Decio Gonçalves1, Luciano Donizeti Varanda2, André Luis Christoforo3, Francisco Antonio Rocco Lahr1

1Department of Structural Engineering, Engineering School of São Carlos (EESC/USP), São Carlos, 13566-590, Brazil

2Department of Science and Engineering Material, Engineering School of São Carlos (EESC/USP), São Carlos, 13566-590, Brazil

3Department of Civil Engineering, Federal University of São Carlos, São Carlos, 13565-905, Brazil

Correspondence to: André Luis Christoforo, Department of Civil Engineering, Federal University of São Carlos, São Carlos, 13565-905, Brazil.

| Email: |  |

Copyright © 2012 Scientific & Academic Publishing. All Rights Reserved.

Abstract

This paper focuses on the main characteristics of a Tree-Shaped Timber Structural System, or simply, Tree-Shaped. One of them is the complexity of its steel connections, responsible for the joint of bar elements, compounding a complex structural system, which requires the application of the CYPECAD software version 2007 to solve the calculations concerns. Its efficiency was confirmed by a variety of laboratory tests carried out with the whole structure. The Tree-Shaped is a timber structure that enables a large number of functional programs, residences, malls, sheds, hangars, etc. Originally it was conceived in Barcelona/Spain based on the well-known masterpiece “Sacred Family”, whose author was Architect Antoni Gaudi I Conet (1852 – 1926). It was designed at the end of XIX Century and its construction is still not finished. Gaudi inverted the logical order of the gothic concepts, i.e, light weights below and heavy weight above. Based on this concept, he always had in mind the figure of a tree in nature. The Tree-Shaped follows the same idea, using timber pieces connected by steel plates. Theoretical and numerical analyses have shown its efficiency and lightness for use in timber structures and roofs.

Keywords:

Tree- shape, Timber structure system, Constructive rationality, Modulated system, Designing ecological issues

Cite this paper: Decio Gonçalves, Luciano Donizeti Varanda, André Luis Christoforo, Francisco Antonio Rocco Lahr, Tree-Shaped Timber Structural System: An Ecological Way of Designing Spatial Structure, Journal of Civil Engineering Research, Vol. 4 No. 1, 2014, pp. 1-7. doi: 10.5923/j.jce.20140401.01.

1. Introduction

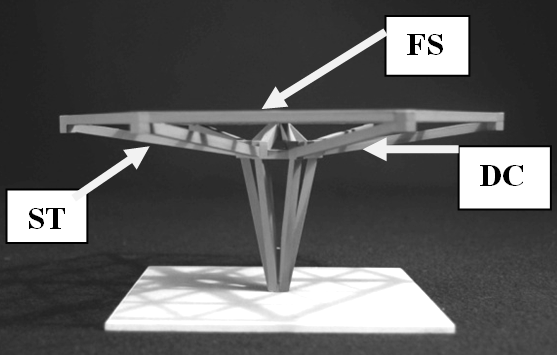

The Tree-Shaped was conceived according to an Architecture that privileged serious concerns about Nature and its preservation, causing minimal environmental impacts on the surroundings. This approach resulted in few support points on the soil and is characterized by a modular fabricated system full of constructive rationality and elements made of wood, a renewable material, comfortable to human touch[1,2,3]. When all these attributes are put together, it becomes a singular and outstanding structural system. It also demands less energy for its process, when compared with other materials, that is why legal and certificated wood would be a natural choice. If all these hypotheses and conditions are considered, the ideal structural system will resemble a metaphorical image of a tree, such as the pillars of “Sagrada Família”, work building designed by Antoní Gaudi in the end of nineteen century.Another projected specificity is the bio climatically aspect involved in this structural system, providing natural ventilation and chimney effect due to special characteristics related to the emptiness of it superior part of the structural system. It is formed by slab plans (SP), with tree-shaped timber columns, and six faces “diamond”- columns (DC) placed above them, resulting in three levels. This system is provided with steel connections able to provide continuity to the members as well as strenght and stability to the system. Differently from rigid nodes of a tree, Tree-Shaped has articulated nodes because of its trussed spatial beams.The aim of this paper is to report on the general specifications and special and unique characteristics of the Tree-Shaped Timber Structural System, presenting its several applications in the timber structural building area.

2. Material and Methods

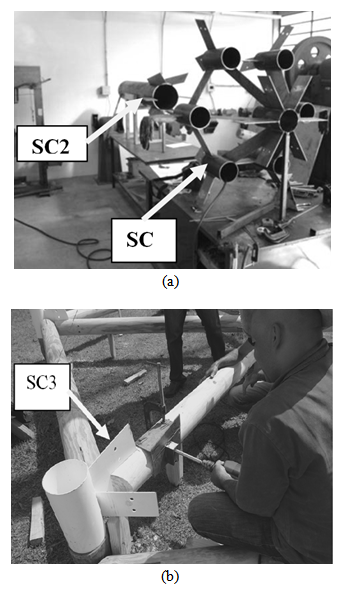

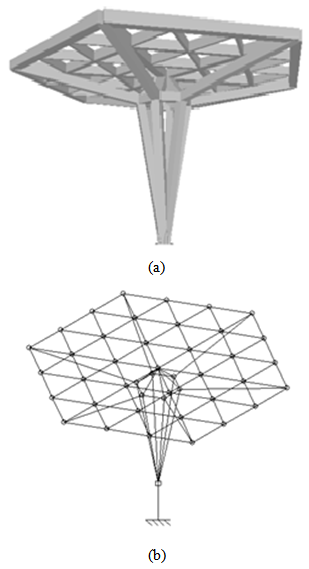

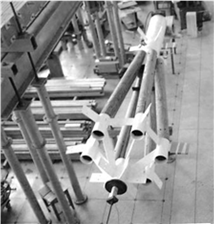

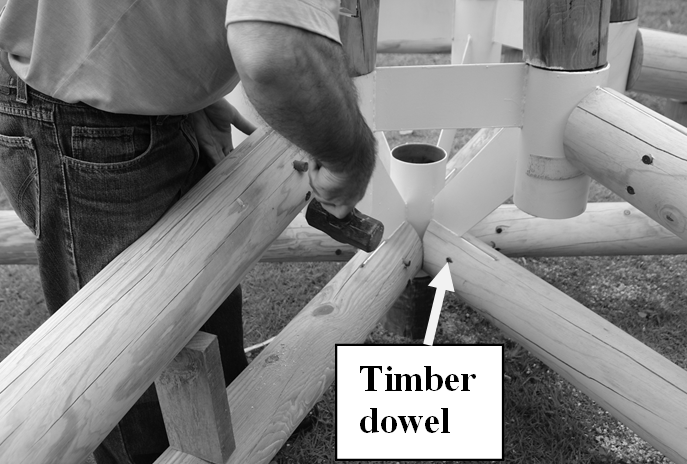

WoodWood is a renewable material that requires very little energy for processing, is pleasant to the touch and has many attributes, especially with regard to its structural characteristics[4]. When conveniently treated with the appropriate chemical substances, wooden material remains in good shape for a long time[5]. Contrary to what people think, wood is generally very resistant to fire, especially when considering solid timber planks thicker than one inch. In this situation, fire spreads out and destroys the superficial layer very rapidly and then slowly in function of the resistant thin layer that is formed to protect the wood.Concerning resistance under fire conditions,[6] discusses that with or without protection against fire, wood has a great probability of resisting efforts at high temperatures, before collapsing. One of the main characteristics of wood is to prevent fire from spreading quickly towards the inner part of timber pieces, thus decreasing the fire’s velocity[7].Raw and round timber comprises a great variety and a large quantity of exploitable Brazilian species.SteelOne of the most important caracteristics of the system is the steel connections (SC), joining the timber bar elements in the whole structural system, including “diamond”-shaped columns (Figures 1a and 1b), spatial trusses and slab plans (SP). | Figure 1. Steel connections: SC, SC2 and SC3 |

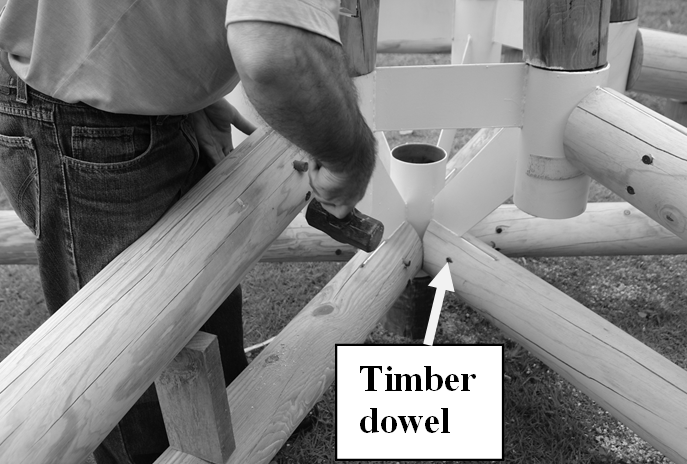

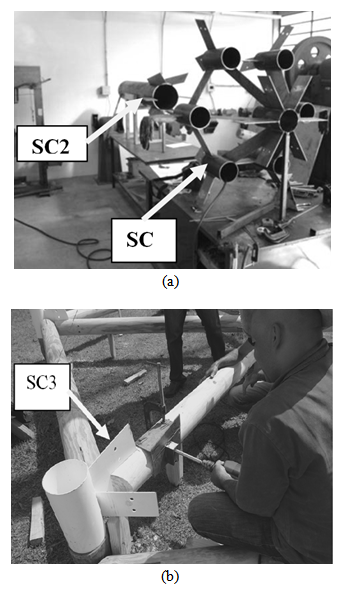

All bar elements are fixed with timber dowels of Pinus oocarpa shiede (softwood specie), with 16 mm diameter (Figure 2). | Figure 2. Fixing timber dowels |

According to this technology, it is possible to visualize some benefits of the Tree-Shaped, considering its design that enables the distribution of loads, with a consequenty decreasing the number of pillars on the soil. Also, the structural weight is substantialy lighter than other convencional timber structural systems, requiring simpler foundations.The technology of the Tree-Shaped is understood as a product innovation, a consequence of the particular and singular assembly process, when compared with similar technologies. It requires small construction site areas because its structural modules can be displaced in pallets, utilizing reduced space in load trucks.The design of the the Tree-Shaped is singular due to these specific support structures and particular nodes. All it also enables structural implementation in different soils with variable topographies, because its pillars adapt to several heights related to the variety of declivities.This structural system has specific design characteristics, simplifying industrialized processes. All its components can be packed in pallets and moved to the working area, just like a structural system kit.It can be reused in other locations because of its assembly process, i.e, the steel connections (SC) are fixed with fasteners (dowels) that allow for easy dismantlement.According to[8] the concept behind the maximization of structural reuse is to generate layouts and designs that produce the least amount (quantity) of solid waste at end-of-life or permit for the greatest amount of whole or partial system utilization and/or structural component reuse.Besides, all the described characteristics making it a singular structural system, according to[9], the Tree-Shaped has a great potential for generating natural resources in the carbon marked (one carbon credit is equal to one equivalent CO2, which means, for instance, to drive a car for 2,084 km) and being registered as a clean technology by the United Nations. This fact reinforces the utilization of wood in a constructive manner and is an effective guarantee of carbon sequestration by plants.

3. Results and Discussions

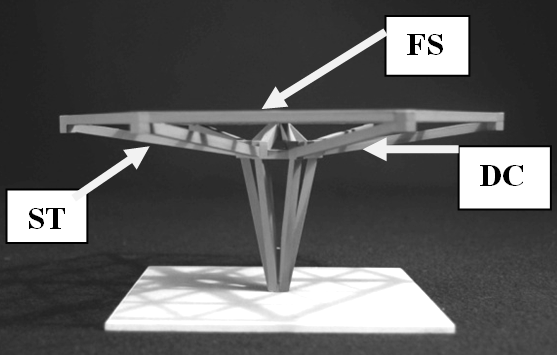

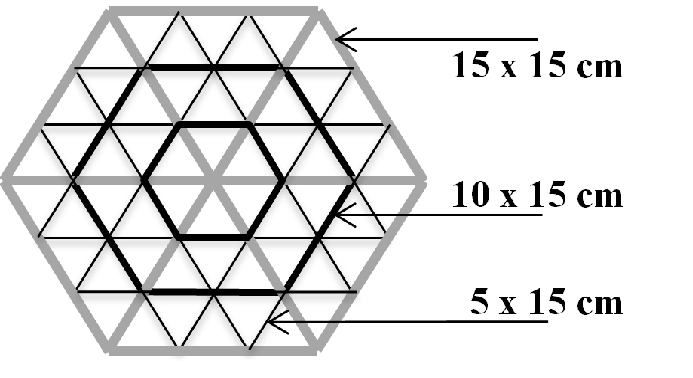

Tree-Shaped and its Functional ProgramsThe Tree-Shaped allows a great variety of functional programs, because of its special and unique design which provides a complete gathering of project building possibilities, such as single and multi-storey residence, research centres, malls, hangars, among others.This system enables a variation of several structural types, according to number of support points in the soils. Particularity in this system, there is one and three options of points in the soils, resulting in specific functional programs related to different structural types derived from the Tree-Shaped.One support in the soilModuleModule (Figure 3) is a structural system with only one support point on the soil, consisting of primary, secondary and beam bars, which together form a cover (flat slab) composed of a modulation of equilateral triangles – the basic geometric module (BGM) in the system –resulting in a hexagonal surface. This hexagon is supported by sloping top bars distributed over an hexagonal support, lying on six bars, forming a “diamond” column. It has one “diamond”-shaped column (DC) with a shell and three spatial trusses (ST), providing a 20 square meter of building area. | Figure 3. Module model in 1:25 scale (ST spatial truss; DC “diamond column and FS flat slab) |

Module ProtoptypeConcerning social applications this structural type can be used as a small community centre, a pavilion for lectures for needy children or a place for recreation activities. This architectonic artefact can be constructed on any University Campus, even in poor communities, where there is a lack of social equipment.The Module Prototype (Figure 4) was assembled in the Laboratory of Wood and Timber Structures (LaMEM) from the Department of Structural Engineering (SET-EESC). | Figure 4. Module Prototype |

Tree-Shaped Timber Stayed Structural System – SETAM: named Stayed systemThis Stayed system is a change in the project conception of the Tree Shaped with specific architectonic characteristics (Figure 5). It allows for different functional programs, but maintaining all the concepts of the original system. | Figure 5. Stayed system: side view (a), rear view (b) and frontal view |

The Stayed system can be applied in single residences with multi-storey. In this example, it is a two-storey residence with 85 square meters of building area.Three support points in the soilTree-Shaped Timer Structural System – SETAThe Tree-shaped design was the first approach in relation to the metaphorical image of the tree. It was created by Architect Antoni Gaudi and developed in Brazil by Architect Marcos Acayaba and his partner Engineer Helio Olga Junior, responsible for the structural system calculation.The system includes almost all architectonic and engineering resolutions, aggregating values through the creation of a “diamond” shape column (DC) and spatial trusses (ST), which permit design slabs with large dimensions.It intends to be completely in accordance with the organic principles applied by master Architect Frank Lloyd Wright in his Usonian House works in the United States, in the late 1920`s. Below, it is shown a residence with 385 square meters of building area (Figure 6). | Figure 6. Tree-Shaped Timber Modular Structural System, model in 1:50 scale of a two-storey single family with 385 m2 of construction area |

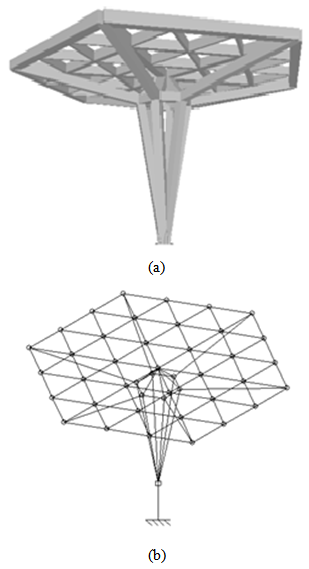

Diamond- Shaped Column (DC)Diamond- shaped column (DC) has unique characteristics of designed and constructive concepts (Figure 4). Visually, it looks like a tree-shape metaphoric image, characterizing a harmonious and singular set, with plenty of plastic beauty. At the same time, from its constructive elegance and visual lightness, conditions of diffused loads through its elements are created, reducing the intensity of the loads applied. Because of the constructive rationality involved in the whole project, the amount of workforce is not significant in the working area needing only one chief-carpenter and staff (two or three carpenters). Since the structure is light there is no need of large equipment for the assembling of the system in the working area.There is minimal environment impact on the Tree-Shaped implementation, because the architectonic artefact has only three support pillars in contact to the ground. This system presents an excellent cost-benefit, while considering market scale, making it possible to apply several functional programs, such as single-family housing, multi-family housings, malls, plane hangars, research centres, etc.The system has specific projected characteristics, consequently, affording easy industrialized processes. All components are packet and moved to the working area and its assembly is similar to those LEGO toys.Calculation and ModellingCYPECAD software, version 2007 (computer program developed by CYPE INGENIEROS SA based on the CAD) was used to calculate the bar solicitations. It is settled in the Finite Elements Method (FEM), which considers[10] Brazilian standards requirements. Three dimensional elements to represent timber pieces were considered in the discretization of the structure (Figure 7). There are two nodes in each bar element and three degrees of freedom per node, i.e, corresponding to translations according to axes x, y and z, with free rotations around the same ones. | Figure 7. Modelling of the Tree-Shaped Module in CYPECAD: real profile (a) and discretization of bar elements and joints (b) |

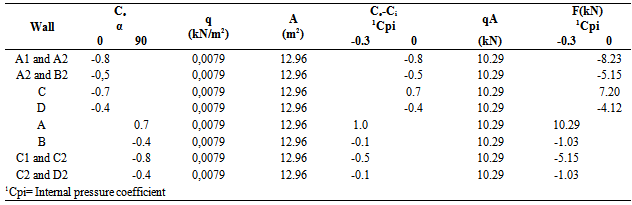

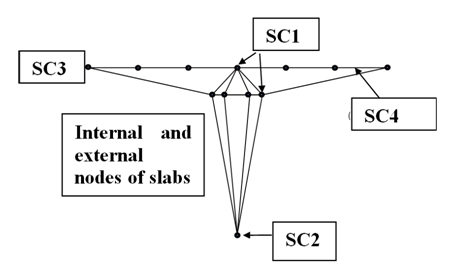

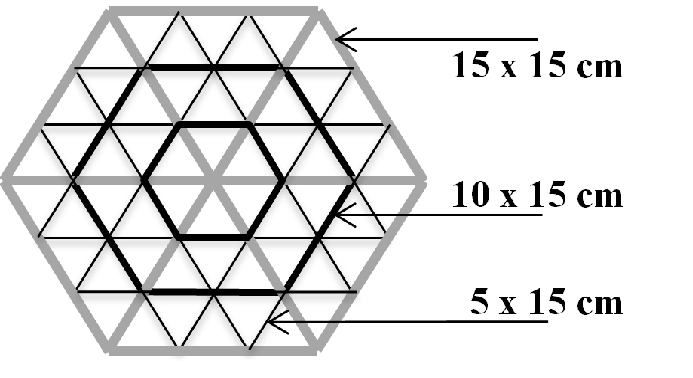

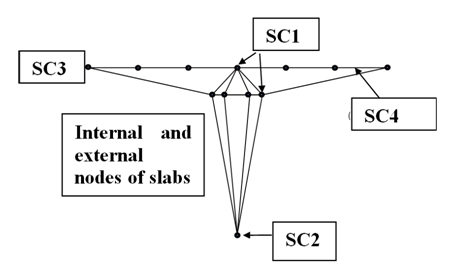

The bar elements are responsible for tension efforts and axial compression, considering that the extremities of all bar elements were articulated, with the exception of the joints of the base. This numerical simulation allowed a detailed analysis of the aspects of interest as the concentration of tension in the areas of larger effort and the connections, which cannot be detected in lab tests. The system incorporates the essence of this concept as a function of its peculiar characteristics, which are much more favourable for this purpose. In relation to dimensional purposes, a numerical simulation was performed to calculate the associated elements and construct a Module named Prototype.Figure 8 illustrates the four steel connection (SC) groups with denominations SC1, SC2, SC3 and SC4. Bar cross-section dimensions of the slab are shown in Figure 11. | Figure 8. Schematic Module profile - four steel connection (SC) groups |

| Figure 9. Bar cross-section dimensions of the Module slab plan |

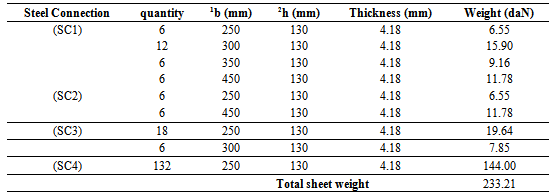

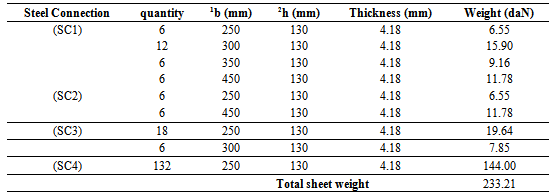

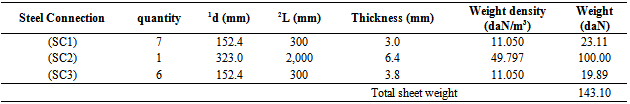

Table 1 (sheet) and Table 2 (tube) show the dimensions of four steel connection groups (SC), where: 1b = weight, 2h = height, 1d = diameter and 2L = length.Table 1. Characteristics of the steel sheet connection of the Module

|

| |

|

The following values were adopted:a) Permanent actions: timber:  ; steel:

; steel:  b) Variable action – Wind maximum action:

b) Variable action – Wind maximum action:  The velocity characteristic Vk and wind dynamic pressure q are expressed by Equations 1 and 2, respectively, relating to[11] Brazilian standard:

The velocity characteristic Vk and wind dynamic pressure q are expressed by Equations 1 and 2, respectively, relating to[11] Brazilian standard: | (1) |

| (2) |

where V0 = 40 m/s is the basic wind speed in the region (Sao Carlos/SP/Brazil), S1 = 1.0 is the ground level, S2 depends upon the terrain and height dimension (h) of the architectural artefact to the ground, and S3 is the factor based on statistical concepts considering the degree of reliability required and the building lifecycle (S3 = 1.0, Group 2).S2 was defined as being in Category II, with a size of Class A, and is given by the Equation 3, where: Fr is the blast factor (in case 1.0); b is the smaller side (b = 1.0); p is the exponent of the exponential variation law of S2 = 0.085 and z is the elevation above the ground (2.925 m). | (3) |

The following results were yielded:  ,

,  and

and  .To determine the wind force on the building wall with an area A (area on which the wind force acted: A = 12.96 m²), the calculation applies the relation between h and b:

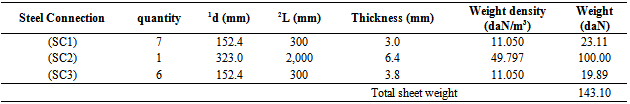

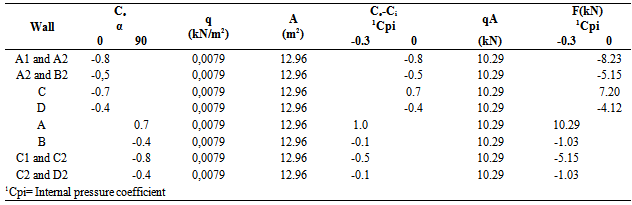

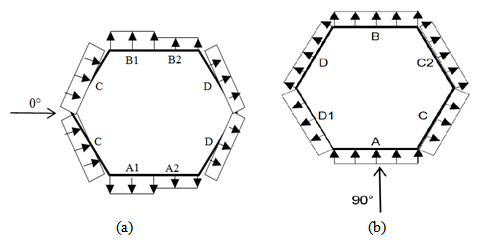

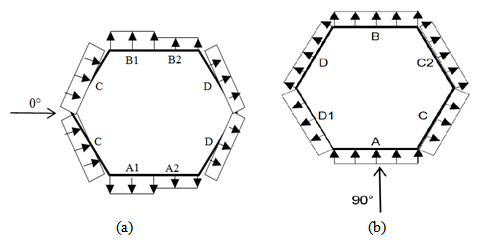

.To determine the wind force on the building wall with an area A (area on which the wind force acted: A = 12.96 m²), the calculation applies the relation between h and b:  .Figure 10 show the pressure coefficient and shape coefficient, outside of the side walls and front walls (wind at 0° and at 90°).

.Figure 10 show the pressure coefficient and shape coefficient, outside of the side walls and front walls (wind at 0° and at 90°).Table 2. Characteristics of the steel tube connection of the Module

|

| |

|

Table 3. Wind parameters and wind force

|

| |

|

| Figure 10. Wind at 0° (a) and 90° (b): pressure coefficient and shape coefficient, external to the side walls and front walls |

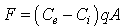

Wind force F was calculated by Equation 4, were Ce is the outer coefficient and Ci the internal coefficient. | (4) |

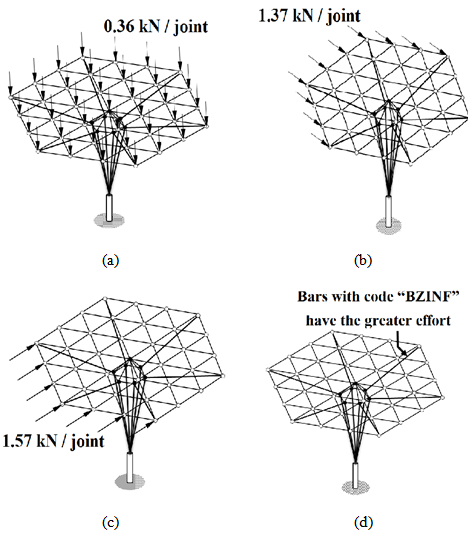

The wind parameters and results are shown in Table 3.Figure 11 shows (a) the permanent actions (dead weight); (b) and (c) show the accidental live loads with wind at 90° and 0°, respectively, and (d) indicates the greater effort bar in the Module of the system: bars with code BZINF. | Figure 11. Actions on the system bars: permanent actions (dead weight) (a), accidental live loads (wind at 90°) (b), accidental live loads (wind at 0°) (c) and System bars with greater effort in the Module: BZINF bars (d) |

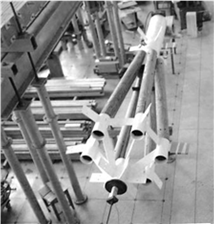

Permanent actions with tile-type ecological (cover) material and accidental live loads with wind at 0° and 90° were considered.The structural forces in the timber elements of the Module were calculated by CYPECAD software. The Module design was introduced in this software and the floor plans and views were imported from CAD drawing.These programs make available the dimensional hypotheses of the structure (timber bars and steel connections) and performed the numeric simulation.The Prototype Module presented the following characteristics:- Support elements (column): 16 cm medium diameter cylindrical bars made of Pinus oocarpa shiede (softwood specie), C30 strength Classes, according to Brazilian standard[10];- Steel Connections: Stainless steel pieces having 4.18 mm thick plates and 15 cm diameter tubes. The welded plates were designed with two holes to allow for the insertion of wooden dowels to connect diamond-shaped elements;- Dowel connectors: 16 mm diameter dowels made from Peltogyne recifencis Ducke species (Roxinho - hardwood specie), C40 strength Classes, related to[10] Brazilian standard.The steel connections (SC) of the diamond-shaped column were constructed in the Mechanical Work Lab (Figure 1a) at the São Carlos Engineering School, Sao Paulo University (EESC/USP). This test was conducted with the diamond - shaped column (DC) in a horizontal position to facilitate the application of compression forces to these structural elements (Figure 12). | Figure 12. Top view of compression tests on the diamond column through the Kyowa device in LaMEM/SET/EESC/USP |

The efforts were transmitted to the structure through a steel cable placed along the longitudinal axis of the device and fixed by means of metal plates at their ends. Strain gauges were fastened and monitored by Kyowa equipment to control the load applied.The relative displacements between the steel components of the structurally solidified compounds were measured through comparison times of 0.01 mm range. These displacements were considered very small (0.03 mm was the maximum measured displacement).The maximum forces employed in the tests were 15 kN calibrations, which are subtly superior to the double calculation (7.3 kN) through numerical simulation.

4. Conclusions

The Tree-Shaped is a timber structural system that supplies a large number of functional programs. The specific and unique characteristics allow its implementation in different declivities of the soil and its cost-effective budget is considerable favourable for investments in building constructions, particularly in housing. It causes a minimal impact on the environment and needs a small space for the working areas, requiring only two or three professionals to work with this system. It is still an on-going project, that is under development in LaMEM plant at School Engineering of São Carlos from São Paulo State University.

ACKNOWLEDGEMENTS

The authors would like to acknowledge CNPq (Federal Agency of Scientific and Technological Improvements, Brazil) for the financial support provided to this research and São Carlos Engineering School at São Paulo University – EESC/USP.

References

| [1] | Christoforo, A. L.; Panzera, T. H.; Batista, F. B.; Borges, P. H.; Rocco Lahr, F. A.; Franco, C. F. The position effect of structural Eucalyptus round timber on the flexural modulus of elasticity. Engenharia Agrícola, v. 31, p. 1219-1225, 2011. |

| [2] | Carvalho, S. S.; Dutra, J. R.; Carvalho, A. L. C.; Vieira, L. M. G.; Christoforo, A. L. Experimental Evaluation of the Employment of a Laminated Composite Material with Sisal Fibres as Reinforcement in Timber Beams. International Journal of Composite Material, v. 2, p. 97-100, 2012. |

| [3] | Christoforo, A. L.; Rocco Lahr, F. A.; Morales, E. A. M.; Panzera, T. H.; Borges, P. H. Numerical Evaluation of Longitudinal Modulus of Elasticity of Eucalyptus grandis Timber Beams. International Journal of Agriculture and Forestry, v. 2, p. 166-170, 2012. |

| [4] | Christoforo, A. L.; Ribeiro Filho, S. L. M.; Panzera, T. H.; Rocco, F. A. L. Metodologia para o cálculo dos módulos de elasticidade longitudinal e transversal em vigas de madeira de dimensões estruturais. Ciência Rural (UFSM. Impresso), v. 43, n. 4, p. 610-615, 2013. |

| [5] | Rocco Lahr, F. A.; Dias, A. A. Determinação das propriedades das madeiras para projetos estruturais. Revista Madeira, v. 1, p. 13-18, 2000. |

| [6] | Moura Pinto, E.; Calil Junior, C.; Munaiar Neto, J.; Regobello, R. Theoretical and experimental study of the thermal degradation of Eucalyptus timber. Forest Products Journal, v. 58, p. 85-89, 2008. |

| [7] | Ferreira, N. S. S.; Calil Junior, C. Estruturas lamelares de madeira para coberturas. Cadernos de Engenharia de Estruturas, n. 18, p. 109-138, 2002. |

| [8] | Danatzko, J. M.; Sezen, H.; Chen, Q. Sustainable design and energy consumption analysis for structural components. Journal of Green Building. v. 8, n. 1, p. 120-135, 2013. |

| [9] | Gonçalves, D. Sistema estrutural tipo Árvore – SETA: agente gerador de ocupação sustentável no uso habitacional de interesse social em terrenos de difícil topografia. Madeira: Arquitetura e Engenharia, v. 9, n. 22, p. 80-91, 2008. |

| [10] | Associação Brasileira de Normas Técnicas - ABNT. NBR 7190. Projeto de estruturas de madeira. Rio de Janeiro, 1997. |

| [11] | Associação Brasileira de Normas Técnicas - ABNT. NBR 6123. Cargas devidas ao vento em edificações. Rio de Janeiro, 1998. |

; steel:

; steel:  b) Variable action – Wind maximum action:

b) Variable action – Wind maximum action:  The velocity characteristic Vk and wind dynamic pressure q are expressed by Equations 1 and 2, respectively, relating to[11] Brazilian standard:

The velocity characteristic Vk and wind dynamic pressure q are expressed by Equations 1 and 2, respectively, relating to[11] Brazilian standard:

,

,  and

and  .To determine the wind force on the building wall with an area A (area on which the wind force acted: A = 12.96 m²), the calculation applies the relation between h and b:

.To determine the wind force on the building wall with an area A (area on which the wind force acted: A = 12.96 m²), the calculation applies the relation between h and b:  .Figure 10 show the pressure coefficient and shape coefficient, outside of the side walls and front walls (wind at 0° and at 90°).

.Figure 10 show the pressure coefficient and shape coefficient, outside of the side walls and front walls (wind at 0° and at 90°).

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML