-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Journal of Civil Engineering Research

p-ISSN: 2163-2316 e-ISSN: 2163-2340

2015; 5(2): 39-44

doi:10.5923/j.jce.20150502.04

The Study of Mixture Design for Foam Bitumen and the Polymeric and Oil Materials Function in Loose Soils Consolidation

Kaveh Ostad-Ali-Askari 1, Mohammad Shayannejad 2

1PhD Student, Department of Water Engineering, Faculty of Civil Engineering, Najafabad Branch, Islamic Azad University, Najafabad, Iran

2Associate Professor, Water Engineering Department, Isfahan University of Technology, Isfahan, Iran

Correspondence to: Kaveh Ostad-Ali-Askari , PhD Student, Department of Water Engineering, Faculty of Civil Engineering, Najafabad Branch, Islamic Azad University, Najafabad, Iran.

| Email: |  |

Copyright © 2015 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Due to the enormous growth of new chemicals, especially polymer materials in construction projects, and the importance and effectiveness of these new materials in poor soil stabilization, recently has closed chemistry and polymer sciences to civil science. The use of materials such as bitumen in stabilization of flowing and loose soil and using of polymer resins reflects the effect of these substances is very high on construction projects. Considering the importance of oil and polymer materials in soil stabilization, in this study performance of polymer materials and their comparison have been investigated. Oil materials such as bitumen can be used to stabilize the soil, and polymer resins such as polyvinyl alcohol and polyvinyl acetate, and also pointed polypropylene synthetic fiber can be considered as polymer materials. Bitumen foam is one of the fixative materials that obtain by adding water to hot bitumen, and is applicable to a wide range of stone materials. In addition to, polymer resins increase the burden go loose soils. Polymer fibers due to high durability and easy application and no problem at saturation conditions are highly regarded by civil engineers.

Keywords: Soil stabilization, Bitumen, New chemical materials, Polymer resins

Cite this paper: Kaveh Ostad-Ali-Askari , Mohammad Shayannejad , The Study of Mixture Design for Foam Bitumen and the Polymeric and Oil Materials Function in Loose Soils Consolidation, Journal of Civil Engineering Research, Vol. 5 No. 2, 2015, pp. 39-44. doi: 10.5923/j.jce.20150502.04.

Article Outline

1. Introduction

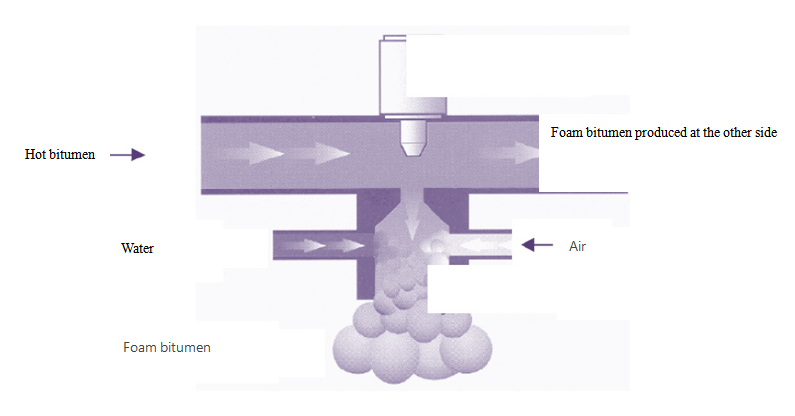

- Use of materials such as bitumen in stabilization of flowing and loose soil and using polymer resins reflects the importance of these substances on construction projects. Each pavement rehabilitation require a certain time period that best rehabilitation method chooses according to the road conditions. One method for rehabilitation is implementation of coating. The main problem is limitation of high quality materials and asphalt factories, which lead to increase costs of transportation of materials to the project site. Nowadays, advancement of technology in cold recycling machines minimizes these problems.Foam bitumen produces by adding a small amount of water (2-3% by weight of bitumen) to hot bitumen (160-180C). After injection of water to hot bitumen, the water evaporates suddenly and leads to explosive bitumen foaming in the saturate stream.

2. Material and Methods

2.1. Foam Bitumen

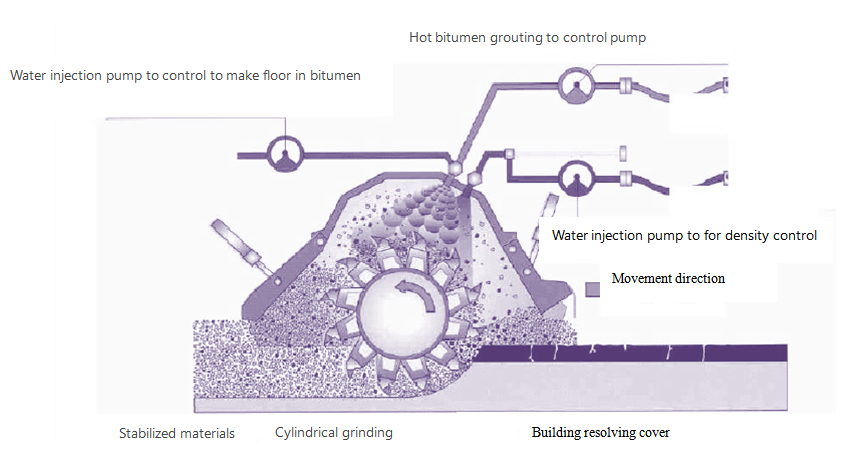

- Figure 1 shows internal system of cold recycling machine. In this figure the asphalt pavement has been destroyed and need cover that is fixed by foam bitumen. A protective asphalt layer with thickness of 3 cm places on the stabilized basis of foam bitumen. Thickness of asphalt layer depends on the volume of traffic passing. This reduces costs of material transportation [1].

| Figure 1. Ground system and distribution of the conversion of bitumen floor covering based on established dissolve |

| Figure 2. The process of foam bitumen production |

2.2. Advantages of using Foam Bitumen

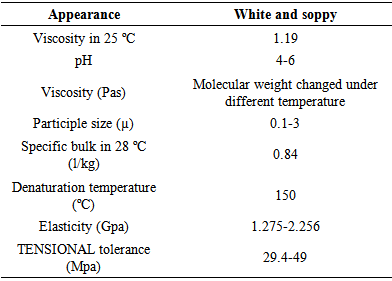

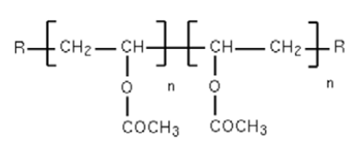

- Easy to use: similar to the bitumen emulsion, Foam bitumen can be used to stabilization of recycled materials by attachment of bitumen reservoir and foam chamber to recycler machine [1].Robust and flexible pavements: stabilized materials with foam bitumen contain flexible mortar that adhere large pieces to together. Therefore, have the resistance to deformation and fatigue properties for example fixed materials with cement have low fatigue properties [1].Economic: foam bitumen obtains from bitumen with the standard penetration thus has not the factory cost. Stabilized materials with foam bitumen have the lower cost than stabilized materials with bitumen emulsion [1].Strength gaining speed: stabilized materials with foam bitumen are reopened on traffic faster than stabilized materials with cement [1].Very low environmental impact: During the curing process, volatile and evaporated materials will not emit from mixture [1].Implementation in bad weather conditions: pavement layers can be stabilization using foam bitumen in bad weather conditions, such as cold weather or light rainfall without negative impact on functionality or quality of the final layer [1]. However, these materials cannot be used for soil stabilization due to environmental problems and fuel costs. Other materials such as PVA and PVA care polymer materials that were investigated. Characteristics of these two polymers are shown in table 1 and 2 and their chemical formulas are shown in figure 3 and 4.

|

|

| Figure 3. Polyvinyl acetate |

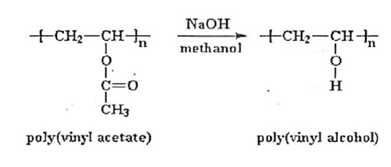

| Figure 4. Polyvinyl alcohol Fibers |

SR= stress ratio,

SR= stress ratio,  = deviator stress,

= deviator stress,  = deviator stress at failureTriaxiad test is defined as a test that measure stress in 3 perpendicular directions. This test is applied to measure the material strength.

= deviator stress at failureTriaxiad test is defined as a test that measure stress in 3 perpendicular directions. This test is applied to measure the material strength.2.3. Polyvinyl Acetate Resin (PVA)

- Polyvinyl acetate is a polymeric material that obtains from free radical vinyl polymerization with vinyl acetate monomer origination. This material firstly was discovered and prepared by Fritz Klatte in Germany in 1912. This material is known as abbreviated name of PVAc in commerce and industry [3]. PVAc formulations are shown in Figure 3.Further researches showed that application of this adhesive material improves soil structure, increase water infiltration and increase soil strength grain. In summary, the application of this material prevents erosion caused by wind and water [4].

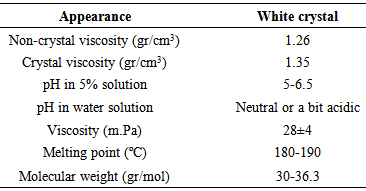

2.4. Polyvinyl Alcohol Resin (PVA)

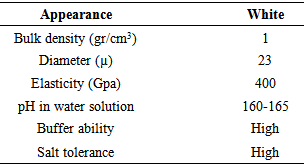

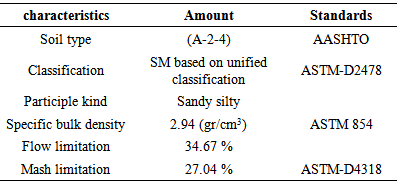

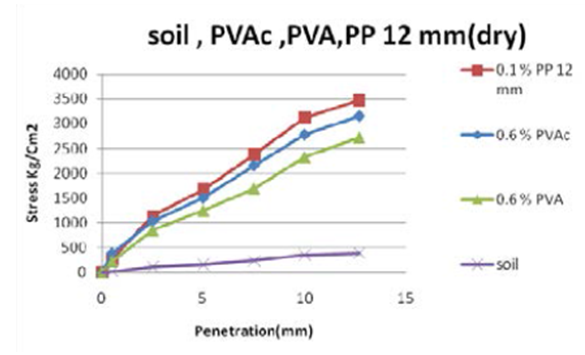

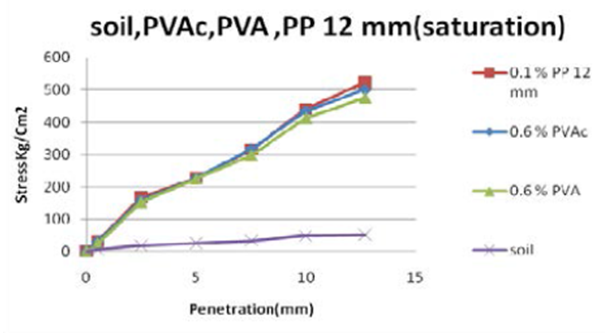

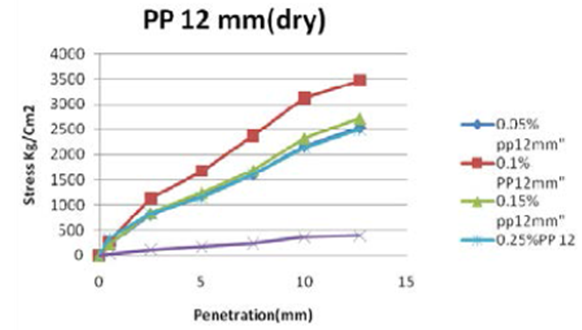

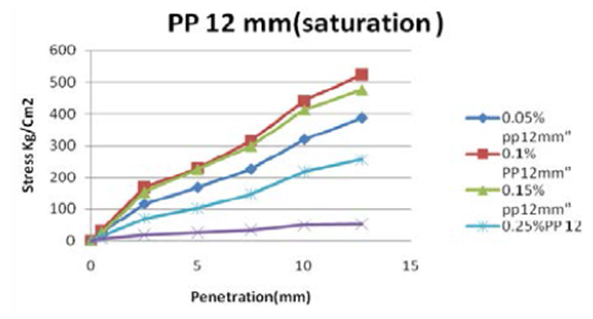

- Polyvinyl alcohol was first prepared by hydrolysis of polyvinyl acetate in methanol in the presence of potassium hydroxide by Hermann and Haehnel in 1924. The acetate groups are hydrolyzed by ester interchange with methanol in the presence of aqueous sodium hydroxide and polyvinyl alcohol is produced (5).The formulation of polyvinyl alcohol is shown in Figure 4. Polyvinyl alcohol is an odorless substance, translucent or opaque; with white or cream colored crystals that has crystal structure. Degree of its solubility is higher than 85°C. It has high strength and stiffness. Its strength properties depend on moisture content. Increase in moisture content lead to reduce the tensile strength [6, 7]. Some of its characteristics are shown in Table 3. Other properties of this material are non-toxic, non-corrosive and non-contaminated water [8, 9]. In 1974 Stefans on stabilized the sandy loam soil using polyvinyl alcohol without any harmful effect on the environment and plant growth [10].Yarn use for reinforcement, polypropylene fibers with a size of 12 mm and the weight percentages of 0.1 0.05, 0.25 and 0.15 were studied. These fiber properties are presented in Table 3. The soil that was examined in this study was selected from sandy-silt soils in Isfahan, Iran city that its characteristics are presented in Table 4. Soil combined with the Yarn and resin matrix was studied by laboratory CBR test that results showed in figures 8 and 5, 6, 7. These results indicate high performance of materials for soil stabilization.

| Figure 5. Power curve CBR experimental pressure of yarn and resin samples in dry condition |

| Figure 6. Power curve CBR experimental pressure of yarn and resin samples in saturated condition |

| Figure 7. Power curve CBR experimental pressure of yarn sample in dry condition |

| Figure 8. Power curve CBR experimental pressure of yarn sample in saturated condition |

3. Results and Discussion

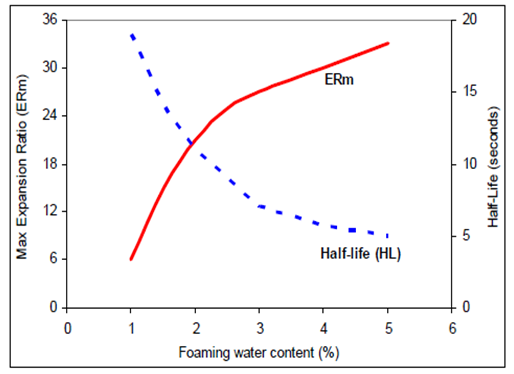

- Figure 9 show characteristics of foamed bitumen including expansion ratio and half-life. It can be seen that expansion ratio increases with increasing foaming water content, whereas the half-life values tend to decrease.

| Figure 9. Characteristics of foamed bitumen in terms of maximum expansion ratio and half-life |

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML