-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Journal of Civil Engineering Research

p-ISSN: 2163-2316 e-ISSN: 2163-2340

2015; 5(1): 18-20

doi:10.5923/j.jce.20150501.03

Effect of Lime Sludge on Strength and Compaction of Soil

Chandak N. R. , Amit Babu

Dept. of Civil Engineering, Noida Institute of Engineering and Technology, Greater Noida, U.P., India

Correspondence to: Chandak N. R. , Dept. of Civil Engineering, Noida Institute of Engineering and Technology, Greater Noida, U.P., India.

| Email: |  |

Copyright © 2015 Scientific & Academic Publishing. All Rights Reserved.

The process of soil stabilization helps to achieve the required properties in a soil needed for the construction work. The attempt had been made to investigate the effect of lime sludge obtained from paper mill as waste on the strength and compaction of sandy soil with plasticity. The basic properties of soil like liquid limit, plastic limit, shear strength and MDD & OMC were determined before and after addition of lime sludge. The lime sludge was added at 3%, 6% and 9% by weight of soil and mixed with soil at optimum moisture content. The direct shear and compaction tests were conducted without curing of the specimens. It was observed that addition of lime sludge in sandy soil improves the shear strength.

Keywords: Lime sludge, Strength of soil, Compaction of soil, Stabilization

Cite this paper: Chandak N. R. , Amit Babu , Effect of Lime Sludge on Strength and Compaction of Soil, Journal of Civil Engineering Research, Vol. 5 No. 1, 2015, pp. 18-20. doi: 10.5923/j.jce.20150501.03.

Article Outline

1. Introduction

- For any land-based structure, the foundation is very important and has to be strong to support the entire structure. The process of soil stabilization helps to achieve the required properties of soil needed for the supporting the suitable structural load. Ancient civilizations of the Chinese, Romans have utilized various methods to improve soil strength etc. In India, the modern era of soil stabilization began in early 1970’s, with a general shortage of petroleum and aggregates, it became necessary for the engineers to look at means to improve soil other than replacing the poor soil at the building site. In recent times, with the increase in the demand for infrastructure, soil stabilization got the momentum. With the better research materials and equipment, it is emerging as a cost-effective method for soil improvement. Here, an attempt had been made to stabilize the soil with the help of waste lime sludge obtained from paper mills.

2. Literature Review

- Lime stabilization is one of the oldest process of improving the engineering properties of soils and can be used for stabilizing both base and sub base materials [1]. The addition of lime to reactive fine-grained soils has beneficial effects on their engineering properties including reduction in plasticity and swells potential, improved workability, increased strength and stiffness, and enhanced durability. In addition, lime has been used to improve the strength and stiffness properties of unbound base and sub base materials. Generally, the oxides and hydroxides of calcium and magnesium are considered as ‘lime’, but the materials commonly used for lime stabilization are calcium hydroxide (Ca (OH) 2) and dolomite (Ca (OH) 2+MgO). Dolomite used as stabilizing agent contains not more than 36 % by weight of magnesium oxide (MgO). The percentage of lime used for any project depends on the type of soil being stabilized. The determination of the quantity of lime is usually based on an analysis of the effect that different lime percentages have on the reduction of plasticity and the increase in strength of the soil. However, most fine-grained soil can be effectively stabilized with 3%-10% of lime, based on the dry weight of the soil. Lime is used extensively to change the engineering properties of fine-grained soils and the fine-grained fractions of more granular soils. It is most effective in treating plastic clays capable of holding large amounts of water. The particles of such clays have highly negative-charged surfaces that attract free cations (i.e., positive charged ions) and water dipoles. The addition of lime to a fine-grained soil in the presence of water initiates several reactions. The two primary reactions, cations exchange and flocculation agglomeration, take place rapidly and produce immediate improvements in soil plasticity, workability, uncured strength, and load-deformation properties. The shear strength behaviour of unmodified and modified clay was studied to determine the potential of using lime-iron sludge as a soil modifier [2]. The optimum dose of lime-sludge was found to be 3% with accompanying optimum moisture content of 20%. They observed that the shear strength of soil increased by 20% together with the rise in cohesion of 15.5%. The lime stabilization of lateritic soil samples as pavement construction materials was also attempted [3]. The soil samples with different ratio of lime varying from 0% to 10% with the increment of 2% each was used for the study. It was observed that the suitability of soil had been improved by optimum lime stabilization at 6% but caused a reduction in plasticity indices of the soil samples. The feasibility of using rice husk ash with lime as soil stabilization material had also been studied [4]. The effect of lime, natural pozzolana or combination of both on geotechnical properties of the soft soil was studied [5]. It was concluded that the soft soil can be successfully stabilized by the combined action of lime and natural pozzolana. The effect of lime on the compaction and strength behaviour of the red earth treated with mine tailings shows that the compressive strength of red earth had increased due to the long term pozzolanic reaction of the calcium oxide present in the mine tailings [6]. The effect of stone powder and lime on the strength, compaction and CBR properties of fine grained soil also shows improvement [7].

3. Materials and Methods

- The soil samples used for the present work were collected from ALISTONIA PARK, Beta-I (Greater Noida) and NIET campus respectively and lime sludge obtained from the waste of paper mill situated at Noida, India.The specific gravity test, particle size analysis and the Atterberg’s limits tests were conducted for each soil. Also compaction test and direct shear test were conducted to determine MDD, OMC and the shear strength of the samples. All the tests were also performed with varying lime sludge percentages at 0, 3, 6 and 9%.

4. Results and Discussions

- The results of the preliminary tests viz. grain size analysis, specific gravity, and Atterberg’s limits test as well as the engineering property tests such as compaction, direct shear test are discussed in following paragraphs.

4.1. Preliminary Tests

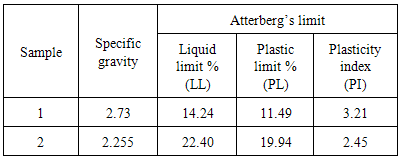

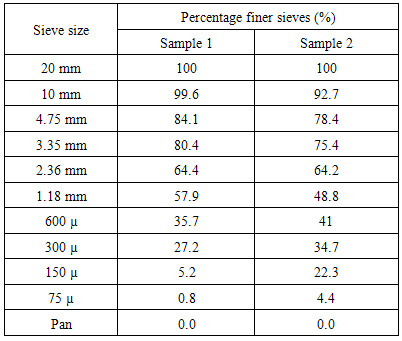

- The properties of soil tested are shown in Table 1. The soils are found to have fines with low plasticity. The grain size analysis for both soil are shown in Table 2. It indicate that both the soils are sandy (S) soils and in both samples less than 5% particles are finer than 75µ sieve. The coefficient of uniformity of sample 1and 2 was observed to be 11.11 and 21.67 respectively and coefficient of curvature as 0.33 and 0.2885 respectively, which indicate the soil sample 1 is well graded sand (SW) and soil sample 2 is poor graded sand (SP).

|

|

4.2. Standard Proctor Test

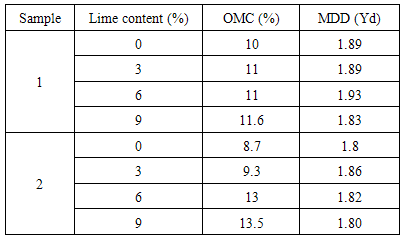

- The standard Proctor test was performed on soil and stabilised soil. The MDD and OMC for each varying percentage of lime sludge obtained during the testing were shown in Table 3. It was observed that the OMC of all the soil samples increases with increase of lime content. It may be due to the additional water needed to enable the pozzolanic soil-lime reactions necessary for the stabilization process. MDD of soil sample in each case reach to maximum value and then decreases. This maximum value represents the optimum percentage of lime required for stabilization.

|

4.3. Direct Shear Test

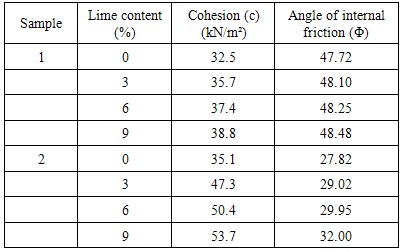

- The unconsolidated un-drained test was performed on the soil samples with the various percentages of lime. Table 4 shows a summary of the test result for both soils. The shear strength of the stabilized soil sample shows increased in the angle of internal friction (Φ) and cohesion (c) with increased in lime sludge content. From the summary given in Table 4, the addition of 3%, 6%, and 9% of lime sludge has increased the angle of internal friction (Φ) by about 0.8%, 1.10%, and 1.57% respectively while cohesion (C) is increased by about 9%, 13.24%, and 16.38% respectively, when compared with the soil sample with 0% of lime content. Also for sample 2, the addition of 3%, 6%, and 9% of lime sludge has increased the angle of internal friction (Φ) by about 4.31%, 7.11%, and 13.06% respectively while cohesion (C) increased by about 25.76%, 30.29%, and 34.64% respectively when compared with the soil sample with 0% of lime content.

|

5. Conclusions

- Based on the experimental work performed on, it can be concluded that:l The optimum lime content varies from 3% to 6%. l The angle of internal friction and cohesion is found to increase with the addition of lime sludge which is waste product of paper mills. l The addition of 3% to 6% of lime sludge imparts considerable strength to the soil.l The lime sludge can be used as a stabilizing material solving the disposal problem of waste.

ACKNOWLEDGEMENTS

- The authors of this paper gratefully acknowledge the support in all the way from management, Noida Institute of Engineering and Technology, Greater Noida, Uttar Pradesh, India for publishing this research work. The first author also would like to express his special thanks of gratitude to Dr. S. Pusadkar, Professor, G.C.O.E, Amravati, India for carrying pre-review of this paper.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML