-

Paper Information

- Next Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Traffic and Transportation Engineering

p-ISSN: 2325-0062 e-ISSN: 2325-0070

2014; 3(1): 1-7

doi:10.5923/j.ijtte.20140301.01

To the Question of Modernization of Current Collectors and Contact Network of the Electric Stock

E. V. Slivinsky1, D. N. Klimov2

1T. E. Mitinа, senior teacher, S.Y. Radin, associate professor, Cand.Tech.Sci

2Assistant, Yelets state university name I.A. Bunin (Russia, Yelets)

Correspondence to: E. V. Slivinsky, T. E. Mitinа, senior teacher, S.Y. Radin, associate professor, Cand.Tech.Sci.

| Email: |  |

Copyright © 2012 Scientific & Academic Publishing. All Rights Reserved.

The materials concerning research and modernization of current collectors of electric locomotives are presented in the present article and the reasons influencing wear of a runner and a contact wire of the last are established. Objective of this research is development at the level of the invention of the technical solution allowing in an automatic mode to carry out movement of a runner of a current collector of rather contact wire at movement of a current collector, and also carrying out the analytical researches, allowing defining the main indicators of the proposed technical solution. Results of research are recommended to research and industrial structures in the field of a locomotive engineering for the purpose of its further studying and possible introduction in practice.

Keywords: The current collector, Slide, Contact wire, Groove, Bridge, Dropper, Spring group, Length of span, Cylinder, Saw cut

Cite this paper: E. V. Slivinsky, D. N. Klimov, To the Question of Modernization of Current Collectors and Contact Network of the Electric Stock, International Journal of Traffic and Transportation Engineering, Vol. 3 No. 1, 2014, pp. 1-7. doi: 10.5923/j.ijtte.20140301.01.

Article Outline

1. Introduction

- Mechanical interaction of current collectors and contact spring group is process on which quality reliability and profitability of electric draft significantly depends. It is known[1,9,12], that the main criterion of quality current collection and efficiency of its use are the minimum given expenses consisting of the current expenses and a share of capital expenditure defined in standard effectiveness ratio on current collectors and a contact network. The analysis of expenses of the electrified railroads connected with operation shows that one of serious articles are the expenses connected with wear of contact wires, and also plates and inserts полозов current collectors. Decrease in wear of the above elements in practice reach at the expense of application of modern wearproof materials and manufacturing techniques of contact plates (inserts) of current collectors and contact wires. However the solution only one such way isn't possible as the serious factor influencing wear of kinematic couple a plate of a runner - the contact wire is value of contact pressing and nature of its change in process of sliding of a current collector of an electric stock on a contact wire. It is known also that real processes of mechanical interaction of current collectors with contact suspension brackets are casual and if to exclude from them wind impact on the last, the major factors influencing casual nature of excitement on a current collector, from a contact suspension bracket, are instability of height of contact wires in flights, a deviation of the geometrical sizes of suspension brackets from optimum values, change of a tension of wires along an anchor site, phase shift of indignations, etc.[1,4-10].

2. Strategic Aim

- Analyzing the above it is visible that existing designs of current collectors of electric locomotives possesses a number of essential shortcomings which considerably reduce operational reliability of cargo and passenger electric locomotives and other electric stock. Therefore, now I ripened need for modernization of current collectors due to uniform wear полозов current collectors. Considering it, in EGU of I.A.Bunin, on chair of applied mechanics in common throughout a row of years NIR on the subject Dynamics, Durability and Reliability of Transport, Construction and Road and Agricultural Cars, and also the Industrial Standard and Non-standard Equipment in relation to the Chernozem Region of the Russian Federation; is carried out and one of its sections is the scientific direction connected with development of perspective designs of knots and units as locomotives, and electric locomotives. possessing increased technical and operational reliability. The analysis of numerous bibliographic sources, and also domestic and foreign patents allowed to develop at the level of the invention (SU1039754) a perspective design of a current collector of an electric locomotive raising its reliability and cutting an expense of a contact wire on the electrified sites of roads. Therefore, a research objective is studying of operability of the offered design and definition of its main geometrical constructional characteristics allowing giving bases for its design and further possible use in practice.

3. Research Technique

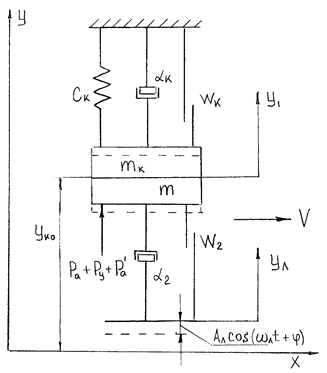

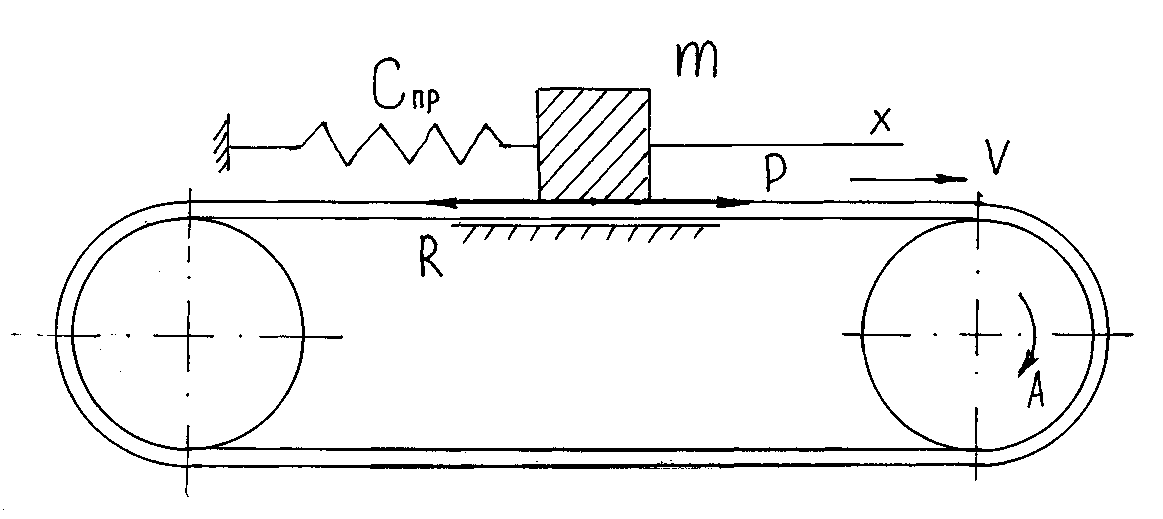

- In view of variety of random factors being shown in field environment to investigate theoretically dynamic system a current collector – a contact suspender in full rather difficult and therefore simpler for theoretical probes and for practical use consideration of the determined processes is sufficient. For drawing up the equations of movement at its interaction with a contact conductor, for example,[1,8,19] the settlement scheme shown in fig. 1 is used.

| Figure 1. Design scheme |

,where, αк and α2 – coefficients of damping of a contact conductor and slip ring snubbers; ск – ruggedness of a suspender of a contact conductor;Wsign – forces of resistance of dry friction;Contact pressing can be determined by dependence also:

,where, αк and α2 – coefficients of damping of a contact conductor and slip ring snubbers; ск – ruggedness of a suspender of a contact conductor;Wsign – forces of resistance of dry friction;Contact pressing can be determined by dependence also: .The inertial force of Pа' calculate on an approximate formula[1]:

.The inertial force of Pа' calculate on an approximate formula[1]: where, G'2 – the gravity of movable frames of a current collector given to a shaft of its top hinges;m2 - proper mass of all current collector.For an assessment of an inertial component of pressing at predesigns usually don't consider influence of fluctuations of locomotives or motor cars in electric trains on process current collection, and are limited to consideration of set process of movement of a contact point with a known mass of a current collector. So, if, for example, conveyance of a runner of a current collector is carried out on the rigid tire, the maximum value of Ra can be calculated, using the following dependences:

where, G'2 – the gravity of movable frames of a current collector given to a shaft of its top hinges;m2 - proper mass of all current collector.For an assessment of an inertial component of pressing at predesigns usually don't consider influence of fluctuations of locomotives or motor cars in electric trains on process current collection, and are limited to consideration of set process of movement of a contact point with a known mass of a current collector. So, if, for example, conveyance of a runner of a current collector is carried out on the rigid tire, the maximum value of Ra can be calculated, using the following dependences: where, Aш – a tire or rail deflection; lш – distance between points of subweight of the tire.At the recordkeeping of fluctuations of a wire the equation of fluctuations of a current collector as a whole has the following appearance[1]:

where, Aш – a tire or rail deflection; lш – distance between points of subweight of the tire.At the recordkeeping of fluctuations of a wire the equation of fluctuations of a current collector as a whole has the following appearance[1]: ,where, yki – conveyance of a runner of a current collector; x – the horizontal coordinate of a contact point of a runner with a wire;аВ – the speed of distribution of the front of a running wave along a conditional wire depending on a total tension of a wire (A cable + the Contact conductor) and firmness ρк both such components)

,where, yki – conveyance of a runner of a current collector; x – the horizontal coordinate of a contact point of a runner with a wire;аВ – the speed of distribution of the front of a running wave along a conditional wire depending on a total tension of a wire (A cable + the Contact conductor) and firmness ρк both such components)  For the solution of the specified equation use Dalamber's method in the form of running waves укi1 = (xi + aВt) и укi2 = (xi + aВt). After decomposition of these functions and yi(t) in a row Fourier on frequency ω and his substitutions in the equation:

For the solution of the specified equation use Dalamber's method in the form of running waves укi1 = (xi + aВt) и укi2 = (xi + aВt). After decomposition of these functions and yi(t) in a row Fourier on frequency ω and his substitutions in the equation: It is possible to define decomposition coefficients αi and βi for PVi. Then having defined yi(t) and having replaced a variable t with xi = υt it is possible to construct a trajectory of movement of a current collector of yi (x) and as a result to determine contact pressing of i of a current collector by a formula:

It is possible to define decomposition coefficients αi and βi for PVi. Then having defined yi(t) and having replaced a variable t with xi = υt it is possible to construct a trajectory of movement of a current collector of yi (x) and as a result to determine contact pressing of i of a current collector by a formula: At high speeds of movement vertical conveyances of wires of chain suspenders, and also a trajectory of movement of current collectors depends not only from ск and P and the mechanical resistance of system a contact suspender – a current collector, but also on a ratio of own and compelled fluctuations of system. So from the theory of fluctuations it is known[3] that the ratio of conveyances in oscillatory schemes under the influence of static and dynamic loadings is defined by dynamic coefficient λД and, for example, for system with one degree of freedom it is equal[4,9]:

At high speeds of movement vertical conveyances of wires of chain suspenders, and also a trajectory of movement of current collectors depends not only from ск and P and the mechanical resistance of system a contact suspender – a current collector, but also on a ratio of own and compelled fluctuations of system. So from the theory of fluctuations it is known[3] that the ratio of conveyances in oscillatory schemes under the influence of static and dynamic loadings is defined by dynamic coefficient λД and, for example, for system with one degree of freedom it is equal[4,9]: where, ω – the frequency of the compelled fluctuations of system;р – own frequency of fluctuations of system;hз – attenuation coefficient.Frequency of own fluctuations of contact suspenders can be determined by a formula[4,9]:

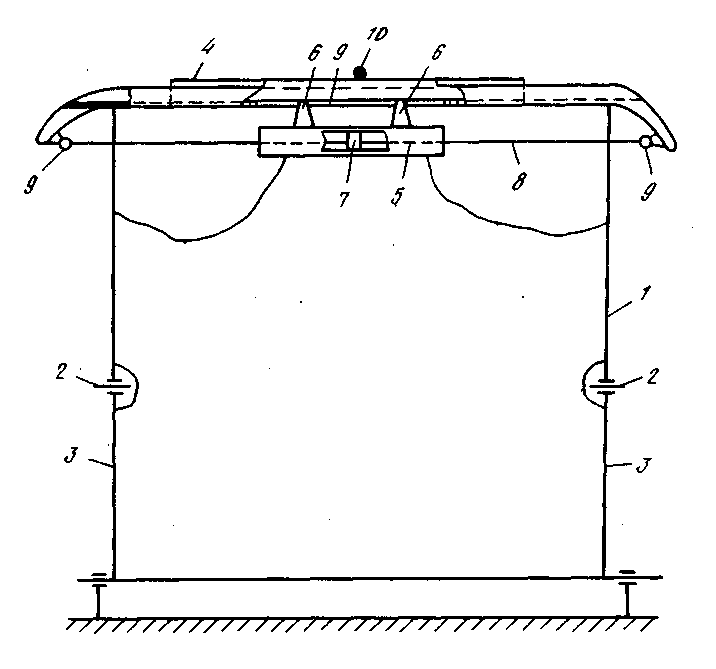

where, ω – the frequency of the compelled fluctuations of system;р – own frequency of fluctuations of system;hз – attenuation coefficient.Frequency of own fluctuations of contact suspenders can be determined by a formula[4,9]: where, α – the coefficient depending on a design of a contact suspender, equal 0,5[1]; qk – loading from 1 m of a contact suspender.On the basis of the frequency characteristic of a suspender it is possible to determine the critical speed which is observed at equality of frequencies of own and compelled fluctuations (resonance) of a suspender of fB = V/3,6l and to determine it by a formula Vkp = 3,6lfk.Analyzing the above it is visible that, despite the mathematical apparatus available and described above allowing to make quite high-quality synthesis of system current collection a rolling stock, modern designs of current collectors and system of subweight of a contact conductor are still far to perfection.Let's consider a technical solution (fig. 2) which is recognized by the invention[2] and contains a runner established on the top frame 1, and it by means of fig. 2.

where, α – the coefficient depending on a design of a contact suspender, equal 0,5[1]; qk – loading from 1 m of a contact suspender.On the basis of the frequency characteristic of a suspender it is possible to determine the critical speed which is observed at equality of frequencies of own and compelled fluctuations (resonance) of a suspender of fB = V/3,6l and to determine it by a formula Vkp = 3,6lfk.Analyzing the above it is visible that, despite the mathematical apparatus available and described above allowing to make quite high-quality synthesis of system current collection a rolling stock, modern designs of current collectors and system of subweight of a contact conductor are still far to perfection.Let's consider a technical solution (fig. 2) which is recognized by the invention[2] and contains a runner established on the top frame 1, and it by means of fig. 2. | Figure 2. General view of the susceptor Patent SU1039754 |

.

. | Figure 3. Settlement scheme of compulsory conveyance of a runner |

| (1) |

,

,  и

и .It is known[3] that the solution of the equation (1) is respectively the sum of the common and private decision of the equations of a look:

.It is known[3] that the solution of the equation (1) is respectively the sum of the common and private decision of the equations of a look:

.In the first case the decision looks like

.In the first case the decision looks like  , in the second

, in the second  . Having differentiated twice the last equation and having defined its coefficients which are respectively equal

. Having differentiated twice the last equation and having defined its coefficients which are respectively equal  ,

,  ,

,  , and, we will receive the common decision of the equation (1) in a look:

, and, we will receive the common decision of the equation (1) in a look:

Coefficients of C1 and C2 are determined proceeding from entry conditions when by t = 0 and x = 0, and are respectively equal to C1 = 0, and

Coefficients of C1 and C2 are determined proceeding from entry conditions when by t = 0 and x = 0, and are respectively equal to C1 = 0, and  . As a result the private decision will become:

. As a result the private decision will become: | (2) |

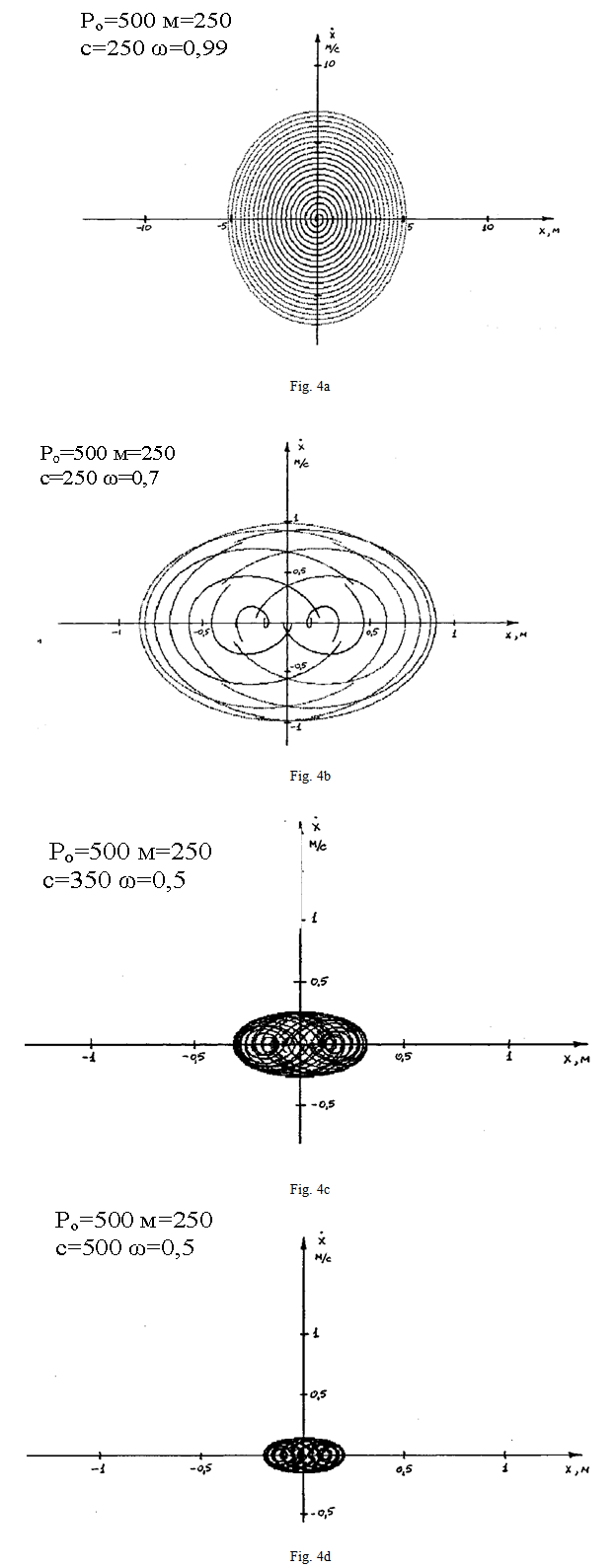

x.For creation of such trajectories, according to data of a source[1] the following numerical values of initial parameters in relation to modern current collectors of domestic electric locomotives and a contact suspender are accepted: m = 2 ∙ 102 - 3∙102 N; CПР =2 ∙ 102 - 5∙102 N/m; P0 = 3 ∙ 102 - 7∙102 N; ω = 0,5 – 2,5 sec-1. As a result, with use of a program complex on the COMPUTER, a number of schedules allowing to study nature of self-oscillatory process of details of the proposed technical solution is constructed. As an example in fig. 4-a, b, с, d are shown characteristic families of phase portraits of movement of a contact conductor on the axes y and x (with dimensions respectively m/s and m) relevant to self-oscillations of the systems with increase in numerical value of СПР.

x.For creation of such trajectories, according to data of a source[1] the following numerical values of initial parameters in relation to modern current collectors of domestic electric locomotives and a contact suspender are accepted: m = 2 ∙ 102 - 3∙102 N; CПР =2 ∙ 102 - 5∙102 N/m; P0 = 3 ∙ 102 - 7∙102 N; ω = 0,5 – 2,5 sec-1. As a result, with use of a program complex on the COMPUTER, a number of schedules allowing to study nature of self-oscillatory process of details of the proposed technical solution is constructed. As an example in fig. 4-a, b, с, d are shown characteristic families of phase portraits of movement of a contact conductor on the axes y and x (with dimensions respectively m/s and m) relevant to self-oscillations of the systems with increase in numerical value of СПР. | Figure 4(a-d). Phase portraits of movement of a contact conductor |

4. Outcome of Interest

- The analysis of a trajectory of fig. 4a shows that behavior of self-oscillatory system at P0 = 5∙102 N, m = 2,5∙102 N, СПР =2,5∙102 N/m and ω = 0,99 sec-1, is in area close to a resonance. In this case it is visible that the speed of movement of a contact conductor and its conveyance grow beyond all bounds, and it finally will lead to failure of a contact conductor from a current collector runner that is inadmissible. Therefore at a choice of frequency of the compelling force created by a drive gear of a runner of a current collector, it is necessary that this frequency was as much as possible other than own frequency of fluctuations of system. In fig. 4-б the phase portrait corresponding to self-oscillations of system with similar values P0, m and CПР as well as for the first case is shown but with a smaller frequency ω = 0,7 sec-1. Therefore it is visible that all the same amplitudes of fluctuations are very considerable that is also inadmissible. In fig. 4-c when ruggedness of СПР = 3,5∙102 N/m is increased, and the frequency of fluctuations is reduced almost twice in comparison with the first case and is equal ω = 0,5 sec-1, amplitude of fluctuations of a contact conductor at a speed of 0,25 m/s makes about 0,37 m. With a known length of a sliding bar of a current collector which on the average for domestic electric locomotives makes 1100 mm such conveyances of a contact conductor the also high. The most optimum characteristics of considered self- oscillatory system is the phase portrait presented in fig. 4-д. In this case, when СПР =5∙102 N/m, and ω = 0,5 sec-1 and at a speed about 0,09 m/s, amplitude of fluctuations doesn't exceed 0,12 m. The carried-out calculations allow to draw the following conclusion. Optimum parameters for the considered self-oscillatory system a contact wire runner of a current collector in relation to the proposed technical solution, are: СПР =5∙102 N/m, ω = 0,5 sec-1, m = 2,5∙102 N and P0 = 5∙102 N. In this case the forward speed of a sliding bar which creates a pneumatic drive of its steering, has to be no more than 1,0 m/min. First, such low forward speed of conveyance of a sliding bar will create favorable conditions on uniform mechanical wear of its contact area and, secondly, won't have essential impact on electric wear of interfaced surfaces of forward kinematic couple sliding bar-contact wire.As a result it should be noted also one more advantage of the proposed technical solution in comparison with known designs of a food of an electric stock which is that it allows to save a contact conductor at creation as new, and at the contents and repair being operated a contact suspender.So, it is known[1,4,7,14] that for the purpose of wear drop, both a runner of current collectors, and a contact conductor the last in a contact suspender have in zigzag fashion in relation to a longitudinal shaft of symmetry of a railway line, and the size of such zigzag in the various countries on the average lies ranging from 200 mm (France Switzerland, etc.) to 400 mm (Great Britain, Poland, Russia, etc.) and the last settles down on length of 50m between bearing parts. Therefore, on 100km of a rectilinear single-line stage at a zigzag in 400mm it is possible to receive economy of a contact conductor about 4,0m. If to consider that a way two-acceptable and there are curves in those and other directions, and also access and station ways that it is possible to receive in such option economy of a contact conductor already more than 15m by 100km a site of the electrified site. Therefore if to use a current collector design with a mobile runner, it allows first, completely to exclude the specified zigzags and secondly it is possible to gain about the country the corresponding economic effect connected with drop of expenses for acquisition of a scarce contact conductor. The calculation of economic efficiency of the possible implementation of the proposed design of current collector, for example, for passenger electric locomotive CS7 made by the method[21] showed that in the year can be produced cost savings associated with the renovation of the susceptor in the amount of 212 thousand rubles in a year on one a locomotive.

5. Deduction

- Results of probe are recommended for further studying, completion and possible introduction of a perspective design of a current collector at the enterprises of heavy mechanical engineering and JSC «Russian Railways» serially issued, repairing and operating not only electric locomotives, but also electric trains, and also in systems of VSNT of domestic and foreign production. The computer program is developed for calculation of the above characteristics of the proposed technical solution with Delphi language use which is approved on an example shown above. It should be noted also that the settlement parameters determined by this technique, are approximate and can't be recommended for momentary application and therefore for a final assessment of efficiency of use of the proposed technical solution it is necessary to carry out its broad tests for working capacity and efficiency of use.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML