Ashebir Belete Werkineh , Bekele Arega Demissie

Department of Civil Engineering, Assosa University, Assosa, Ethiopia

Correspondence to: Ashebir Belete Werkineh , Department of Civil Engineering, Assosa University, Assosa, Ethiopia.

| Email: |  |

Copyright © 2020 The Author(s). Published by Scientific & Academic Publishing.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Abstract

Pavement distress is a common problem for an opening road network and this distress is caused due to overloading of vehicles, poor maintenance, rapid traffic growth and improper design and implementation. This research study focused in Assosa to Mendi road section. The main objective of this research work was to assess the performance of pavement structure due to subsurface course materials along a road section from Assosa to Mendi. In order to achieve the desired objectives, a systematic methodology was performed which include field survey to capture the road surface condition such as type of distress and level of severity and laboratory test was performed for distress and non-distress pavement condition. The pavement condition survey along the selected road shows that it was affected by different failure type such as alligator cracking, block cracking, depression, edge cracking, longitudinal and transverse cracking, potholes and rutting. Based on the pavement distress type and for non-distress pavement area, eight soil samples were collected using manual hand auger. Samples were air-dried before taken to laboratory test determination of subgrade, sub-base and base-course soil. The soil samples collected were analyzed based on the geotechnical analysis: wash gradation, Atterberg limit, Modified proctor test and California bearing ratio (CBR). For subgrade soil the liquid limit varies from 39.6% -64.2% and Plasticity index from 24.3% -35.9%. The soaked CBR values of subgrade soil materials are between 9% -13% compared with 5% minimum specified by ERA manual; therefore the CBR values of the subgrade soils are Excellent for pavement structures. The soils were classified by ASSHTO under the A-2-6 and A-2-7 category which showed that the soils was Excellent to Good as a sub-grade material while USCS classification showed that the soil falls into CH and CL group. Therefore, the failures frequently observed on the road surface are significantly influenced by Base-Course soil; the sub-base layers materials satisfies minimum requirements but base courses materials along Assosa-Mendi Road section did not satisfied the standard requirements set by ERA. According to the pavement condition survey the road section from Assosa to Mendi required maintenance and based on this, possible maintenance option had been recommended for pavement distress with respect to level of severity on the pavement condition of the study area in order to sustain the design life of the Pavement.

Keywords:

Pavement defects, Subgrade, Sub-base, Base-course

Cite this paper: Ashebir Belete Werkineh , Bekele Arega Demissie , Assessment on the Performance of Pavement Structure Due to Subsurface Course Materials: A Case Study from Assosa to Mendi, International Journal of Advanced and Multidisciplinary Engineering Science, Vol. 3 No. 1, 2020, pp. 8-15. doi: 10.5923/j.james.20200301.02.

1. Introduction

1.1. Background of the Study

Pavements form a greater part of our society’s infrastructure system whose proper functioning is essential for development. Similar to other types of infrastructure assets, pavements deteriorate over time. Therefore, there is the need to find ways to preserve these capital intensive assets to ensure they perform as expected (Offie, 2013).A pavement section may be generally defined as the structural material placed above a subgrade layer (Woods and Adcox, 2006). The characteristic of the soil bed over which the entire pavement system rests on represents subgrade soils (Mcghee, 2010).The increasing traffic intensity, high tire pressure, increasing axle loads etc… are causing early signs of distress to bituminous pavements throughout the world. The deterioration of the paved roads in tropical and subtropical countries differs from those in the more temperate regions of the world. This can be due to the harsh climatic conditions and sometimes due to the lack of good pavement materials and construction practices (AASHTO, 1993).The properties of soil may vary from place to place due to the variation in soil formation, drainage condition and climate. When the soils within the possible corridor for the road vary in strength significantly from place to place, it is clearly desirable to locate the pavement on the stronger soils, if this does not have other constraints. Thus, since selection process of route corridor influence the pavement structure and the construction costs, thorough investigation should be done on the characteristics of subgrade. Failures of roads are being observed before their design period and are greatly affecting the economic growth of the country. Such failures could be overcome by undertaking through investigation on the subgrade material and the materials overlaying the subgrade and incorporating it in the design (Awoke Sime, 2005).Some part of Ethiopia is covered by expansive soils of which along the main trunk roads were constructed. Currently, different construction activities are taking place in the road sector on this soil types. It had been observed that construction on expansive soils, inevitable that results to numerous problems. Causes of these problems are not given proper attention in Ethiopia. Most of the roads constructed in Ethiopia on this type of soils failed before their expected design life has reached (Tanzania, 1999).A road pavement is a structure of superimposed layers of selected and processed materials that are placed on the basement soil or subgrade. Flexible pavements constructed for heavy duty vehicles are composed of asphaltic layers (wearing, binder and base course) and sound sub base layer which laid over a well compacted and strong subgrade foundation. The main structural functions of a pavement are to support the wheel loads applied to the carriageway and ultimately distribute them to the underlying subgrade layer (Birhanu A, 2009).Large structures are usually constructed with materials that exhibit distresses after construction because of loading, environmental conditions, and aging. The large structures include pavement, chimneys of nuclear power plants, skyscrapers, pipelines, and others. The distresses are presented in the form of surface cracking in most situations (David et al., 2004). Damage appears slowly at first, and then gradually accelerates, accumulating to become visible as structural distress and tangible as ride quality reduced. If distress is observed and corrected in a timely manner, low cost strategies will restore the road to nearly its original condition. However, if early treatment is neglected or postponed, the accumulated damage will require a more costly repair treatment. Recognizing that damage accumulation and acceleration is a key to understanding the need for early, low-level, low-cost preventive maintenance treatments (Hoffman, 2009).Road Failure as the inability of a normal road to carry out its functional services is not providing a smooth running surface for operating vehicles. Most roads in Ethiopian today are characterized by failure of all kinds like surface deformation, cracks, disintegration, surface defects etc. and there is not just one reason for each type of failure. Factors affecting the pavement performance are climate, material properties, structure and traffic load. The movement of the sub grade is the major cause of road pavement failure which makes road network unsafe and not suitable to the road users (ERA, 2002).The main objective of this research work was to assess the performance of pavement structure due to subsurface course materials along a road section from Assosa to Mendi. In order to achieve the desired objectives, a systematic methodology was performed which include field survey to capture the road surface condition such as type of distress and level of severity and laboratory test was performed for distress and non-distress pavement condition. The pavement condition survey along the selected road shows that it was affected by different failure type such as alligator cracking, block cracking, depression, edge cracking, longitudinal and transverse cracking, potholes and rutting. Based on the pavement distress type and for non-distress pavement area, eight soil samples were collected using manual hand auger. Samples were air-dried before taken to laboratory test determination of subgrade, sub-base and base-course soil.The research study was focus on the Assessment of the Performance of Pavement Structure due to Subsurface Courses along Assosa-Mendi road section. The estimated road length was about 94kms.

2. Objectives

The general objective of this study is to assess the performance of pavement structure due to subsurface course materials along a road section from Assosa to Mendi. To accomplish the general objectives the following specific objectives were set:1. To identify the types and level of severity of pavement distress.2. To find out the properties of existing soil along the damaged and non-damaged section of the road from Assosa-Mendi.3. To identify the cause of pavement distress due to the existing properties of subsurface courses based on ERA standards.4. To identify the maintenance option for the pavement distress.

3. Methodology

3.1. Study Area

The study area is located in Benishangul Gumuz and oromia regional state.

3.2. Study Period

The study period set for this research has been from October 2018 to June 2020.

3.3. Study Procedure

The procedure utilized throughout the conduct of this research study are as follows: Continuous Reviewed related literatures on relevant areas of influence of sub surface courses materials on pavement performance includes articles, reference books, research papers, standards specifications like ERA, AASHTO and ASTM. Necessary data collection, organization, comparison and analysis will be obtained, and then subsequently compared the results with standard specifications.

3.4. Study Design

The research study was conducted by using both experimental and analytical method. Qualitative and quantitative data will be gathered in the study area. Qualitative study gives focuses on the findings where a quantitative study will used to describe the numerical values of the research findings, based on field investigation and laboratory results.

3.5. Population

The total number of populations that were considered in the study area is, the total pavement distress existing along a road section from Assosa to Mendi.

3.6. Sample Size and Sampling Procedures

The sample size were depend on the amount of distress exists in the study area. Based on the pavement failure existed in the study area a subsurface course sample is taken for laboratory investigation.

3.7. Study Variable

3.7.1. Independent Variables

Ø Grain size / Gradation Ø Atterberg limits Ø Compaction test Ø California bearing ratio (CBR) and

3.7.2. Dependent Variable

Ø Performance of pavement structure due to subsurface courses materials

3.8. Data Collection Instruments

Ø Meter tape, plastic bags, manual hand auger equipment, GPS and field test instrument Ø Laboratory equipment’sØ Digital camera: for documentationØ Ms word and Ms excel: for analysis of field and laboratory dataØ Pick-up vehicle: during sampling

3.9. Data Collection Process

In order to attain the purpose of this research proposal work ethical considerations will be concentrating on the context of quantitative and qualitative research. Data collection process included field visual inspection, Field measurements and laboratory tests will be conducted.Quantitative and qualitative data will be utilized based on the necessary input parameters for the analysis by comparing with ERA manuals. Data collection process included field visual inspection, Field investigation, sampling representative samples along study area, field test, Field measurements and Laboratory tests will be conducted.

3.10. Data Processing and Analysis

The field work and laboratory data will be processed and analysis using Microsoft word and excel.

3.10.1. Field Work

Before starting of the detail pavement evaluation, the entire road length will be visually assessed and it is attempted to identify the types of failures occurred on the road surface. After finishing of the pavement condition survey, soil samples will be collected for damaged and non-damaged section of the road. A manual survey will be performed following ASTM D 6433. The type and severity of sample distress will be assessed by visual inspection of the pavement sample. Typically, this procedure requires a team of at least two engineers (US Army, 2001).

3.10.2. Laboratory Tests

I) Atterberg limitII) Grain Size Distributions (Gradation)III) Soil compactionIV) Subgrade soil classificationV) California Bearing Ratio (CBR)

4. Result and Discussion

4.1. General

Asphalt Concrete (AC) Surfaced Pavement—individually inspect each sample unit chosen. Conduct the distress inspection by walking over the sidewalk/shoulder of the sample unit being surveyed, measuring each severity level of distress type present, and recording the data. Each distress must correspond in type and severity. The method of measurement is included with each distress description.The pavement condition surveys investigation along the study area shows that different types of distress observed along the Road section such as Cracking, surface deformation, and Disintegration and Surface defects along route section during pavement condition survey on the route was identified. The road inventory from the visual inspection would become reliable, proper identification was made along the road sections and identify the common distress types compares with non-distress test pits along study area.

4.2. Field Condition Survey Result and Discussion

4.2.1. Types and Level of Severity of Pavement Distress

For entire section inspections, measures each distress type and severity, and records the data on the Asphalt Pavement Inspection Sheet. The letter L (low), M (medium), and H (high) severity level. Distresses and severity level definitions are listed in Chapter two. | Figure 1. Potholes |

| Figure 2. Longitudinal cracking |

| Figure 3. Edge cracking |

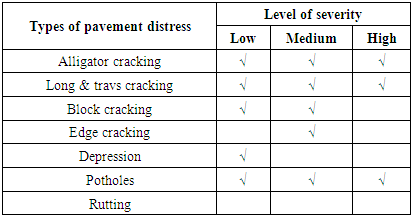

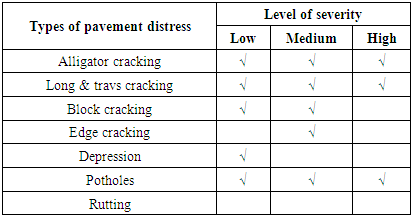

There are more than 10 pavement distresses in the study area. The following table shows the types of pavement exists along the study area.Table 4.1. Types of pavement exist on the study area

|

| |

|

In Table 4.1 there were seven (7) major types of Road failures observed along the study area of Assosa-Mendi Road section. Relative to this, the researcher had organized the possible distress types based on the existing Road condition of the pavement surface together with the extent of damage.

4.3. Laboratory Test Result and Discussion

4.3.1. Grain Size Analysis

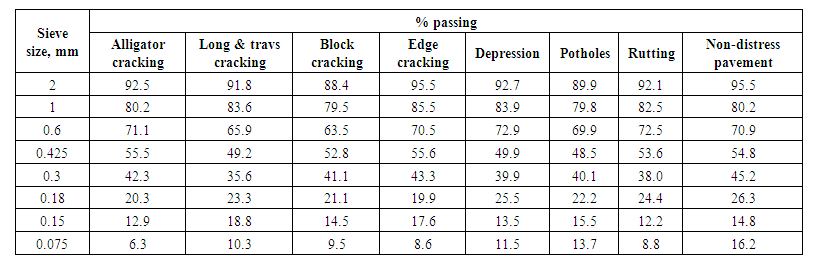

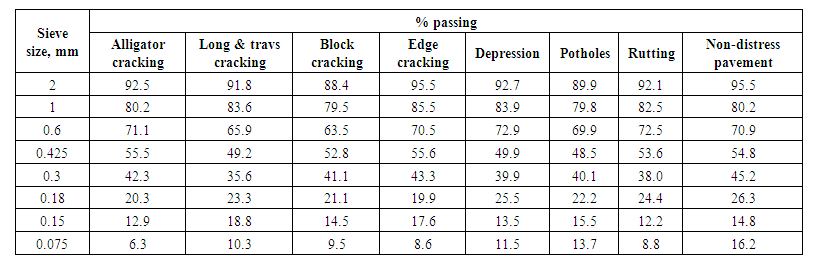

Gradation, or the distribution of particle size within a soil, is an essential descriptive feature of soils. Soil texture such as gravel, sand, silty and clay and engineering classifications are based large on gradation. | Table 4.2. Grain size distribution of Subgrade course with results of failures sections and non- failures section |

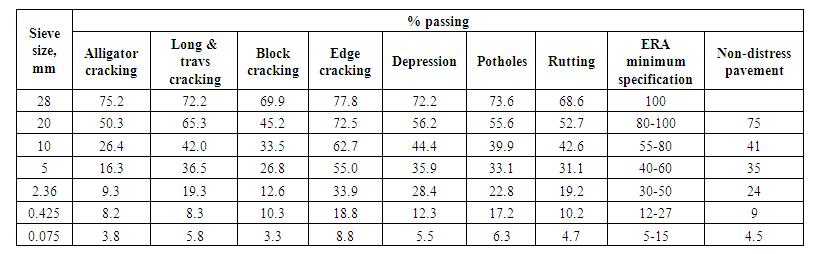

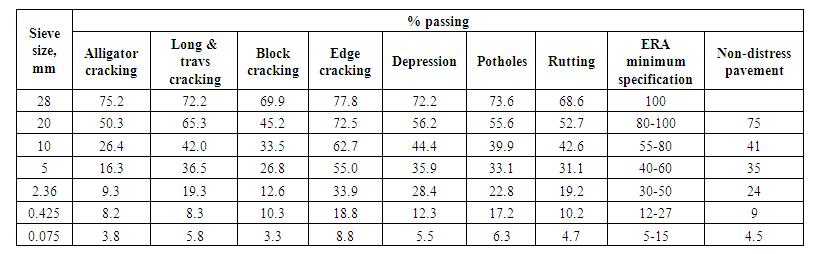

| Table 4.3. Comparison ERA pavement Design manual specification of Sub-Base course with results of failures sections and non- failures section |

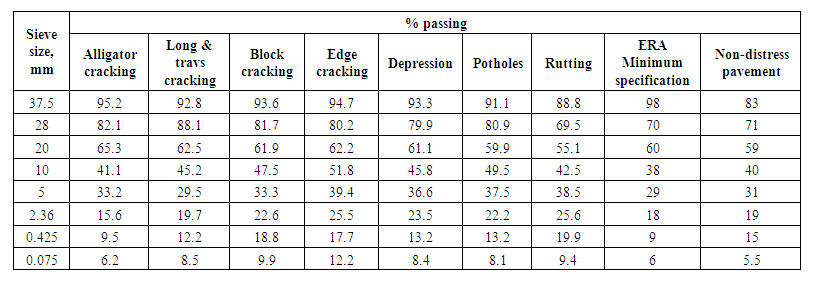

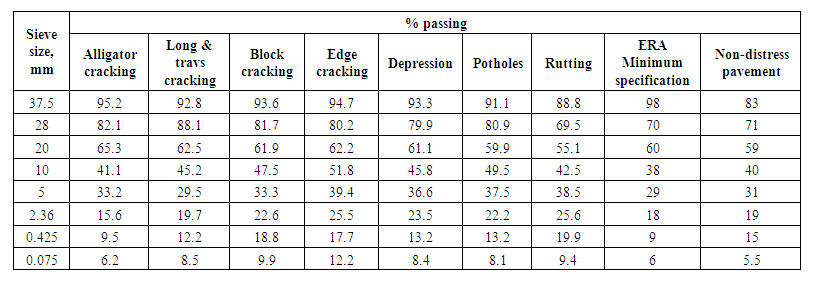

| Table 4.4. Comparison ERA pavement Design manual specification of Base course with results of failures sections and non- failures section |

Grain Size Analysis: Ø The sub grade materials at all failures samples and non-distress are classified as Clay gravel and sand.

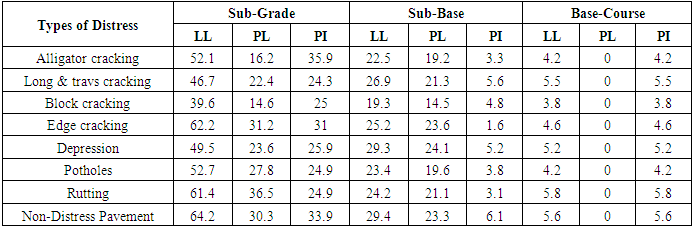

4.3.2. Atterberg’s Limit Test Result and Discussion

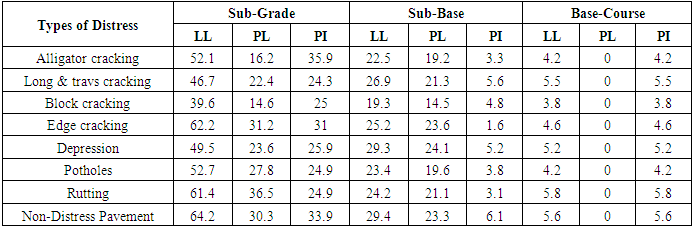

The Plasticity of base course, sub-base and sub-grade materials is tabulated below. Table 4.5. Atterberg’s limit test

|

| |

|

Atterberg’s limits analysis Ø In sub-grade soil (i.e. LL < 80% and PI <55%) it satisfies the specification; grouped into A-2-6 and A-2-7 in AASHTO soil classification system and USCS as CH-CL.Ø In sub-base course (i.e. LL < 35% and PI <25%) it satisfies the specification.Ø In base course (i.e. LL < 25% and PI <6%) it satisfies the specification.

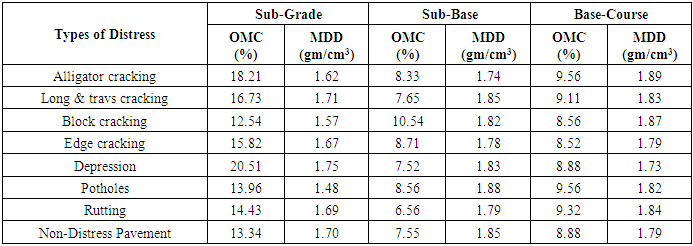

4.3.3. Compaction Test

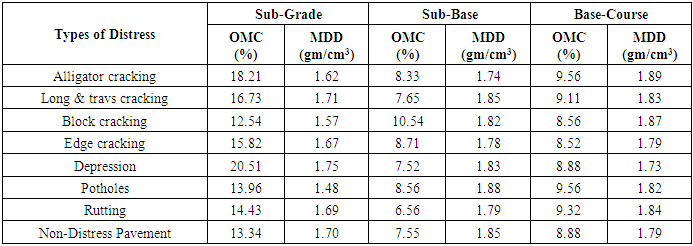

A soil was mixed with water to form samples at various moisture contents ranging from the dry state to wet state. Soil compaction tests were performed using disturbed soil sample. These samples are compacted in five layers in a mould by a hammer in accordance with specified nominal compaction energy. Dry density is determined based on the moisture content and the unit weight of compacted soil. The water content at which this dry density occurs is termed as the optimum moisture content (OMC). The test is done in the laboratory according to AASHTO T 180-95 (Modified proctor test). Table 4.6. Compaction test

|

| |

|

Compaction tests analysis: Ø The Subgrade soil laboratory test maximum dry densities are between 1.48gm/cm3 – 1.75gm/m3 while optimum moisture content ranges from 12.54% -20.51%.Ø The Sub-Base course laboratory test maximum dry densities are between 1.74gm/cm3 – 1.88gm/m3 while optimum moisture content ranges from 7.52% -10.54%. Ø The Base course laboratory test maximum dry densities are between 1.73 gm/cm3 – 1.89gm/m3 while optimum moisture content ranges from 8.56% -9.56%.

4.3.4. California Bearing Ratio (CBR) Test

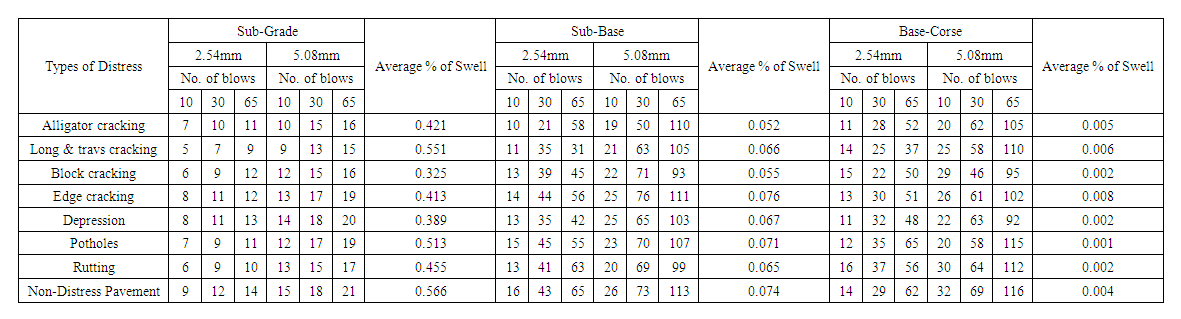

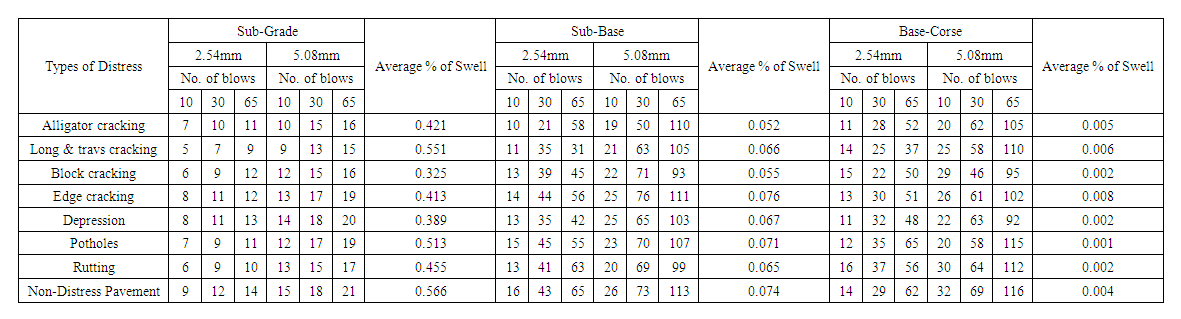

| Table 4.7. California Bearing Ratio (CBR) Test |

California Bearing Ratio (CBR) Test analysis From the recommendation given from ERA Pavement Design Manual volume I, for natural coarsely graded granular material, including processed and modified gravels (GB3), the CBR after soaking should be greater than 80%. The laboratory test results given in Table 4.7, the CBR of the base material use ranges from 37%-65%. Hence, from the point of CBR the material is not suitable to use as base course when compacted at optimum moisture content and compacted to its maximum dry density. When we see the case of sub-base course, the recommendation given in ERA manual for natural gravel (GS), the CBR after soaking should be greater than 30. And the result obtained from the laboratory is all greater than the specified values ranging from 31%-63%. From Table 4.7, it is observed that the soaked CBR values for sub-grade course materials varied between 9% and 13% in all the boreholes, which is grater than the specified value (i.e. Soaked CBR >5%).

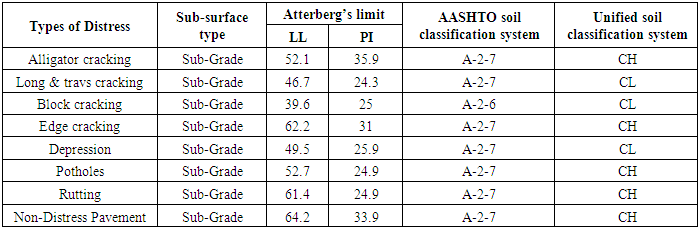

4.3.5. Subgrade Soil Classification

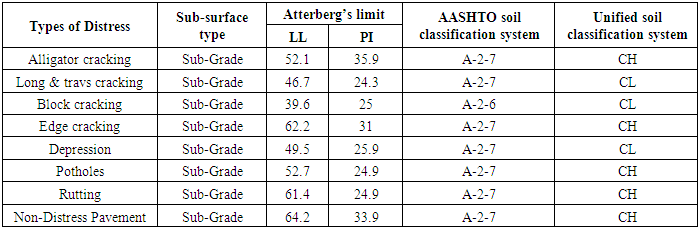

AASHTO soil classification system usually used for highway construction. The method of classification used in this study was the AASHTO soil classification system. The particle size analysis and the plasticity characteristics are required to classify a soil. The table below shows the soil classification according to AASHTO standard and unified soil classification system.Table 4.8. Result of subgrade, sub-base and base course soil classification

|

| |

|

5. Conclusions and Recommendations

5.1. Conclusions

Based on the pavement condition survey and laboratory tests result the following conclusions are drawn: Ø The pavement condition survey along the selected road shows that there were different failure type such as alligator cracking, block cracking, depression, edge cracking, longitudinal and transverse cracking, potholes and rutting.Ø The pavement condition survey along the study area affects by different failures types such as cracks, disintegrating, surface defect and problems related to road failures was identified during field investigation; this show indicates that lack of routine and periodic maintenance along on a road section.Ø The results of the subgrade soils investigation along Assosa-Mendi road showed that the road pavement structures are underlined by A-2-6 and A-2-7 category of soils which shows that the soils Excellent to poor subgrade materials according to AASHTO. USCS shows that the soil categorize in to Clay of high plasticity (CH) and clay of low to high plasticity (CL). The liquid limit varies from 39.6% - 64.2% and Plasticity index from 24.3% - 35.9%. The soaked CBR values of subgrade soil materials are between 9% - 13% compared with 5% minimum specified, therefore, the failures frequently observed on the road surface are not significantly influenced by subgrade soil rather significantly influenced by the base-course material due to CBR value.

5.2. Recommendations

Ø Periodic inspection is necessary to provide current and useful evaluation data. Ø Periodic pavement maintenance practices should be employed to reduce aging of pavement failure. Ø Effective maintenance can extend a pavement's life. Crack sealing and surface treatments can reduce in aging of asphalt pavement.Ø Scarification and reconstruction of the distress road section specially affected by raveling .The sections with various sizes of potholes should be patched with good quality asphalt and distress sections of pavement with poor material due to drainage problems should be removed and replaced to required depth. Adequate longitudinal drainage, cross drainages and other drainage facilities should be provided in order to control the drainage problem. Seal coats shall be applied to prevent infiltration of water through cracked surfaces. Ø The influence of other factors such as poor drainage courses, level of groundwater table, variation of geologic materials along the road route and poor construction materials should be thoroughly addressed before beginning rehabilitation the road section in the future. Ø Detail investigation should be carried out on project areas; also the properties of material and method of construction should be according to the design specification of project in order to serve the design period of a project in order to avoid the failure. Ø For future research, it is recommended that detailed in-depth investigation should be carried out on related project; compliance with quality of materials and construction methods in accordance with ERA Standard Specifications in order to avoid future failure.

ACKNOWLEDGEMENTS

We would like to give our deepest gratitude to Assosa university for financial support in order to complete this research work and we would like also thanks engineering college research coordinator Mr. Lemesa D. (MSc in Communication stream) for his advice, patience and guidance throughout the process of completing this research work. We would like to extend our sincere gratitude to the people that helped us in one or the other way which made this research study possible. Acknowledgements are due to our parents for their love and encouragement during my study. Last but not least we would like to extend our deepest thanks to all our friends for their encouragement.

References

| [1] | AASHTO, (1993). Guide for design of pavement structures, American Association of State Highway and Transportation Officials. |

| [2] | Ann M., Johnson, P.E. (2000). Best Practices Handbook on Asphalt Pavement Maintenance, Centre for Transportation Studies, University of Minnesota. |

| [3] | ASTM D 6433-07, (2007) Standard Practice for Roads and Parking Lots Pavement Condition Index Surveys, American Society for Testing and Materials. |

| [4] | Awoke S. Further Investigation of Road Failures Constructed on Expansive Soils of Central Ethiopia Addis Ababa-Jimma Road as a Case Study. A Master's Thesis, Addis Ababa University. 2005. |

| [5] | Berhanu A. Analysis and Modeling of Rutting for Long Life Asphalt Concrete pavement. A PhD. Thesis, Technische Universität Darmstadt, German. 2009. |

| [6] | Bowles, J.E. (1984) Engineering Properties of Soils and Their Measurement, McGraw-Hill, Singapore, second edition. |

| [7] | David, T., Jason, M.Q. (2004). A Study of Manual vs. Automated Pavement Condition Surveys. Auburn Alabama. |

| [8] | Deepika, C.V. (2012). Evaluation of properties of soil sub grade using dynamic cone penetration index-a case study. International journal of engineering research and development. 7. |

| [9] | ERA. (2002) Ethiopian Roads Authority Standard Manuals. Pavement Design Manual: Flexible Pavements and Gravel Roads, Volume I. |

| [10] | Ethiopian Roads Authority Standard Manuals. Pavement Rehabilitation and Asphalt Overlay Manual. 2002. |

| [11] | Gainesville. F (2000). Soils and foundation handbook; p5-12. |

| [12] | Gary. M, Hao. Z., Qinghin. C. (2009). Stochastic Modeling for Pavement Warranty cost Estimation, Journal of construction engineering and management. 135 (2). |

| [13] | Gupta, K.A., Adlinge, S.S. (1998). Pavement Deterioration and its Causes. Journal of Mechanical & Civil Engineering. Shivaji University, India. |

| [14] | Hoffman, C. (2009). Pavement maintenance, Pavement Interactive. |

| [15] | Mcghee KH (2010). Development and Implementation of Pavement Condition Indices. J. Sci. Res., 1(2): 10-18. |

| [16] | Murthy, V.N. (1990). Principles and Practices of Soil Mechanics and Foundation Engineering. New Delhi. |

| [17] | Offei, O.A. (2013). Pavement condition survey-overview of current practices. Delaware department of transportation. University of Delaware. |

| [18] | Tanzania Pavement and Material Design Manual. 1999. |

| [19] | U.S. Army Corps of Engineers. (2001). Paver Asphalt Surfaced Airfields Pavement Condition Index (PCI), UNIFIED FACILITIES CRITERIA (UFC). |

| [20] | www.goggle earth.com |

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML