Slivinsky E. V., Radin S. Y., Gridchina I. N.

Yelets state university of Bunin I. A.

Correspondence to: Slivinsky E. V., Yelets state university of Bunin I. A..

| Email: |  |

Copyright © 2014 Scientific & Academic Publishing. All Rights Reserved.

Abstract

In the present article the materials concerning development of perspective construction of a frame for autotractor trailers and semi-trailers are provided. The key geometrical parameters such are calculated, construction which is recognized by the invention, a row of perspective bearing systems of the increased reliability also protected by patents for inventions is provided. Development is recommended to research and development and industrial structures in the field of automobile and agricultural mechanical engineering for the purpose of its further study and possible implementation in practice.

Keywords:

Chassis, Frame, Cross-piece, Longeron, Bracket, Reference leaf, Oval disk, Welded seam, Shoulder

Cite this paper: Slivinsky E. V., Radin S. Y., Gridchina I. N., Reliability Augmentation of Frames Autotractor Trailers and Semi-Trailers, International Journal of Traffic and Transportation Engineering, Vol. 3 No. 2, 2014, pp. 52-64. doi: 10.5923/j.ijtte.20140302.03.

1. Introduction

It is known [1-3] that the most responsible element basis of autotractor trailers and semi-trailers are their bearing systems which usually represent the longerons connected among themselves by means of electrical welding to cross-pieces. In front part of frames of trailers the place for mounting of the turntable of the podkatny cart, and in back installation of a spring suspension bracket with slave wheels by means of brackets of springs rigidly the associated to longerons is provided. In front part of frames of semi-trailers called the shoulder on the lower shelves of longerons and cross-pieces welded a reference leaf with shkvorny, intended for interaction with the reference coupling device of the car of the tractor. The fodder part of semi-trailers also as well as at trailers is supplied with brackets of springs for fixing of a suspension bracket of slave wheels.It is known also that in the course of movement of autotractor trains of their frame receive the vertical, angular and cross relocation arising from roughnesses of roads and as they have high torsion stiffness, in their welded nodes there are the considerable on value of tension of the constrained torsion, promoting appearance of cracks and other failures. In too time insufficient longevity nodes of frames the fixings of brackets of springs located in a zone which, possessing high rigidness on a bend and the constrained torsion considerably possess also reduce durability of longerons and the cross-pieces which are in this zone. Therefore in practice for elimination of the specified failures and maintenance of frames, in too time having low maintainability of a motor transport service incur the considerable material and labor inputs. It is necessary to mark that in the course of long-term experience of design and maintenance of tractors, trailers and semi-trailers of their frame took certain arrangement forms but, despite it, they don't meet already today the escalating requirements of reliability and lowering of their metal consumption. The significant contribution to development of methods of design and constructioning of bearing systems of trackless vehicles entered Bocharov N. F. Gelfgat D.B., Humpbacks B.N., Vlasov V. Z. Legislative Assembly M. I., Lelchuk L.M. Kobrin. M.M., Dmitrichenko S. S., Proskuryakov V. B., Koprov V.P., M.B.'s School students, etc. [1-23].Now by development new and upgrades of existing constructions of transport machines including tractor trailers the following technique of study of force loading and oscillations of their main nodes and details is widely used:1. The analytical researches consisting in representation of the researched machine in the form of many multimass mechanical system, considering elastic communications, existence of gaps, losses on overcoming of frictional forces, operation modes, etc. Thus the system of the differential equations considering levels of freedom of the researched machine or its node is formed. Such approach allows to vary a large number of parameters of agricultural machines defining operating conditions in the given boundaries and to reveal the unfavorable operation modes influencing their dynamic durability [1, 5, 7, 9, 13].2. The pilot studies consisting in carrying out field or road tensometric tests with registration of oscillatory and force parameters, separate nodes defining a tension and elements of constructions of the researched machine. In practice stand tests which allow to set endurance of elements of machines and, therefore, their resource in the conditions of confidants to operational [1, 9] are also widely applied.For the majority of researchers the account micro and macro a profile of roads, modes of movement of vehicles, their tractive and weight characteristics, and also a type of a transported load is characteristic. However in the dynamic diagrams provided by them influence of gaps in their conjugate main nodes, such as, for example, connection of a pole of the trailer with the tractor and its podkatny cart, connection of a body with a frame, etc. isn't studied. In too time, existing methods of calculation of frames, for example, explained in operation [15-17] are very labor-consuming and allow to set their tension with use of a matrix of influence which is generalization of the line of influence, and integrates in a whole all set of lines of influence, a certain internal force factor for different sections of rod system. Proskuryakov [21] based that the frame is represented in the form of the thin-walled rod with a rigid circuit of a transverse section.We will consider slightly in more detail the method described in operation [1], allowing as a result to calculate tension of the constrained torsion arising in nodes of a frame of the tractor dumping trailer 2ПТС-4-793A. The estimated diagram of the tractor train, the equivalent full-scale consisting of the four-wheel T28X4M tractor and the trailer 2ПТС-4-793A is developed for analytical researches of oscillations and force loading of load-carrying structures of the tractor dumping trailer 2ПТС-4-793A (fig. 1.). | Figure 1. Estimated diagram of the tractor train |

On the estimated diagram the tractor train is provided in the form of four mass systems with appropriate to nodes in specified masses, m and the inertia moments of J connected among themselves by elastic communications with constant coefficients of the linear with and rotating to rigidities. Having defined absolute relocation of masses of m by a method of algebraic addition of the relative relocation and using Lagrange's equation of the second kind: ,The system of 17 differential equations of the second order is received:

,The system of 17 differential equations of the second order is received: where:

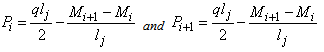

where:  and

and  - matrixes of constant coefficients;

- matrixes of constant coefficients; - the generalized coordinates.Solving these equations widely known methods, receive system of the linear algebraic equations. As a result, being set by a broad spectrum of forced oscillation frequencies of masses of the tractor train, it is possible to set the loadings arising in the appropriate nodes of their conjugation. Considering also that frames of tractor trailers are subject to multi-axial stress, use Vlasov V. Z. formula. [14]:

- the generalized coordinates.Solving these equations widely known methods, receive system of the linear algebraic equations. As a result, being set by a broad spectrum of forced oscillation frequencies of masses of the tractor train, it is possible to set the loadings arising in the appropriate nodes of their conjugation. Considering also that frames of tractor trailers are subject to multi-axial stress, use Vlasov V. Z. formula. [14]: .For calculation of a frame of the tractor trailer on a bend the estimated diagram (fig. 2) is used. The bend of such frame and its twisting, is described respectively by ordinary differential equations of the fourth order:

.For calculation of a frame of the tractor trailer on a bend the estimated diagram (fig. 2) is used. The bend of such frame and its twisting, is described respectively by ordinary differential equations of the fourth order: ;

;

| Figure 2. Frame of the tractor trailer "ПТС-4-793A |

As a result of solutions of such equations it is possible to determine tension of a bend and the constrained torsion by dependences:

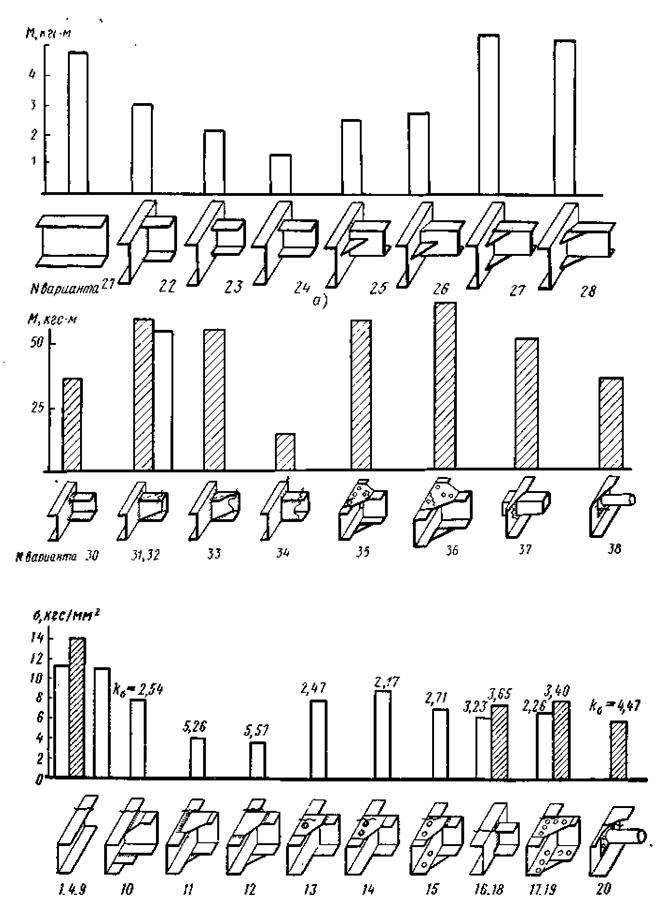

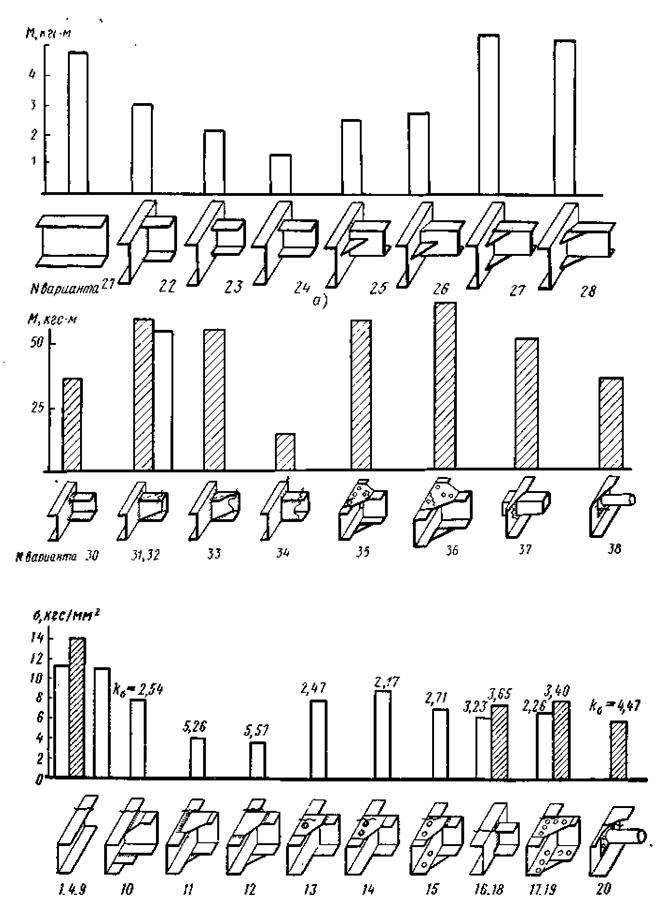

.For carrying out the pilot studies of the full-scale tractor train consisting also of a four-wheel tractor and the tractor dumping trailer 2ПТС-4-793A, the method of the electrical strain-gauging which has allowed, for example, for fixing of tension in nodes of a frame to set 62 2PKP-5-100V tensoresistors is used. Moving the tractor train on different roads and off road terrain by means of a magnetoelectric oscillograph of H-010M and the semiconductor amplifier TUP-12M with power supply unit located on a tractor allowed to receive the different oscillograms which decryption is made on known a technique of their statistical processing.It is known [16] that in case of design and creation of frames of tractor trailers the bent profiles received from sheet preparations of flexible, stamping or rolling are widely applied. Such profiles have a row of advantages and allow to reduce metal consumption of frames significantly. Further from these profiles create frames of the elements called by longerons and cross-pieces. Last, in connection among themselves by means of electrical welding will form nodes (fig. 3), which then test for a bend and the constrained torsion is normal in case of the symmetric cycle of loading on different benchs on construction, bringing them to corrupting, determining number of the cycles, allowing to define as a result longevity of a frame.

.For carrying out the pilot studies of the full-scale tractor train consisting also of a four-wheel tractor and the tractor dumping trailer 2ПТС-4-793A, the method of the electrical strain-gauging which has allowed, for example, for fixing of tension in nodes of a frame to set 62 2PKP-5-100V tensoresistors is used. Moving the tractor train on different roads and off road terrain by means of a magnetoelectric oscillograph of H-010M and the semiconductor amplifier TUP-12M with power supply unit located on a tractor allowed to receive the different oscillograms which decryption is made on known a technique of their statistical processing.It is known [16] that in case of design and creation of frames of tractor trailers the bent profiles received from sheet preparations of flexible, stamping or rolling are widely applied. Such profiles have a row of advantages and allow to reduce metal consumption of frames significantly. Further from these profiles create frames of the elements called by longerons and cross-pieces. Last, in connection among themselves by means of electrical welding will form nodes (fig. 3), which then test for a bend and the constrained torsion is normal in case of the symmetric cycle of loading on different benchs on construction, bringing them to corrupting, determining number of the cycles, allowing to define as a result longevity of a frame.  | Figure 3. Welded nodes of frames of trailers |

Analyzing the above, it is visible that processes of a finishing of new machines of initial stage of design before their setting on a mass production are rather difficult and take the considerable time. Therefore for simplification and time abbreviation as widely use a method of estimated determination of fatigue longevity of details and nodes of machines by comparison of characteristics of fatigue and operational tension therefore define coefficients of an inventory of their durability of n and longevity to.

2. Research Objective

Practice of maintenance of autotractor trains shows that construction of the last is still far from perfect, and especially it is shown in insufficient reliability of bearing systems and enough their high metal consumption. Considering it, and also above-mentioned materials, the purposes and tasks of this research are:1. Development of the perspective technical solutions, allowing to increase reliability of frames of autotractor trailers. 2. Development of the estimated diagram and method of calculation of design data of bearing system of the autotractor train providing the free deplanation of shelves of longerons in a zone of fixing of brackets of springs. 3. To provide a technical and economic assessment of the proposed technical solution in case of manufacture and carrying out maintenance and repair works of hook-on links as at repair shops and the enterprises of their service service.

3. Research Technique

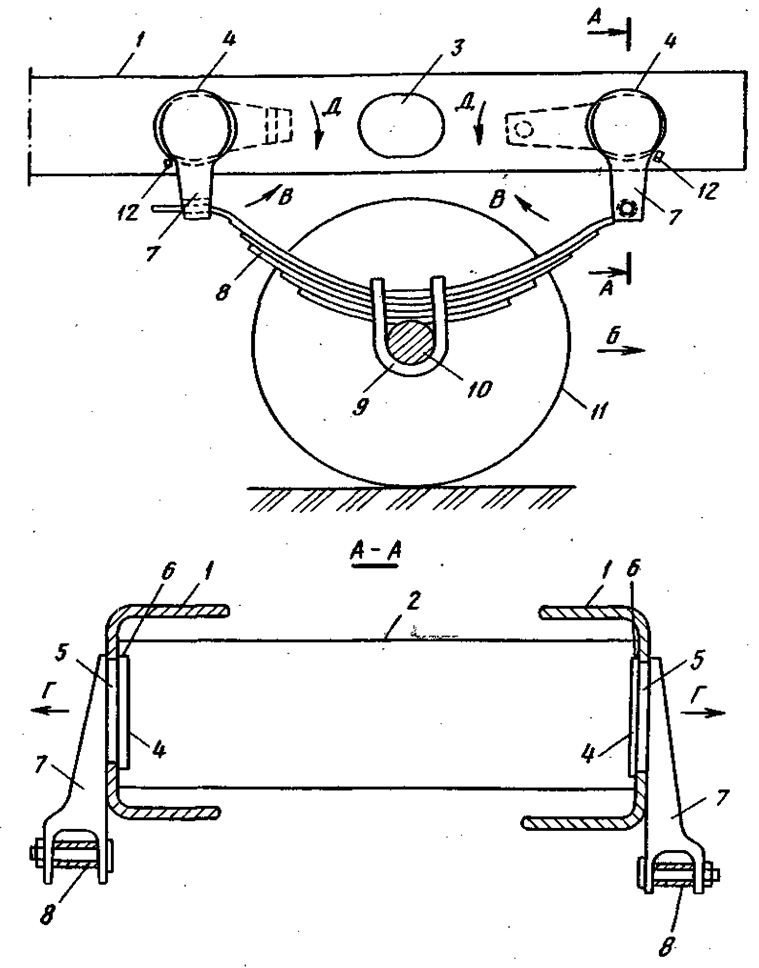

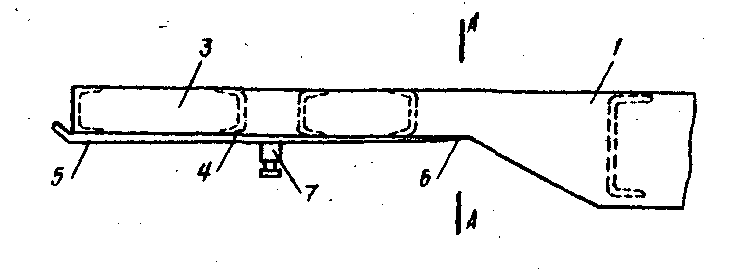

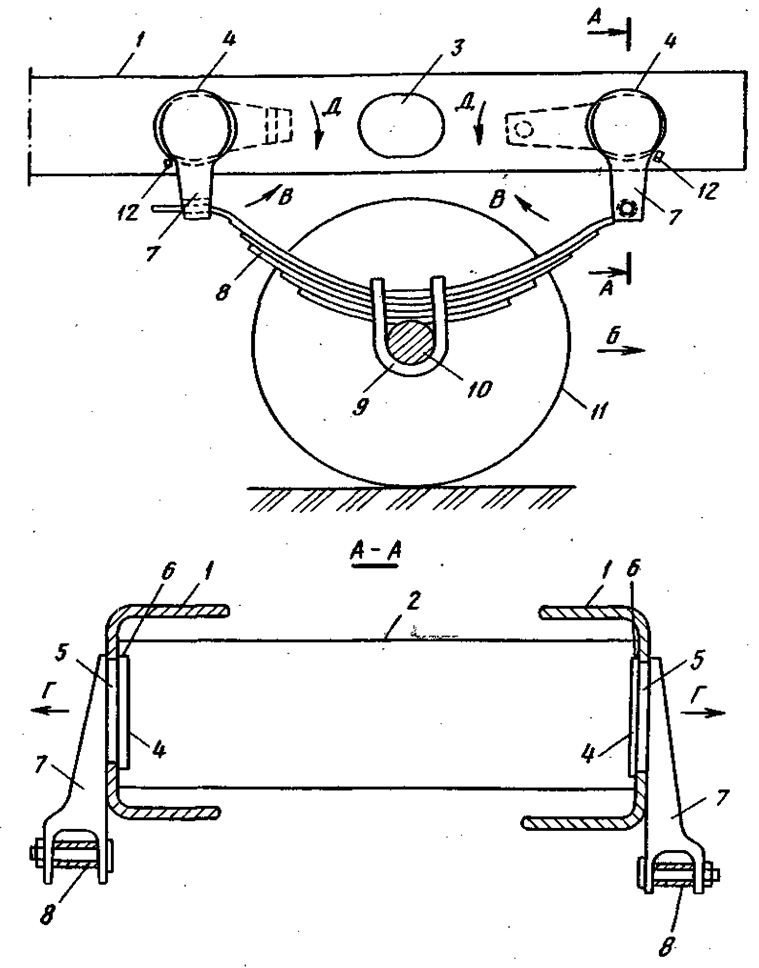

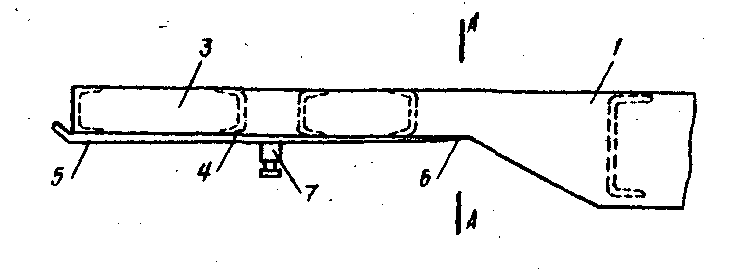

Considering the above NIR is carried out for a number of years to EGU of I.A. Bunin on chair of application-oriented mechanics and an engineering graphics on the subject "Dynamics, Durability and Reliability of Transport, Agricultural, Construction and Road Machines and Industrial Equipment, in relation to the Chernozem Region of the Russian Federation", and to one of its sections is directed on development of technical actions for reliability augmentation and maintainability of constructional elements of load-carrying structures of autotractor trailers and semi-trailers.The analysis of numerous references, domestic and foreign patents allowed to develop at the level of the invention of SU1189718 perspective construction of a frame for trackless vehicles of the increased reliability and maintainability.In fig. 4 the fastening assembly of a spring suspension bracket which can be used in constructions of autotractor trailers and semi-trailers is shown. | Figure 4. spring Fastening assemblies a side view and a view of a frame from an end face in section on AA |

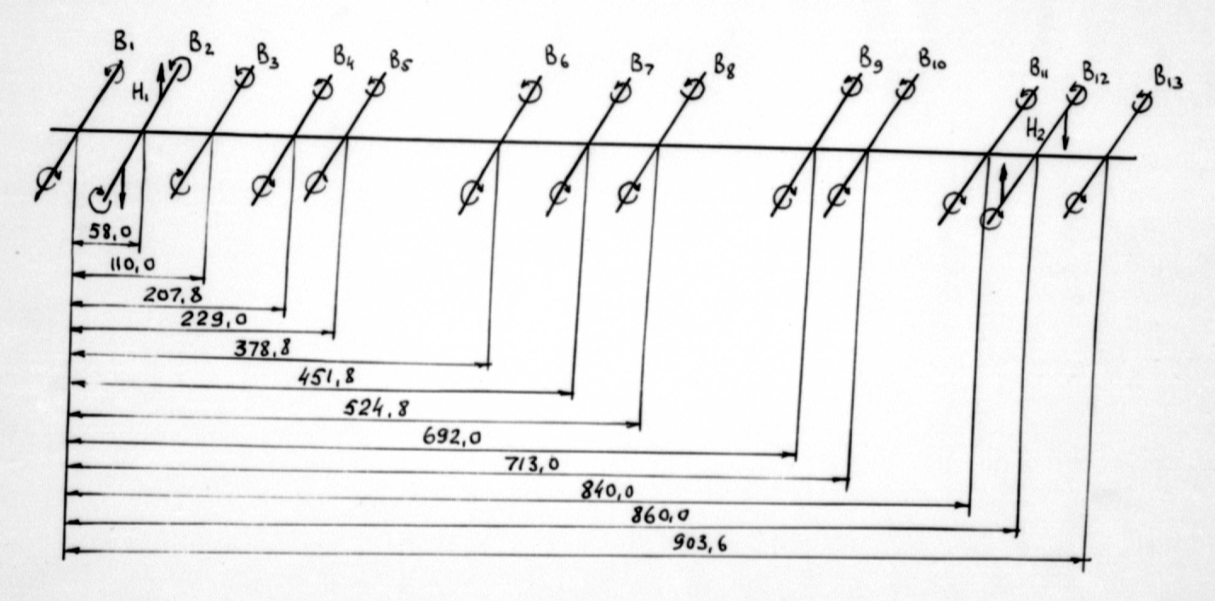

| Figure 5. Rod estimated diagram of force loading of a frame of the trailer |

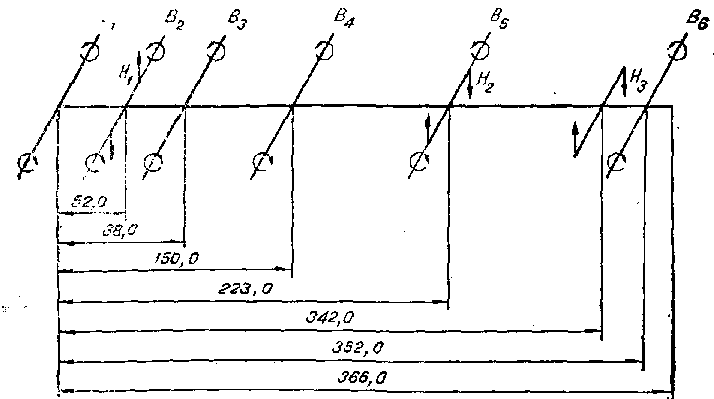

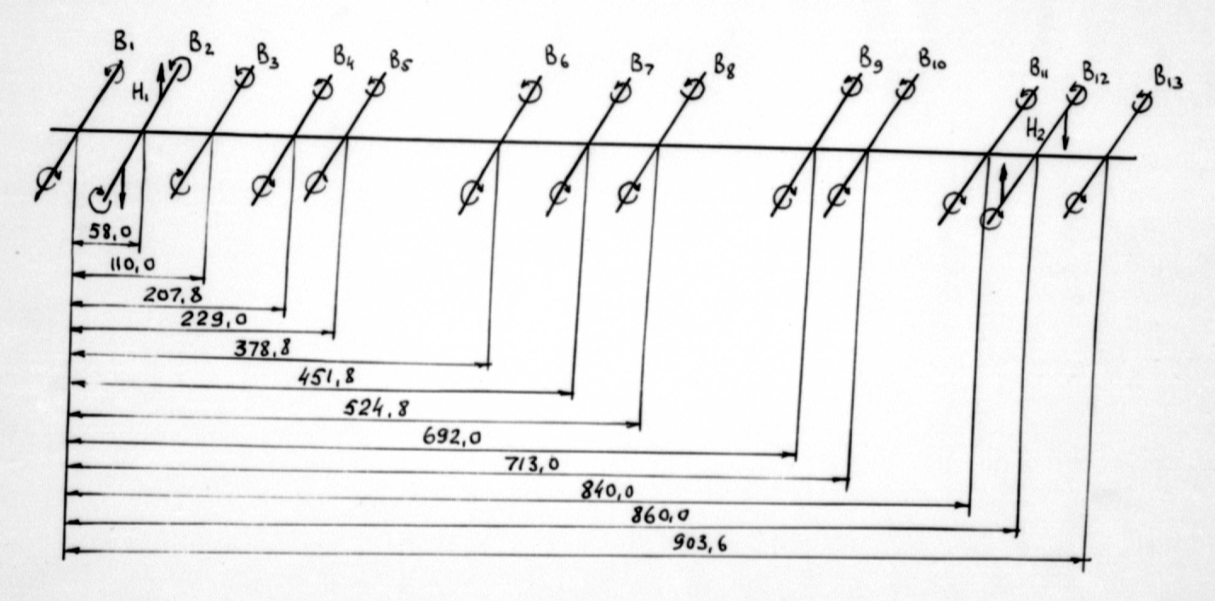

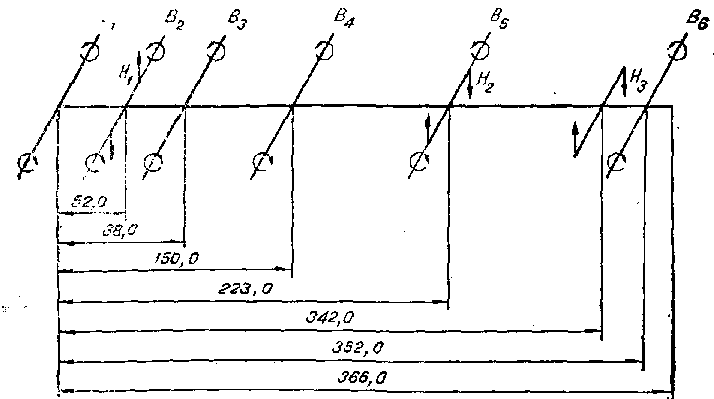

Such device of fixing of springs is bound to a trailer frame which is executed from longerons 1 and cross-pieces 2. In longerons oval holes 3 in which oval disks 4 having troughs 5 and overhangs 6 are placed are executed. Oval disks are rigidly connected to brackets of 7 springs of the 8th suspension bracket. Springs by means of step-ladders 9 are fixed on an axis of 10 wheels 11. On longerons an emphasis 12 is placed. It is clear that the trailer frame in this case is repair and suitable due to possible dismantling of brackets of springs, thus such operation happens as follows. First disconnect, for example, the right end of a spring of 8 (fig. 1) from a bracket 7 and remove an axis 10 with wheels 11 on an arrow B, thus other left end of a spring freely quits the left bracket 7.Secondly by means of known methods in technique, for example, using stationary or figurative hydraulic press or jacks, with enough ongoing effort turn brackets of 7 springs on arrows B, thus, as soon as oval disks 4 will reach position by 1 dotted line shown in fig., them freely delete on an arrow G together with brackets of 7 springs. It is possible because the disk oval by the sizes can be a little smaller, than an oval hole of 3 orders executed in a longeron in limits the 2-5th depending on the size of section of a longeron 1. Further the described procedure allows to make repair of longerons and them, for example, editing, and also brackets of springs separately, without breaking durability of elements gas sharp or electrical welding as it takes place in case of repair of all-welded serial frames. After execution of scheduled operations on frame repair oval disks enter into oval holes 3 and together with brackets of springs turn with use of the above equipment on arrows D until they isn't reached an emphasis 12, and then connect to them springs 8 together with axes 10 and wheels 11. In view of the fact that disks 4 press in holes 3, they are reliably connected to walls of longerons, and brackets of 7 springs don't superimpose tight coupling on shelves of longerons and provide that their free deplanation, and, therefore, the trailer frame well works for torsion and will be under operating conditions rather safe.For calculation of tension of the constrained torsion  arising in elements of a frame, for example, of the tractor dumping trailer 2ПТС-4-793A in case of its twisting, we will use the estimated diagram in fig. 5, where the frame is provided in the form of the elastic rod with a sectoral inertia moment

arising in elements of a frame, for example, of the tractor dumping trailer 2ПТС-4-793A in case of its twisting, we will use the estimated diagram in fig. 5, where the frame is provided in the form of the elastic rod with a sectoral inertia moment  .Bimoments are attached to an elastic midstream in sections of installation of cross-pieces of a frame, and in sections of installation of lobbies and back axes of wheels of the trailer external torsional moments. The equation describing a twisting of the elastic rod (trailer frame) has an appearance [1,21]:

.Bimoments are attached to an elastic midstream in sections of installation of cross-pieces of a frame, and in sections of installation of lobbies and back axes of wheels of the trailer external torsional moments. The equation describing a twisting of the elastic rod (trailer frame) has an appearance [1,21]: | (1) |

The solution of the equation (1) it is made with use of a method of the initial parameters. The accounting of force factors is realized metokdy superimposing. Final expression leaking the kinematic and external force factors will register in a look:

| (2) |

The analysis of the equations (2) shows that a twisting angle in nasal part of a frame and value of external twisting moment

The analysis of the equations (2) shows that a twisting angle in nasal part of a frame and value of external twisting moment  are known [1]. Remain unknowns two elementary parameters

are known [1]. Remain unknowns two elementary parameters  . We will provide the general diagram a task decision as follows [1]. Let the considered frame

. We will provide the general diagram a task decision as follows [1]. Let the considered frame  have the сross of the communications located in sections

have the сross of the communications located in sections  . For finding of bimoments

. For finding of bimoments  we will write out expressions of a derivative of an angle of a twisting

we will write out expressions of a derivative of an angle of a twisting  for

for  adding

adding  Connecting to the expression

Connecting to the expression  equations for

equations for  , we will receive

, we will receive  the equations of rather

the equations of rather  known

known  In this case the coefficient of proportionality

In this case the coefficient of proportionality  depends from the zhestkostnykh of properties of a cross-piece and sectorial coordinate

depends from the zhestkostnykh of properties of a cross-piece and sectorial coordinate  reflecting influence of a place of its fixing to a frame longeron;

reflecting influence of a place of its fixing to a frame longeron; According to data [21] cross-pieces tilted to a longitudinal axis of a frame under angles φ = 0, φ = 900, have the zhestkostny coefficients determined respectively by dependences

According to data [21] cross-pieces tilted to a longitudinal axis of a frame under angles φ = 0, φ = 900, have the zhestkostny coefficients determined respectively by dependences

where

where  — trailer track.Having calculated in this way numerical values

— trailer track.Having calculated in this way numerical values  , normal tension from the constrained torsion can be calculated on dependence

, normal tension from the constrained torsion can be calculated on dependence | (3) |

Knowing values of tension of a bend of a frame and torsion, we will define summary tension in researched its sections:  .For execution of calculations with use the software for the computer program was developed, which engages the following cases of loading of a frame of the trailer was made: movement of trailer with the maximum load in its body in mass 4,0 ton; load unloading in mass 4,0 ton on one side; load unloading in mass 4,0 ton back.For numerical calculation of tension

.For execution of calculations with use the software for the computer program was developed, which engages the following cases of loading of a frame of the trailer was made: movement of trailer with the maximum load in its body in mass 4,0 ton; load unloading in mass 4,0 ton on one side; load unloading in mass 4,0 ton back.For numerical calculation of tension  , in case of movement of the tractor train with a load 4,0 ton we will use the dynamic сomponent vertical load

, in case of movement of the tractor train with a load 4,0 ton we will use the dynamic сomponent vertical load  operating on the specified mass

operating on the specified mass  of a dynamic model [1]:

of a dynamic model [1]:  ton.For computation of efforts

ton.For computation of efforts  it is representable the concentrated force

it is representable the concentrated force  ton of t in the form of the uniform distributed load of

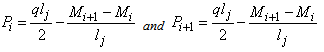

ton of t in the form of the uniform distributed load of  N/cm attached to the bottom of a platform, and we will use the empirical formulas provided to the slave those [2]:

N/cm attached to the bottom of a platform, and we will use the empirical formulas provided to the slave those [2]: | (4) |

Based on dependences (4) loadings attached to one longeron of a frame in points 1, 2, 3, 4 and 5, will be equal: The bending moment

The bending moment  operating on welded nodes of a frame from applied longitudinal forces

operating on welded nodes of a frame from applied longitudinal forces  will be defined

will be defined  , where

, where  — dynamic component efforts enclosed on the tractive hook of a tractor, equal to

— dynamic component efforts enclosed on the tractive hook of a tractor, equal to  N,

N,  — distance from an axis of application of effort

— distance from an axis of application of effort  to the center of gravity of a longeron of a frame, equal 23 cm,

to the center of gravity of a longeron of a frame, equal 23 cm,  N∙cm. The bending moment

N∙cm. The bending moment  arising on a front bracket of springs from action of effort

arising on a front bracket of springs from action of effort  , we will determine by dependence of M2 = - 0,5(T1 +T2 +T3)0,05l2 4,7∙103 N∙cm, where

, we will determine by dependence of M2 = - 0,5(T1 +T2 +T3)0,05l2 4,7∙103 N∙cm, where  — distance from a point of application of loading of a finger of a spring to the longeron center of gravity, equal 17cm; 0,05 — rolling friction coefficient of wheels of the trailer. Geometrical characteristics of welded nodes, sections of a frame of the I—XI are respectively equal [1]

— distance from a point of application of loading of a finger of a spring to the longeron center of gravity, equal 17cm; 0,05 — rolling friction coefficient of wheels of the trailer. Geometrical characteristics of welded nodes, sections of a frame of the I—XI are respectively equal [1] Numerical values of the flexural moments M (Z ) and bimoments B(ω) make [1]:

Numerical values of the flexural moments M (Z ) and bimoments B(ω) make [1]: For calculation of summary tension numerical values them are used known for dependences as a result made [1]:

For calculation of summary tension numerical values them are used known for dependences as a result made [1]: Analyzing last it is visible that their greatest values arise around the fifth cross-piece set in a place of a perkvy spring node of a frame of the trailer, and make 292,3 МPа, and in this zone of tension of the constrained torsion reach 148,5 МPа, and flexural tension 143,8 МPа. Such values of tension considerably exceed fatigue value of welded nodes of a frame, koktory, according to some information [1], doesn't exceed 50 МPа therefore in practice the longevity of a frame of the trailer 2ПТС-4-793A will be neudovletkvoritelny. Similar calculations are executed and for a frame of the tractor dumping trailer 2ПТС-4-793A supplied with a frame including removable brackets of springs executed according to the patent SU1189718. Calculations showed that tension of the constrained torsion reaches in this case 36,5 МPа, and flexural tension remained same 143,8 МPа. As a result it is visible that tension of the constrained torsion is much lower, than at a serial frame 36,5МPа < 148,5МPа and doesn't exceed fatigue value 50 МPа. Therefore, reliability of a frame of the upgraded trailer will be much higher.It was marked above that in operational conditions of a frame of trailers and semi-trailers shall respond the principal criterion of operability of machines - reliabilities. It is known that as reliability understand – property of a product to execute the functions during the preset time or the given operating time, saving in the given limits operational indexes. Reliability of products is caused by their faultlessness, longevity, maintainability and a keeping. It is clear that the offered construction of a frame shall be under repair together with that machine on which it is mounted, at the mashinoremontny enterprise representing variety of machine-building and executing according to specifications of repair of machines (aggregates, nodes, details, etc.) lost normal working capacity, but still peculiar preparations maintainable and executing a role for this production. Unlike mechanical engineering repair production includes specific technological processes such as: washing, disassembling, troubleshooting and repair of elements of machines. To customer it is the extremely important that in case of repair of machines, and also in case of changeover of their short-lived details there would be as little as possible ballast operations, i.e. machines with the minimum expenses of work, materials and energies on their disassembling and washing, exception replaced constructive and deleting short-lived nonconstructive elements are necessary. Proceeding from the expenses, the appropriate ballast operations in case of repair, maintenance or changeover of constructive elements of machines, give the quantitative assessment of their maintainability characterized by coefficient of maintainability [20].The coefficient of maintainability of the machine can be determined as the relation of average expenses of work, energy and the materials which are required for introduction in the machine of replaced and renewable elements, to the amount of expenses of work, energy and materials on its disassembling and washing together with assembly, regulation and restoration of other nonconstructive elements by dependence:

Analyzing last it is visible that their greatest values arise around the fifth cross-piece set in a place of a perkvy spring node of a frame of the trailer, and make 292,3 МPа, and in this zone of tension of the constrained torsion reach 148,5 МPа, and flexural tension 143,8 МPа. Such values of tension considerably exceed fatigue value of welded nodes of a frame, koktory, according to some information [1], doesn't exceed 50 МPа therefore in practice the longevity of a frame of the trailer 2ПТС-4-793A will be neudovletkvoritelny. Similar calculations are executed and for a frame of the tractor dumping trailer 2ПТС-4-793A supplied with a frame including removable brackets of springs executed according to the patent SU1189718. Calculations showed that tension of the constrained torsion reaches in this case 36,5 МPа, and flexural tension remained same 143,8 МPа. As a result it is visible that tension of the constrained torsion is much lower, than at a serial frame 36,5МPа < 148,5МPа and doesn't exceed fatigue value 50 МPа. Therefore, reliability of a frame of the upgraded trailer will be much higher.It was marked above that in operational conditions of a frame of trailers and semi-trailers shall respond the principal criterion of operability of machines - reliabilities. It is known that as reliability understand – property of a product to execute the functions during the preset time or the given operating time, saving in the given limits operational indexes. Reliability of products is caused by their faultlessness, longevity, maintainability and a keeping. It is clear that the offered construction of a frame shall be under repair together with that machine on which it is mounted, at the mashinoremontny enterprise representing variety of machine-building and executing according to specifications of repair of machines (aggregates, nodes, details, etc.) lost normal working capacity, but still peculiar preparations maintainable and executing a role for this production. Unlike mechanical engineering repair production includes specific technological processes such as: washing, disassembling, troubleshooting and repair of elements of machines. To customer it is the extremely important that in case of repair of machines, and also in case of changeover of their short-lived details there would be as little as possible ballast operations, i.e. machines with the minimum expenses of work, materials and energies on their disassembling and washing, exception replaced constructive and deleting short-lived nonconstructive elements are necessary. Proceeding from the expenses, the appropriate ballast operations in case of repair, maintenance or changeover of constructive elements of machines, give the quantitative assessment of their maintainability characterized by coefficient of maintainability [20].The coefficient of maintainability of the machine can be determined as the relation of average expenses of work, energy and the materials which are required for introduction in the machine of replaced and renewable elements, to the amount of expenses of work, energy and materials on its disassembling and washing together with assembly, regulation and restoration of other nonconstructive elements by dependence:

where

where  and

and  - mean values of the conformance and the costs appropriate to the volume of ballast operations in case of maintenance, repair or changeover of short-lived constructive elements.For determination of coefficient of maintainability of a frame of the trailer, for example, models 2ПТС-4-887A of the Balashov plant of automobile and tractor trailers of fixing of brackets of springs supplied with offered construction and serial, the analysis of financial activities of a workshop of agro-industrial complex of the Yelets region of the Lipetsk region for the period 2009-2013g.g is carried out. on which major repair of similar trailers is made. The analysis showed that the general expenses of work, energy and materials for repair of one frame average Qic = 18856 rub, and ballast operations are equal to qic = 9950 rub. Therefore, the coefficient of maintainability of a serial frame is equal to Fp = 0,65. For offered construction of a frame of the trailer approximately at the expense of easily deleted from its longerons, without use of gas-welding operations and traumatizing in this case shelves and walls of longerons and cross-pieces, brackets of springs, repair costs can make no more Qic = 12230 rub in case of reduction in cost of ballast operations to qic = 5050 rub. In this case the coefficient of maintainability will be equal to Fp = 0,71. It is visible that construction of a frame of the trailer executed according to the patent SU1189718 has higher coefficient of maintainability that speaks about efficiency of use of this technical solution in practice.The analysis of numerous references, domestic and foreign patents also allowed to develop perspective constructions of frames of semi-trailers of the increased reliability at the level of inventions (SU1539117, SU1638056 and RU1066871). Such constructions differ from known domestic and foreign analogs that reference sheets of shoulders of frames don't superimpose tight coupling on shelves of longerons and allow them freely deform elastically in case of their torsion in the longitudinal plane of the semi-trailer, and brackets of springs represent removable nodes also providing the free deplanation of the lower shelves of longerons and the cross-pieces which are in a zone of their contiguity to brackets of springs.In fig. 6 the end view of a frame of the semi-trailer, and a frame node with one of brackets of springs in the long term (SU1539117 and SU1638056) is shown.

- mean values of the conformance and the costs appropriate to the volume of ballast operations in case of maintenance, repair or changeover of short-lived constructive elements.For determination of coefficient of maintainability of a frame of the trailer, for example, models 2ПТС-4-887A of the Balashov plant of automobile and tractor trailers of fixing of brackets of springs supplied with offered construction and serial, the analysis of financial activities of a workshop of agro-industrial complex of the Yelets region of the Lipetsk region for the period 2009-2013g.g is carried out. on which major repair of similar trailers is made. The analysis showed that the general expenses of work, energy and materials for repair of one frame average Qic = 18856 rub, and ballast operations are equal to qic = 9950 rub. Therefore, the coefficient of maintainability of a serial frame is equal to Fp = 0,65. For offered construction of a frame of the trailer approximately at the expense of easily deleted from its longerons, without use of gas-welding operations and traumatizing in this case shelves and walls of longerons and cross-pieces, brackets of springs, repair costs can make no more Qic = 12230 rub in case of reduction in cost of ballast operations to qic = 5050 rub. In this case the coefficient of maintainability will be equal to Fp = 0,71. It is visible that construction of a frame of the trailer executed according to the patent SU1189718 has higher coefficient of maintainability that speaks about efficiency of use of this technical solution in practice.The analysis of numerous references, domestic and foreign patents also allowed to develop perspective constructions of frames of semi-trailers of the increased reliability at the level of inventions (SU1539117, SU1638056 and RU1066871). Such constructions differ from known domestic and foreign analogs that reference sheets of shoulders of frames don't superimpose tight coupling on shelves of longerons and allow them freely deform elastically in case of their torsion in the longitudinal plane of the semi-trailer, and brackets of springs represent removable nodes also providing the free deplanation of the lower shelves of longerons and the cross-pieces which are in a zone of their contiguity to brackets of springs.In fig. 6 the end view of a frame of the semi-trailer, and a frame node with one of brackets of springs in the long term (SU1539117 and SU1638056) is shown. | Figure 6. Transverse section of a frame of the semi-trailer and fastening assembly of a bracket of its springs |

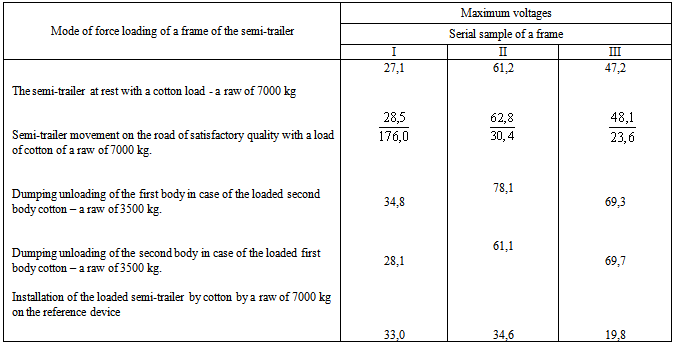

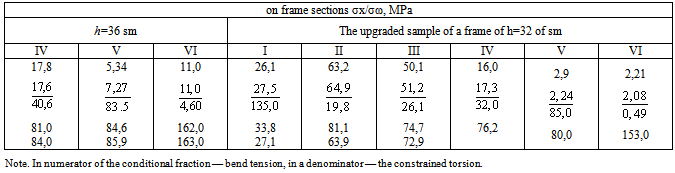

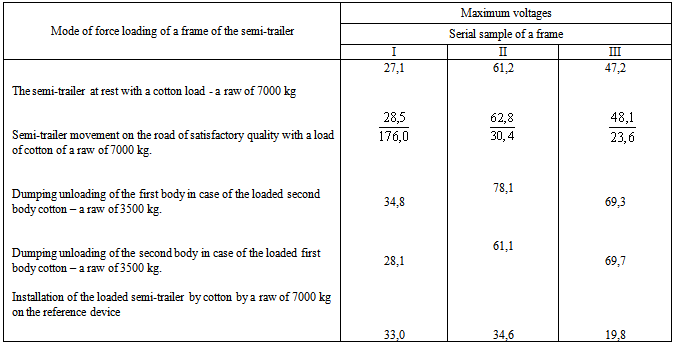

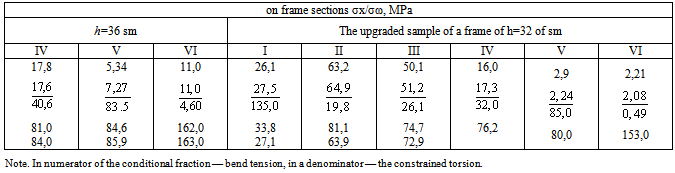

In the first case (SU1539117) the frame of the automobile semi-trailer consists of longerons 1 which are connected in a zone of its shoulder by means of the notches 3 executed in their walls, to reference sheet 5. It is clear that in case of semi-trailer movement on different roads with different macro and a micro profile and frame curling in its longitudinal plane of tension of the constrained torsion on shelves of longerons are absent due to superimposing of tight coupling on them from a reference leaf as it takes place in existing constructions.At the same time in case of repair of the offered construction of a frame to delete, for example, the worn-out reference leaf doesn't present technological difficulties as after deleting welded seams 8 last is easily brought from notches 3, without injuring shelves and walls of longerons as it usually takes place in serial constructions. In the second case (SU1638056) longerons of a frame 1 and cross-pieces 2 in the lower part are connected to the support plate 3 of the steel executed from elastic sorts having the curved sections 4 forming notches 5, and sections 4 envelop shelves of 6 longerons 1 and cross-pieces 2. Cheeks of 7 brackets of springs are rigidly connected to the lower part of the support plate 3. Operation of such frame happens similarly above described as spring brackets don't superimpose tight coupling on the lower shelves of longerons and cross-pieces and therefore the last is free deplanation in case of frame torsion. In too time they can be rather easily dismantled from a frame due to elastic deformation by the special adaptation of sections 4.In the third case (RU1066871) the reference sheet 5 of a shoulder of a frame of the semi-trailer on its length is executed different thickness. Such technical solution allows to reduce tension of the constrained torsion because rotating rigidness of a longeron of a frame in a place of transition from a shoulder to its main section is much lower than it, than at a serial frame having the constant thickness of a reference leaf.For calculation of tension of the constrained torsion σω arising in elements of a perspective frame of automobile the semi-trailer of the ТМЗ-879A model by loading capacity 10,0 ton, in case of its twisting at which height of longerons is equal to h = 36 of cm and h = 32 cm, and also the part of constructive elements is executed according to the patents SU1638056 and RU1066871, the estimated diagram (fig. 8) where the frame is provided in the form of the elastic rod with a sectoral inertia moment is used Jω.As the semi-trailer frame generally works for torsion in case of its movement on different roads, in case of calculation of tensions σω, with software use on a computer, the mode of movement of the semi-trailer, and these, characteristic frames for its sections was considered only, were brought together in tab. 1.The analysis of tab. 1 shows that they reach the greatest values 176,0 МPа (a section of the II frame in a zone of a welding of a reference leaf of a shoulder of a frame) and 83,5 МPа (a section of the V frame in fastening zone of brackets of springs of the semi-trailer). This results from the fact that sections of I and VI have the considerable torsion stiffness. So, in front part of a frame on a section of I there is a shoulder which consists of four cross-pieces which have been rigidly connected among themselves by a reference leaf δ = of 8 mm, and in back part on a section the VI existence on 600 mm lengths of a frame of three cross-pieces one of which is executed box-shaped section, and all three cross-pieces are connected among themselves by the longitudinal elements forming a fastening assembly of towing device. In case of use of construction of a shoulder executed according to the patent RU1066871 which reference leaf is executed with different thickness and a longeron with h section = 32 cm at which more stout side of a reference leaf (δ = 8 mm) is located in front part of a shoulder, and more thin (δ = 2,0 mm) in its back part (see fig. 7), and the reference leaf is welded only to cross frames, tension of the constrained torsion in this zone decrease to 135 МPа. | Figure 7. Shoulder of a Frame of the Semi-trailer with different thickness reference leaf |

| Figure 8. Rod estimated diagram of force loading of a frame of the semi-trailer |

At the same time from tab. 1 it is visible that total tension σx +ω on a section of the I frame of a prototype makes 238,8 МPа that is 3,8 times higher than fatigue value for steel 25 PS (of what the frame is made), which is equal σ-1 = 62,2 MPa At the upgraded sample of tension considerably decrease and reach values in the same section of a frame in 187,9 МPа that only exceeds material fatigue value three times. The similar pattern is watched and in fastening assemblies of springs of a suspension bracket of the semi-trailer. So if mean value of summary tension at serial construction of the semi-trailer on the lower shelves of its longerons reach values 197,4 МPа, with use of a technical solution according to the patent SU1638056 they don't exceed 93,8 МPа. Therefore, the longevity of a frame with use of upgraded its shoulder and fastening assemblies of support brackets of springs will be much higher, than at a serial sample of the semi-trailer of the ТМЗ-879A model.Table 1. The results of calculations voltage at nodes of the trailer frame

|

| |

|

Table 1. continuation

|

| |

|

4. Results of Research

Based on the above it is possible to draw the following outputs and sentences:1. Proposed article has important theoretical and practical importance, since it is aimed at strength calculation frame structures trackless vehicles using modern approaches to establish restrained torsion stresses arising in structural elements of the past as they move on different roads and off-road conditions in agricultural production. The advantages of such techniques related to the definition of stress restrained torsion formula V.Z. Vlasov when calculating the strength of thin-walled compared to known techniques, allows us to give a qualitative assessment of the strength of welded assemblies bearing systems used in vehicles such as trucks, trailers and semi-trailers for them, and develop practical recommendations to improve the reliability of the whole frame. This method of calculation of frames in the restrained torsion stress is widely used in the calculations chassis wheeled vehicles, both in our country and abroad.2. The analysis both domestic, and foreign constructions of autotractor trailers and semi-trailers shows that the last possess the essential shortcoming, consisting, in low reliability of load-carrying structures which are under operating conditions subject not only to a bend, compression and stretching, but also the constrained torsion. Such force loading causes the high tension of the constrained torsion in welded nodes of frames, as brings not only to corrupting of welded connections, but also nodes as a whole. As a result of the enterprise exploiting such technique incur the considerable labor and financial expenditures connected to repair and restoration of frame constructions of trailers and semi-trailers.3. Considering the above at the level of inventions (SU1539117, SU1638056 and RU1066871) technical solutions allowing to raise not only operational but also operational reliability of frames of hook-on links of autotractor trains are developed. For establishment of a tension of frames and development of rational parameters of the upgraded constructions of frames estimated diagrams are accepted and the known technique on its study is used. So, the carried-out calculations, in relation to the automobile semi-trailer of the ТМЗ-879A model with use of a technical solution according to the patent RU1066871показали that as a whole in relation to a serial sample of a frame of tension decrease by 1,3 times and don't exceed material fatigue value. The similar pattern is watched and in fastening assemblies of springs of a suspension bracket of the semi-trailer. So if mean value of summary tension at serial construction of the semi-trailer on the lower shelves of its longerons reach values 197,4МPа, with use of a technical solution according to the patent SU1638056 they don't exceed 93,8МPа. Therefore, the longevity of a frame with use of upgraded its shoulder and fastening assemblies of support brackets of springs will be much higher, than at a serial sample of the semi-trailer of the ТМЗ-879A model. 4. Results of research are recommended to the domestic and foreign motor transportation enterprises, automotive industry and the scientific and designer subdividings working in the field of automotive industry for study and the analysis of offered constructions for the purpose of possible further of their implementation in practice.

References

| [1] | Glushchenko A.D. Slivinsky E.V. Dynamics and durability of transport system for transportation of light-weight loads. Tashkent: Fan, 1988. 116с. |

| [2] | Vysotsky M. S., Dobras L.I., Sirotkin Z.L. Automobile and tractor trailers. M.: Mashgiz. 1962. 161 pages. |

| [3] | Osingurov V. V. Cars dump trucks. M.: Mashgiz, 1952. Page 124. |

| [4] | Markelov S. P., Krylov Yu. N. The modern constructions of automobile trailers of the capitalist countries. M.: Tsniiavtoprom, 1976. - 118с. |

| [5] | D. P's giants. Development of road trains and their dynamic qualities//Automotive industry, 1960, No. 2. Page 22. |

| [6] | Dmitrichenko S. S. Research of fatigue resistance of tractor trailers//Tractors and agricultural machines. 1986 . No. 6. Page 16 — 17. |

| [7] | Zakin Ya. X. Application-oriented theory of movement of the road train. M.: Transport, 1987. Page 286. |

| [8] | Bakhmutsky M. M., Sharapov V. K. Researches the course stability of the road train with the trailer having the turning device of automobile type//Automotive industry. 1969. No. 7. Page 26. 15. |

| [9] | Nazarenko A. G. Dynamics of the tractor train and technique and equipment development for test of autotractor trains for oscillations//Avtoref. yew. Doctor of Engineering. Novosibirsk, 1963. 46 pages. |

| [10] | Rotenberg R. V. Сar syspender and its oscillations. M.: Mashgiz, 1960, 354 pages. |

| [11] | Yatsenko N. N. Smoothness of a course of trucks. M.: Mechanical engineering, 1969. 219 pages. |

| [12] | Schukin M. M. Coupling devices of cars and tractors. M — L. : Mashgiz, 1961. 206 pages. |

| [13] | M. I. Legislative Assembly a tension in nodes of automobile frames in case of its torsion//Works us. Vyp. 61 . M, 1963. 38 — 60. |

| [14] | Vlasov V. 3. Thin-walled elastic rods. M, 1955. 566 pages. |

| [15] | Bocharov N. F. Calculation on durability of frames of trucks. Avtoref. yew. Cand.Tech.Sci. MVTU of Bauman, 1954. 32 pages. |

| [16] | Gelfgat D. B. Frames of trucks/M: Mashgiz, 1959. 230 pages. |

| [17] | Humpbacks B. N., Strelbitskaya A. I. Approximate methods of calculation of carriage frames. M.: Mashgiz, 1946. 106 pages. |

| [18] | Kobrin M. M. Classification and analysis of the fatigue operational corruptings of frames of trucks//STATE THREAD Works, 1964. Page 54 — 66. |

| [19] | Dmitrichenko S. S. About a resource of operability of frames tractor trailers and other machines//Welding production. 1968. No. 10. Page 22 — 23. |

| [20] | Proskuryakov V. B. Dynamics and durability of frames and casing of transport machines. L.: Mechanical engineering, 1972. 229 pages. means. The bus is twisted. USSR No. 1217699//Bulletin of inventions. 1986. No. 10. |

| [21] | Slivinsky E. V. Research of oscillations and force loading of the tractor dumping trailer 2ПТС-4-793A. Avtoref. yew. Cand.Tech.Sci. Alma-Ata: SHI, 1977. 165 pages. |

| [22] | Glushchenko A. D., Grokhovsky Yu. V., Slivinsky E. V. Research of oscillations and force loading of the tractor dumping trailer 2ПТС-4-793A//Tractors and agricultural machines, 1980. No. 4. Page 8 — 11. |

| [23] | Slivinsky E. V. Improving of utilization properties of hook-on vehicles on the basis of effective scientific and technical solutions. Avtoref. yew. Doctor of Engineering. Eagle: GTU, 2010. 334 pages. |

,The system of 17 differential equations of the second order is received:

,The system of 17 differential equations of the second order is received: where:

where:  and

and  - matrixes of constant coefficients;

- matrixes of constant coefficients; - the generalized coordinates.Solving these equations widely known methods, receive system of the linear algebraic equations. As a result, being set by a broad spectrum of forced oscillation frequencies of masses of the tractor train, it is possible to set the loadings arising in the appropriate nodes of their conjugation. Considering also that frames of tractor trailers are subject to multi-axial stress, use Vlasov V. Z. formula. [14]:

- the generalized coordinates.Solving these equations widely known methods, receive system of the linear algebraic equations. As a result, being set by a broad spectrum of forced oscillation frequencies of masses of the tractor train, it is possible to set the loadings arising in the appropriate nodes of their conjugation. Considering also that frames of tractor trailers are subject to multi-axial stress, use Vlasov V. Z. formula. [14]: .For calculation of a frame of the tractor trailer on a bend the estimated diagram (fig. 2) is used. The bend of such frame and its twisting, is described respectively by ordinary differential equations of the fourth order:

.For calculation of a frame of the tractor trailer on a bend the estimated diagram (fig. 2) is used. The bend of such frame and its twisting, is described respectively by ordinary differential equations of the fourth order: ;

;

.For carrying out the pilot studies of the full-scale tractor train consisting also of a four-wheel tractor and the tractor dumping trailer 2ПТС-4-793A, the method of the electrical strain-gauging which has allowed, for example, for fixing of tension in nodes of a frame to set 62 2PKP-5-100V tensoresistors is used. Moving the tractor train on different roads and off road terrain by means of a magnetoelectric oscillograph of H-010M and the semiconductor amplifier TUP-12M with power supply unit located on a tractor allowed to receive the different oscillograms which decryption is made on known a technique of their statistical processing.It is known [16] that in case of design and creation of frames of tractor trailers the bent profiles received from sheet preparations of flexible, stamping or rolling are widely applied. Such profiles have a row of advantages and allow to reduce metal consumption of frames significantly. Further from these profiles create frames of the elements called by longerons and cross-pieces. Last, in connection among themselves by means of electrical welding will form nodes (fig. 3), which then test for a bend and the constrained torsion is normal in case of the symmetric cycle of loading on different benchs on construction, bringing them to corrupting, determining number of the cycles, allowing to define as a result longevity of a frame.

.For carrying out the pilot studies of the full-scale tractor train consisting also of a four-wheel tractor and the tractor dumping trailer 2ПТС-4-793A, the method of the electrical strain-gauging which has allowed, for example, for fixing of tension in nodes of a frame to set 62 2PKP-5-100V tensoresistors is used. Moving the tractor train on different roads and off road terrain by means of a magnetoelectric oscillograph of H-010M and the semiconductor amplifier TUP-12M with power supply unit located on a tractor allowed to receive the different oscillograms which decryption is made on known a technique of their statistical processing.It is known [16] that in case of design and creation of frames of tractor trailers the bent profiles received from sheet preparations of flexible, stamping or rolling are widely applied. Such profiles have a row of advantages and allow to reduce metal consumption of frames significantly. Further from these profiles create frames of the elements called by longerons and cross-pieces. Last, in connection among themselves by means of electrical welding will form nodes (fig. 3), which then test for a bend and the constrained torsion is normal in case of the symmetric cycle of loading on different benchs on construction, bringing them to corrupting, determining number of the cycles, allowing to define as a result longevity of a frame.

arising in elements of a frame, for example, of the tractor dumping trailer 2ПТС-4-793A in case of its twisting, we will use the estimated diagram in fig. 5, where the frame is provided in the form of the elastic rod with a sectoral inertia moment

arising in elements of a frame, for example, of the tractor dumping trailer 2ПТС-4-793A in case of its twisting, we will use the estimated diagram in fig. 5, where the frame is provided in the form of the elastic rod with a sectoral inertia moment  .Bimoments are attached to an elastic midstream in sections of installation of cross-pieces of a frame, and in sections of installation of lobbies and back axes of wheels of the trailer external torsional moments. The equation describing a twisting of the elastic rod (trailer frame) has an appearance [1,21]:

.Bimoments are attached to an elastic midstream in sections of installation of cross-pieces of a frame, and in sections of installation of lobbies and back axes of wheels of the trailer external torsional moments. The equation describing a twisting of the elastic rod (trailer frame) has an appearance [1,21]:

The analysis of the equations (2) shows that a twisting angle in nasal part of a frame and value of external twisting moment

The analysis of the equations (2) shows that a twisting angle in nasal part of a frame and value of external twisting moment  are known [1]. Remain unknowns two elementary parameters

are known [1]. Remain unknowns two elementary parameters  . We will provide the general diagram a task decision as follows [1]. Let the considered frame

. We will provide the general diagram a task decision as follows [1]. Let the considered frame  have the сross of the communications located in sections

have the сross of the communications located in sections  . For finding of bimoments

. For finding of bimoments  we will write out expressions of a derivative of an angle of a twisting

we will write out expressions of a derivative of an angle of a twisting  for

for  adding

adding  Connecting to the expression

Connecting to the expression  equations for

equations for  , we will receive

, we will receive  the equations of rather

the equations of rather  known

known  In this case the coefficient of proportionality

In this case the coefficient of proportionality  depends from the zhestkostnykh of properties of a cross-piece and sectorial coordinate

depends from the zhestkostnykh of properties of a cross-piece and sectorial coordinate  reflecting influence of a place of its fixing to a frame longeron;

reflecting influence of a place of its fixing to a frame longeron; According to data [21] cross-pieces tilted to a longitudinal axis of a frame under angles φ = 0, φ = 900, have the zhestkostny coefficients determined respectively by dependences

According to data [21] cross-pieces tilted to a longitudinal axis of a frame under angles φ = 0, φ = 900, have the zhestkostny coefficients determined respectively by dependences

where

where  — trailer track.Having calculated in this way numerical values

— trailer track.Having calculated in this way numerical values  , normal tension from the constrained torsion can be calculated on dependence

, normal tension from the constrained torsion can be calculated on dependence

.For execution of calculations with use the software for the computer program was developed, which engages the following cases of loading of a frame of the trailer was made: movement of trailer with the maximum load in its body in mass 4,0 ton; load unloading in mass 4,0 ton on one side; load unloading in mass 4,0 ton back.For numerical calculation of tension

.For execution of calculations with use the software for the computer program was developed, which engages the following cases of loading of a frame of the trailer was made: movement of trailer with the maximum load in its body in mass 4,0 ton; load unloading in mass 4,0 ton on one side; load unloading in mass 4,0 ton back.For numerical calculation of tension  , in case of movement of the tractor train with a load 4,0 ton we will use the dynamic сomponent vertical load

, in case of movement of the tractor train with a load 4,0 ton we will use the dynamic сomponent vertical load  operating on the specified mass

operating on the specified mass  of a dynamic model [1]:

of a dynamic model [1]:  ton.For computation of efforts

ton.For computation of efforts  it is representable the concentrated force

it is representable the concentrated force  ton of t in the form of the uniform distributed load of

ton of t in the form of the uniform distributed load of  N/cm attached to the bottom of a platform, and we will use the empirical formulas provided to the slave those [2]:

N/cm attached to the bottom of a platform, and we will use the empirical formulas provided to the slave those [2]:

The bending moment

The bending moment  operating on welded nodes of a frame from applied longitudinal forces

operating on welded nodes of a frame from applied longitudinal forces  will be defined

will be defined  , where

, where  — dynamic component efforts enclosed on the tractive hook of a tractor, equal to

— dynamic component efforts enclosed on the tractive hook of a tractor, equal to  N,

N,  — distance from an axis of application of effort

— distance from an axis of application of effort  to the center of gravity of a longeron of a frame, equal 23 cm,

to the center of gravity of a longeron of a frame, equal 23 cm,  N∙cm. The bending moment

N∙cm. The bending moment  arising on a front bracket of springs from action of effort

arising on a front bracket of springs from action of effort  , we will determine by dependence of M2 = - 0,5(T1 +T2 +T3)0,05l2 4,7∙103 N∙cm, where

, we will determine by dependence of M2 = - 0,5(T1 +T2 +T3)0,05l2 4,7∙103 N∙cm, where  — distance from a point of application of loading of a finger of a spring to the longeron center of gravity, equal 17cm; 0,05 — rolling friction coefficient of wheels of the trailer. Geometrical characteristics of welded nodes, sections of a frame of the I—XI are respectively equal [1]

— distance from a point of application of loading of a finger of a spring to the longeron center of gravity, equal 17cm; 0,05 — rolling friction coefficient of wheels of the trailer. Geometrical characteristics of welded nodes, sections of a frame of the I—XI are respectively equal [1] Numerical values of the flexural moments M (Z ) and bimoments B(ω) make [1]:

Numerical values of the flexural moments M (Z ) and bimoments B(ω) make [1]: For calculation of summary tension numerical values them are used known for dependences as a result made [1]:

For calculation of summary tension numerical values them are used known for dependences as a result made [1]: Analyzing last it is visible that their greatest values arise around the fifth cross-piece set in a place of a perkvy spring node of a frame of the trailer, and make 292,3 МPа, and in this zone of tension of the constrained torsion reach 148,5 МPа, and flexural tension 143,8 МPа. Such values of tension considerably exceed fatigue value of welded nodes of a frame, koktory, according to some information [1], doesn't exceed 50 МPа therefore in practice the longevity of a frame of the trailer 2ПТС-4-793A will be neudovletkvoritelny. Similar calculations are executed and for a frame of the tractor dumping trailer 2ПТС-4-793A supplied with a frame including removable brackets of springs executed according to the patent SU1189718. Calculations showed that tension of the constrained torsion reaches in this case 36,5 МPа, and flexural tension remained same 143,8 МPа. As a result it is visible that tension of the constrained torsion is much lower, than at a serial frame 36,5МPа < 148,5МPа and doesn't exceed fatigue value 50 МPа. Therefore, reliability of a frame of the upgraded trailer will be much higher.It was marked above that in operational conditions of a frame of trailers and semi-trailers shall respond the principal criterion of operability of machines - reliabilities. It is known that as reliability understand – property of a product to execute the functions during the preset time or the given operating time, saving in the given limits operational indexes. Reliability of products is caused by their faultlessness, longevity, maintainability and a keeping. It is clear that the offered construction of a frame shall be under repair together with that machine on which it is mounted, at the mashinoremontny enterprise representing variety of machine-building and executing according to specifications of repair of machines (aggregates, nodes, details, etc.) lost normal working capacity, but still peculiar preparations maintainable and executing a role for this production. Unlike mechanical engineering repair production includes specific technological processes such as: washing, disassembling, troubleshooting and repair of elements of machines. To customer it is the extremely important that in case of repair of machines, and also in case of changeover of their short-lived details there would be as little as possible ballast operations, i.e. machines with the minimum expenses of work, materials and energies on their disassembling and washing, exception replaced constructive and deleting short-lived nonconstructive elements are necessary. Proceeding from the expenses, the appropriate ballast operations in case of repair, maintenance or changeover of constructive elements of machines, give the quantitative assessment of their maintainability characterized by coefficient of maintainability [20].The coefficient of maintainability of the machine can be determined as the relation of average expenses of work, energy and the materials which are required for introduction in the machine of replaced and renewable elements, to the amount of expenses of work, energy and materials on its disassembling and washing together with assembly, regulation and restoration of other nonconstructive elements by dependence:

Analyzing last it is visible that their greatest values arise around the fifth cross-piece set in a place of a perkvy spring node of a frame of the trailer, and make 292,3 МPа, and in this zone of tension of the constrained torsion reach 148,5 МPа, and flexural tension 143,8 МPа. Such values of tension considerably exceed fatigue value of welded nodes of a frame, koktory, according to some information [1], doesn't exceed 50 МPа therefore in practice the longevity of a frame of the trailer 2ПТС-4-793A will be neudovletkvoritelny. Similar calculations are executed and for a frame of the tractor dumping trailer 2ПТС-4-793A supplied with a frame including removable brackets of springs executed according to the patent SU1189718. Calculations showed that tension of the constrained torsion reaches in this case 36,5 МPа, and flexural tension remained same 143,8 МPа. As a result it is visible that tension of the constrained torsion is much lower, than at a serial frame 36,5МPа < 148,5МPа and doesn't exceed fatigue value 50 МPа. Therefore, reliability of a frame of the upgraded trailer will be much higher.It was marked above that in operational conditions of a frame of trailers and semi-trailers shall respond the principal criterion of operability of machines - reliabilities. It is known that as reliability understand – property of a product to execute the functions during the preset time or the given operating time, saving in the given limits operational indexes. Reliability of products is caused by their faultlessness, longevity, maintainability and a keeping. It is clear that the offered construction of a frame shall be under repair together with that machine on which it is mounted, at the mashinoremontny enterprise representing variety of machine-building and executing according to specifications of repair of machines (aggregates, nodes, details, etc.) lost normal working capacity, but still peculiar preparations maintainable and executing a role for this production. Unlike mechanical engineering repair production includes specific technological processes such as: washing, disassembling, troubleshooting and repair of elements of machines. To customer it is the extremely important that in case of repair of machines, and also in case of changeover of their short-lived details there would be as little as possible ballast operations, i.e. machines with the minimum expenses of work, materials and energies on their disassembling and washing, exception replaced constructive and deleting short-lived nonconstructive elements are necessary. Proceeding from the expenses, the appropriate ballast operations in case of repair, maintenance or changeover of constructive elements of machines, give the quantitative assessment of their maintainability characterized by coefficient of maintainability [20].The coefficient of maintainability of the machine can be determined as the relation of average expenses of work, energy and the materials which are required for introduction in the machine of replaced and renewable elements, to the amount of expenses of work, energy and materials on its disassembling and washing together with assembly, regulation and restoration of other nonconstructive elements by dependence:

where

where  and

and  - mean values of the conformance and the costs appropriate to the volume of ballast operations in case of maintenance, repair or changeover of short-lived constructive elements.For determination of coefficient of maintainability of a frame of the trailer, for example, models 2ПТС-4-887A of the Balashov plant of automobile and tractor trailers of fixing of brackets of springs supplied with offered construction and serial, the analysis of financial activities of a workshop of agro-industrial complex of the Yelets region of the Lipetsk region for the period 2009-2013g.g is carried out. on which major repair of similar trailers is made. The analysis showed that the general expenses of work, energy and materials for repair of one frame average Qic = 18856 rub, and ballast operations are equal to qic = 9950 rub. Therefore, the coefficient of maintainability of a serial frame is equal to Fp = 0,65. For offered construction of a frame of the trailer approximately at the expense of easily deleted from its longerons, without use of gas-welding operations and traumatizing in this case shelves and walls of longerons and cross-pieces, brackets of springs, repair costs can make no more Qic = 12230 rub in case of reduction in cost of ballast operations to qic = 5050 rub. In this case the coefficient of maintainability will be equal to Fp = 0,71. It is visible that construction of a frame of the trailer executed according to the patent SU1189718 has higher coefficient of maintainability that speaks about efficiency of use of this technical solution in practice.The analysis of numerous references, domestic and foreign patents also allowed to develop perspective constructions of frames of semi-trailers of the increased reliability at the level of inventions (SU1539117, SU1638056 and RU1066871). Such constructions differ from known domestic and foreign analogs that reference sheets of shoulders of frames don't superimpose tight coupling on shelves of longerons and allow them freely deform elastically in case of their torsion in the longitudinal plane of the semi-trailer, and brackets of springs represent removable nodes also providing the free deplanation of the lower shelves of longerons and the cross-pieces which are in a zone of their contiguity to brackets of springs.In fig. 6 the end view of a frame of the semi-trailer, and a frame node with one of brackets of springs in the long term (SU1539117 and SU1638056) is shown.

- mean values of the conformance and the costs appropriate to the volume of ballast operations in case of maintenance, repair or changeover of short-lived constructive elements.For determination of coefficient of maintainability of a frame of the trailer, for example, models 2ПТС-4-887A of the Balashov plant of automobile and tractor trailers of fixing of brackets of springs supplied with offered construction and serial, the analysis of financial activities of a workshop of agro-industrial complex of the Yelets region of the Lipetsk region for the period 2009-2013g.g is carried out. on which major repair of similar trailers is made. The analysis showed that the general expenses of work, energy and materials for repair of one frame average Qic = 18856 rub, and ballast operations are equal to qic = 9950 rub. Therefore, the coefficient of maintainability of a serial frame is equal to Fp = 0,65. For offered construction of a frame of the trailer approximately at the expense of easily deleted from its longerons, without use of gas-welding operations and traumatizing in this case shelves and walls of longerons and cross-pieces, brackets of springs, repair costs can make no more Qic = 12230 rub in case of reduction in cost of ballast operations to qic = 5050 rub. In this case the coefficient of maintainability will be equal to Fp = 0,71. It is visible that construction of a frame of the trailer executed according to the patent SU1189718 has higher coefficient of maintainability that speaks about efficiency of use of this technical solution in practice.The analysis of numerous references, domestic and foreign patents also allowed to develop perspective constructions of frames of semi-trailers of the increased reliability at the level of inventions (SU1539117, SU1638056 and RU1066871). Such constructions differ from known domestic and foreign analogs that reference sheets of shoulders of frames don't superimpose tight coupling on shelves of longerons and allow them freely deform elastically in case of their torsion in the longitudinal plane of the semi-trailer, and brackets of springs represent removable nodes also providing the free deplanation of the lower shelves of longerons and the cross-pieces which are in a zone of their contiguity to brackets of springs.In fig. 6 the end view of a frame of the semi-trailer, and a frame node with one of brackets of springs in the long term (SU1539117 and SU1638056) is shown.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML