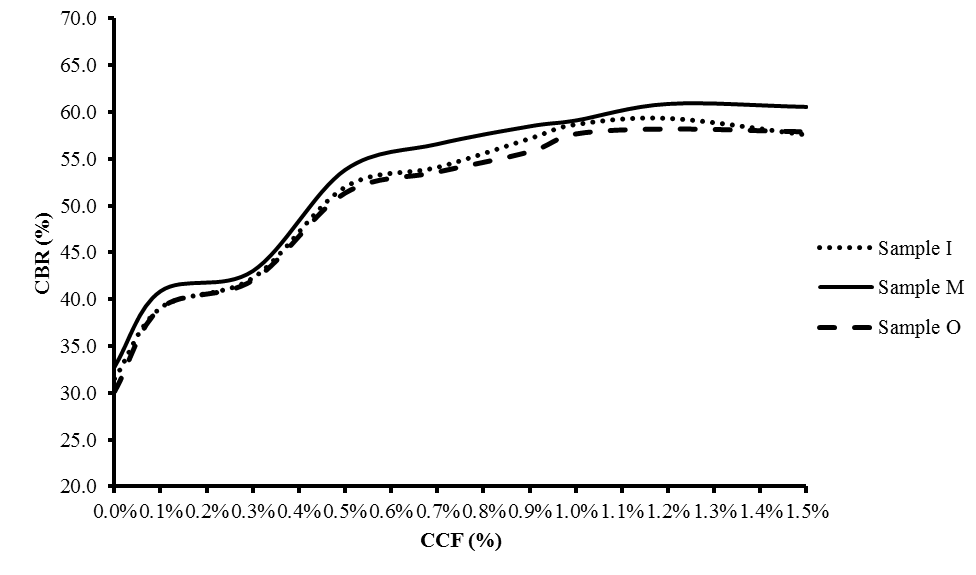

3. Results and Discussion

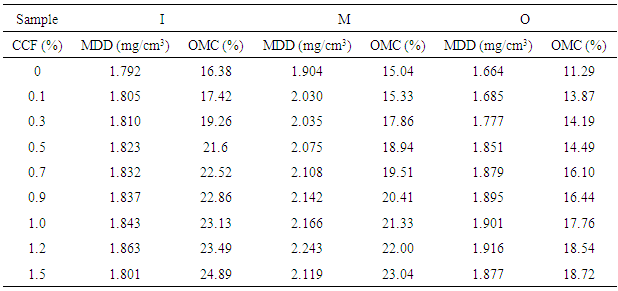

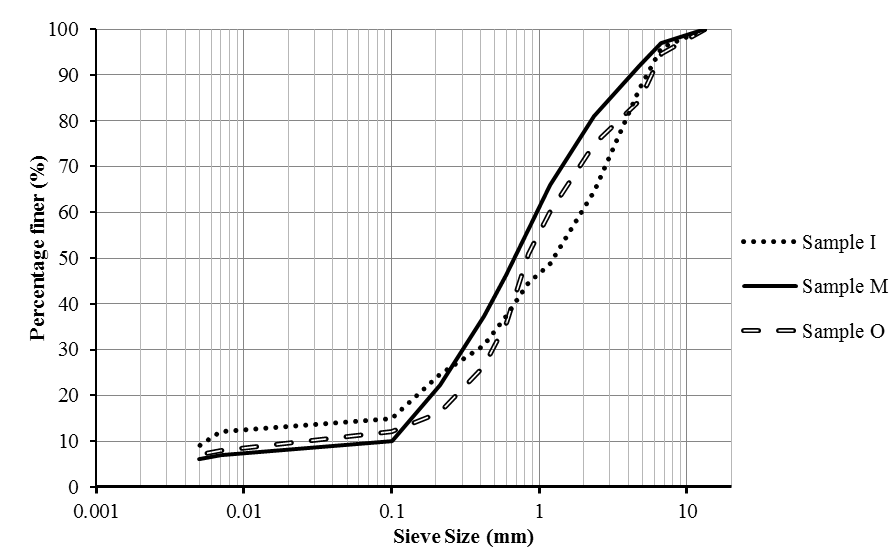

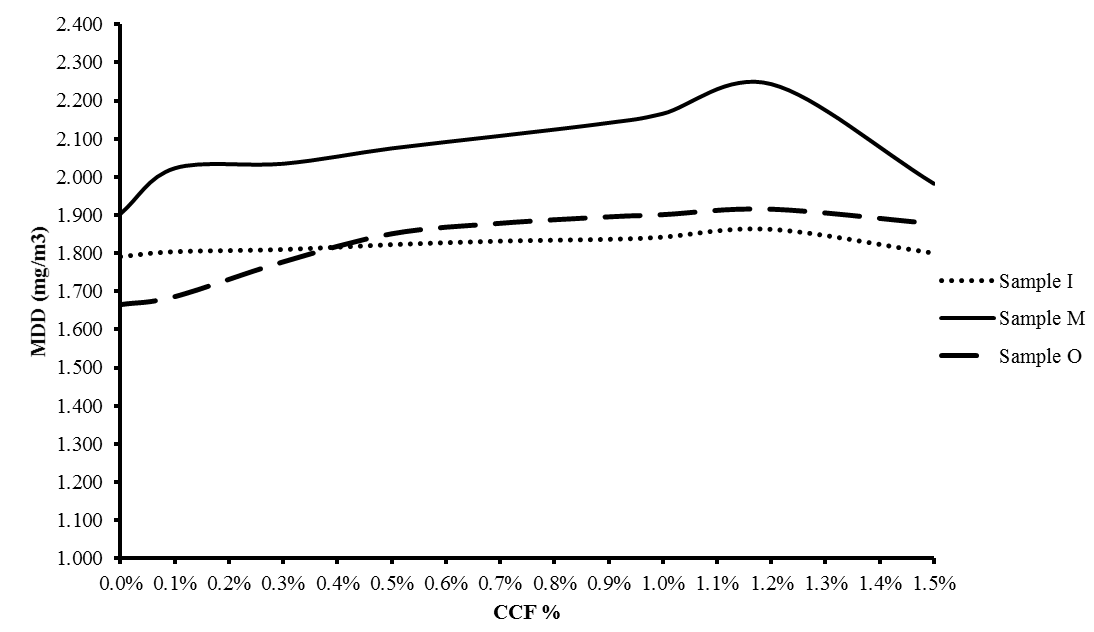

- All control tests were tests conducted on samplies with 0% of fiber. Sample obtained from Academy Area, Iwo road was represented as I, Mokola Area represented as M and Olorunda Abaa Area represented as O. Particle size analysis test, Atterberg limits test, California bearing ratio (CBR), compaction test and triaxial test were performed in accordance with ASTM Standards as shown in Figures 3 to 5. Sieve analysis tests were performed on control samples I, M and O.

| Figure 3. Properly mixing the fiber-soil with water |

| Figure 4. CBR machine set-up |

| Figure 5. Multiplex 50 set up for shear strength test |

|

| Figure 6. Particle distribution curve of the three soil samples |

| Figure 7. Curve of soil samples maximum dry density against different percentages of coconut coir fiber |

| Figure 8. CBR values of Samples I, M and O at different fiber percentages |

| Figure 9. Cohesion values of the 3 samples at different fiber percentages |

| Figure 10. The different internal friction angles of Samples I, M and O at different percentages of CCF |

4. Conclusions

- The in-depth experimental study revealed that the soil samples geotechnical parameters reached peak values when the percentage of coir coconut fiber added reached 1.2%. This showed that enough quantity of fiber is in the soil to hold its particles together to supplement the resistance of soil against external load.

ACKNOWLEDGEMENTS

- The authors wish to express our profound gratitude to the members of staff of the soil laboratory of the Department of Civil Engineering University of Ibadan. They rendered high level of assistance during the experimental set up of the research.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML