-

Paper Information

- Next Paper

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Journal of Civil Engineering Research

p-ISSN: 2163-2316 e-ISSN: 2163-2340

2012; 2(6): 100-107

doi: 10.5923/j.jce.20120206.06

Effect of Wirand FS7-II Steel Wire Fibre on Flexural Capacity of Reinforced Concrete Beam

Amir Hossein Jodeiri , Ronaldo J. Quitalig

School of Graduate Studies, Mapua Institute of Technology (MIT) Manila, 1550, Philippines

Correspondence to: Amir Hossein Jodeiri , School of Graduate Studies, Mapua Institute of Technology (MIT) Manila, 1550, Philippines.

| Email: |  |

Copyright © 2012 Scientific & Academic Publishing. All Rights Reserved.

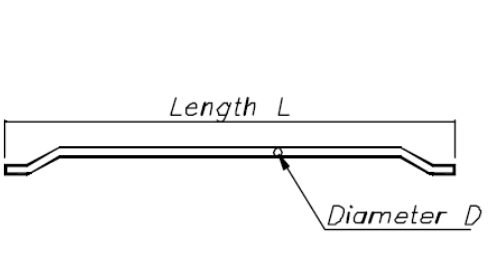

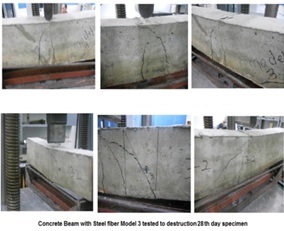

Concrete is good in compression but today fibre reinforced concrete is perhaps one of the most realistic possibilities to develop the use of concrete in load bearing structures. The hooked-end steel fibre with the dimensions of 0.55 mm in diameter, 33 mm in length and with the aspect ratio of 60 were used in this study. It was concluded that the volume fraction of steel fibre FS7-II was 1 % (23.77 kg/m3). In conventional concrete two beams are used whereas concrete beam with steel fibre FS7_II 1% also had two model and model three removed from reinforced rebar at the top. The overall dimensions of the beams were 200 mm in height, 150 mm in width, and 940 mm in length. The beams were tested under third-point loading test for 28 days. The results showed that the addition of steel fibres in concrete increases the first cracking load, ultimate load, stiffness and ductility of the concrete beams. In comparison with the control concrete group’s maximum increase in the compressive strength at 1% steel fibre was 12.37 at 7 days, 10.44 % at 14 days and 5.58% at 28 days. Increase in the flexural strength at 1% steel fibre was 19.42% at 28 days for model two and 6.76% at 28 days for model three. In general, the significant improvement strength was observed with the inclusion of steel fibres in the conventional concrete with 1%. In this study concrete beam to continued carry load after cracking had occurred, called post crack behaviour or toughness. The first crack load (Pcr) was determined from the curve and SFRC beams showed significant increase in the first crack load over reinforced concrete beams. This increased the flexural modulus of rupture which showed that model two got 19.48% and model three got 6.7% if the beams were containing 1% steel fibres. The SFRC beams with 1% volume fraction of fibres showed an average increase model two with 19.44 % and model three with 6.76% in ultimate load (Pu) when compared to RC beams.

Keywords: Flexural Strength, Compressive Strength, Steel Fibre, Ultimate Load, First Cracking Load

Cite this paper: Amir Hossein Jodeiri , Ronaldo J. Quitalig , "Effect of Wirand FS7-II Steel Wire Fibre on Flexural Capacity of Reinforced Concrete Beam", Journal of Civil Engineering Research, Vol. 2 No. 6, 2012, pp. 100-107. doi: 10.5923/j.jce.20120206.06.

Article Outline

1. Introduction

1.1. Back Ground

- Steel fibres have been used in concrete since the early 1900s. The early fibres were rounded, smoothed and the wire was cut or chopped to the required lengths. The use of straight, smooth fibres had largely disappeared and modern fibres have either rough surfaces, hooked ends or are crimped or undulated through their length. The use of steel fibre has been well established as complementary reinforcement to improve certain properties of concrete elements. Fibre reinforcement has been shown to improve the ductility, toughness, flexural strength, and shear strength of cementations materials. As defined in this template, but do not change or redefine them in any way as this will lead to unpredictable results. You do not need to remember shortcut keys.Steel fibre reinforced concrete should only be used in a supplementary role to inhibit cracking to improve resistance to impact or dynamic loading and to resist material disintegration. The study concluded that the beneficial effects of steel fibres decrease with increasing bar. Steel fibres uniformly distributed the volume of concrete and rebar much higher shear strength are close to each other. Steel fibres can also provide an adequate internal restraining mechanism when shrinkage-compensating cements are used.The use of steel fibre reinforced concrete beam for structural applications was hindered by the absence of a codified design approach. Therefore there was a need to establish and assess design models for various design aspects on the use of steel fibre reinforced in various structural applications. In order to improve the tensile strength stability and cracking properties in RC beams were used with steel fibres. Effects of steel fibres on flexural capacity performance, shrinkage and improved resistance cracking mechanical properties of RC beams were investigated in this study.

1.2. Objective

| Figure 1. Influence of amount of steel fibres on the compressive stress behaviour |

1.3. Review of Related Literature

- The compressive behaviour of concrete was influenced by properties of its constituent materials. Concrete with a low water-to-cement ratio may display high compressive strength. Normal concrete with high compressive strength usually shows more brittle behaviour. For small amounts of steel fibres added to concrete, the compressive strength in concrete does not significantly improve .However, post-cracking ductility of the composite may be improved with the addition of steel fibres figure 1[1].Fatih Altun et al, (2005) consider addition effects of two different dosage of hooked steel fibres (30 and 60 kg/m3) on toughness strength of concrete. Steel fibres were added into two grades of concrete, 20 and 30. The steel fibres used in their research were 60 mm in length and 0.75 mm in diameter with tensile strength of 1050 N/mm2. Their results showed that energy absorption of 2 capacities (toughness) of concrete grade 20 and 30 increased by 121% and 135% with addition of steel fibre dosages of 30 kg/m3 and 60 kg/m^3[2].Research of Darwish et al, showed that an addition of up to 1.5% of fibres by volume increases the compressive strength from 0 to 15%. A gradual slope in the descending portion of the fibre reinforcement concrete (FRC) stress-strain curve indicates improved spelling resistance, ductility and toughness as shown in Figure2[3].

| Figure 2. Effects of Steel Fibres Content on Compressive Stress-Strain Curve of FRC (Padmarajaiah and Ramaswamy, 2002) |

2. Methodology

- The observation in this research was concentrated on determining the flexural capacity of RC beams with the addition of 1% steel fibre FS7- II was 23.77 kg/m3 in concrete. Furthermore, the research wanted to study how well the steel fibres would improve the flexural capacity of the concrete beams with the conventional steel bar reinforcement. In this study, steel fibre reinforced concrete (SFRC) was a composite material made of hydraulic cements, water, fine and coarse aggregate and a dispersion of discontinuous, small fibres. All admixtures meeting ASTM specifications for use in concrete are suitable for use in steel fibre reinforced concrete SFRC which was shown in Table1.

|

| Figure 3. Steel Fibre Winrad @FS7_II Used in This Study |

| Figure 4. Cross Section of RC Beams |

| Eq. (1) |

| Figure 5. Concrete with 1% Steel Fiber FS7 _II |

3. Results and Discussion

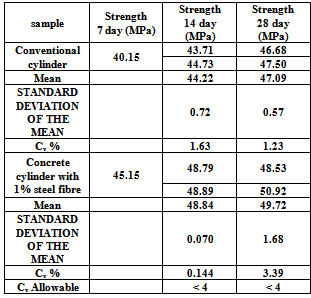

- The results of compressive strength test of concrete cylinder with 1% steel fibre FS7_II (23.77 kg/m3) and conventional concrete cylinder at 7, 14 and 28 days were shown in Table 3.

|

| Figure 6. Failure of cylinder in compressive test at 28th |

| Figure 7. Linear Regression |

|

| Figure 8. Schematic of Typical Fracture Patterns under Bending |

| Figure 9. Schematic of Typical Fracture Patterns under Bending |

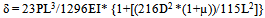

| Eq.(2) |

| |||||||||||||||||||||||||||||||||

|

| Eq. (3) |

|

|

4. Conclusions

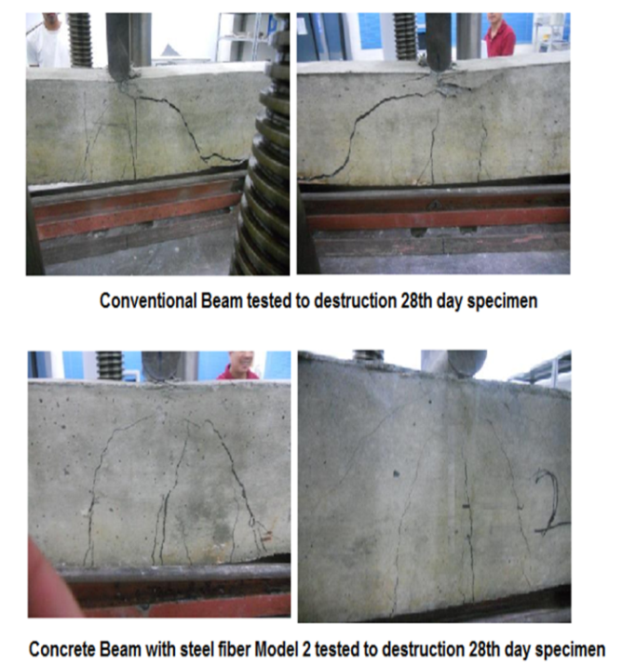

- The aim of this study was to provide determination effect of Winrad FS7- II steel fibre on flexural capacity of reinforced concrete beams compared with conventional reinforced concrete beams and concrete beams with bottom rebar. It was anchored to the based information that greater volume of steel fibre has to conventional concrete. Generally, this study showed that the addition of 1% steel fibre FS7_II improved the mechanical properties of concrete and RC beams.Based on the finding of this study, the following conclusions were drawn: addition of steel fibres increases flexural and compressive strength of concrete. In comparison with control concrete the maximum increase in the compressive strength with 1% steel fibre was 12.37% at 7 days, 10.44 % at 14 days and 5.58% at 28 days. The increase in compressive strength of high performance steel fibre concrete was attributed to the capability of steel fibre to delay the unstable development of micro cracks as well as to limitation the propagation of these micro cracks and the composite effect for concrete and steel fibres under load. Increase in the flexural strength with 1% steel fibre was 19.42 % at 28 days for model two and 6.76% at 28 days for model three. In general, the significant improvement in various strengths was observed with the inclusion 1% of steel fibres in the conventional concrete. However it can be showed increase for model three because the model removed the reinforced rebar at the top. The initial cracks on the concrete beams model two specimens were not visible until such time the maximum load was reached, the increase in the propagation of the cracks was visible enough. Addition of steel fibres in the concrete mix significantly influenced the cracking behaviour and ultimate strength of beams. In the study the main reason for incorporating steel fibres in concrete was to impart ductility to an otherwise brittle material. They enable concrete to continue carry load after cracking had occurred called post crack behaviour, or toughness. The most remarkable changes in increasing strength by the used of short fibres to concrete occurs in bending. These changes included the increasing of flexural strength in pre-cracking stage and ductility of the concrete in post-cracking stage. It showed that the increasing amount of short fibres increase the load bearing capacity of the concrete. The first crack load Pcr in Table 6 was determined from the curve. All the SFRC beams showed significant increase in first crack load over reinforced concrete beams. This increase flexural modulus of rupture was model two with 19.48% and model three with 6.7 % in case beams containing 1% steel fibres. The SFRC beams with 1% volume fraction of fibres, showed an average increase of model two with 19.44 % and model three with 6.76% in ultimate load (Pu) when compared to RC beams. (8) The addition of 1% steel fibres increased the ultimate load but the deflection at ultimate load was less than the conventional concrete beams. Hence, it can be said that the SFRC beams were stiffer than conventional concrete beams. The reason can be due to the effects of steel fibres and good bonding between steel fibres with the surrounding concrete which was act as confinement to the concrete and also energy absorption under flexural loading which was greatly enhanced with steel fibre reinforcement.

ACKNOWLEDGEMENTS

- I would like to express my sincere gratitude to my advisor Engineer Ronaldo J. Quailing, for his continuous support of my study and research, for his patience, motivation, enthusiasm and immense knowledge. He has given me guidance and advice on a personal and professional level that has been instrumental in my growth as an engineering student preparing to be a professional structural engineer.

References

| [1] | ACI Committee 544.4R (1988) (Reapproved 2002). Design considerations for steel fiber reinforced concrete. ACI Structural Journal, volume 85(5), 563-580.New York.. |

| [2] | Fatih.A, Tefaruk. H., Kamura. A. (2005). Effects of steel fiber addition on mechanical properties of concrete and RC beams. Construction and Building Materials Volume 21 (21), 654–661. |

| [3] | Darwish et al, (2008). Influence of fiber ratio in the size effect, Proceedings. International conference Concrete. Constructions sustainable option, Dundee.UK, PP 123-130.J. Padhye, V. Firoiu, D. Towsley, "A stochastic model of TCP Reno congestion avoidance and control", Univ. of Massachusetts, Tech. Rep. 99-02, 1999. |

| [4] | 0. Olariu, I., A. Ioani, N. Poeinar (1988). Steel Fiber Reinforced Ductile Joints. Ninth World Conference on Earthquake Engineering, Tokyo-Kyoto, Japan, Aug.1988, 657-662. |

| [5] | ASTM, C 78 -08 (2009). Standard Test Method for Flexural Strength of Concrete (Using Simple Beam with Third-Point Loading). ASTM International, PP. 41, West Conshohocken, USA. |

| [6] | ASTM, C 1609/C1609M (2009). Standard Test Method for Flexural Performance of Fiber-Reinforced Concrete (Using Beam with Third-Point Loading). ASTM International, PP. 837, West Conshohocken, USA.demic Publishing, Journal of Civil Engineering Research, vol.1, no.1, pp.1-8, 2011. |

| [7] | Barros, J.A.O., Figueiras, J. (1999). Flexural behavior of steel fiber reinforced concrete, testing and modeling. Journal of Materials in Civil Engineering, Volume 11(4), 331-39.Online Available: http://journal.sapub.org/ajb. |

| [8] | Ezeldin, A., Balagurur, P. (1992). Normal-high strength fiber reinforced concrete under Compression. Journal of Materials in Civil Engineering, Volume 4(4), 415-29. |

| [9] | F.B.A. Beshara, et al, (2009). Nominal Flexural Strength of High Strength Fiber Reinforced Concrete Beams. The 11th Arab Structural Engineering Conference, October 2009 KFUPM, Dhahran, Saudi Arabia. |

| [10] | Ibrahim I.S., Che Baka, M.B. Procedia (2011). Effects on mechanical properties of industrialized steel fibers addition to normal weight concrete. International Journal of Recent Trends in Engineering, Volume 1, (2616), 130-145. |

| [11] | Lakshmipathy, M., A. Santhakumar (1986). Experimental Verification of the Behavior of reinforced Fibrous Concrete Frames Subjected to Seismic Type 72 of Loading. Third International Symposium on Developments in Fiber Reinforced Cement and Concrete, Rilem, July (1986). |

| [12] | Nasir. B. (2009). Steel Fiber Reinforced Concrete Made with Fibers Extracted from Used Tyers. M.S. Thesis submitted to the Schools of Graduate Studies. Addis Ababa University. |

| [13] | Padmarajaiah, S.K., Ramaswamy, A. (2002). Finite Element Assessment of Flexural Strength of Fiber Reinforced High Strength Concrete Prestressed Beams. Journal of Cement and Concrete Composites, Volume 24, (2), 229-241. |

| [14] | Rocco, C., Guinea, G., Planas, J. & Elices, M.,( 2001). Review of the splitting-test standards from a fracture mechanics point of view. Cement and Concrete Research, Volume 31, 73-82. |

| [15] | Soranakom, C., Mobasher, B. (2009). Flexural Design of Fiber-Reinforced Concrete. ACI Materials Journal, Volume 106(5), 870-75. |

| [16] | Soranakom, C., Mobasher, B. (2007). Closed-form solutions for flexural response of fiber reinforced concrete beams. Journal for Engineering and Mechanics, Volume 133(8), 933-41. |

| [17] | Vandewalle, L. et al. (2002). Recommendations of Rilem TC162-TDF: Test and Design Methods for Steel Fiber Reinforced Concrete Bending test final recommendation. Materials and Structures, Volume 35(2), 579-82. |

| [18] | Tan, K.H., Paramasivam, P., Tan, K., (1995). Cracking characteristics of reinforced steel fiber concrete beams under short- and long - term loadings. Journal of the American Concrete Institute, Volume 65(3), 592-606. |

| [19] | Wiliamson. G.R (1978). Steel Fibers as Reinforcement in Reinforced Concrete Proceeding, US Army Science Conference, West Point, Volume.3, 363-377. |

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-Text HTML

Full-Text HTML