-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Instrumentation Science

p-ISSN: 2324-9994 e-ISSN: 2324-9986

2013; 2(2): 25-33

doi:10.5923/j.instrument.20130202.02

Aircraft Flight Control Simulation Using Parallel Cascade Control

K. Hema

Electronics &Instrumentation, GNIOT, Greater Noida, 201310, India

Correspondence to: K. Hema, Electronics &Instrumentation, GNIOT, Greater Noida, 201310, India.

| Email: |  |

Copyright © 2012 Scientific & Academic Publishing. All Rights Reserved.

Aircraft flight simulation is a billion dollar industry worldwide that requires vast engineering resources. A method for modeling flight control systems using parallel cascade system identification is proposed as an addition to the flight simulator engineer’s toolbox. This method is highly efficient in terms of the data collection required for the modeling process since it is a black box method. This means that only the input and the output to the flight control system are required and details of the inner workings of the system can be largely ignored resulting in significantly fewer real data signals that need to be recorded. The paper views on two objectives. One the specific parallel cascade models can be identified that reproduce the behavior of a particular part of an aircraft flight control system. i.e. the pilot input control meet the objective test requirements of a commercial aircraft flight simulator. The second is to produce such a model which also meets the basic requirements for implementation in a working flight simulator.

Keywords: Aircraft Flight Simulation, Parallel Cascade Control, Black Box Method

Cite this paper: K. Hema, Aircraft Flight Control Simulation Using Parallel Cascade Control, International Journal of Instrumentation Science, Vol. 2 No. 2, 2013, pp. 25-33. doi: 10.5923/j.instrument.20130202.02.

Article Outline

1. Introduction

- Aircraft Flight control systems consist of flight control surfaces, cockpit controls, connecting linkages and necessary operating mechanisms to control an aircraft’s direction in flight. Aircraft engine controls are also considered as flight controls as they change speed. They can be divided in to three main groups:-Primary Flight Control-Secondary Flight Control-Auxiliary Flight Control.An aircraft flight control system is highly complex, dynamic, and nonlinear and contains a significant amount of hysteresis. Parallel cascade identification is well suited to cope with reduced number of real data signals. A new faster method of producing flight control models is proposed in a black box manner, using only input and output data from the flight control system and ignoring the system's physical structure almost entirely.The aileron flight control system poses significant challenges to black box identification methods since it has nonlinearities of high order is dynamic and contains significant hysteresis. The parallel cascade method of system identification used is however able to handle these challenges. A simulation using a traditional flight control mode1 is used as the system whose behavior is to be reproduced by the parallel cascade model. The criteria used by the U.S. Federal Aviation Authority are to certify commercial Full Flight Simulators.The paper focuses on the main unknown remains to what extent the simulator environment reflects in the-air conditions and to what extent this is required to achieve a certain training or test objective. First, the simulator is only as good as the data it contains i.e. the quality of the model representing the aircraft and the flight environment to be simulated. Secondly, inherent limitations of the system used to simulate can be the cause of mismatches. The motion system of a simulator does posses one of the most obvious constraints with its very limited amount of travel. Fortunately, the pilot can be made to perceive the motion desired if the main cues are correctly simulated, allowing for some deviation in the others.

2. Aircraft and Flight Simulation Overview

- An aircraft simulation that allows pilots to start training to fly the new aircraft without ever having set foot in it. This kind of device is known as a Full Flight Simulator (FFS). FFS is meant to simulate the environment of the aircraft cockpit and behavior of the aircraft with accuracy requires that the visual, aura and tactile inputs which the pilot receives, whether from the aircraft systems or the environment or both be simulated realistically. Additionally it must run in real-time.A main concern is the speed at which the model can be run; since the simulator must run in real-time and at a high enough iteration rate that the effects seem real. In most cases a tradeoff between accuracy and complexity must be negotiated. The primary simulator components make up the pilot-in-the-loop of the FFS where the pilot provides the inputs to the simulator and receives a feedback response through his or her hands, eyes, ears and "seat-of-the-pants". These systems are: the flight controls. e.g. the pilot control stick wheel and rudder pedals and flight control models, through which the pilot provides inputs to the simulator: the aerodynamic model which computes the effects of those inputs on the aircraft; the visual system which provides the visual feedback on the airplane behaviour and the environmental conditions: the motion system which gives feedback on the behaviour of the airplane with motion and acceleration cues; and the flight control (again) which provides feedback to the pilot's hand. There are also many secondary and auxiliary systems that require simulation including secondary flight control systems such as the flap system and the throttle controls.

2.1. Aircraft Flight Control Simulation using Parallel Cascade System

- Microsoft's Flight Simulator gives an onscreen representation of an aircraft instrument panel and a view of the scene in front of the aircraft, while a joystick provides the "pilot" with control over the simulated aircraft. Full Flight Simulator replicates the appearance of the aircraft cockpit, the functionality of almost al1 the aircraft's systems. its aerodynamic behavior, the tactile (feel) cues from the light controls, the acceleration (motion) cues and the visual cues from the scene in front of the aircraft. These FFS are multi-million dollar, custom made devices that rely on an array of powerful computers and electrical, mechanical, pneumatic and hydraulic systems to produce the simulated environment.Basic requirements to be considered as a suitable software model are as follows:i. The behavior of the real flight control system can be reproduced by the simulation system to meet the predatory requirements;ii. It can be run at a high enough iteration rate to be used in a Full Flight Simulator;iii. The required outputs for implementation with the standard hydraulic servo-electric actuator controllers are produced: andiv. It must accept the appropriate inputs from other systems and provide the appropriate outputs.

2.2. Identification of Aircraft System Models

- Two of the most common methods include(1) Identification of transfer functions from test input and output data(2) Physically based models.

2.2.1. Identification of Transfer Functions

- The identification of transfer functions is “The inverse problems of the second type". It requires the collection of test data from the aircraft and then the determination of the frequency response of the system. This method can be described as a "black box" method in that only input and output data are used to find the model. The flight test can be performed either by oscillating the elevator about its trim position at various frequencies or by applying step or pulse motions to the elevator. In both cases the elevator angle. The response of the steady-state angle of attack (the angle of the aircraft from horizontal relative to its direction of motion) and the pitch-rate are measured.The first method produces the frequency response of the longitudinal motion of the aircraft directly. The second method requires that the transfer function be computed in some way. For instance, from Fourier transform of the output and input signals. Once these frequency response curves have been obtained, an equation of the following formG (jω) = (a +b jω) / (A +Bjω –ω2)Where: G (jω) is the transfer function of pitch control input to pitch-rate.J is the imaginary number *- 1.ω is the angular frequency.a, b, A, B are real parameters formed from inertia constants and stability derivatives.This method works if the system is nearly linear and if a second order differential equation is well suited to the system being identified. The transfer function describes the input of the control stick to the longitudinal motion of the aircraft. However, the control stick input is only the primary input into this aspect of the aircraft behaviour.

2.2.2. Physical Models

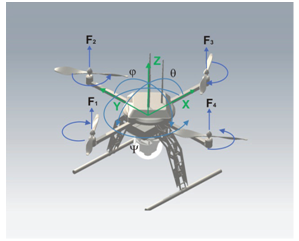

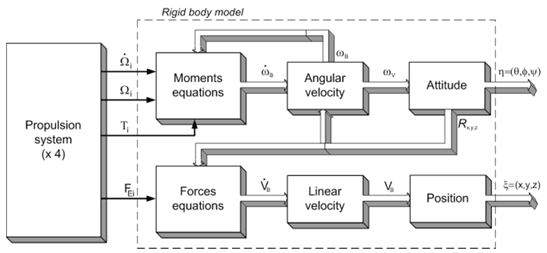

| Figure 1. Quad rotor Model |

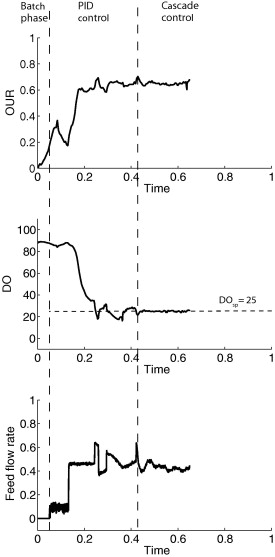

3. Flight Simulation Issues

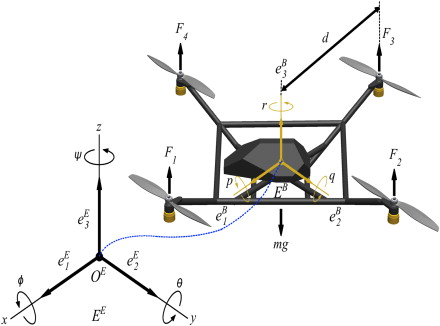

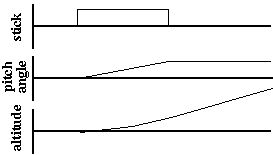

- The most common error encountered in flight simulation involves the issue of the level of modeling chosen for the simulation. Consider the issue of stability. When you pull back on the stick from level flight, and hold the stick slightly of center, the nose begins to rise, and the plane begins immediately to climb. As the nose rises the airspeed begins to decay very slowly and almost imperceptibly, and as this occurs, the rate of climb also falls off. Due to the inherent longitudinal stability, this reduced airspeed has the effect of changing the trim to more nose-down, so that with the stick held steady, the rate at which the nose rises begins to decay. If held long enough, the pitch attitude will eventually equilibrate at some nose-up angle, at a reduced airspeed, and at a rate of climb much smaller than that experienced when the climb was initiated, as suggested in Fig 2.

| Figure 2. Aircraft Orientation using Euler Angles |

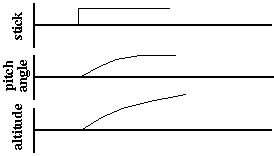

| Graph 1. Stability Control |

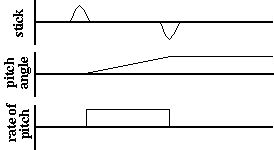

| Graph 2. Elevator Control |

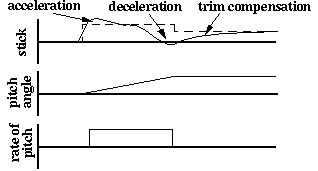

| Graph 3. Pitch Control |

| Graph 4. Actual Control Input |

| Figure 3. Second Order Differential System Block diagram |

| Figure 4. Cascade Control |

| Figure 5. Aircraft Cascade Loop Control |

4. Formulation of Differential Equations

- The formulation of differential equations for mechanical systems begins with the concepts of mass, inertia and particle dynamics (Newton’s Laws of Motion). Rotational dynamics and conservation of momentum are also used as appropriate. Ryswick and Taft describe a four step procedure for the formulation of the differential equations that describe the dynamic system:1. System definition:-procedure using free body diagrams.2. Isolation of each rigid body: - external forces and reactions 3. Formulation of differential equations: - apply the equilibrium equations of d'Alembert to each rigid body:∑Fext + Fi = O (in any direction)Where:Fe, are the external forces applied to the system andF is inertial force.4. Equation reduction: - using matrix manipulation techniques.These free bodies can be joined together to form layer complex systems and additionally nonlinear and or time-varying structures can be included. Nonlinear effects are very difficult to mode1 in this way as the determination of the system equations becomes cumbersome. However this method can deal with nonlinearities in an ad hoc manner.Damping force = Velocity*Damping constantSpring force = Position*Spring constantAcceleration = (Input force – Damping force –Spring force)* 1 /Mm:Velocity += Acceleration*Time constant'A first order exact differentiator is used in order to estimate the virtual control inputs, which simplifies the control law design. In addition, the wind parameter resulting from the aerodynamic forces is also estimated in order to ensure robustness against these unmatched perturbations. The performance and effectiveness of the proposed controller are tested in a simulation study taking into account external disturbances. The design of a controller based on the block control technique combined with the super twisting control algorithm for trajectory tracking of a quad rotor helicopter.

5. Cascade and Parallel Cascade Models

- Many nonlinear systems can be modelled as a sum of cascades each of which approximates a portion of the system. Each cascade comprises alternating dynamic (i.e. finite memory) linear (L) and static (i.e. memory less) nonlinear (N) elements. They can be abbreviated LNL, NLN, and LN. etc. depending on the type and order of the elements.Other forms of cascades are possible. Simpler versions include LN and NL cascades, which are known as Wiener and Hammerstein models respectively. While Hammerstein models can be used to approximate only a narrow class of nonlinear systems. Wiener models can be used to approximate a very wide class of nonlinear systems. Kornberg IKOR82, KOR90. KOU91 1 showed that any system having a Wiener functional expansion could be approximated to an arbitrary degree of accuracy by a sum of LN (Wiener model) or LNL cascades developed one at a time. He also showed that a finite sum of LN cascades could exactly represent any discrete-time finite-memory, finite-order.MSE, the error in a designed experiment, σ 2, is the natural variation in the response when one of the experimental combinations is replicated. One important challenge in a designed experiment is obtaining an unbiased estimate of σ 2. Too often, experimenters do not realize the impact that data collection and analysis assumptions have on the estimate of σ 2. If the estimate is biased, tests of the effects in the analysis will be adversely affected. It is important to carefully inspect the data collection and model reduction process for signs of bias in MSE before the results are used to reach any conclusions. To avoid a biased MSE term, statistically valid model- reduction techniques should be used and the experiment should be properly randomized. The individual cascades are identified in two stages. First the impulse response of the dynamic linear element is defined using a slice of a first- or higher-order cross correlation of the input with the residue. The output from the dynamic linear element is then the input to the static nonlinear stage for which a polynomial is best-fit to minimise the MSE of the residue. These impulse responses and polynomials form the individual LN cascade models and are used to determine the residue for the next cascade to be identified. This process is continued until the MSE of the residue is sufficiently small or no further meaningful reduction is obtained by further cascades. Cascade paths that are identified can be evaluated as to their effectiveness in terms of MSE reduction and used or discarded appropriately.

5.1. Obtaining the Cascade Output

- Once the polynomial coefficients have been found, the cascade output is found. The individual cascade outputs are then summed to get the final output. In order to avoid numerical overflow and underflow problems that can result with such high order polynomial elements it is important to normalise the input and output data. In order to use the parallel cascade method with a reasonably small memory length in the dynamic linear element while running the model at a high sampling (iteration) rate. The data is simply sampled at the high rate but only every n-th sample is used to calculate the linear element's output at any particular instant, where n is the ratio of the higher sampling rate to the parallel cascade model rate.

5.2. Extracting the Output Derivatives from the Parallel Cascade Mode1

| Graph 5. Time Vs Control Simulation |

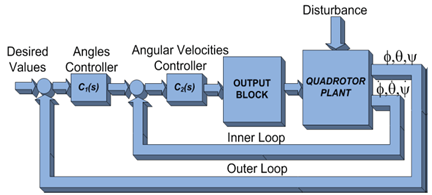

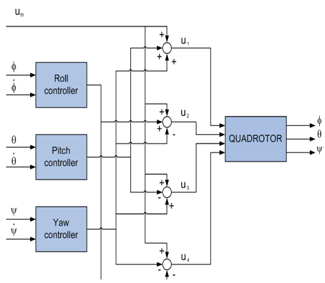

6. Cascade Control Scheme

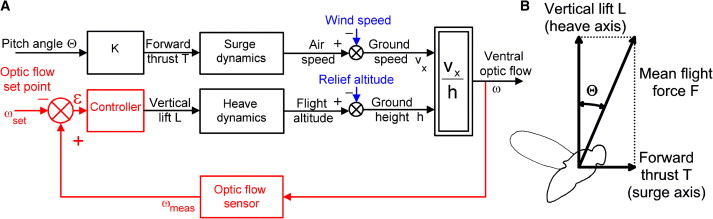

- In control applications, the rejection of external disturbances and performance improvement are major concern. In order to fulfill such requirements, the implementation of a cascade control system can be considered .Basically, in a cascade control scheme the plant has one input and two or more outputs. This requires an additional sensor to be employed so that the fast dynamics can be measured. The primary controller and the primary dynamics are components of the outer loop. The inner loop is also a part of the outer loop, since the primary controller calculates the set point for the secondary controller loop. Furthermore, the inner loop represents the fast dynamics, whereas the outer should be significantly slower (with respect to the inner loop). This assumption allows interaction that can occur between the loops to be restrained, improving stability. Therefore, a higher gain in the inner loop can be adopted. An additional advantage is that the plant nonlinearities are handled by the controller in the inner loop, and exert no meaningful influence on the outer loop .

| Figure 6. Quadrotor Control |

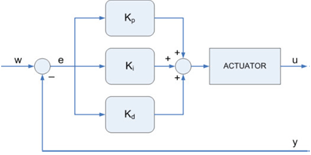

6.1. PID Controller Types

- PID Controller-type AIn control theory the ideal PID controller in a parallel structure is represented in the continuous time domain as follows:u(t) = Kp e(t) + Ki 0ʃt e(τ) dτ+Kd de(t)/dtWhere:Kp ‐ proportional gain,Ki ‐ integral gain,Kd ‐ derivative gain.

| Figure 7. Type A PID Controller |

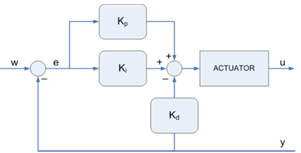

| Figure 8. Type B PID Controller |

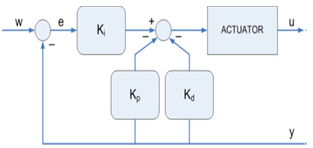

| Figure 9. Type C PID Controller |

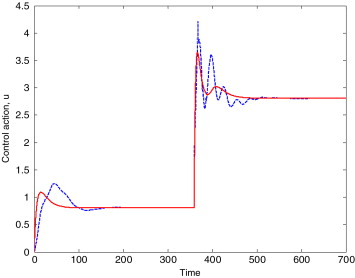

6.2. Time History of Pitch angle and Angular Velocities

| Graph 6. Pitch Angle Vs Angular Velocity |

7. Significance

- This paper showed that parallel cascade models could be used to reproduce the behaviour of an aircraft flight control system. One particular aspect of the control behaviour was looked at namely, the response of the control to the pilot input. Parallel cascade system identification has been used to model the physical behaviour of any pan of a flight control system and the first time that the method has been shown to work when identifying the behaviour of systems with significant hysteresis.Simulation Graphs:

| Graph 7. Time Vs Control Action |

| Graph 8. Frequency Characteristics |

8. Conclusions

- In this paper the cascade control structure is proposed as a solution to control tasks formulated as angular stabilization. The angular velocities of the rotating platform are additional measurements that can be used in the inner loop. In this case, there is no need to assemble any extra sensors, and the AHRS (Altitude and Heading Reference Signal) therefore provides not only angles but also other raw data, such as accelerations, angular velocities and gravitational field strength. The outer loop is based on the Euler angles and the measurements are calculated from the combination of the accelerometers, gyroscopes and magnetometers. The conducted simulations and analysis proved the ability of the designed cascade structure in controlling the orientation platform angles and providing the promising fundamentals for practical experiments with a physical plant. The cascade PID control system can be introduced together with the requirements and appropriate constraints for the system to validate such control algorithm applications in real conditions.

9. Future Work

- The complete Flight control system is not simulated and requirement is limited to accepting inputs only in terms of direct pilot inputs and other inputs that can be considered to be additive to the pilot input. e.g. aerodynamic turbulence modeled as input noise. The outputs of the model are limited to the primary output of the portion of the target flight control system modeled: the control position, velocity and acceleration. Higher order differential equations modeling are difficult.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML