-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Journal of Civil Engineering Research

p-ISSN: 2163-2316 e-ISSN: 2163-2340

2016; 6(3): 47-54

doi:10.5923/j.jce.20160603.01

Design of a Compost Waste Heat to Energy Solar Chimney Power Plant

Kevin R. Anderson1, Yasser Salem2, Suzanne Shihadeh1, Pedro Perez1, Benjamin Kampen1, Souha Jouhar3, Saman Bahrani3, Kainan Wang3

1Solar Thermal Alternative Renewable Energy Lab, Mechanical Engineering, California State Polytechnic University, Pomona, USA

2Civil Engineering, California State Polytechnic University, Pomona, USA

3Construction Engineering Technology, California State Polytechnic University, Pomona, USA

Correspondence to: Kevin R. Anderson, Solar Thermal Alternative Renewable Energy Lab, Mechanical Engineering, California State Polytechnic University, Pomona, USA.

| Email: |  |

Copyright © 2016 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

This paper presents the design of a Compost Waste Heat to Energy Recovery Hybrid Solar Chimney Power Plant (SCPP). The project illustrates the concept of using compost waste heat to power generators housed in the SCPP. The design of the Hybrid Compost Waste Heat to Energy Recovery Hybrid Solar Chimney Power Plant is based on a full-scale 24 acre facility which can accommodate a community waste disposal needs. This paper presents the design and fabrication of the SCPP, followed by a building construction estimate for the project, and concludes with an economic analysis of the SCPP, factoring in the renewable energy, composting, recycling (waste management) and infra-structure sustainability aspects of the project. The proposed 24 acre hybrid SCPP facility has the potential of generating 100 MW with 83 M$ in revenue annually. The engineering construction cost estimate for fabrication of the SCPP is found to be 156 M$. The total cost per unit of energy produced for the SCPP is 0.62 US $ / kWh (0.56 € / kWh).

Keywords: Compost Engineering, Renewable Energy, Cost Estimate, Construction Engineering, Waste Management

Cite this paper: Kevin R. Anderson, Yasser Salem, Suzanne Shihadeh, Pedro Perez, Benjamin Kampen, Souha Jouhar, Saman Bahrani, Kainan Wang, Design of a Compost Waste Heat to Energy Solar Chimney Power Plant, Journal of Civil Engineering Research, Vol. 6 No. 3, 2016, pp. 47-54. doi: 10.5923/j.jce.20160603.01.

Article Outline

1. Introduction

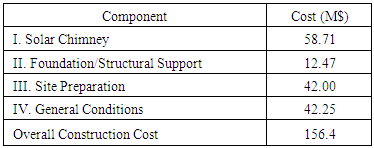

- Previous investigations in the literature have dealt with using solar chimneys as alternative energy resources. The concept of the solar chimney as a means to generate electricity is a feasible means of renewable energy technology. A comprehensive overview of solar chimney power technology is given in [1]. A prototype of a Solar Chimney Power Plant (SCPP) was constructed and operated in Spain between 1981 and 1990 as outlined in [2-6]. The study of [7] presents a solar thermal power plant utilizing a combination of a solar air collector and a central updraft tube to generate a solar induced convective flow which drives turbines to generate electricity. In the work of [8] the first pilot demonstration of a solar updraft tower power plant in Jordan is presented. The study of [9] evaluates the performance of a large-scale solar chimney power plant in South Africa. Results of [9] indicate 24 hour plant power operation, while illustrating considerable daily and seasonal power output variations. It is shown that plant power production is a function of the collector roof shape and inlet height. In the work of [10] a SCPP is proposed to be built as the first national SCPP in central regions of Iran. Studies show that Iran can be a part of the Mediterranean solar power generation chain in 2050 to provide electrical power demand of Europe. In order to evaluate SCPP performance, and power generation throughout Iran several different areas across the country were considered. The obtained results clear that solar chimney power plants can produce up to 28 MWh/month of electrical power. This power production is sufficient for the needs of the isolated areas and can be used to feed the grid. In the work of [11] the performance of SCPPs in parts of Iran are studied theoretically to estimate the quantity of the produced electric energy. The solar chimney power plant with a 350 m chimney height and 1000 m collector diameter is capable of producing monthly average up to 2 MW of electric power over a year. In the study of [12] a solar collector, chimney and turbine are modeled and iteration techniques are performed to solve the resulting mathematical model. In addition, the study proposes that the most suitable plant, affordable by local government standards to respond to the electricity demand of a typical village in Thailand, is the one with a collector radius and chimney height of 200 m and 400 m, respectively. In the work of [13] dimensionless variables are proposed to guide the experimental study of flow in a small-scale solar chimney. The recent work of [14] provides a comprehensive analytic study regarding the thermal modeling and design of SCPPs. In the work of [15] a sloped SCPP to provide electric power for remote villages in Northwest China is designed. The plant with chimney height of 252 m and chimney radius of 14 m has a solar collector having a radius of 607.2 m inclined at an angle of 31° produces 5 MW electric power on a monthly annual average. In the work of [16] four designs of 100 MW SCPPs with different combinations of collector and chimney radii are proposed and the most cost effective one is chosen from among the four SCPPs. In the study of [17] a SCPP used to provide electric power for remote villages in northwestern China is analyzed. Three counties in the Ning Xia Hui Autonomous region where solar radiation is better than other regions of China were selected as pilot locations to construct a SCPP. The SCPP, in which the height and diameter of the chimney are 200 m and 10 m, respectively, and the diameter of the solar collector cover is 500 m, is capable of producing up to190 kW of electric power on a monthly annual average. In the research of [18] a SCPP is proposed to be built in the Qinghai-Tibet Plateau where there is abundant solar radiation, large diurnal temperature range, and salt lakes which can work as a heat storage system to improve the power output of the SCPP. The yearly power potential for the SCPP in Qinghai-Tibet Plateau is estimated to be 86.8 million TJ. When approximately 15% of the plateau land is used for the SCPP, the yearly power output may reach up to 17.4 million TJ which accounts for approximately 20% of China's energy consumption in 2008. The study of [19] considers the practice of sorting at the source and the use of combustible Municipal Solid Waste (MSW) components as fuel to generate heat for a hybrid solar, flue gas, chimney power plant in Malaysia. Energy recovery from MSW incineration using a hybrid solar, flue gas, chimney power plant (HSFGCPP) is proposed. The introduction of the HSFGCPP has the objective of solving the problem of the night operation mode of the SCPP by utilizing the exhaust/waste heat in the flue gas from different sources, and also by enhancing the power generation both during the day and at night. The Malaysian HSFGCPP system utilizes flue gas waste heat to supplement the solar energy input during daytime operation, and also utilizes waste heat at night. The hybrid solar, flue gas, chimney power plant of [19] is designed to include a flue gas channel where incineration waste heat or waste heat from other industrial purposes can be recovered as useful energy. The hybrid system is made with a transparent cover, which allows solar radiation into the collector, and a flue gas channel where the hot flue gas flows and transfers/loses its heat to the collector (which acts as a heat exchanger). The current research extends the concept of a SCPP by proposing a hybrid use of compost waste heat recovery to augment the convection in the solar chimney without the use of incineration as outlined in the works of [20-24]. The Solar Chimney Power Plant (SCPP) operational principle is shown in Fig. 1.

| Figure 1. Hybrid Compost Waste Heat SCPP Tower |

2. Design of Compost Waste Heat to Energy Recovery Hybrid Solar Chimney Power Plant (SCPP)

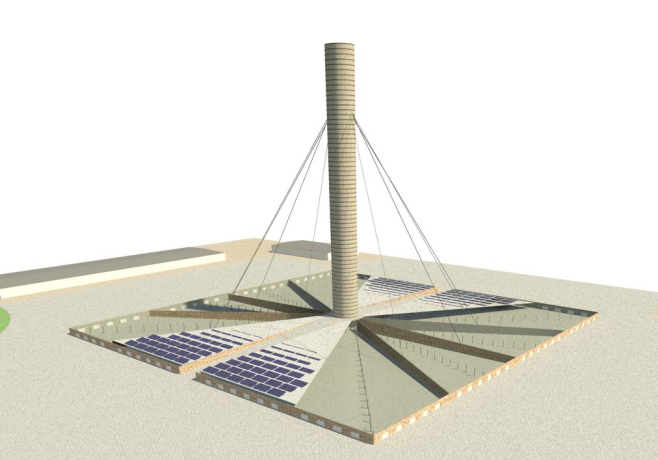

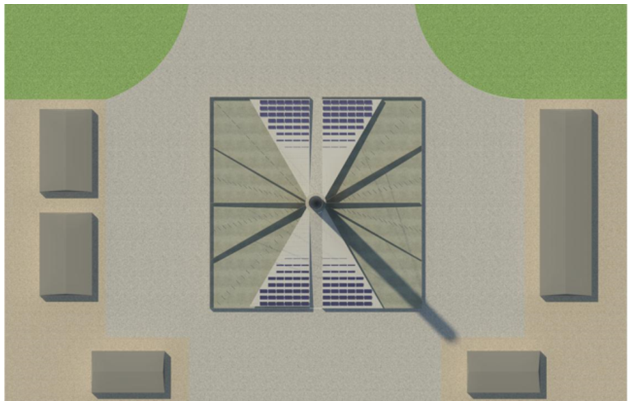

- Figure 2 and Fig. 3 show renderings of the SCPP using 12 chambers covering 24 acres. Figure 2 illustrates an isometric view of the facility, while Fig. 3 shows a plan view of the facility. For the proposed facility shown in Fig. 2 and Fig. 3 the following parameters are assumed (for a typical baseline design); chimney height, h = 200 m, chimney diameter, d = 20 m, building square plan side length, L = 300 m, total square footage of building A = 97125 m2 = 24 acres. As seen in Fig. 2 and Fig. 3, the power plant is comprised of a large metal building having 12 chambers covered with transparent roofing material, a large solar chimney supported by guidewires, and surrounding supporting infrastructure including the pressure-staged wind turbo generators.

| Figure 2. Hybrid Compost Waste Heat SCPP (Isometric View) |

| Figure 3. Hybrid Compost Waste Heat SCPP (Top View) |

2.1. Review of Compost Engineering

- In this section a brief review of compost engineering is given in order to place required compost control parameters into the context of the design of the hybrid SCPP being proposed. The compost engineering handbook by Haug (1993) [29] as well as the comprehensive treatise by Epstein (2011) [30] are essential references for the compost engineering design. Compost is organic matter which has been decomposed and recycled as fertilizer. Compost is a key ingredient to organic farming. Composting is the biological decomposition of organic matter under aerobic conditions, in to fermentation which is anaerobic decomposition which occurs under anaerobic conditions. Composting is currently being carried out for feedstocks, sewage sludge, biosolids, septage, manure, animal carcasses, food waste, yard waste, industrial waste, and military wastes. Composting is an excellent way to disinfect wastes as it destroys bacteria, viruses and parasite. Composting can play a role in disinfecting human and animal wastes in developing countries. When a good composting process is reached and thermophilic temperatures for several days, the compost can be used for crop production including vegetables. As outlined in [30] the design of composting facilities must take into account, siting, planning, economic/cost analysis, and compost management issues such as odors and pathogens.The process of compost must by controlled and managed. Composting involves making a heap of wetted organic material (green waste) and waiting for the materials to break down into humus after a period of months. Organic ingredients intended for composting can alternatively be used to generate biogas through anaerobic digestion. Composting is a multi-step, closely monitored process with measured inputs of water, air, and carbon- and nitrogen-rich materials. The decomposition process is aided by shredding the plant matter, adding water and ensuring proper aeration by regularly turning the mixture. Worms and fungi further break up the material. Bacteria requiring oxygen to function (aerobic bacteria) and fungi manage the chemical process by converting the inputs into heat, carbon dioxide and ammonium. The ammonium (NH4) is the form of nitrogen used by plants. When available ammonium is not used by plants it is further converted by bacteria into nitrates (NO3) through the process of nitrification. Monitoring the parameters of moisture, pH, odor and temperature helps aids the waste management engineering team in determining the status of the compost and gives a comparison of the progress of system with different initial conditions or ingredients. Moisture needs to be monitored, since composting proceeds best at a moisture content of 40% to 60% by weight. At higher moisture levels, the process is anaerobic and foul-smelling and at lower moisture levels, microbial activity is limited. Aeration needs to be controlled since if too much air is blown through the compost system, the compost can potentially dry it out. If the temperature drops sooner than expected and the compost looks dry, moisture may have become the limiting factor. In this case water is added the temperature should rise again. Odor is a concern when dealing with compost facilities, since the compost starts to smell bad if it is too wet. Excess water fills the pore spaces, impeding diffusion of oxygen through the compost materials and leading to anaerobic conditions. Mixing in additional bulking agent such as dry wood chips, cardboard pieces, or newspaper strips is likely to alleviate the problems affiliated with odor. The Cornell University [31] compost worksheet is useful to the waste management / compost engineering team as a design tool to aid in the selection of the right type of components in the compost pile. The Cornell composting spreadsheet is a tool which allows the compost engineering team to select the correct proportions of ingredients such as leaves, garbage, food wastes, water, etc. in order to meet a C/N goal. The optimum C/N ratio can then be used as a metric to gage the health and progress of the compost pile.Temperature is a measure of the amount of heat being generated as a byproduct of microbial breakdown of organic material. The overall temperature of the compost is an indication of how far along the system has progressed in the decomposition process. If the compost heats up to 40 or 50°C the ingredients contain adequate nitrogen and moisture for rapid microbial growth. A typical composting system will heat up to 40 or 50°C within 2 to 3 days. As readily decomposable organic matter becomes depleted, the temperature begins to drop and the process slows considerably. Estimates provide heat flux emanating from a compost pile as 6548 W/m2 [32] and on a volumetric (tonnage) basis 0.516 kW/t [33]. Monitoring the pH is important since, during the initial stages of decomposition, organic acids are formed. The acidic conditions are favorable for growth of fungi and breakdown of cellulose. As composting proceeds, the organic acids become neutralized, and mature compost generally has a pH between 6 < pH < 8. If anaerobic conditions develop during composting, organic acids may accumulate rather than break down. Aerating or mixing the system helps to reduce the acidity. The above compost engineering parameters must be considered when designing the hybrid compost waste heat to energy / SCPP system discussed herein.

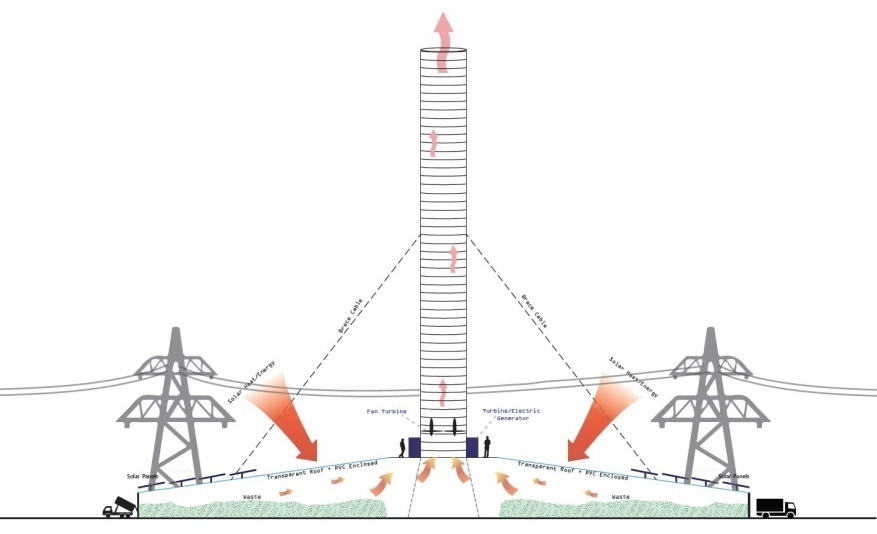

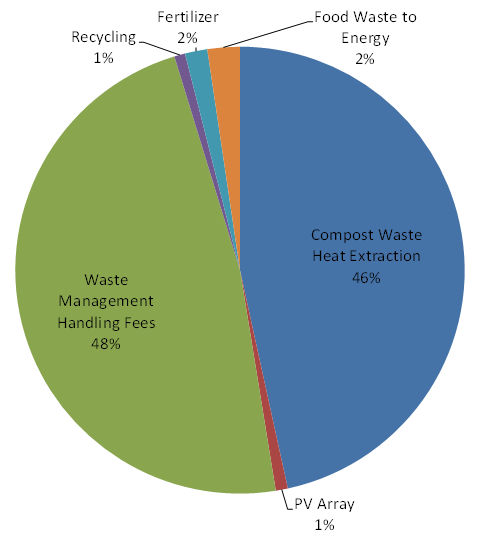

3. Economic Analysis of Compost SCPP

- In this section of the paper, we present an economic analysis of the proposed hybrid compost waste heat to energy SCPP project. The various renewable energy technologies which generate revenue are address individually in the following sections. The analysis below has been made by referring to the USA standard costs.1. Waste Heat to Energy Conversion EconomicsAn accurately constructed compost system will heat up to 40 to 50C within 2 to 3 days [31]. As readily decomposable organic matter becomes depleted, the temperature begins drop and the process slows considerably. For the waste heat to energy extraction technology, the heat generation on a tonnage basis is estimated to be on the order of Q = 0.516 kW/ton [33]. On a tonnage basis, the SCPP will process 17,000 t/chamber, for 24 chambers this gives 204,000 t. Thus, Q = 0.516 kW/t*204,000 t = 105 MW is the estimated potential for compost waste heat to energy conversion. Taking the duty to be 365 days and 8 hours per day gives 105 MW*365*8 hr = 307,371 MWh. For conservatism we assume an energy conversion efficiency of 80%, to obtain 245,897 MWh for the waste to heat energy conversion process. Taking the rate of electricity in San Bernardino, California, USA to be 0.1598 $/kWh, affords $39.3 M due to waste heat to energy conversion.2. Tipping Fee Revenue EconomicsConsidering 4055 m2 per acre, for 2 acres/chamber and a 3.048 m pile of waste yields 24,720 m3. Assuming 1.5292 m3/t affords 16,165 t/chamber. An assumed tipping fee of 52 $ per ton [24], gives $840,572 per chamber. Assuming the chambers will operate 4 per cycle gives 3.36 M$ per chamber. For 12 chambers, this gives 40.3 M$ annually for tipping revenue.3. Recycling Revenue GenerationAssuming 8% of the waste can be recycled gives 16,320 t of waste which can be sold for recycling. At a rate of $40/t [25], this gives 0.65 M$ of revenue generated by selling the recycled waste. 4. Compost Fertilizer GenerationFor composting, assuming 2/3rd of the waste can be used for composting gives at an assumed rate of $10 per ton of composting [25], 1.36 M$ of revenue generation from composting. 5. Solar PV Electricity GenerationThe SCPP shown in Fig. 1 accommodates multiple renewable energy technologies to be realized in synergy. Using the available transparent roof real estate, one can populate that area with solar photovoltaic (PV) panels. Assuming a PV solar array area density of 27 W/m2. For the 24 acre structure, assume that 80% of the roof is populated with PV panels. Then for a duty of 12 hours of sunlight per day, for 183 days of sunshine (since other days it will be raining and cloudy) gives 4232 MWh, at a rate of 0.16 $/kWh gives 0.68 M$ for PV solar.6. Hydrothermal Carbonization (HTC) The Hydrothermal Carbonization (HTC) Food Waste to Energy technology of (Pham et al. 2014) is assumed to comprise an additional 5% of the overall waste heat to energy conversion economics lending an additional anticipated $2 M annually. 7. Economics Analysis SummaryThe above values which tally $83M annually are summarized in Figure 4. From Fig. 4, the majority of revenue 48% ($40.3 M) is due to tipping (waste management) handling fees, followed by 46% ($39.3 M) due compost waste heat to energy conversion, 2% ($1.4 M) for compost fertilizer sales, 2% ($2 M) for food waste to heat energy conversion, 1% ($0.7M) for recycling, and 1% ($0.68 M) for solar photovoltaic energy conversion. The above economic analysis is only a representative example. Actual values will change according to the size of the solar tower, PV array real estate population, feed-rate of waste to the power plant, etc. This analysis can be used as a roadmap to implement the proposed hybrid technologies offered by the hybrid compost waste heat to energy SCPP proposed herein.

| Figure 4. Economic Potentials for Hybrid Compost SCPP (values based on $83M annually) |

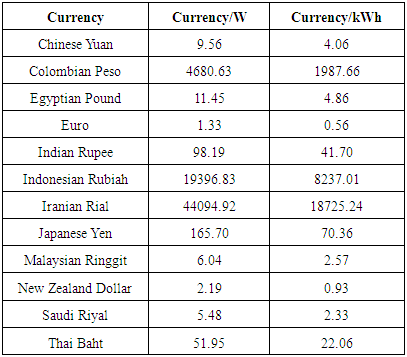

4. Construction Engineering Cost Estimation of SCPP

- The cost estimate was prepared using fundamentals of building construction estimating taking into consideration quantity surveying, employment rates, specifications, code compliance, materials and equipment costs. Typical industry standard values based on experience and judgement were assumed when preparing the cost estimate summary of Table 1. The total cost estimate of 156.4 M$ of Table 1 is found to be in agreement with prior estimates obtained by COMPO Energy, Inc. from general contractors.

|

|

5. Prototype Facility

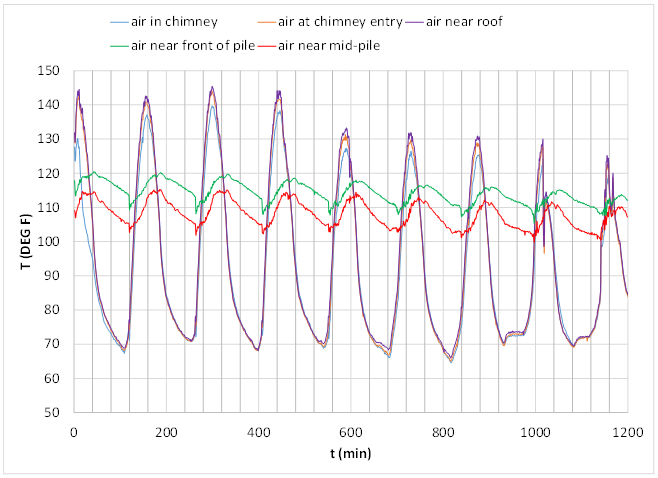

- In order to validate the concept of using compost waste heat to augment the convection in a solar chimney, an experimental prototype was constructed at California State Polytechnic University at Pomona’s Lyle Center for Regenerative Studies. The experimental prototype facility of the compost waste-to-heat / solar tower is shown in Fig. 6. The data acquisition set-up used in the prototype facility is shown in Fig. 7. The facility includes access doors, a solar chimney and an aeration system. The prototype holds 27.9 m2 of compost 1.524 m, affording 42.47 m3. The actual power plant is 24 acres, with 12 chambers, thus each chamber is 2 acres = 8094 m2, and the compost pile is 3.048 m tall, affording 24,670 m3 per chamber. Thus the test prototype facility is 1:290 scale based on square footage and 1:580 based on cubic volume of the actual SCPP shown in Fig. 1. Figure 8 shows temperature versus time for the chamber experimental data. Noticeable from Fig. 8 is the presence of a solar diurnal load (due to the solar loading on the roof), which heats and cools the compost pile over the 24 hour period from sunrise to sunset. Regardless of the solar diurnal fluctuation, the air entrapped between the top of the compost pile and the transparent roof remains at 49°C < T < 54.4°C. Results of the prototype for aerated average surface pile temperature are: 248°C, outdoor air: 194°C. These findings are in agreement with those of the experiments of [26]. This provides a ΔT to the chimney of 272 K on average. From Fig. 8 the decay rate of the compost pile is seen to be on the order of -15°C/day. Thus, Fig. 8 can be used to estimate the thermal time constant (growth rate) and monitor the health of the compost system.

| Figure 6. Prototype facility overview |

| Figure 7. Prototype facility data acquisition |

| Figure 8. Temperature transient for prototype |

6. Conclusions

- This paper has presented the design of a hybrid compost waste heat to energy solar chimney power plant (SCPP) for addressing sustainable renewable energy needs. The paper has presented the concept of a hybrid power plant which uses a solar chimney, waste heat to energy conversion, and composting/recycling facility in unison. The baseline parameters for the SCPP, which include a chimney height of h = 200 m a chimney diameter of d = 20 m, and a collector footprint of 97,125 square meters. Results from experiments taken from a scale model prototype facility have been analyzed in order to predict the actual SCPP operation which shows that wind speeds on the order of 10 m/s (adequate to power commercial shrouded pressure-staged wind turbo generators) are witnessed. A detailed construction engineering cost estimate has been presented which bids the building cost to be 156 M$. The proposed 24 acre facility has the potential of generating on the order of 100 MW of compost waste-heat to energy extraction/conversion annually with a yield of 83 M$ in revenue. The total cost per unit of energy produced for the SCPP is 0.62 US $ / kWh (0.56 € / kWh).

ACKNOWLEDGEMENTS

- The authors would like to thank COMPO Energy, Inc. for sponsoring the present research.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML