Hicham Lotfi , Bouazza Faiz , Ali Moudden

Laboratory of Metrology and Information Processing, Ibn Zohr University, Faculty of Sciences, B.P. 8106, Agadir, Morocco

Correspondence to: Hicham Lotfi , Laboratory of Metrology and Information Processing, Ibn Zohr University, Faculty of Sciences, B.P. 8106, Agadir, Morocco.

| Email: |  |

Copyright © 2012 Scientific & Academic Publishing. All Rights Reserved.

Abstract

To understand the relation between the hardening of cementitious materials and the evolution of the mechanical properties of mortar specimen, we developed an experimental study to evaluate the effect of particles seize of sand and temperature on the evolution of acoustic impedance of mortars specimens. The results obtained indicated that particles of sand seizes was found to have an effect on ultrasound wave in the evolution of acoustic impedance. It was also found that the variation of environment temperature has a significant effect in the evolution of acoustic impedance of mortar.

Keywords:

Ultrasonic Testing, Acoustic Impedance, Mortar, Microstructure

Cite this paper: Hicham Lotfi , Bouazza Faiz , Ali Moudden , Characterization the Acoustic Impedance of Mortar Using Ultrasonic Technique, Journal of Civil Engineering Research, Vol. 3 No. 1, 2013, pp. 46-51. doi: 10.5923/j.jce.20130301.05.

1. Introduction

Mortar used in civil infrastructures is obtained after mixing sand and cement in water. Firstly the mortar is transformed to a fluid state, with time there is a progression in its mechanical properties, and the mortar transformed into a solid state. The transformation of mortar from a fluid to a rigid material is a result of the development in the microstructure of mortar specimens. This development modifies significantly the character and the behavior of the initial mixture of solid particles (sand particles, cement), water and air bubbles trapped during the hardening[1]. The first measurement techniques are mainly based on the Vicat apparatus, but the results obtained by this apparatus is largely insufficient to judge the time which the material is cured. The study of hydration of cementitious materials is also advanced by other techniques based on the measurement of heat release induced by hydration, electron microscopy and electrical conductivity. The use of press machine to measure the compressive strength of the specimens is also another technique to determinate the rigidity of mortars and concretes. Therefore, these techniques are destructive and they require a lot of samples, and the information obtained is not local, then the use of ultrasonic waves.The technique of continuously investigating and monitoring the development of properties of cementitious materials after mixing is currently under development. T.Voigt et al.[2] and[3] studied the ability of shear wave reflection (WR) method to monitor microstructure changes of Portland cement mortar during hydration, however Limaye et al.[4] studied the attenuation and propagation of ultrasonic waves in concrete using frequencies in the range 25-250 KHz, Facaoaru[5] reported that the ultrasonic wave velocity in concrete is directly proportion to concrete strength. Reinhardt et al.[6] developed a technique for monitoring the through thickness ultrasonic compression wave velocity in concrete. After casting, they used the compression wave velocity to study the development of elastic materials properties of concrete with varying composition; however, this technique does not provide sufficient sensitivity while the concrete is in a fluid state.A one similar ultrasonic technique to investigate the cement and concrete has been used also by M.I. Valic[7] and Kolluru.V[8] to study the early hydration in cement pastes. In the same respect H.K. Kim and al.[9] investigated the various characteristics of lightweight aggregate concrete with a high volume of entrained air. They concluded that the lightweight aggregate cellular concrete containing an adequate amount of air entraining agent was shown to have excellent characteristics including very-high workability.In this paper we developed a non-destructive technique based on backscattered of ultrasonic wave to investigate the early age response of mortar material in function with microstructure of sand and environment temperature. We analyzed the echoes of temporal signal backscattered by various mortar samples to test the rigidity of mortar. The paper discusses two objectives. The first objective is to assess the response of ultrasound signal used to interpret the change in the acoustic impedance of mortar during hydration, and the second to investigate the response of mortars varying the size of sand particles and effect of environment temperature.

2. Problem Statement

The ultrasonic techniques become used in the civil engineering industry to evaluate and investigate the quality and strength of mortar structure. The acoustic impedance of materials depends on the density and velocity of the material. Thus, mortar aggregate, environment temperature, water /cement (w/c), cement-sand (c/s) ratios and particles sand sizes have a significant effect on the propagation of ultrasonic wave.Many studies which evaluate mortar properties using ultrasonic techniques have been performed. Most of these studies did not study the effect of mortar mix parameters like the size particles sand and effect of temperature on propagation of ultrasound waves in mortar specimen.

3. Ultrasonic Measuring Technique

3.1. Measuring the Acoustic Impedance

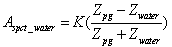

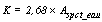

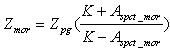

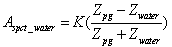

The behavior of the materiel with the propagation of ultrasound is expressed by a constant named acoustic impedance Z. It characterizes the quality of the material to transmit the ultrasonic waves, and is defined as the product of the density and the ultrasonic velocity in materiel. It is expressed by the following relation Z=ρ×C, with C referring to the ultrasonic velocity in the materiel in m.s-1 ,and ρ to the density of the materiel in Kg.m-3.The measurement of the spectral amplitude of the signal backscattered by a container enclosing water considered the reference state in evolution of the acoustic impedance. The Equation (1) expresses the relation between the spectral amplitude and the acoustic impedance of Plexiglas and water. | (1) |

Zpg is the acoustic impedance of Plexiglas equal to 3,21 106 Kg/m2.s, and Zwater is the acoustic impedance of water equal to 1,48 106 Kg/m2.s. K is a constant which depends on the transfer functions of the generator, oscilloscope, transducer, Plexiglas and water, its value equal to  . The value K is determined by the calculated value of the amplitude spectrum Aspct_water for each temperature.Example: at T = 42℃ the constant K equal to 45,85. At this temperature, the impedance acoustic of mortar is expressed by the equation (2). Table 1 shows the values of constant at different temperatures.

. The value K is determined by the calculated value of the amplitude spectrum Aspct_water for each temperature.Example: at T = 42℃ the constant K equal to 45,85. At this temperature, the impedance acoustic of mortar is expressed by the equation (2). Table 1 shows the values of constant at different temperatures. | (2) |

| Table 1. Value of K of each temperature |

| | Temperatures °C | 42 | 32 | 25 | | Constant K | 45,82 | 63,28 | 84,36 |

|

|

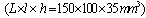

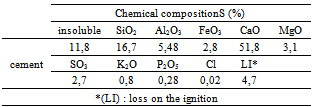

3.2. Preparation of specimens

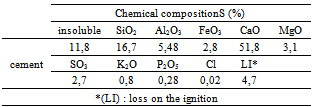

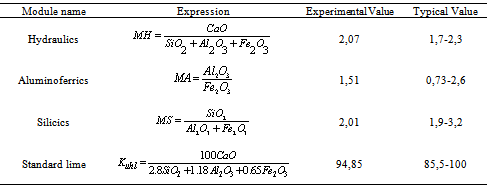

The measurements were performed on samples with mass ratios water / cement (w/c=0,65) and cement / sand (c/s=0,5). These samples were prepared with Portland Cement CPJ 45 produced by Agadir factory. The samples of mortar prepared are introduced in a vessel parallelepiped with dimension . In this vessel, we place the mixture of mortar. The vessel contained the mortar is then emerged in a tank filled with water and excited with a transducer of central frequency is 0,5 MHz. This transducer is put in a distance equal to 10cm of the vessel. The sand used is that extracted in Oued Souss river, the diameters of sand studied are (0,200; 0,250; 0,315 and 0,500mm), with absolute density 2630g/cm3, apparent density 1460 g/cm3 , Blaine specific surface 4092 cm2/g and water content equal to 3,3%. The Chemical compositions and physical properties of Portland Cement CPJ 45 are given in Table 2. In Table 3 we show the norms which characterize Agadir cement.

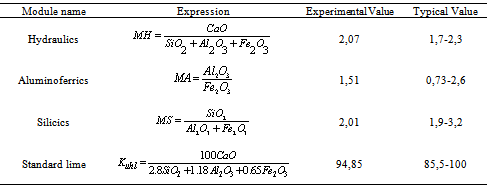

. In this vessel, we place the mixture of mortar. The vessel contained the mortar is then emerged in a tank filled with water and excited with a transducer of central frequency is 0,5 MHz. This transducer is put in a distance equal to 10cm of the vessel. The sand used is that extracted in Oued Souss river, the diameters of sand studied are (0,200; 0,250; 0,315 and 0,500mm), with absolute density 2630g/cm3, apparent density 1460 g/cm3 , Blaine specific surface 4092 cm2/g and water content equal to 3,3%. The Chemical compositions and physical properties of Portland Cement CPJ 45 are given in Table 2. In Table 3 we show the norms which characterize Agadir cement. Table 2. Chemical compositions of cement CPJ 45

|

| |

|

Table 3. Characters norms of Portland cement CPJ 45 produced by Agadir factory

|

| |

|

4. Principle of the Experiment

4.1. Experimental Setup

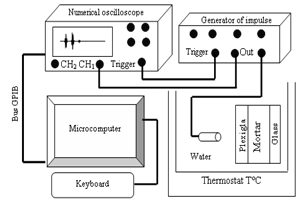

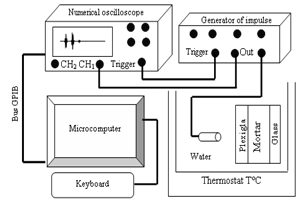

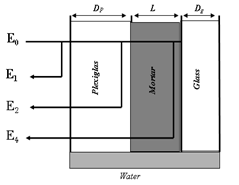

To investigate the hydration behavior of the mortar we described in figure 1 the schema of the experimental setup of the reflection method developed. The Mortar will be characterized is contained in a parallelepiped vessel immersed in water maintained at a temperature and excited with a transducer. The ultrasonic transducer functions as the transmitter and receiver, and is excited by an impulse generator. The transducer is a parametric (V302) transducer with a central frequency 0,5 MHz. The pulse generator sends an electrical pulse to the transducer, which is transformed into an ultrasonic wave. After propagation in water, the incident ultrasonic wave is partly reflected on the vessel and partly transmitted in the mortar sample through the vessel. The reflected acoustic signal composed of series of echoes is converted into analogy electrical signal, and is amplified and digitalized by Lecroy digital oscilloscope. The data are sent through an IEEE 488 interface to a computer that calculated the different parameters of mortar. The experimental method consists of analyzing the echo reflected at the interface between second face of Plexiglas and mortar specimen. | Figure 1. Experimental setup |

4.2. Paths of Ultrasonic Signal

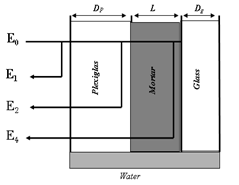

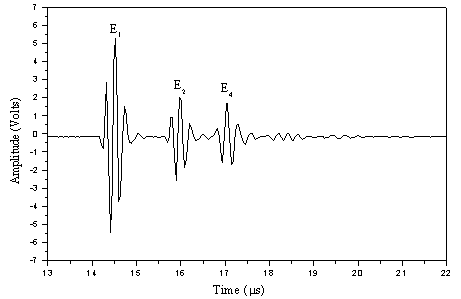

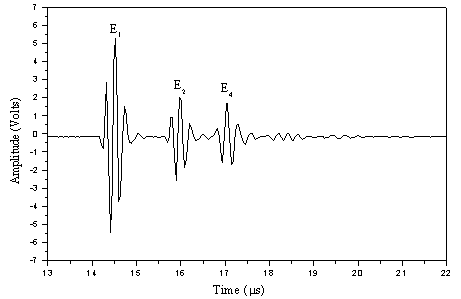

The incident ultrasonic wave is considered as a plan wave. Part of the ultrasonic energy is transmitted into the mortar through plate 1(Plexiglas), and after propagation in the mortar part of the energy is reflected from plate 2 (Glass) and returns to the same transducer used as receiver. Figure 2 shows the different paths taken by the ultrasonic wave. Each path provides an echo which is labelled En. Figure 3 presents the signal composed of echoes E1, E2 and E4 reflected by the vessel enclosing the mortar. The first E1 echo reflected on the bottom surface of plate 1 is not important because it is not used in this study. The second echo E2 corresponds to the reflection on the interface between the second Plexiglas face and the mortar sample enclosed in the vessel. The last echo E4 corresponds to the reflection on the interface between the mortar and the first face of plate 2. The choice of the vessel material (Plexiglas) is done in relation with the characteristics of the mortar and its thickness (Dp=2cm) is chosen in order to sufficiently attenuate echoes (reflection in plate 1). In this study, only spectral properties of echoes E2 and E4 was analyzed to determine the acoustic impedance of mortar in real time. | Figure 2. Different paths of ultrasonic signal in mortar |

| Figure 3. Reflected echoes by the mortar, time domain |

5. Results and Discussion

5.1. Effect of Particles Size

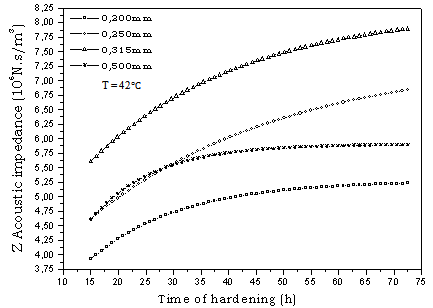

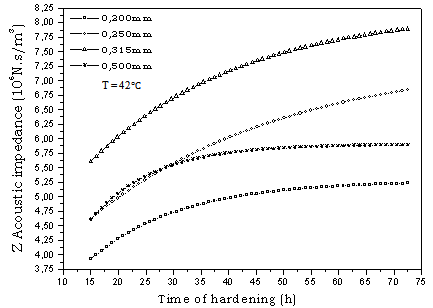

Recently several microstructural and micromechanical models of evolution microstructure of cementitious materials have been developed. The technique developed in this paper has the ability to know information about the rigidity of mortar by analyzing their acoustic impedance. Figure 4 show the evolution of the acoustic impedance during the 72h for all mortars (0,200; 0,250; 0,315 and 0,500mm). It can clearly be seen that the initial setting starts from the 15h of hydrating of mortar, and the final period of stiffness state begins at the 40h, in this phase the mortar characterized by stability in its structure. This result is same result deduced by Yunsheng Z.[10] using a specially designed ultrasonic monitoring apparatus (UMA) to studying of the early age hydration process of cementitious materials made with various mineral admixtures.We also noted that the presence of the impurities in the small particles of sand, and their mineralogical character inhibits the hardening of the mortars. The acoustic impedance of large size sand particles as well is low due to the interconnection between grains, thus formed the anomalies and cracks in the structure of mortar. Therefore, the mortar prepared with 0,315mm size of sand presents a high performance and acoustic impedance comparing it with other mortars (0,200; 0,250; and 0,500mm). Consequently, the former has a massive strength.

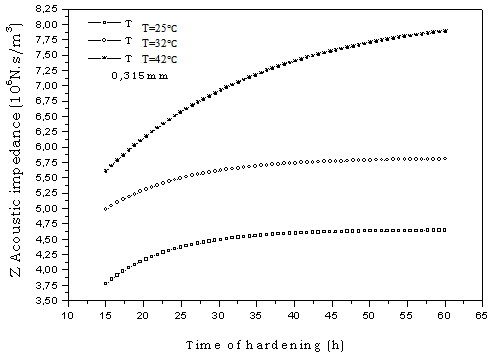

5.2. Effect of Temperature

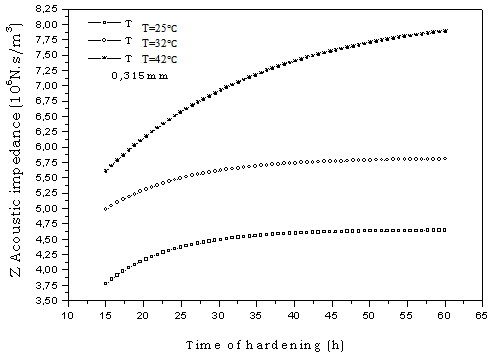

It is obvious that conditions (atmospheric pressure, temperature ...) have an effect on the quality of the sites, and then it’s necessary to study this influence during the preparation and monitoring of mortars. Han and Kim[11] prepared specimens by two types of cement with the mass ratios water /cement (w / c) 0,400 and 0,500 for temperatures 10℃, 23℃ and 50℃. These specimens are tested at the age of 1, 3, 7 and 28 days. Han and Kim found that the type of cement did not significantly affect the quality of the cement but the age of the specimen conservation and temperature conditions have a relationship with the dynamics modules and the compressive resistance of the concrete. Bjontegaard[12] performed measurements of withdrawals on concrete made with the mass ratio w/c= 0,400 and for various types of temperature. Bjontegaard observed for different isothermal temperatures that autogenous shrinkage increases as well as reduction of temperature in comparison with the results obtained at 20℃.To improve the quality and management of mortars we proceeded to try three different temperatures 25, 32 and 42℃ for the same size of grains of sand equals 0,315mm, and the mass ratios cement /sand and water/cement. In Figure 5 we represent the evolution of the acoustic impedance for different temperatures 42, 32 and 25℃, and only for particles sand size equal 0,315mm, it is clearly that the acoustic impedance increase with time of hardening, however the effect of time of hardening is more significant at 25℃. For fewer temperatures acoustic impedance increase with time of hardening, though for the higher temperatures 42℃, the rigidity is in early age but the mortar structure is in less strength comparing it with fewer temperature neighbors of 25℃. This result is consistent with those reported by other authors[13, 14] | Figure 4. Evolution of acoustic impedance of mortar for various sand sizes |

| Figure 5. Acoustic impedance of mortar of three environment temperature |

6. Conclusions

In the present paper we presented the results of an experimental study using ultrasonic reflection technique to study the evolution of acoustic impedance of mortar enclosed in a vessel of Plexiglas and glass. This technique is based on the analysis of ultrasonic signal backscattered by the mortar where the hydration using a transducer of central frequency 0,5MHz.The major conclusions from the investigation described in this paper are:1. Experimental investigations have shown that sand particle size influences in acoustic impedance measurements, and thus the effect development of strength and durability of mortar.2. It is shown that the specimen realized with 0.315mm had high acoustic impedance than others.

References

| [1] | T.P. Philippidis, D.G.Aggelis, "Experimental study of wave dispersion and attenuation in concrete", Ultrasonics. 43 ,2005, pp. 584–595. |

| [2] | Thomas Voigt, Guang Ye, Zhihui Sun, Surendra P. Shah, Klaas van Breugel, "Early age microstructure of Portland cement mortar investigated by ultrasonic shear waves and numerical simulation", Cement and Concrete Research. 35, 2005, pp. 858– 866. |

| [3] | T. Voigt, Y. Akkaya, S.P. Shah, " Determination of early age mortar and concrete strength by ultrasonic wave reflections", ASCE J. Mater. Civ. Eng. 15 (3), 2003, pp. 247–254. |

| [4] | Gaydecki P, Burdekin F, Damaj W, John D, Payne P." The propagation and attenuation of medium-frequency ultrasonic waves in concrete: a signal analytical approach", Meas Sci Technol, 1992 (3), pp. 126–33. |

| [5] | Facaoaru.I " Non-destructive testing of concrete in Romania. In: Proceedings of symposium on non-destructive testing of concrete and timber", London, UK: Institution of Civil Engineering, 1969. |

| [6] | H.W. Reinhardt, C.U. Gro e, A.T. Herb. "Ultrasonic monitoring of setting and hardening of cement mortar-a new device", Mat. Struct. 33, 2000, pp. 580– 583. |

| [7] | M.I. Valic¡, J. Stepis¡nik, "A study of hydration of cement pastes by reflection of ultrasonic shear waves: Part I. Apparatus, experimental method and application examples", Kovine Zlit. Tehnol. 32 (6) ,1996, pp. 551– 600. |

| [8] | Kolluru.V, "Monitoring the setting behavior of cementitious materials using one-sided ultrasonic measurements", Cement and Concrete Research, 35, 2005, pp. 850– 857. |

| [9] | H.K. Kim, J.H. Jeon and H.K. Lee. " Workability, mechanical acoustic and thermal properties of lightweight aggregate concrete with a high volume of entrained air". Construction and Building Materials, volume 29, April 2012, Pp 193–200. |

| [10] | Yunsheng Zhang,Wenhua Zhang, Wei She, Liguo Ma and Weiwei Zhu, "Ultrasound monitoring of setting and hardening process of ultra-high performance cementitious materials", NDT & E International, volume 47, April 2012, Pp 177–184. |

| [11] | Han, S. H., J. K.Kim, "Effect of temperature and age on the relationship between dynamic and static elastic modulus of concrete", Cement and Concrete Research. vol. 34, no. 7, 2004, pp. 1219–1227 |

| [12] | O.Bjontegaard, "Thermal dilatation and autogenous deformation as driving forces to selfinduced stresses in high performance concrete". Thèse, Trond-heim,Norway, 1999. |

| [13] | Kim J.-K., Hun Han S., Kyun Park S., "Effect of temperature and aging on the mechanical properties of concrete: Part ii. Prediction model", Cement and Concrete Research 2002, 32, pp. 1095-1100. |

| [14] | Kim J.K., Moon Y.H. Eo S.H., "Compressive strength development of concrete with different curing time and temperature", Cement and Concrete Research,1998, 28, pp. 1761-1773. |

. The value K is determined by the calculated value of the amplitude spectrum Aspct_water for each temperature.Example: at T = 42℃ the constant K equal to 45,85. At this temperature, the impedance acoustic of mortar is expressed by the equation (2). Table 1 shows the values of constant at different temperatures.

. The value K is determined by the calculated value of the amplitude spectrum Aspct_water for each temperature.Example: at T = 42℃ the constant K equal to 45,85. At this temperature, the impedance acoustic of mortar is expressed by the equation (2). Table 1 shows the values of constant at different temperatures.

. In this vessel, we place the mixture of mortar. The vessel contained the mortar is then emerged in a tank filled with water and excited with a transducer of central frequency is 0,5 MHz. This transducer is put in a distance equal to 10cm of the vessel. The sand used is that extracted in Oued Souss river, the diameters of sand studied are (0,200; 0,250; 0,315 and 0,500mm), with absolute density 2630g/cm3, apparent density 1460 g/cm3 , Blaine specific surface 4092 cm2/g and water content equal to 3,3%. The Chemical compositions and physical properties of Portland Cement CPJ 45 are given in Table 2. In Table 3 we show the norms which characterize Agadir cement.

. In this vessel, we place the mixture of mortar. The vessel contained the mortar is then emerged in a tank filled with water and excited with a transducer of central frequency is 0,5 MHz. This transducer is put in a distance equal to 10cm of the vessel. The sand used is that extracted in Oued Souss river, the diameters of sand studied are (0,200; 0,250; 0,315 and 0,500mm), with absolute density 2630g/cm3, apparent density 1460 g/cm3 , Blaine specific surface 4092 cm2/g and water content equal to 3,3%. The Chemical compositions and physical properties of Portland Cement CPJ 45 are given in Table 2. In Table 3 we show the norms which characterize Agadir cement.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML