Charles A. Adams1, Ernest Apraku1, Richter Opoku-Boahen2

1Department of Civil Engineering, Kwame Nkrumah University of Science and Technology, Kumasi, Ghana

2Department of Civil Engineering, Takoradi Polytechnic, Takoradi, Ghana

Correspondence to: Charles A. Adams, Department of Civil Engineering, Kwame Nkrumah University of Science and Technology, Kumasi, Ghana.

| Email: |  |

Copyright © 2015 Scientific & Academic Publishing. All Rights Reserved.

Abstract

Geosynthethic reinforcement application in roadworks is finding increased application. In many tropical countries. gravel borrow material of adequate quality which meets the technical specifications for pavement layer construction is problematic. In this study, the effect of geotextile strengthon California bearing ratio values when placed at predetermined location in anexperimental pavement layer was studied. Natural gravel soil was selected and tested without reinforcement. Then by placing a layer of a certain geogrid above the third layer within the sample height, the effect of geogrid reinforcement on California bearing ratio values were investigated. This was undertaken for two strengths of geogridin both soaked and unsoaked conditions. The results show that California bearing ratio values increases with increasing goegrid strength for soaked and unsoaked conditions. The California bearing ratio increased by 12% and 31% in the soaked condition for Tx160 and Tx170 geogrids respectively. The CBR also increased for unsoaked conditions. The use of geogrid reinforcement in road pavements layers can result in increased strength and environmental benefits.

Keywords:

CBR Value, Geosynthetics Reinforcement, Lateritic Gravel, Highway, Pavement

Cite this paper: Charles A. Adams, Ernest Apraku, Richter Opoku-Boahen, Effect of Triaxial Geogrid Reinforcement on CBR Strength of Natural Gravel Soil for Road Pavements, Journal of Civil Engineering Research, Vol. 5 No. 2, 2015, pp. 45-51. doi: 10.5923/j.jce.20150502.05.

1. Introduction

Ground improvement is a general term used for the modification of soil to enhance the strength and other engineering properties. There are many methods of ground improvement such as using additives (like cement, lime et cetera) and compaction (both static and dynamic). Geogrids represent a rapidly growing segment within geosynthetics. Rather than being woven, non-woven or knitted textile fabric, geogrids are plastics formed into a very open gridlike configuration. Geogrids are formed in three ways: 1) stretched in one or two directions for improved physical properties, 2) made on weaving or knitted machinery by standard and well established methods and then coated, or 3) made by bending rods or straps together. Geogrids mostly function exclusively as reinforcement material [1].In order to determine the exact effect of geosynthetics on road pavements the placement of the geotextiles within the layers is vital, therefore the need to know how to achieve maximum California Bearing Ratio (CBR) with geotextile positioning and strength. Also, the strength of geosynthetic material to achieve given strength increase is always desirable. The aim of this research was to study the effect of placement of a geogrid material in a selected lateritic soil, on the strength of the soil; the specific objectives were the following, (a) To determine the effect of strength of geogridon the California Bearing Ratio of a lateritic soil material under soaked and unsoaked conditions, (b) To study the variation of geogrid reinforced material with penetration under static loading.

2. Literature Review

Geosynthetic is defined as a planar product manufactured from a polymeric material that is used with soil, rock, or other geotechnical-related material as an integral part of a civil engineering project, structure, or system. Most of the geosynthetics are made from synthetic polymers of polypropylene, polyester, or polyethylene. Geotextile is a permeable geosynthetic made of textile materials. Geotextile type is determined by the method used to combine the filaments or tapes into the planar structure [2].[1] states that the first use of fabrics in reinforcing roads was attempted by the South Carolina Highway Department in 1926. A heavy cotton fabric was placed on a primed earth base, hot asphalt was applied to the fabric, and a thin layer of sand was put on the asphalt. The department published the results of this work in 1935, describing eight separate field experiments until the fabric deteriorated, the results showed that the roads were in good condition and that the fabric reduced cracking, raveling and localized road failures. This project was certainly the forerunner of the separation and reinforcement functions of geosynthetic materials as we know them today. There are specific types of geosynthetics: geotextiles, geogrids, geonets, geomembranes, geosynthetic-clay liners, geofoams and geocomposites [1].Geogrids consist of heavy strands of plastic materials arranged as longitudinal and transverse elements to outline a uniformly distributed and relatively large grid-like array of apertures in the resulting sheet. These apertures allow direct contact between soil particles on either side of the sheet [3]. Geogrids are characterized by integrally connected elements within-plane apertures (openings) uniformly distributed between the elements. The apertures allow the soil to fill the space between the elements, thereby increasing soil interaction with the geogrid and ensuring unrestricted vertical drainage. Their applications are not only in highway, but also in railroad track construction and rehabilitation [4].Geogrids have been used successfully in pavement layer studies; [5] placed geogrid between gravel base course and sand subgrade and showed the increase in CBR value of the subgrade material. Gosavi et al, [6] also investigated the strength behavior of soils reinforced with mixed geogrid woven fabric and showed that the soaked CBR without the geogrid was about 4.9% and after application of the geogrid test results showed an improvement in the CBR value. Naeini and Moayed, [7] indicated that using a geogrid at top of the layer 3 in a soil sample with different plasticity index causes a considerable increase in the CBR value compared with unreinforced soil in both soaked and unsoaked conditions. In order to quantify the amount of increase in the penetration resistance, the reinforcement ratio is taken into consideration. The reinforcement ratio according to [1] is defined as the ratio of the Load with the geotextile to the Load without the geotextile.

2.1. Product Specifications for a Typical Triax Geogrid

By examining all the design characteristics of a geogrid, through testing and research, certain factors were identified to affect its performance. These are the profile of the rib section, rib thickness, junction efficiency, aperture size and stiffness. Rigorous testing has been conducted in line with the rib directions of the geogrid. In each direction tested, the junction strength was found to be essentially equal to rib strength giving a junction efficiency of 100%. Biaxial geogrids have tensile stiffness predominantly in two directions. Triaxial (TriAx) geogrids on the other hand have three principal directions of stiffness, which are further enhanced by their rigid triangular geometry. This produces a significantly different structure than any other geogrid and provides high stiffness through 360 degrees, a truly multi-directional product with near isotropic properties [8].In a mechanically stabilized layer, aggregate particles interlock within the geogrid and are confined within the apertures, creating an enhanced composite material with improved performance characteristics. The structural properties of the mechanically stabilized layer are influenced by the magnitude and depth of the confined zones. The shape and thickness of the geogrid ribs and the overall structure of TriAx have a direct influence on the degree of confinement and efficiency of the stabilized layer. TriAx geogrids have greater rib depth compared with conventional biaxial geogrids. Trafficking tests and analytical modelling have been undertaken by Tensar International to compare performance advantages between the two forms of geogrid with various rib depths in a mechanically stabilized layer. The results were conclusive in confirming that an improved structural performance was achieved with the TriAx geogrid with its deeper rib depth and unique profile. Numerical modeling techniques confirm the importance of geogrid rib thickness on aggregate confinement and load dissipation [8].

3. Methodology

3.1. General

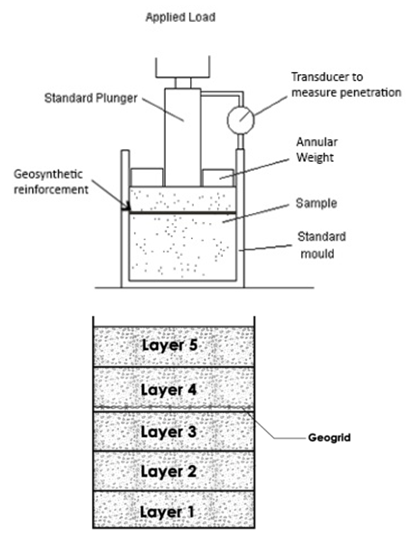

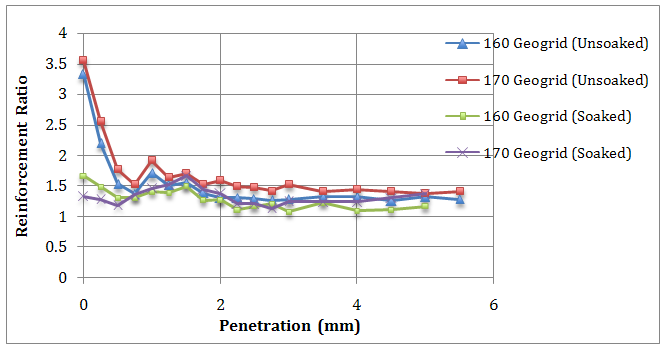

Natural gravel soil material was taken from a heap at a gravel borrow pit for a construction site near Kumasi. The material was being considered for use as natural gravel layers for the construction of a low volume urban road pavement. The material was air dried and tested for consistency limits, particle size distribution and compaction according to the requirements set out in [9]. Gradation test and consistency limits were done as per ASTM D422 [10] and ASTM D4318 [11] respectively, which are both in accordance with [12]. Compaction test was carried out in the laboratory to determine the optimum moisture content and the maximum dry density of the soil sample using test method ASTM D1557 [13] and BS 1377-4 [14]. The CBR was tested according to the test procedure as per [15] and [14]. All test results were compared with the Ghana specifications for various roadway pavement layers found in [9]. Two different samples of Triaxialgeogrids Tx160 and Tx170 obtained from Tensar, United Kingdom were used as the reinforcement. The composite material was tested in the laboratory. The experimental setup is schematically shown in Figure 1. | Figure 1. CBR experimental setup and schematic arrangement of sample in mould |

3.2. California Bearing Ratio Laboratory Experiment

The experimental study involved performing a series of laboratory CBR tests on the unreinforced and geogrid reinforced natural gravel specimens. Two kinds of Geogrid Tx 160 and Tx 170 were selected and used to reinforce the natural gravel obtained from Kumasi area. One layer of geogrid placed on top of layer three of the sample height and the CBR tests were carried out. All tests were performed inside a modified proctor mould at soaked and unsoaked condition according to ASTM-D 1883 [15]. The mould was a rigid metal cylinder with an inside diameter of 152 mmand a height of 178 mm. A manual loading machine equipped with a movable base that travelled at a uniform rate of 1.27 mm/min and a calibrated load indicating device were used to force the penetration piston with a diameter of 50 mm into the specimen. The test specimens were compacted in accordance with the procedures given in ASTM-D 1557 using modified effort [13]. The soil at the optimum water content (OMC) were placed in 5 layers within CBR mould. Each of the layers were compacted by 56 blows of a 44.5 N rammer dropped from a distance of 457 mm. The soil samples are compacted in CBR mould at its optimum water content and then the CBR tests were carried out under soaked and unsoaked conditions. The pavement layers were simulated by the experimental setup for a CBR test. Three sets of tests: that is soil material with no geogrid, soil material reinforced with Tx160 and soil material reinforced with Tx170 were used for soaked CBR test according to [15]. The moulds were soaked in a drum of water with a surcharge placed on them for four (4) days. The reinforced and unreinforced soil samples were tested for CBR under unsoaked and soaked conditions, using the CBR testing machine. The penetration resistance of the specimens was determined up to penetration of 7mm due to equipment limitations.

4. Results and Discussions

4.1. Characteristics of Natural Gravel Used

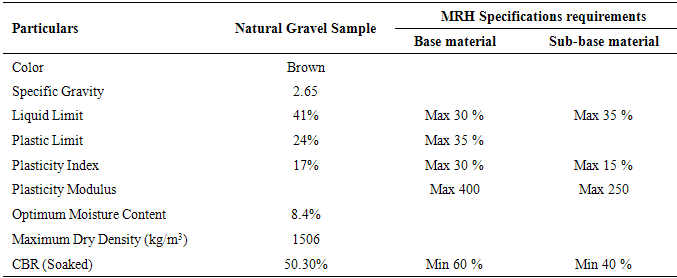

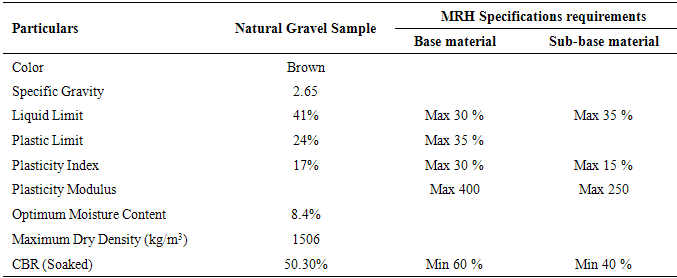

The properties of the tested natural gravel soil without any geogrid are presented in Table 1.Table 1. Properties of Soil Sample

|

| |

|

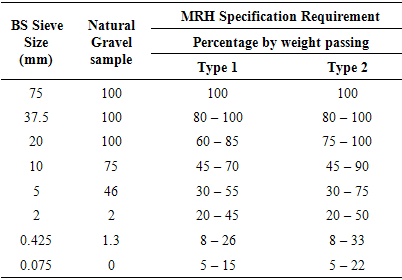

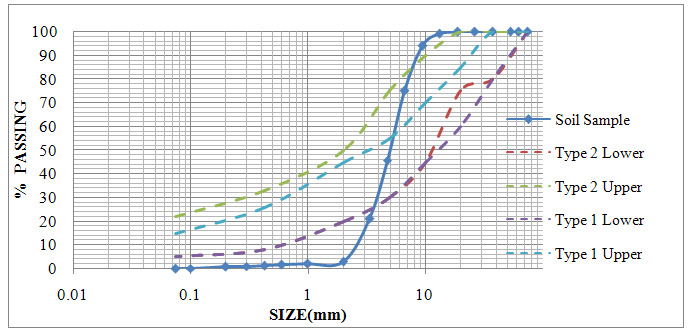

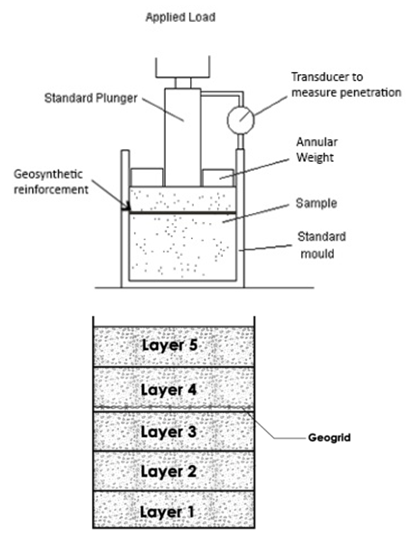

When the natural gravel sample test results were compared with the Ministry of Road and Highway (MRH) technical specification for natural gravel subbase layer as outlined in [9], it did not meet the requirement but for base course it satisfied the plastic limit with 24% (max 35%) and the plasticity Index with 17% (max 30%). The natural gravel sample failed to meet the Liquid Limit requirement for a base course with 41% (max 30%) and the soaked CBR requirement with 50.3% (min 60%). Ordinarily, this material may be considered for stabilization if the CBR could be improved. This is because obtaining suitable natural gravel which fulfils all requirements for road works within economic haulage distance is increasingly becoming difficult.The Particle size distribution of the natural gravel test sample and the MRH specification envelopes for Type 1 and Type 2 natural gravels for base course material are shown in Figure 2 and presented in Table 2. | Figure 2. Particle size distribution report |

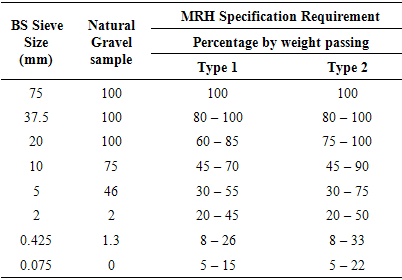

Table 2. Comparison between MRH Specification and Soil Sample

|

| |

|

The gradation results of the test sample were compared with the Type 1 and 2 natural gravel requirements for road pavements of the MRH as outlined in [9], The gradation meets all the criteria for Type 2 except that it is deficient in fine particle sizes less than 5mm (2mm, 0.425mm and 0.075mm). The natural gravel sample may be said to marginally satisfy the Type 2 gravel material gradation specifications and therefore require some improvement to qualify for use on the basis of gradation.From the foregoing we can conclude that the natural gravel sample marginally satisfied Type 2 base course requirement but has inadequate CBR probably due to the deficiency in fine particle sizes. The lack of fines could be the reason for the non-attainment of high compaction density (1506kg/m3) and therefore an inadequate CBR (50.3%). Ordinarily such a soil may be improved by stabilization or soil blending techniques. In this research geosynthetic material has been applied for improvement of strength.

4.2. Geosynthetic Materials

4.2.1. Product Specification for the TriAxTx160 and Tx170Geogrid

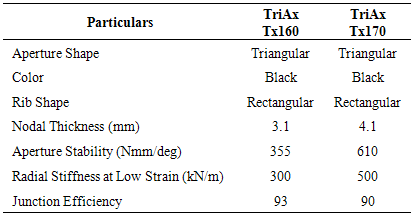

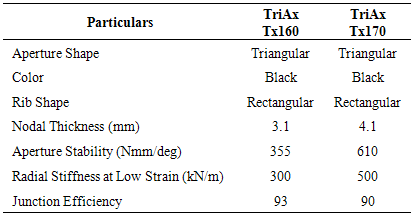

The geogrid is manufactured from a punched polypropylene sheet, which is then oriented in three equilateral directions so that the resulting ribs of the triangular apertures have a high degree of molecular orientation, which continues through the mass of the integral node. It was manufactured in accordance with a management system which complies with the requirements of British standards in [16]. The properties contributing to the performance include the following: Aperture Stability, Radial Stiffness at Low Strain and Junction Efficiency. Table 3, presents the geogrid characteristics for TriAx Tx160 and TriAx Tx170 obtained from manufacturer’s catalogue accompanying the samples [8].Table 3. Properties of Geogrid

|

| |

|

4.3. CBR Strength Development Results

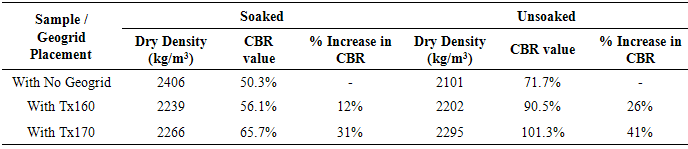

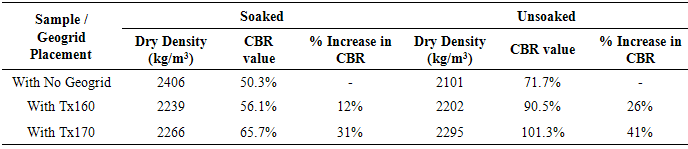

Table 4 shows a summary of the CBR values, dry density and moisture content variations for the soil sample and the soil sample interfaced with the geogrids.Table 4. CBR Tests Results (Soaked and Unsoaked)

|

| |

|

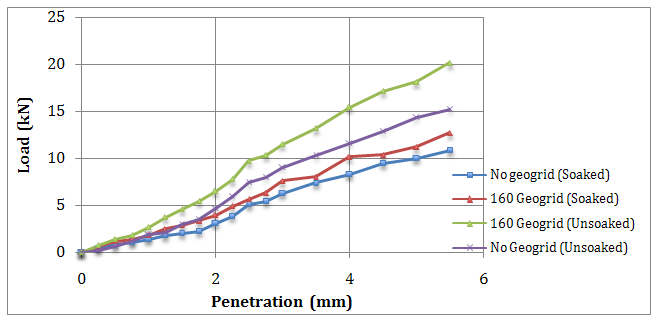

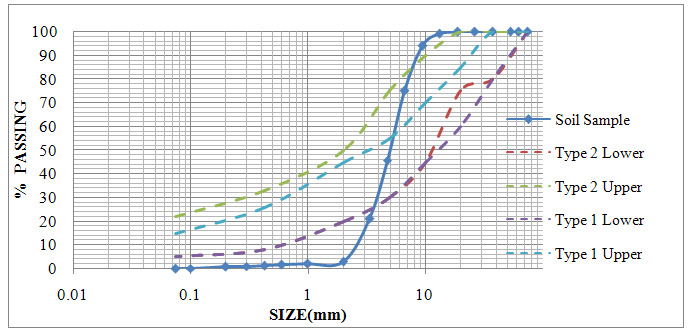

Figure 3 presents the variation of the load-penetration curve for the soil sample without reinforcement and the soil sample with TriAx Tx160 geogrid in both soaked and unsoaked conditions. | Figure 3. Comparison between soil-aggregate and soil-Tx160 geogrid-aggregate |

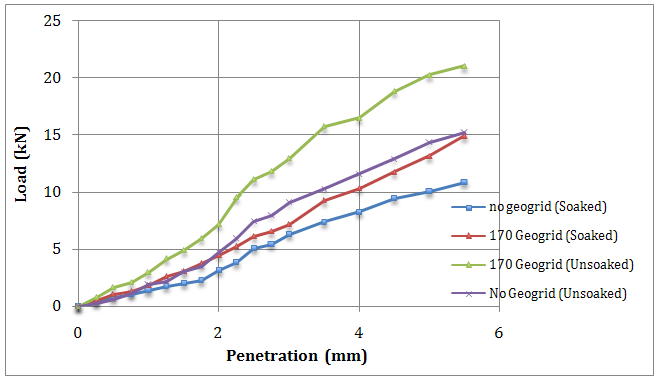

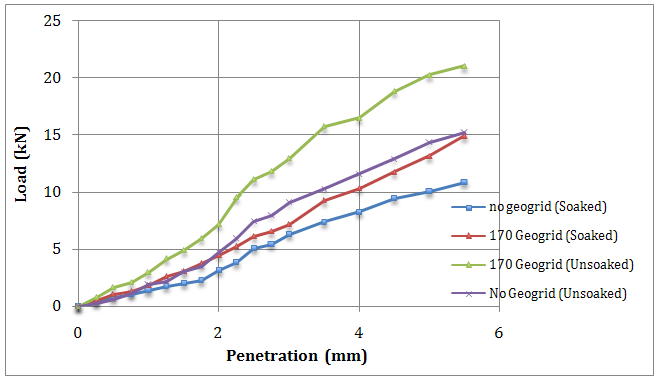

It was observed that there is an increase in resistance to penetration, when the geogrid is interfaced between the soil samples. For unsoaked conditions, the CBR value at 5.1mm penetration when the TriAx Tx160 geogrid was introduced at layer 3 was 90.5%, compared to a CBR value when there was no geogrid of 71.7%, thus increasing the CBR by 26%. Considering the soaked condition, the CBR without the geogrid was 50.3%, when the Tx160 geogrid was interfaced the CBR value improved to 56.1% with the geogrid at layer 3.Figure 4 produces the variation of load-penetration curve for the soil sample without reinforcement and soil sample with TriAxTx170 geogrid in both soaked and unsoaked conditions. | Figure 4. Comparison between soil-aggregate and soil-Tx170 geogrid-aggregate |

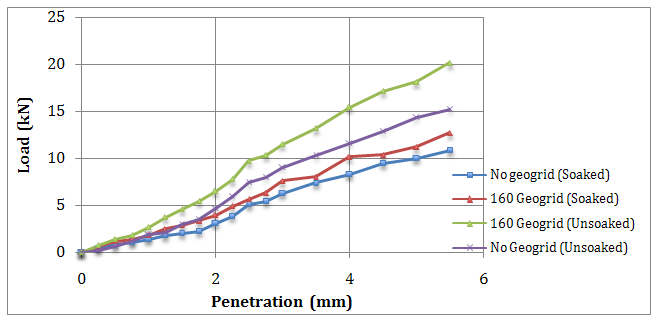

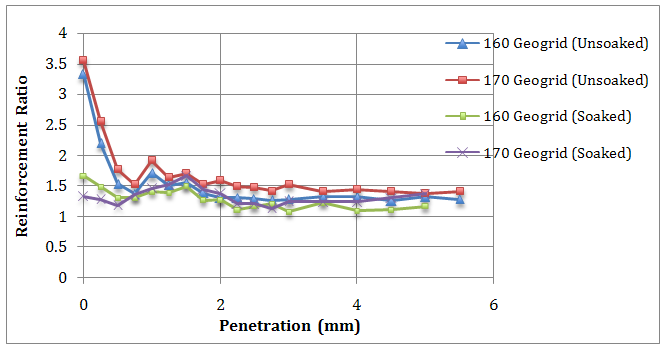

When the TriAx Tx170 geogrid was interfaced between the soil samples, for unsoaked conditions, the CBR value at 5.1mm penetration increased from 71.7% (CBR without geogrid) to 101.3%. After four days soaking of the soil sample, the CBR without the geogrid was 50.3%, when the geogrid was interfaced the CBR improved to 65.7%. In both cases, the CBR of the soil improved remarkably with the geogrid, however, the TriAx Tx170 geogrid increased the strength more than the TriAx Tx160. Earlier studies by [17] on the effect of geotextile on CBR strength reported similar results in which interfacing of a geotextile in an unpaved road, increases the penetration resistance and hence the CBR strength. [7] also showed that placing a geogrid on the third layer of a clay soil caused an increase in CBR by 25% under soaked conditions. The variation of the reinforcement ratio for both Tx160 geogrid and Tx170 geogrid in both soaked and unsoaked conditions are shown in the plot of reinforcement ratio against penetration curve in Figure 5. | Figure 5. Variation of Reinforcement ratio for soil with TriAx Tx160 and Tx170 Geogrids |

Figure 5 shows that the reinforcement ratio is more than one throughout the test, which indicates that the introduction of the geogrid offers a good resistance even at lower penetration. It also shows that TriAx Tx170 geogrid in both soaked and unsoaked conditions offers better resistance even to lower penetration (1-3mm) than the Tx160 in the soaked and unsoaked conditions. [17] showed a similar reinforcement ratio, which was more than one throughout their test, indicating that the geotextile offers good resistance.From the foregoing we observe that increasing the strength of the geogrid from Aperture Stability 355Nmm/deg to 610Nmm/deg, and from Radial Stiffness at Low Strain from 300kN/m to 500kN/m increases the penetration resistance of the composite soil-reinforcement sample. For soaked specimens, the reinforcement ratios were slightly more than one.

5. Conclusions

In this study two types of triaxial geogrids namely Tx170 and Tx160 were used to interface a lateritic gravel sample at layer 3. The sample was tested without geogrid in soaked and unsoaked conditions. Then by placing the geogrid at the third layer, CBR tests were performed on the soil sample. The test results from the research showed that using a single layer of any of the geogrids at the top of layer 3 in the soil samples caused a considerable increase in the penetration resistance hence an improvement in the CBR value. From the research, it was also observed that Tx170 offered a better resistance than the Tx160 geogrid. From the above analysis, it is of economic benefit to use geogrids in road construction as it reduces the act of filling with materials from borrow pits to improve strength of weak soils.

6. Recommendations

It can be inferred from the research results that, interfacing with geogrids into soils will help improve the CBR of a subbase material to perform as a base coarse material. For dry weather conditions, the use of geogrid should be strongly advised since it shows considerable CBR improvement. For situations where the pavement is likely to be in constant soaked conditions, the use of the TriAx Tx170 should be considered because it improves the CBR significantly unlike the TriAx Tx160. The results indicate that it might be economical to introduce the usage of geogrids in road construction. Since the increase in layer strength may imply reduced thickness, the use of geogrid has environmental benefits since lesser volumes of gravel borrow material may be required and exploited.

ACKNOWLEDGEMENTS

The authors hereby acknowledge the support offered by Tensar International, UK through the provision of samples for the laboratory tests.

References

| [1] | R. M. Koerner, “Designing with Geosynthetics: Volume 1,” 2005. [Online]. Available: Amazon.com [Accessed 2 June 2014]. |

| [2] | A. C. Lopes, “Definition of Geosynthetics: Geosynthetics in engineering,” 2008. [Online]. Available: http://www.woodhead.com/geosynthetics/[Accessd 2 March 2014]. |

| [3] | D. T. Bergado, and H. M. Abuel-Naga, “Tsunami devastations and reconstruction with Geosynthetics,” 2005. [Online]. Available: http://www.freelibrary.com [Accessed 2 March 2014]. |

| [4] | A. Olawale, “Use of geosynthetics in road construction,” Department of Civil Engineering, Federal University of Technology, 2011. [Online]. Available: http://www.google. com/googlebooks. |

| [5] | Motanelli, F., Zhao, A., and Rimoldi, P., 1997, Geosynthetics-reinforced pavement system: testing and design., Proceedings of Geosynthetics, 97, 549-604. |

| [6] | G. Gosavi, K. A.Patil, and S. Saran, “Improvement of properties of black cotton soil subgrade through synthetic reinforcement,” Department of Civil Engineering, IIT Roorkee, 2004. |

| [7] | Naeini, S. A., and Moayed, R., 2009, Effect of plasticity index and reinforcement on CBR value of soft clay., International Journal of Civil Engineering,7(2), 124 – 130. |

| [8] | Tensar Geosynthetics in Civil Engineering, “A guide to products, systems and services,” Tensar-international limited, United Kingdom, 2014. |

| [9] | Ministry of Roads and Highway, “Technical specification for roads and bridges,” Republic of Ghana, 2006. |

| [10] | ASTM D422, “Standard test method for particle-size analysis of soils,” American Society for Testing and Materials, West Conshohocken, PA, 2002. |

| [11] | ASTM D4318, “Standard test methods for liquid limit, plastic limit and plasticity index of soils,” American Society for Testing and Materials, West Conshohocken, PA, 2001. |

| [12] | BS 1377-2, “Methods of test for soils for civil engineering purposes, Classification tests,” 1990. |

| [13] | ASTM D1557, “Standard test methods for laboratory compaction characteristics of soil using modified effort,” American Society for Testing and Materials, West Conshohocken, PA, 2002. |

| [14] | BS 1377-4, “Methods of test for soils for civil engineering purposes, Compaction related tests,” 1990. |

| [15] | ASTM D1883, “Standard test method for CBR (California Bearing Ratio) of laboratory-compacted soils,” American Society for Testing and Materials, West Conshohocken, PA, 2005. |

| [16] | BS EN ISO 9001:2008 British Standard Institution. United Kingdom. |

| [17] | Kumar, P. S., and Rajkumar, R., 2012, Effect of geotextile on CBR strength of unpaved road with soft subgrade.,Electronic Journal of Geotechnical Engineering(EJGE), 17, 1355 – 1363. |

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML