-

Paper Information

- Next Paper

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Journal of Civil Engineering Research

p-ISSN: 2163-2316 e-ISSN: 2163-2340

2013; 3(1): 16-21

doi:10.5923/j.jce.20130301.02

Determination of Several Properties of a Bamboo of Bangladesh

H. M. A. Mahzuz , Mushtaq Ahmed , Jotan Dutta , Rezwanul Haque Rose

Department of Civil and Environmental Engineering, Shahjalal University of Science & Technology, Sylhet, Bangladesh

Correspondence to: H. M. A. Mahzuz , Department of Civil and Environmental Engineering, Shahjalal University of Science & Technology, Sylhet, Bangladesh.

| Email: |  |

Copyright © 2012 Scientific & Academic Publishing. All Rights Reserved.

The paper attempts to understand several properties of a bamboo (Bambusa balcooa) which is easily available in many parts of Bangladesh. All the bamboo samples used in this study were collected from one three years old tree. A total thirty samples were tested to find the ultimate strength. Among them the stress-strain curve of five samples were studied to find out Modulus of Elasticity (MoE) and Yield Strength (YS) using Offset Method. Attempts were also made to understand the bond strength of bamboo with concrete by the experimental setup of Pull out test. Here three types of specimens were prepared. Each type includes two specimens. Pull out test of steel were also made to report a relative comparison. Finally the relative comparison between the unit weight, strength and cost were made.

Keywords: Bamboo, Cost, Pullout Test, Stress, Strain, Steel, Tension Test, Unit Weight

Cite this paper: H. M. A. Mahzuz , Mushtaq Ahmed , Jotan Dutta , Rezwanul Haque Rose , Determination of Several Properties of a Bamboo of Bangladesh, Journal of Civil Engineering Research, Vol. 3 No. 1, 2013, pp. 16-21. doi: 10.5923/j.jce.20130301.02.

Article Outline

1. Introduction

- There are more than 33 bamboo species have been found in Bangladesh out of which 7 are occurring naturally in the forests of Chittagong Hill Tracts, Cox's Bazar, Sylhet and northern Mymensingh[3]. Sylhet –a Northeastern district of Bangladesh where bamboo (Bambusa balcooa) grows in abundance. It is locally known as Borak Bash. This bamboo was taken in this research for testing its several properties. The strength of bamboo is greater than many timber products which are advantageous, but it is quite less than the tensile strength of steel. Tension test is the most basic type of mechanical test. It is easy to perform and relatively inexpensive compared to other tests. The stress- strain characteristics of bamboo have been derived from the results of this tension test.Construction industry is one of the most polluting industries in the world. Production of both concrete and steel causes considerable deterioration of the environment. For example cement requires over 1400℃ by burning fossil fuel[1,20]. Even the flame temperature may reach to 1650℃ (Neville, 1995). Production of every ton cements results in emission of at least one ton of CO2[2]. Similarly, production of per ton of steel releases over two tons of CO2 in the atmosphere[17]. The steel making process is very energy intensive. The majority of energy used in the production of steel comes from coke/coal, electricity, liquid oxygen, and the raw ingredients themselves[16]. Even transportation of the construction material is also associated with the emission of CO2[15]. K. Gavami carried out several research programs using indigenously available local materials such as bamboo, coconut fibres, sisal and other natural fibres as construction materials[5-10]. For low cost housing, search of low cost material is always a good area of research[11]. Bamboo is one of the oldest building materials. It is easy to work with, structurally strong, suitable for framing, flooring, roofing, lining etc[12, 21]. In Bangladesh, a South-Asian country, bamboo is a common material to build low cost houses especially in rural areas[13,14]. It is also used as a common fuel product in Bangladesh as well as different part of South Asia[4, 18, 19]. Whereas the mechanical properties and behaviour of steel have been thoroughly studied and well documented, there exists no comprehensive data describing the characteristics of bamboo. Therefore, the aim of this study is to provide a preliminary contribution toward the collection of several physical and mechanical properties of bamboo.

2. Objectives of the Research

- The study was conducted keeping the following objectives in mind:1) Understanding the stress-strain relationship of bamboo splints.2) To compare the Strength-density ratio and Strength- cost ratio with steel.3) To investigate the bond with concrete.

3. Sample Preparation

- Three years old, any type of fault-free bamboo (Bambusa balcooa) was selected from careful visual inspection for tension test. After cutting the bamboo it was kept in open air for two months to be removed from moisture. Thirty specimens were prepared for tension test at the Universal Testing Machine (UTM). Among them five samples were tested to find out the Modulus of Elasticity (MoE) and the yield strength. Based on the result, statistical analysis was also performed using the computer program-SPSS.

| Figure 1. Prepared samples for Pull-out test |

| Figure 2. Failed bamboo after Tension test in UTM |

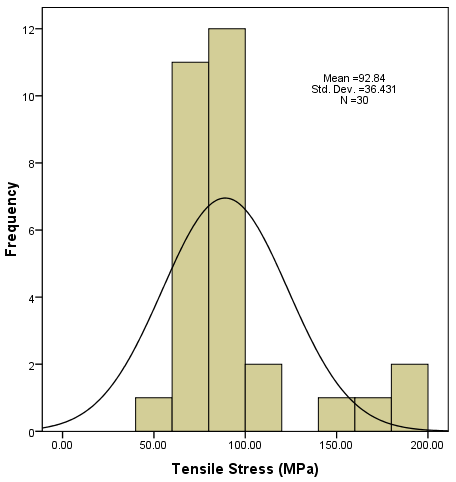

| Figure 3. Normality curve of Frequency Vs Stress of the bamboo samples |

4. Test Result

4.1. Tension Test

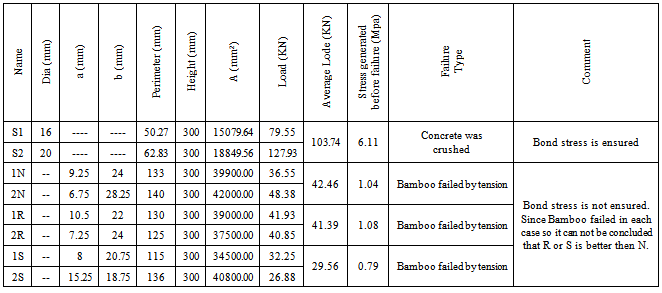

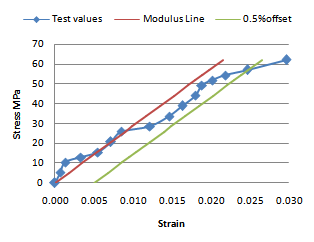

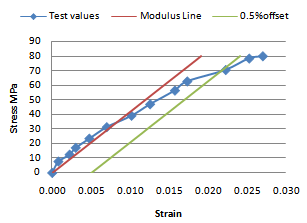

- The tensile tests (Fig 2) were conducted at 15.5% moisture content. Their failure pattern, ultimate and yield strength is discussed in the following section. Table 1 shows detailed information about the size of bamboo samples, maximum load and maximum stress taken by each bamboo specimen. Table 2 shows the statistical analysis of the results of Table 1. Fig 3 shows the normality curve of Frequency Vs Stress of the bamboo samples. The Stress-strain curves of five samples are shown from Fig 4-8.

| Figure 4. Stress-strain diagram of Sample-1 |

| Figure 5. Stress-strain diagram of Sample-2 |

| Figure 6. Stress-strain diagram of Sample-3 |

| Figure 7. Stress-strain diagram of Sample-4 |

| Figure 8. Stress-strain diagram of Sample-5 |

4.2. Pull-Out Test

| Figure 9. Pull-out test of steel |

| Figure 10. Pull-out test of bamboo |

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

4.3. Unit Weight

- A total number of four samples of each type were tested. The elaborate result is shown in Table-5. It is seen from the result that bamboo possesses much less density than that of steel.

5. Discussion

5.1. Stress Strain Relation

|

|

5.2. Comparison of Several Ratios

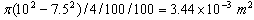

- For being a natural material the weight of bamboo is much less than steel. Bamboo has more then twice the Unit Strength-Weight ratio than that of Steel (Table 7). For the abundance availability the cost bamboo is low. That’s why, bamboo has higher Strength-cost ratio than that of steel. Three years old well grown one bamboo costs Taka 300 (1 Dollar ≈ 78 Taka). If its inner dia = 10 cm and outer dia 7.5 cm then its cross-sectional area is

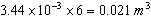

Considering the effective usable height 6m the volume of one bamboo is

Considering the effective usable height 6m the volume of one bamboo is . From Table 5 It seen that volume of 0.51 m long sample (Bamboo-1) is 0.00011934 m3. Therefore the volume of 1 m bamboo is 0.000238 m3. So the equivalent cost is

. From Table 5 It seen that volume of 0.51 m long sample (Bamboo-1) is 0.00011934 m3. Therefore the volume of 1 m bamboo is 0.000238 m3. So the equivalent cost is  o=3.4 Taka/m. On the other hand, the present market price of #3 is Taka 52000 per ton. The nominal Weight of #3 bar is 0.376 lb/ft which equal to 0.000188 Ton/ft (since 1 lb=0.0005 Ton). Therefore Cost/ft is Taka 9.78. This can be said as 32.08 Taka/m, (since 1m = 3.28 ft). This value is almost 9.5 times higher than that of steel.

o=3.4 Taka/m. On the other hand, the present market price of #3 is Taka 52000 per ton. The nominal Weight of #3 bar is 0.376 lb/ft which equal to 0.000188 Ton/ft (since 1 lb=0.0005 Ton). Therefore Cost/ft is Taka 9.78. This can be said as 32.08 Taka/m, (since 1m = 3.28 ft). This value is almost 9.5 times higher than that of steel.

| ||||||||||||||||||||

5.3. Pullout Test

- It is seen from the experimental data (Table 4) that, the bond strength of steel with concrete is more than five times higher than all the three cases of bamboo. Both of the samples of steel were failed due to the crushing of concrete. For bamboo specimens in all cases Bamboo failed by tension rather the splitting out from concrete or the crushing of concrete. Since, it is Bamboo that failed first in each case so it can not be concluded that R or S is better then N. Therefore it is worthless to try to increase the bond strength using GI ring or spiral under the above mentioned condition. It can be said that since bamboo failed in all cases so the actual bond strength can not be reported from this test. Therefore, the values (i.e. 1.04 Mpa 1.08 Mpa and 0.79 Mpa shown in Tble-4) are the skin friction before the failure of bamboo- not the bond strength. Bond strength can be achieved by reducing the height of concrete. Therefore more tests have to be done in this area.

6. Conclusions

- The tensile tests were performed taking the natural state of bamboo. Except air drying (for 60 days) no other chemical and physical treatments were performed. The moisture content was 15.5%. From the Pull-out test the actual bond strength could not be reported. Therefore more tests should be carried out reducing the height of concrete (obviously the than 300 mm), or reducing the values of 28 days compressive strength (less than 27.5 Mpa- as reported at Table-3), or increasing the cross-sectional area of bamboo splints (the value should be more than the values of bamboo shown in table 4). Being a natural material bamboo offers much less strength than that of steel. Yet it exhibits double Strength-weight ratio than that. Strength-Cost ratio of bamboo is also more than nine times higher than that of steel. This scenario certainly provides interesting information for the prospect of more research in this field.

References

| [1] | Aziz MA, ‘Engineering Materials’, Z and Z Computer and Printers, Dhaka, Bangladesh, p. 65, 1995. |

| [2] | Baba M, ‘Mini Project Report on Shed Type Structures-Steel vs Bamboo”, Dept. of Civil Engineering, Indian Institute of Technology, Delhi, p/5, (2009). http://www. bambootechnologies. org/pdf/Report_Moti.pdf. |

| [3] | Banik, R.L, “Propagation of bamboos by clonal methods and by seed”, Pages 139-150. In: Bamboo research in Asia. (Eds. Lessard, G. and Chouinard, A.) Proc. of a workshop, Singapore, IDRC, OTTAWA, Canada, 1980. |

| [4] | Bhatt BP, Sachan MS, “Firewood consumption pattern of different tribal communities in Northeast India”, Energy Policy, 32(1): 1-6, 2004, doi:10.1016/S0301-4215(02)00237 -9. |

| [5] | Ghavami, K., “Application of Bamboo as a Low-cost Energy Material in Civil Engineering”, 3rd CIB RILEM Symposium on Materials for Low Cost Housing, Mexico, pp. 526-36, 1989. |

| [6] | Ghavami, K. & Zielinski, Z. A., “Permanent Shutter Bamboo Reinforced Concrete Slab”, Publication BRCSZ, Dept of Civil Eng., Concordia Univ., Montreal, Canada, 1988. |

| [7] | Ghavami, K. & Hombeeck, R. V., “Application of Bamboo as a Construction Material, Part I – Mechanical Properties and Water-repellent Treatment of Bamboo; Part II - Bamboo Reinforced Concrete Beams”, Proceedings of the Latin American Symposium on Rational Organization of Building Applied to Low Cost Housing, sponsored by IPT and CIB, Brazil, pp. 49-66. 1981. |

| [8] | Ghavami, K., “Application of Bamboo as a Low cost Construction Material”, International Bamboo Workshop, Cochin, India, pp. 270-79, 1988. |

| [9] | Ghavami, K. & Fang, H. Y., Low cost and energy saving construction materials. ENVO Publishing Company, Lehigh, USA (1984). |

| [10] | Ghavami, K., “Ultimate Load Behaviour of Bamboo-Reinforced Lightweight Concrete Beams” Cement & Concrete Composites (17) Elsevier Science Limited, p. 281-288 0. 1995. |

| [11] | http://www.energytechpro.com/DemoIC/Business_Sector/Industrial/Stee l_Production.htm (2004). |

| [12] | Joseph P, Mc-Nally ST, “Sustainable Non-metallic Building Materials”, Sustainability, 2: 411, (2010), doi: 10.3390/ su2020400, http://eprints.ulster. ac. uk/10111/1/ PJPub14. pdf. |

| [13] | Leach G, “Household energy in South Asia, Biomass, 12(3): 155-184, (1987), doi:10.1016/0144-4565(87)90034-5. |

| [14] | Miah MD, Kabir RRMS, Koike M, Akther S, Shin MY, “Rural household energy consumption pattern in the disregarded villages of Bangladesh”, Energy Policy, 38(2): 997-1003, Feb. 2010, doi:10.1016/j.enpol.2009.10.051. |

| [15] | Monitor CS, http://www.csmonitor.com/2008/0312/p14s01- stgn.html, (2008). |

| [16] | Mahzuz HMA, Alam R, Alam MN, Basak R, Islam MS, “Use ofarsenic contaminated sludge in making ornamental bricks” is published in the Int. J. Environ. Sci. Technol., 6(2): 291-298, (2009). |

| [17] | Neville AM, “Properties of Concrete”, 4th edition, Pearson Education, p. 6, 1995, ISBN 81-7758-587-8. |

| [18] | Rashid R,”Traditional House of Bangladesh: Typology of houses according to materials and location, Virtual Conference on Sustainable Architectural Design and Urban Planning”, AsiaSustainabilityNet.upc.edu, Sept., pp. 15-24, 2007. |

| [19] | Shila DV, “Bamboo Construction Technology for Housing in Bangladesh: Opportunities and Constraints of Applying Latin American Bamboo Construction Technologies for Housing”, International Network for Bamboo and Rattan Eindhoven University of Technology ActionAid, page-108, 2002, found at:http://www.sheltercentre.org/library/Bamboo+ Construction+Technology+Housing+Bangladesh+ Opportunities +and+Constraints+Applying+ Lat. |

| [20] | Scientific American, http://www.sciam.com/artical.cfm?id= cement- fromcarbondioxide, 2008. |

| [21] | Sun M, Rydh CJ, Kaebernick H, “Material Grouping for Simplified product life cycle assessment”, J. Sustainable product Des, 3: 45-48, 2003. |

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML