-

Paper Information

- Next Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Journal of Civil Engineering Research

p-ISSN: 2163-2316 e-ISSN: 2163-2340

2015; 5(2): 21-27

doi:10.5923/j.jce.20150502.01

State-of-the-Art Review of the Applications of Nanotechnology in Pavement Materials

Faruqi M. , Castillo L. , Sai J.

Department of Civil and Architectural Engineering, Texas A&M University-Kingsville, Kingsville, USA

Correspondence to: Faruqi M. , Department of Civil and Architectural Engineering, Texas A&M University-Kingsville, Kingsville, USA.

| Email: |  |

Copyright © 2015 Scientific & Academic Publishing. All Rights Reserved.

Nanotechnology is the understanding and control of matter at the nanoscale of dimensions between approximately 1 and 100 nanometers, where unique phenomena enable novel applications. The use of nanotechnology in pavement materials is an area that shows great promise and the potential to change commonly used materials. The overall objective of this paper is to present a state-of-the-art literature review of nanoscience based principles to improve the performance of transportation construction materials. The article is organized into six sections, namely: applications of nanotechnology in concrete pavements, application of nanotechnology in asphalt pavements, application of nanotechno-logy in soils, cost-benefit, challenges, and trends to the future. It is observed from this review that nanoscience can help improve the performance of transportation construction materials and this may eventually lead to the extension of their life cycle.

Keywords: Nanotechnology, Pavements Cost-Benefit, Challenges, Future

Cite this paper: Faruqi M. , Castillo L. , Sai J. , State-of-the-Art Review of the Applications of Nanotechnology in Pavement Materials, Journal of Civil Engineering Research, Vol. 5 No. 2, 2015, pp. 21-27. doi: 10.5923/j.jce.20150502.01.

Article Outline

1. Introduction

- Even as traffic on the Nation’s highways has increased from 65 million cars and trucks in 1955 to almost 246 million today, the condition of U.S highways and bridges has deteriorated. According to estimates by the U.S. Department of Transportation, the current backlog of unfunded but needed repairs and improvements total $495 billion. The increased traffic volume has generated an escalating need for high-performance, durable construction materials for roadway pavements. This need, in turn, is driving research to develop the next generation of materials [1]. Nanotechnology is in its infancy, especially as a road science, but super concretes, smart aggregates, and self-healing structures are coming [2]. The typical expectations of nanotechnology based innovations in pavement materials is that they will change the properties of the materials such as the negative effects of environment and traffic loading (i.e. temperature and moisture sensitivity, fatigue cracking and rutting) can be minimized or reversed [3]. Nanoscience and nanotechnologies represent a new revolutionary approach in the way of thinking and producing, as they somehow revert to the traditional scientific approach and production process, from “big” to “small” [4]. The development of improved materials using nanotechnology based techniques can be very beneficial in pavement engineering. Pavement engineers use a wide range of materials that are modified using products such as bitumen, cement and other chemical admixtures. The bulk of the materials, however; remains naturally occurring aggregates and soils. Problems often exist in the application of these materials for specific conditions, i.e. incompatibility between certain aggregates and binders (bituminous or cementitious), deterioration of the material during environmental conditions (i.e. water susceptibility of granular materials and temperature sensitivity of bituminous materials) and deterioration with use (i.e. fatigue due to overloading) [5]. Concrete and asphalt pavements are widely used throughout the world, however; they are expensive materials. Applying nanotechnology innovations with these materials can improve performance and increase durability, which in the long run can lead to a cost effective solution.

2. Nanotechnology

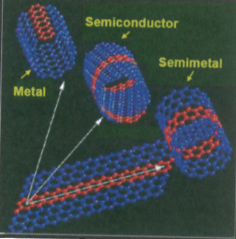

- Nanotechnology is the understanding and control of matter at the nanoscale of dimensions between approximately 1 and100 nanometers, where uniq-ue phenomena enable novel applications. Encompassing nanoscale science, engineering and technology involves imaging, measuring, modeling, and manipulating matter at this length scale [6]. We have seen that the majority of the nanotechnological developments are occurring in areas such as chemistry, physics, and in electrical engineering. Matter can exhibit unusual physical, chemical, and biological properties at the nanoscale, differing in important ways from properties of bulk materials and single atom or molecules. Some nanostructured materials are stronger or have different magnetic properties compared to other forms or sizes of the same material. Others are better at conducting heat and electricity. They may become more chemically reactive or reflect light better or change color as their size or structured is altered. Nanotechnology is not simply working at ever-smaller dimensions; rather, working at the nanoscale enables scientists to utilize the unique physical, chemical, mechanical, and optical properties of materials that naturally occur at that scale [7]. For our society to get an impact from this great development, there has been strives to apply nanotechnology into pavement materials. Nanotechnology has led to advanced characterizations, prediction and control of material properties at submicron level. This technology has enhanced the understanding of “origins” of key properties of everyday materials and interactions between materials, structures, external elements and internal components [8]. Therefore, this works makes an attempt to present a state-of-the-art literature review of nanoscience based principles to improve the performance of transportation construction materials.

3. Previous Studies

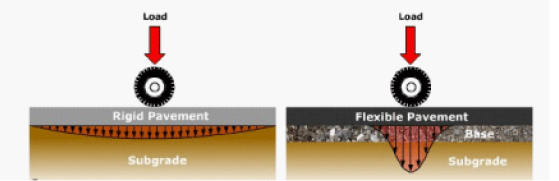

- Pavements consist of a combination of engineered materials that generally provide all-weather access to a vehicle to travel in a safe economical way. The layers of materials used are selected and engineered to provide a structure which can withstand the applied vehicular loads under a range of environmental conditions for a defined minimum life [9]. There are two types of pavements, namely: concrete and asphalt. The primary structural difference between a concrete and asphalt pavement is the manner in which each type of pavement distributes traffic loads over the subgrade. A concrete pavement (rigid) also known as Portland Cement Concrete (PCC) has high stiffness and distributes loads over a relatively wide area of subgrade, a major portion of the structural capacity is contributed by the slab itself [10]. With a whopping consumption of over 11 billion metric ton per year, PCC is the most widely manufactured and extensively utilized product in the construction industries throughout the world. Despite its widespread use, a considerable portion of the physical/mechanical properties of cementitious products, specially concrete, have remained ambiguous and unexplained. The other common type is asphalt pavement (flexible). Asphalt pavement is one of America’s building blocks. The United States has more than 2 million miles of paved roads and highways, and 94 percent of those are surfaced with asphalt [11]. The load carrying capacity of an asphalt pavement is derived from the load-distributing characteristics of a layered system [12]. Fig. 1 shows stress distribution under rigid and flexible pavements.

| Figure 1. Typical stress distribution under a rigid and flexible pavement [10] |

| Figure 2. Typical stress distribution under a rigid and rigid and flexible pavement [19] |

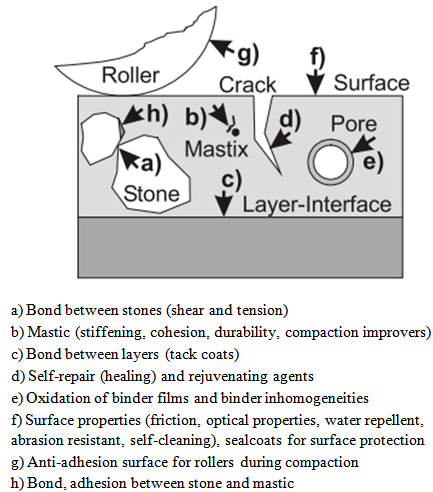

| Figure 3. Schema to visualize focus areas for nanoscience and technology with respect to asphalt pavement structures: |

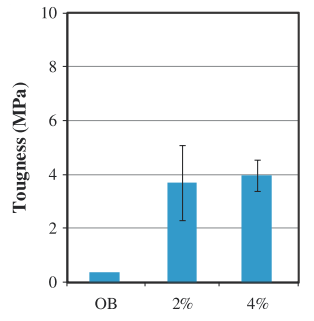

| Figure 4. Toughness results for the original binder, nanoclay at 2%, and nanoclay at 4% [33] |

4. Cost-Benefit

- The costs of most nanotechnology equipment and materials are currently relatively high. This is partly due to the novelty of the technology, but also due to the complexity of the equipment. However, in the case of the nanomaterials, costs have shown to decrease over time and the expectations are that, as manufacturing technologies improve, the costs of the materials will decrease [4]. Since 1990 the cost of producing CNTs has fallen 100-fold and can be expected to fall further [19]. Whether such decreases will render the materials as run-of-the-mill pavement engineering materials will have to be seen. Current opinion is that in special cases, the materials will enable unique solutions to complicated problems that cause them to be cost effective, which will lead to large scale applications of these specific technologies. In other cases the traditional methods for treating the problem may still remain the most cost effective. As indicated earlier, the job of the engineer is to solve real-world problems and provide a facility to the general public at a reasonable cost [19]. Furthermore, it is expected that the multifunctional and smart CNTs reinforced cement-based materials will feature high performance price ratio and low life cycle cost. Therefore, the cost of CNTs should no longer be the critical issue [19].For asphalt pavements, bitumen is a by-product of the production of fuel from crude oil. In typical asphalt pavements the bitumen comprises about 0.5 percent of the mass and between 5 and 17 percent of the cost of the road. Internationally, the reserves of crude oil are viewed as being decreasing. The direct implication for pavement engineering is that the price of bitumen may increase drastically in future as the availability decreases [4]. Therefore, nanotechnology will play a role in alleviating this problem.

5. Challenges

- Some of the main challenges that can be imposed are the health, safety, and environmental impacts. Although a large number of potential ideas and applications for nanotechnology and pavement engineering exist, it is also important to remain realistic and identify and accept the current limitations and challenges inherent in this field [9]. With the advent of new technologies, including nanotechnology, one should consider the potential unintended consequence to human health and the environment that might accompany development and use of the technology [37]. Users of nano-particles should endeavor to mitigate the potential risks of nanoparticles during the design stage rather than downstream during manufacturing or customer use (i.e. when the material is already embedded in the pavement) [4]. Five principles to design safe nanotechnologies are summarized below [38]:● Reduction (evaluate the option to use smaller quantities of nanoparticles in the product while maintaining functionality).● Encapsulation (enclose a potential hazardous nanoparticle with a material that is less hazardous).● Functionalization (bond molecules to nanoparticles to change the properties that can reduce the hazard potential while preserving the desired product properties).● Alternative materials (identify an alternative material that can be used to replace the hazardous nanoparticle).● Size, surface, and structure (change the size, surface, or structure to reduce the hazard potential of the nanoparticle while maintaining its functionality).Another major challenge to implement nanotechnology is the scale effect. Applying this technology to materials and making these nanomodified materials work in infrastructures can be difficult. The unique environment of the pavement engineer who works with large volumes of material should always be appreciated when evaluating potential applications of nanotechnology. The effects on manufacturing capacity and performance of the nanomaterials when combined with bulk aggregates and binders should be evaluated to ensure that the beneficial (nanoscale) properties are still applicable and cost-and-energy-efficient at these scales [4].

6. Trends to the Future

- Based on this literature review, we may find that there are many characteristics of nanotechnology that can be applied to pavements to provide a better performance. However, successful nanotechnology application may need 5 or 10 years to be commercialized.Some of the potential future directions are listed below [39]:● Engineered materials using nanotechnology will allow maximum use of locally available materials and avoid unnecessary transport. ● Design ductile, flexible, breathable, permeable or impermeable concrete properties on demand.● Design concrete and asphalt mixes which are resistant to freeze-thaw, corrosion, sulfate, ASR, and other environmental attacks.● Develop specialty products such as products with blast resistant, conductive properties as well as temperature, moisture, and stress-sensing abilities.Future nanotechnology applications will lead to reduce maintenance costs, increase pavement lifespan, reduce accidents, and increase construction efficiency.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML