-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Journal of Civil Engineering Research

p-ISSN: 2163-2316 e-ISSN: 2163-2340

2016; 6(3): 55-60

doi:10.5923/j.jce.20160603.02

Effect of Polymer Modification on Rheological Properties of Asphalt

Muhammad Ashraf Javid

Department of Civil and Environmental Engineering, University of Nizwa, Nizwa, Oman

Correspondence to: Muhammad Ashraf Javid, Department of Civil and Environmental Engineering, University of Nizwa, Nizwa, Oman.

| Email: |  |

Copyright © 2016 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Flexible pavement structures are subjected to heavy traffic loading and repetition of such loading deteriorates the pavement. Fatigue cracking and permanent deformation (rutting) in pavement layers are the results of this deterioration. These problems arise due to improper characterization of asphalt binder. The conventional testing procedure does not provide deeper picture about behaviour of asphalt. It is required to characterize the asphalt after making some polymer modification and by using some advance testing protocol. This paper tries to evaluate the temperature susceptibility behavior of virgin and polymer modified asphalt and suggests some practical implication considering local industry use. Six polymer modified asphalt samples were prepared in the laboratory and tested with two virgin grades and one factory polymer modified sample using Dynamic Shear Rheometer (DSR). The testing results revealed that polymer modification has significant impact on reheological properties of asphalt binder. Viscosity-temperature susceptibility changes with the addition of polymer which makes asphalt suitable to use in warmer and colder regions in order to control the various distresses in flexible pavements. The finding of this paper would be helpful for local road construction industry for characterization of locally available asphalts and their modified versions.

Keywords: Polymer, Modified Asphalt, Viscosity-Temperature Susceptibility

Cite this paper: Muhammad Ashraf Javid, Effect of Polymer Modification on Rheological Properties of Asphalt, Journal of Civil Engineering Research, Vol. 6 No. 3, 2016, pp. 55-60. doi: 10.5923/j.jce.20160603.02.

Article Outline

1. Introduction

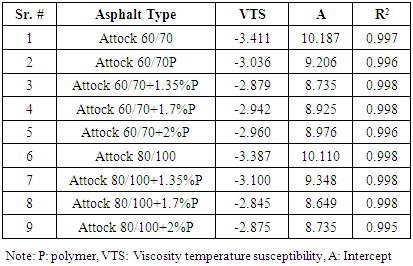

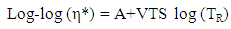

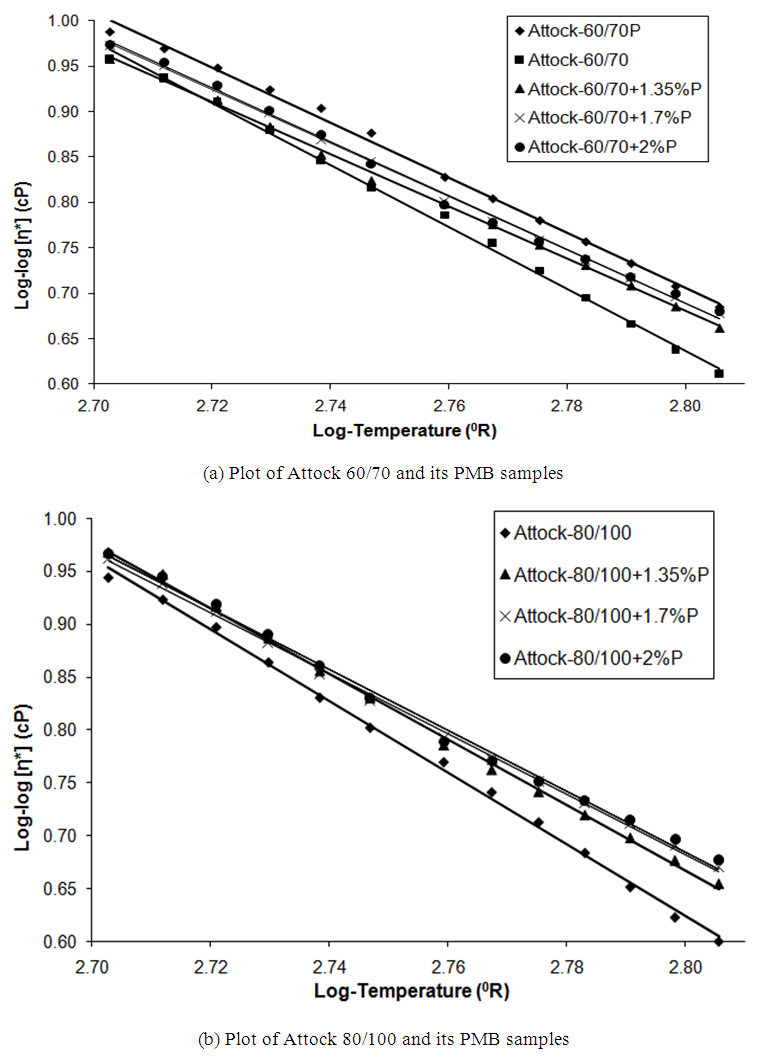

- Asphalt is largely used to construct pavements for highways and airports. Both asphalt binder and asphalt aggregate mixtures show temperature and time dependent behavior. Fatigue cracking and rutting are two major flexible pavement distresses. Temperature, loading and time dependent behaviour of asphalt binder affect the rutting and cracking characteristics of asphalt concrete mixture. Rutting is a major reason of premature deterioration of asphalt pavements in warm climatic regions of Pakistan whereas fatigue and thermal cracking is a common problem in cold regions. In Pakistan, the maximum temperature lies in the range of 45-50°C whereas average minimum temperature fall in the range of -20 to -15°C (Mirza et al., 2011). It is believed that early failure of asphalt pavement (e.g. rutting) usually results from inadequate strength properties of mix, while long-term failure is the result of significant fatigue in the pavement structure (Abojaradeh, 2013). These problems arise in asphalt pavements due to improper mix design and lack of asphalt binder characterization. Therefore, now-a-days polymer modification has been increasingly employed in asphalt concrete, primarily for control of short-term permanent deformation (Javid and Rahim, 2011, Lu and Isacsson, 1999, Bouldin and Collins, 1992). Polymer modification typically improves asphalt binder ductility, thereby providing asphalt binder that is more durable to pavement stress and deformation (Javid, 2014, Glover et al., 2005, Bahia et al., 2001).Temperature susceptibility of asphalt cement is an important control parameter during the mixing, placing, compaction, and performance of asphalt concrete. Viscosity temperature susceptibility and temperature relationship is used to predict the rheological properties of asphalt binder. A regression of the double logarithm of the viscosity points versus the logarithm of respective temperatures in the Rankine scale (TR) provides the basis of the ASTM (American Society for Testing and Materials) Ai-VTSi relationship as follows in Eq. 1 (Anderson et al., 1994).

| (1) |

2. Materials and Experimental Setup

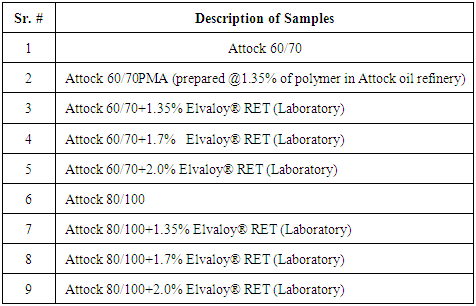

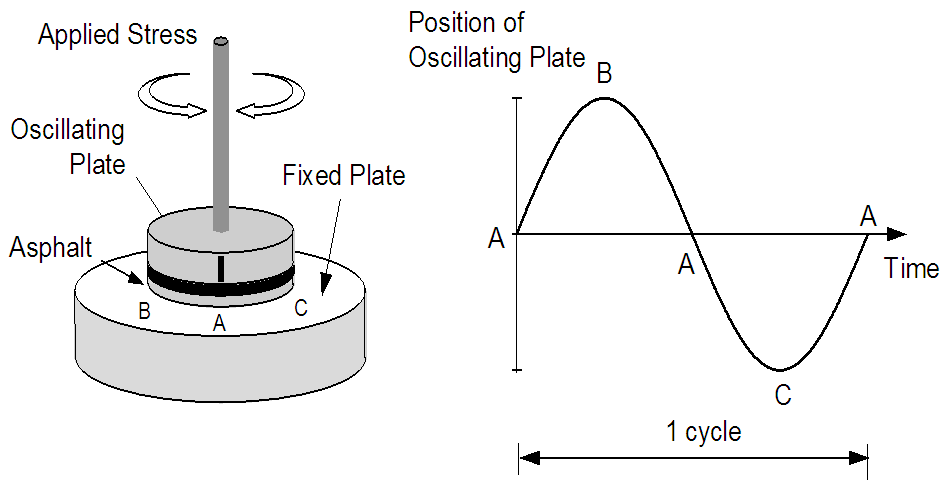

- This research included laboratory testing to study the effect of polymer modification on temperature susceptibility of asphalt binder. Three asphalt samples from Attock Oil Refinery 60/70, 60/70P (polymer), 80/100 were obtained and six PMA (polymer modified asphalt) samples were prepared in the laboratory by blending three percentages (i.e. 1.35, 1.7 & 2%) of DuPont™ Elvaloy® RET polymer with two virgin grades i.e. 60/70 & 80/100. It is a reactive elastomeric polymer that bonds with asphalt through a chemical reaction and gives elastomeric properties to improve road performance at high temperature. At low-temperature (below approximately 4°C) the properties of polymer-modified asphalt are determined mainly by the base asphalt. This polymer is provided as free-flowing pellets that melt into hot asphalt to form permanently modified asphalt binder. The PMA remains easy-to-use, and also delivers improved long-term resilience and climate resistance. The improved asphalt binder remains homogenous, with good aggregate coating and adhesion properties (DuPont).Total nine samples as presented in Table 1 were tested at a frequency of 10 rad/sec and at thirteen test temperatures covering a range of intermediate temperature (7, 13, 19, 25, 31, 37°C) and high temperature range (46, 52, 58, 64, 70, 76, 82°C) using Dynamic Shear Rheometer (AASHTO TP51). In DSR test operation, the asphalt sample is sandwiched between two parallel plates, one of which is fixed and the other one is moveable, as shown in Figure 1.

|

2.1. Preparation of Polymer Modified Asphalt in the Laboratory

- Required quantity of virgin asphalt (i.e. 800 grams) was taken for blending purpose in the mixer. This quantity of asphalt was taken considering that it should be enough to perform different tests. To make asphalt sample workable, it was heated in oven at a temperature of 165°C. The sample was placed on hot plate at 165°C. Then required amount (1.35%, 1.7% and 2% of asphalt sample by weight) of Elvaloy® RET polymer was added into the virgin asphalt with the continuous mixing at speed of 120 rpm. The mixing was done with the help of mechanical stirrer. It was assured that there should not be any formation of clogs while adding the polymer into the asphalt binder. After the addition of whole polymer, the asphalt was kept on agitating for further half an hour to insure the proper mixing. Super Phosphoric Acid (SPA) was also added (i.e. 1.4 gram) as a catalyst in the blended sample. After the addition of SPA the viscosity was measured at 165°C. Again after 30 minutes viscosity was measured and mixing process remained continue until the viscosity become constant. After completion of mixing the prepared sample was kept in oven for two hours for curing purpose.

| Figure 2. Operational mechanism of DSR test |

3. Analysis of Testing Results

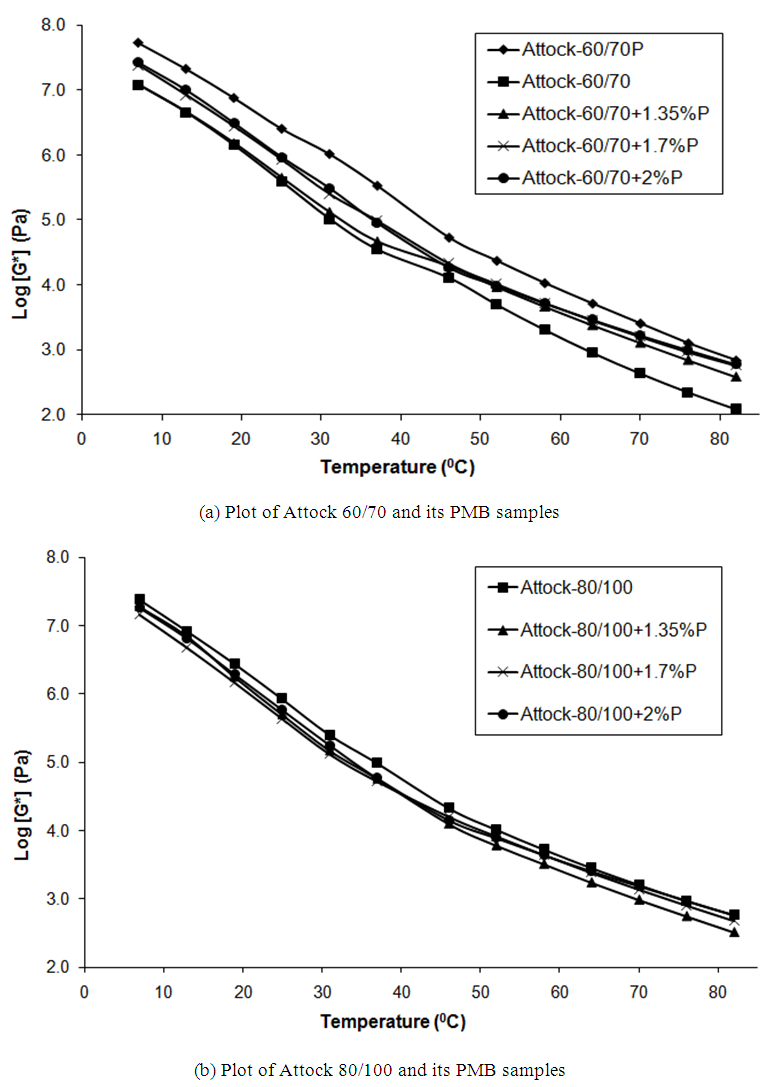

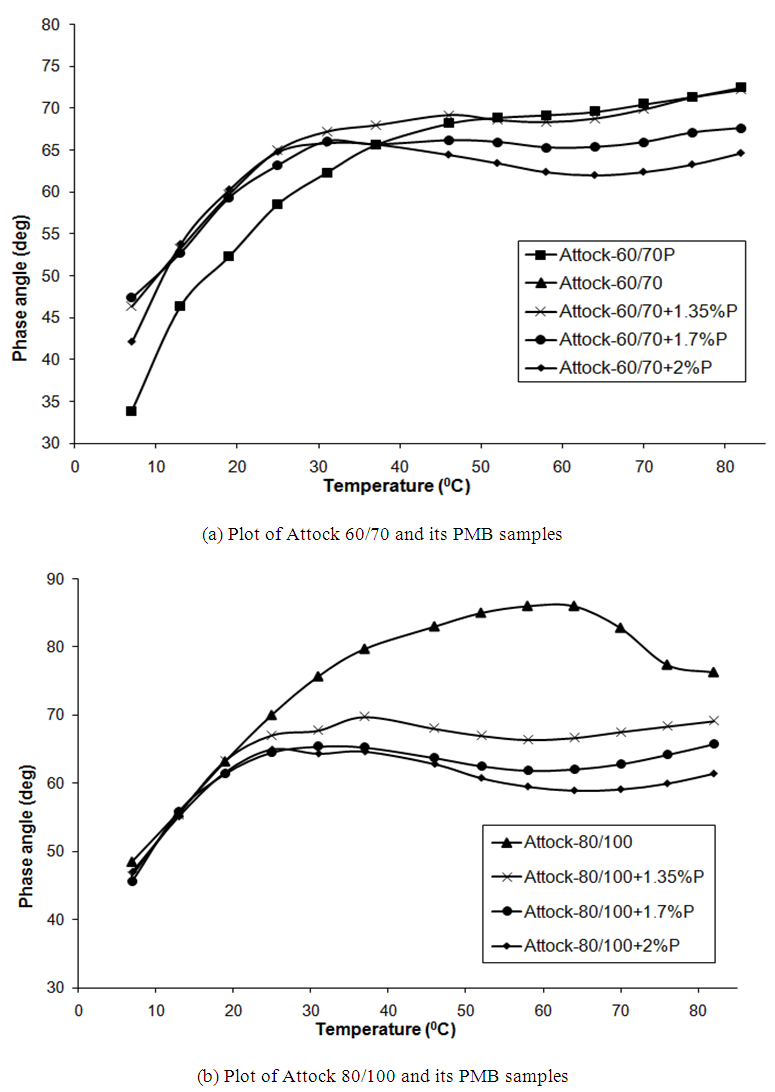

- The complex shear modulus (G*) and phase angle (δ) were obtained by using DSR for all the asphalt samples and log of complex shear modulus was plotted against temperature as given in fig. 3 whereas phase angle plot against temperature as follows in fig. 4.

| Figure 3. Comparative plots for complex shear modulus (G*) |

| Figure 4. Comparative plots for phase angle (δ) |

| Figure 5. Comparative plots for Viscosity Temperature Susceptibility (VTS) |

|

4. Conclusions

- This research was conducted to investigate the effect of polymer modification on temperature susceptibility of asphalt binder. The testing and analysis results reveal that there is significant effect of polymer modification on reduction of viscosity temperature susceptibility (VTS) as temperature susceptibility of laboratory PMBs is less compared with virgin asphalts. This makes polymer modified asphalt binder more suitable to use in extreme climatic conditions i.e. to control rutting in high temperature regions and to control fatigue cracking in colder regions. It is found that the behaviour of modified asphalt is almost same at 1.7% and 2% of polymer contents; therefore, it can be argued that 1.7% is optimal content of polymer for modification. The elastic component of laboratory PMB samples is more as compared to virgin asphalt and Attock 60/70P which makes them more suitable to resistant rutting and fatigue cracking. The findings of the paper would be helpful for local road construction industry in improving the performance of pavement.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML