Slivinskiy Е. V., Gridchina I. N., Radin S. Yu.

Yelets State University name I. A. Bunin

Correspondence to: Slivinskiy Е. V., Yelets State University name I. A. Bunin.

| Email: |  |

Copyright © 2012 Scientific & Academic Publishing. All Rights Reserved.

Abstract

This article presents information on the development of advanced device structures aimed at improving the sustainability of full trailers, transported in the train car, wagging at last. Based on the analysis of existing designs automotive trains revealed their significant drawbacks, and one of them is the question of stability of motion trailed their links. Therefore, the aim of this study is to develop technical solutions created at the level of inventions so as to avoid wagging trailer as it moves in the automotive trains. As a result of conducted analyzes of vibrations and force loading of structural elements of the trailer, can justify the basic rational geometric parameters of such structures. For this purpose developed numerical schemes and methods of the study, with the help of which explored issues of reducing vibration trailers. Results of the study are recommended for both domestic and foreign research and industrial structures in the automotive industry for the purpose of further study and possible implementation in practice.

Keywords:

Trailer-truck, Pick Up, Driving Rod, Dolly, Torsion Bar, Roughness, Wabling, Cushioning, Place Tractive, Drawbar

Cite this paper: Slivinskiy Е. V., Gridchina I. N., Radin S. Yu., Technical Development Activities to Improve Stability of Motion Tow Links Automotive Train, International Journal of Traffic and Transportation Engineering, Vol. 2 No. 5, 2013, pp. 120-133. doi: 10.5923/j.ijtte.20130205.04.

1. Introduction

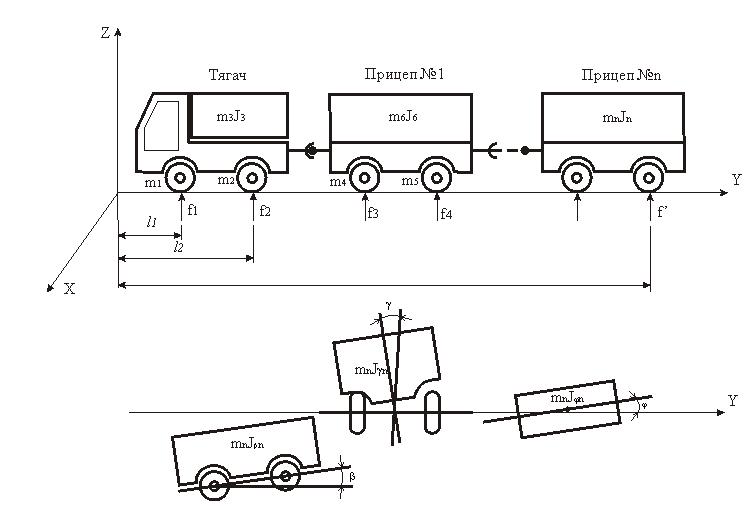

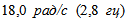

It is known[1-8] that one of the most important industrial structures of the national economy are the vehicles and the general development of their infrastructure. The development of the transport system is especially important for geographically large states, so for Russia, this problem has been, is and will be one of the most important parts of the effective economic development and quality of life.At present, the international community widely used car trains for the transport of cargo and vehicle consisting of a tractor and two-axle trailer-truck (Fig. 1). | Figure 1. General view of the train |

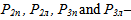

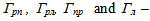

One of the most important structural elements of automotive trains, from the point of view of safety of their movement, as well as ease of use and security of cargo, are the fifth wheel, brake, electrical and pneumatic-hydraulic equipment. A distinctive feature of the towed vehicles is the availability of devices that enhance the stability of the motion, which perform a number of important functions, to ensure the stability of the longitudinal and transverse motion cushioning of impacts under varying modes of interaction of the individual components of the train units, as well as the convenience and minimum time for the formation of the composition.A distinctive feature of the towed vehicles is the availability of devices that enhance the stability of the motion, which perform a number of important functions, to ensure the stability of the longitudinal and transverse motion cushioning of impacts under varying modes of interaction of the individual components of the train units, as well as the convenience and minimum time for the formation of the composition.It is known[5] that the vehicle, the driver and the road is a part of an existing single objective, the whole system called Vadsø. Reliability, as a single vehicle and multi-hop trains, and, hence, its safety in an operational environment depends primarily on three main indicators characterizing the quality of design, manufacturability, and proper exploitation related not only to traffic safety, but and to maintenance and repair.Given this general analyzes information available in the literature to assess the vibration and motion stability of automotive trains based on an analysis of studies on the interaction of links automotive trains in their tractive connection authors Khachaturova A.A., Zakina Ya.Kh., Shchukin M.M., Velykanova D.P., Morozov V.I., Bakhmutsky M.M., Aksenov A.I., Nazarenko A.G., Rothenberg R.V., Yatsenko N.N., Ellis D.R. and etc. The nature of oscillations of the links automotive trains similar to the vibrations of rail rolling stock and therefore approaches the study of such processes and techniques in general the same. In this area also has a large number of works performed by authors such as Galeev А.U., Lazaryanov V.А.. Phlorinskiy Ph.V., Vershinskiy S.V., Chelnokov I.I., Kovalev N.А., Kochnov А.D., Кostin G.V., Struvillo А.B. and atc. At the same time known. that all the dynamic forces in the movement of automotive trains and rolling stock are perceived not only the fifth wheel of their devices but also Suspension spring kits, and, hence, their frame structures and bodies. In the course of many years of experience in the design and operation of vehicles towed their frames taken some form layout but, despite this, they are already not meet the ever increasing requirements of reliability and reducing their metal content. A significant contribution to the development of design methods and design of the chassis and support systems trackless vehicles have Bocharov N.Ph., Gelphgat D.B., Gorbunov B.N., Vlasov V.Z., Zaks М.I., Кobrin М.М., Dmitrichenko S.S., Proskuryakov V.B. and etc. Road Train is a complex multi-axis lot of mass dynamic system with a set of elastic and dissipative elements, different types of disturbances which take place to be linear and angular, own, forced, parametric and other fluctuations.In general, the generalized model of the dynamics of train consisting of a pick up and trailer-truck N is shown in Figure 2, thus, the following assumptions are:1) Not taken into account the stiffness and cushioning elements to the frame mounting: engine, body, cabin, etc.2) We do not consider fluctuations acting on the driver's view of the cushioning devices seats.3) Not counted cushioning lateral elasticity of tires.4) Mass and moments of all elements of the sprung one link are considered uniform.5) The mass of the wheels and axles make only vertical movement.Based on the assumptions made, consider the motion of the pick up with the linear displacement of the center of mass pick up X0, Y0, Z0 and angles of  rotation about the axes of pick up Z, X, Y.As a result of the assumed model using the Lagrange equation of the second kind (1) deciding which known methods allows you to set the resonant oscillation of the mass units train and develop as a result of practical recommendations on the modernization of trains running parts.

rotation about the axes of pick up Z, X, Y.As a result of the assumed model using the Lagrange equation of the second kind (1) deciding which known methods allows you to set the resonant oscillation of the mass units train and develop as a result of practical recommendations on the modernization of trains running parts. | (1) |

Modern Motor and trains usually consist of a pick up pivotally connected with the coupling devices with trailer-trucks, the number of which is limited in the train GOST 9314-59. | Figure 2. Generalized model trains |

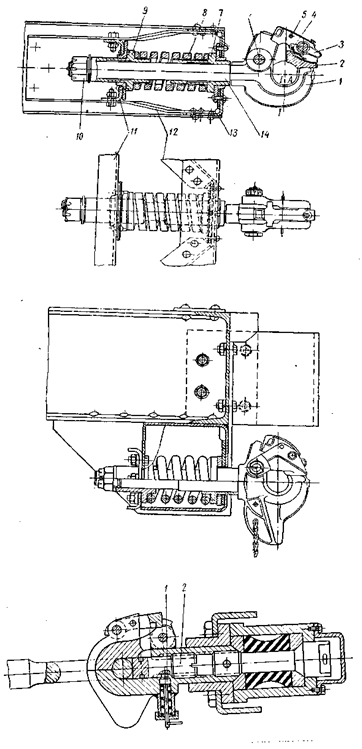

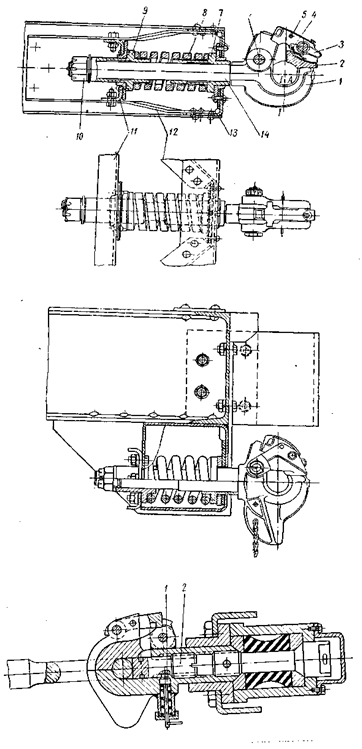

In the process of pulling away, braking, or of uniform motion in the frames of a pick up and trailer links there are significant dynamic loads, as well as the spatial variation (twitching, lateral pitching, pitching, wagging, lateral drift, etc.) that have a significant impact on the reliability such machines and the safety of their operation. To reduce the dynamic loads in the trailer coupling devices of motor rolling enter different in design depreciation absorbing devices and apparatus. According to the classification of Shchukin M.M. amortized-absorbing mechanisms to share with the damping resistance mechanisms without it. These in turn are divided into a viscous dampers, internal and Coulomb friction. The main part of an amortization-absorbing mechanism is an elastic element with linear or non-linear characteristics. The most widely-absorbing shock-absorbing mechanisms, which include elastic elements made in the form of a twisted coil springs, ring springs and rubber bushings (Fig. 3). | Figure 3. Types of absorbing mechanisms |

It is known that under the action of road unevenness oscillation (in a transverse vertical plane) of the variable excited magnitude and direction of the dynamic forces. The action of the latter leads to significant angular oscillations trailers.Operating experience road train indicates that the rectilinear motion pick up having sizeable transverse trailer up oscillations in the horizontal plane, called wagging. Such fluctuations increase the width of the dynamic train, promote folding under braking, increase the wear chassis trailer and lead to rapid fatigue of the driver, etc. Given the above it at YSUname I.A. Bunin for a number of years at the Department of Applied Mechanics and Engineering Graphics conducted research on "Dynamics, durability and reliability of transport, road-building and agricultural machinery, as well as industry-standard and non-standard equipment in relation to the Black Earth region of Russia" and one of its sections through the NIRS is a scientific field that is associated with the development of advanced technological solutions that increase driving stability trucks. A number of these developments is recognized inventions - RU500086, RU521152, RU2232099, RU2258018, RU2284942, RU2268824, RU2341400, RU2341401, RU2337850, RU2339534, RU2372242, RU2397906, RU2397904, RU2464197, RU2457141, RU2465165 etc.Each of these structures has certain advantages and disadvantages. However, despite the fact that this problem the subject of many papers none to date has not found wide application because of its complexity, low reliability and efficiency of instability, a relatively high cost, etc.

2. The Purpose of the Study

The analysis set out above shows that despite the variety of technical solutions and design of damping devices installed in the vehicle seat tractive connection tractor-trailer and a trailer tongue of the junction with the dolly, the latter have not found wide use in practice due to imperfections in their design, high metal content, and low reliability etc. All this leads to the fact that the probability of collision with overtaking trailers or oppositely moving traffic is large, and it directly reduces traffic safety and eventually leads to substantial material losses of people and equipment. Therefore, the object and purpose of the study is:1. Working out at the level of the invention, high performance and easy on the design of damping devices installed at the junction with the frame dolly trailer-truck type 2PTS-4 and aimed at improving the safety of automotive multi-tier trains.2. Numerical calculations to substantiate the rational parameters above dampers meeting the requirements of safe operation of the trailer-trucks. 3. Development of a program for the solution of such a problem on a computer, with a view to the possible installation of dampers for different purposes-axle trailer-trucks, used both in this country and abroad.4. Develop practical methods of calculation promising devices for vibration damping of yaw to the existing two models of automotive axle trailer-trucks.

3. Method of Research

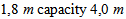

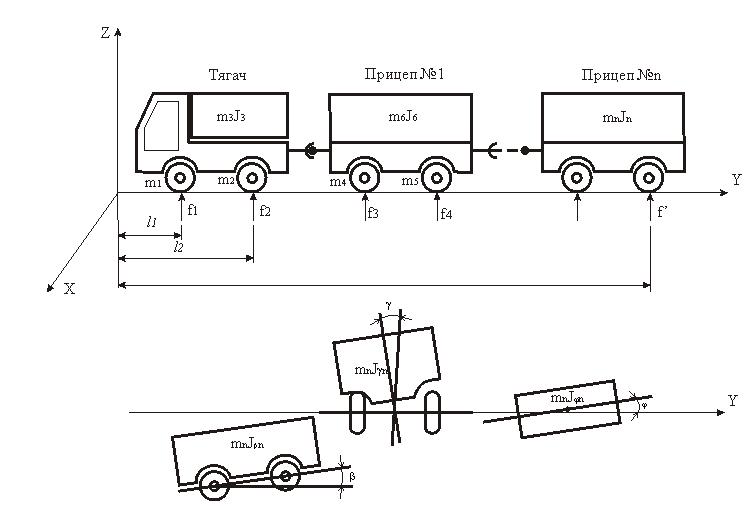

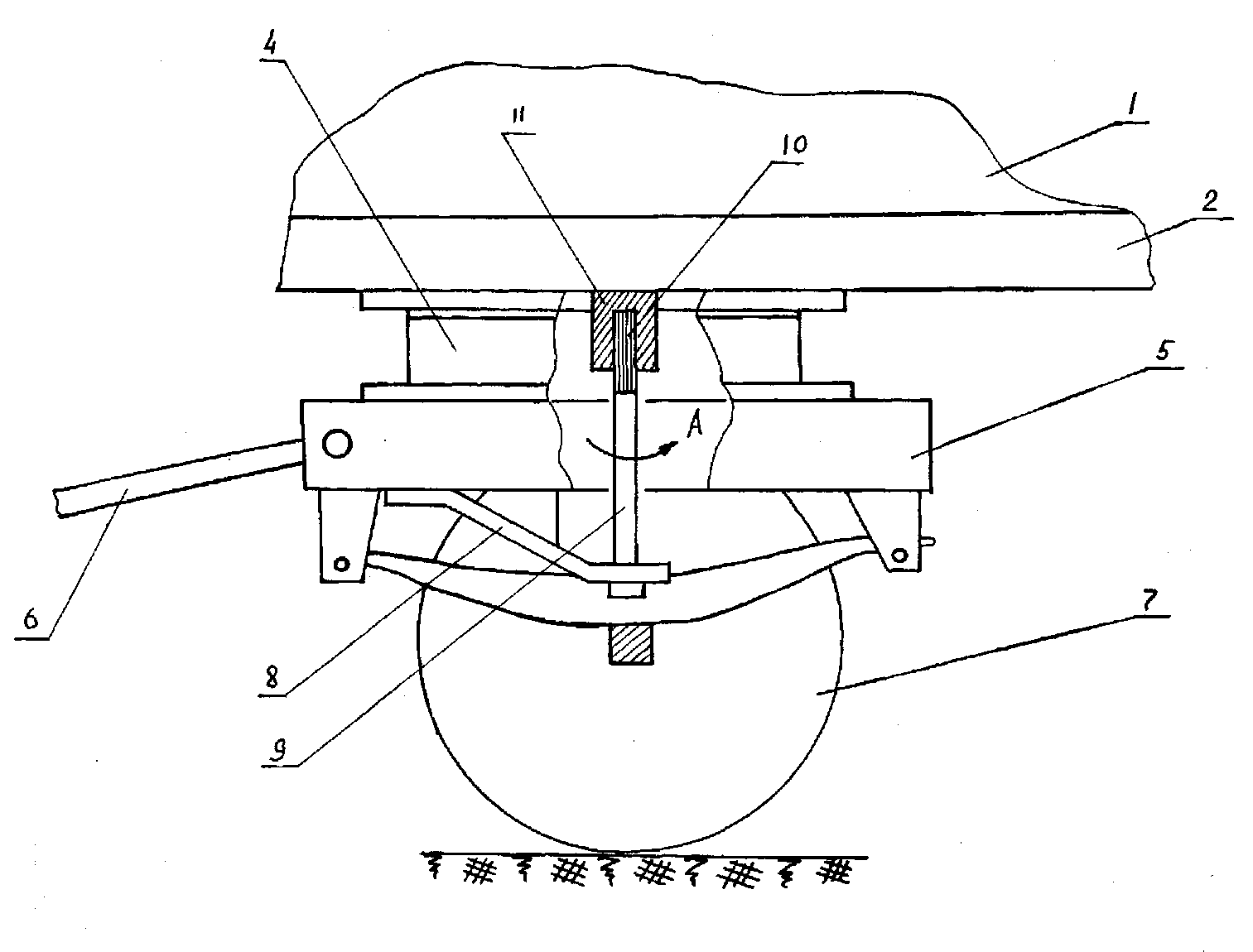

Analysis of the numerous existing structures damping devices installed in place of tractive connection pick ups and trailer-trucks, as well as patent and literature has allowed to develop a promising solution (RU2338658), having in comparison with the known simplicity of design and high performance in multi-tier environments of automotive trains.Figure 4 shows the front of the trailer with his dolly and a cut-away, which is a device for damping vibrations of trailer-truck yaw motion in the automobile and tractor train. The trailer consists of a body 1 mounted on the frame 2, which in its rear part with a driven wheel 3. At the front of the frame 2 mounted turntable 4, the bottom of which is attached to the dolly 5 equipped with a drawbar 6 and steering wheels 7. By dolly 5 is rigidly attached lever 8 is also rigidly attached to the elastic rod 9, the end of which is provided with splines 10 interconnected with counter executed in the sleeve 11 mounted on the frame 2.Works trailer-truck follows. If it moves in the automobile and tractor trains are known at speeds over 20 km / h in the straight running pick up begin to arise wagging vibrations. However, in this case, the amplitude of vibration is sharply reduced as follows. Since the angular rotation is accompanied by a wagging dolly 5 is an angular rotation gets together with her and arm 8 which is rigidly attached to the bogie 5. Since the lever 8 is also fixedly connected to the elastic rod 9, _ then it gets to a certain twist of the arrow A about its longitudinal axis. This angular rotation of the elastic rod 9 is further because the end thereof is provided with slots 10 is located in sleeve 11. It is known that the torsional rigidity of the device which is a matter of fact determined by the torsion dependence: ,when γ – twist angle of the elastic rod 9 (torsion bar), which is defined by the formula

,when γ – twist angle of the elastic rod 9 (torsion bar), which is defined by the formula  .Therefore it is clear the higher the twist angle of torsion bar γ generated torque Мкр attached to the dolly 5, the higher the damping capacity of the elastic rod 9. Picking up the rational dimensions d – diameter of the elastic rod and its working length ℓ can effectively extinguish not only wagging vibrations trailer vehicle, but also to provide angular rotation dolly 5 in a steep maneuvering of Automotive pick up.Let us first consider the ability to install the proposed technical solutions for automotive tractor trailer 2PTS-4-793A own weight

.Therefore it is clear the higher the twist angle of torsion bar γ generated torque Мкр attached to the dolly 5, the higher the damping capacity of the elastic rod 9. Picking up the rational dimensions d – diameter of the elastic rod and its working length ℓ can effectively extinguish not only wagging vibrations trailer vehicle, but also to provide angular rotation dolly 5 in a steep maneuvering of Automotive pick up.Let us first consider the ability to install the proposed technical solutions for automotive tractor trailer 2PTS-4-793A own weight  of mounted with the truck GAZ-53A own weight

of mounted with the truck GAZ-53A own weight  The masses of units train in this case are, respectively, will be

The masses of units train in this case are, respectively, will be

and the weight ratio of the characteristics of its reach

and the weight ratio of the characteristics of its reach

| Figure 4. Device eliminates wobble trailer-truck |

We define the critical force that arises in coupling device depending on the train[6]: ,when

,when  - коэффициент dynamism into account the effect of gaps in strip and equal 1,5;

- коэффициент dynamism into account the effect of gaps in strip and equal 1,5; - dynamic factor in the resonant vibrations of the system and equal 1,25;q0 - height of the bumps in the road, which is equal 6см;L – wave length roughness 2,5м.Assume that the trailer-truck tongue wagging in the trailer-truck with the dolly under the influence

- dynamic factor in the resonant vibrations of the system and equal 1,25;q0 - height of the bumps in the road, which is equal 6см;L – wave length roughness 2,5м.Assume that the trailer-truck tongue wagging in the trailer-truck with the dolly under the influence  turned at an angle 50 and then the shear force in its tractive connection with the hitch of the tractor is defined as

turned at an angle 50 and then the shear force in its tractive connection with the hitch of the tractor is defined as

In this case, at the time of dolly caused an angular rotation will be equal

In this case, at the time of dolly caused an angular rotation will be equal

(when

(when  drawbar length equal 1,8 м). Consequently, the angular rotation of the moment of resistance of an elastic rod Т an angle 50 should be slightly smaller than the moment М with the intention that after the disappearance of a specific point dolly back to the starting position straight-ahead the trailer-truck. Define the diameter of an elastic rod d the stabilizing device from the fact that Т = 2500 Н∙м well-known formula:

drawbar length equal 1,8 м). Consequently, the angular rotation of the moment of resistance of an elastic rod Т an angle 50 should be slightly smaller than the moment М with the intention that after the disappearance of a specific point dolly back to the starting position straight-ahead the trailer-truck. Define the diameter of an elastic rod d the stabilizing device from the fact that Т = 2500 Н∙м well-known formula: ,

, – allowable shear stress for steels 60С2А .We define the length of the working part of an elastic rod (torsion bar) based on the fact that the truck turned at the wabling an angle

– allowable shear stress for steels 60С2А .We define the length of the working part of an elastic rod (torsion bar) based on the fact that the truck turned at the wabling an angle  which corresponds to the lateral drift of the order of the trailer-truck body 200 мм recorded during tests the trailer-truck 2PTS-4-793A in the operating conditions, and consequently, for the same angle of twist has occurred, and it depends on:

which corresponds to the lateral drift of the order of the trailer-truck body 200 мм recorded during tests the trailer-truck 2PTS-4-793A in the operating conditions, and consequently, for the same angle of twist has occurred, and it depends on: ,when G – shear modulus,

,when G – shear modulus,  For the analytical study of vibrations and force loading of structures, both standard automobile and tractor trailer-truck 2PTS-4-793A, as well as the trailer-truck with the device performed by Pat RU2338658, developed the design scheme of Automotive train (Fig. 5), the equivalent full-scale train consisting of a car pick up GAZ -53A and trailer-truck 2PTS-4-793A.On the design scheme of the geometric dimensions as follows by train: ат — distance from the axis of the driven wheels of the car to pick up's center of gravity; Lт — base vehicle pick up; lT — distance from the axis of the driven wheels of the car pick up it to the point of tractive connection with drawbar the trailer-truck; dт — distance from the center of gravity of the car pick up to the horizontal plane of tractive connection; Вр and Вк— its front wheels of the car pick up and the trailer-truck

For the analytical study of vibrations and force loading of structures, both standard automobile and tractor trailer-truck 2PTS-4-793A, as well as the trailer-truck with the device performed by Pat RU2338658, developed the design scheme of Automotive train (Fig. 5), the equivalent full-scale train consisting of a car pick up GAZ -53A and trailer-truck 2PTS-4-793A.On the design scheme of the geometric dimensions as follows by train: ат — distance from the axis of the driven wheels of the car to pick up's center of gravity; Lт — base vehicle pick up; lT — distance from the axis of the driven wheels of the car pick up it to the point of tractive connection with drawbar the trailer-truck; dт — distance from the center of gravity of the car pick up to the horizontal plane of tractive connection; Вр and Вк— its front wheels of the car pick up and the trailer-truck  — its rear wheels of the tractor and trailer-truck; а1 — distance from the center of gravity of the trailer truck to his seat mate with a car towing pick up; l1,— distance from the center of the turntable to the place of tractive connection with the car bogie pick up; L1 — distance from the rear axle of the trailer truck to the turntable; dк — distance from the center of gravity and the plane dolly driving rod connection with dolly;

— its rear wheels of the tractor and trailer-truck; а1 — distance from the center of gravity of the trailer truck to his seat mate with a car towing pick up; l1,— distance from the center of the turntable to the place of tractive connection with the car bogie pick up; L1 — distance from the rear axle of the trailer truck to the turntable; dк — distance from the center of gravity and the plane dolly driving rod connection with dolly;  — distance from the center of gravity of the trailer truck to the plane of the vehicle tractive connection pick up and trailer truck.The adopted model consists of

— distance from the center of gravity of the trailer truck to the plane of the vehicle tractive connection pick up and trailer truck.The adopted model consists of  which respectively mean: weight of the vehicle pick up , reduced to its center of gravity, the mass of the trailer truck frame platform, with the axes of the wheels and spring group.To these masses in process of moving tractor train accompanied by the following external loads: РТ – traction vehicle pick up;

which respectively mean: weight of the vehicle pick up , reduced to its center of gravity, the mass of the trailer truck frame platform, with the axes of the wheels and spring group.To these masses in process of moving tractor train accompanied by the following external loads: РТ – traction vehicle pick up;  horizontal longitudinal rolling resistance of steering and driving wheels attached at the point of contact with the road and causing spatial variation vehicle pick up;

horizontal longitudinal rolling resistance of steering and driving wheels attached at the point of contact with the road and causing spatial variation vehicle pick up;  horizontal shear forces that cause side pull the wheels and attached at the point of contact wheels of the car pick up to the road;

horizontal shear forces that cause side pull the wheels and attached at the point of contact wheels of the car pick up to the road;  horizontal longitudinal force of rolling resistance and steering the driven wheels and the trailer-truck attached in_ the contact points of the wheels and cause spatial variation the trailer-truck;

horizontal longitudinal force of rolling resistance and steering the driven wheels and the trailer-truck attached in_ the contact points of the wheels and cause spatial variation the trailer-truck;  and

and  horizontal shear forces that cause side pull the wheels and attached to the contact point of the trailer wheels and the road.

horizontal shear forces that cause side pull the wheels and attached to the contact point of the trailer wheels and the road. | Figure 5. Design scheme trains |

Regulation of the system mass in space at any given time is determined by the coordinates:  - absolute displacement of mass m1 the trailer-truck characterizing wagging the trailer-truck;

- absolute displacement of mass m1 the trailer-truck characterizing wagging the trailer-truck;  - absolute displacement of mass m1 the trailer-truck, which characterizes the twitching the trailer-truck;

- absolute displacement of mass m1 the trailer-truck, which characterizes the twitching the trailer-truck;  - absolute displacement of mass m1, which characterizes the bouncing the trailer-truck; The relative elastic deformation dolly the trailer-truck characterized by the following notation:

- absolute displacement of mass m1, which characterizes the bouncing the trailer-truck; The relative elastic deformation dolly the trailer-truck characterized by the following notation:  - angle mass

- angle mass  determines its displacement in the horizontal transverse plane of motion;

determines its displacement in the horizontal transverse plane of motion;  - mass transfer

- mass transfer  determining its displacement in the horizontal transverse plane of motion;

determining its displacement in the horizontal transverse plane of motion;  - mass transfer

- mass transfer  determine its displacement in the horizontal plane of the longitudinal motion;

determine its displacement in the horizontal plane of the longitudinal motion;  - angles weight

- angles weight  determining its displacement in the longitudinal vertical plane of motion;

determining its displacement in the longitudinal vertical plane of motion;  - mass transfer

- mass transfer  determining its displacement in the longitudinal vertical plane of motion;Vibrational excitation of the dynamic model is carried out following kinematic coordinates:

determining its displacement in the longitudinal vertical plane of motion;Vibrational excitation of the dynamic model is carried out following kinematic coordinates:  - the yaw angle in pick up_ the plane of

- the yaw angle in pick up_ the plane of  , causing the wobble the trailer-truck; х0 – move the car pick up along the axis of

, causing the wobble the trailer-truck; х0 – move the car pick up along the axis of  , contributing to the development and yaw twitch the trailer-truck;

, contributing to the development and yaw twitch the trailer-truck;  - move the car pick up along the axis of

- move the car pick up along the axis of  , contributing to the emergence twitching the trailer-truck;

, contributing to the emergence twitching the trailer-truck;  - the yaw angle in pick up_ the plane of

- the yaw angle in pick up_ the plane of  causing the trailer-truck bouncing;

causing the trailer-truck bouncing;  - roughness height of micro and macro and micro Profile roads causing fluctuations on the trailer-truck axle

- roughness height of micro and macro and micro Profile roads causing fluctuations on the trailer-truck axle  ;In developing the design scheme following assumptions. The coefficients of friction in the kinematic pairs are constant, linear characteristics of the suspension, the gaps in the kinematic pairs replaced by an equivalent stiffness, bending vibrations of the frame and the base platform are ignored, side-slip tires does not adopted by the XYZ coordinate system is located at the level of conventional road and moves along it at a constant speed.A general equation of motion of trains, using the well-known Lagrange equation:

;In developing the design scheme following assumptions. The coefficients of friction in the kinematic pairs are constant, linear characteristics of the suspension, the gaps in the kinematic pairs replaced by an equivalent stiffness, bending vibrations of the frame and the base platform are ignored, side-slip tires does not adopted by the XYZ coordinate system is located at the level of conventional road and moves along it at a constant speed.A general equation of motion of trains, using the well-known Lagrange equation: | (2) |

when, Т – the kinetic energy of the system; the potential energy of the system;Q – generalized force;q – generalized coordinate.Analysis of the physical model (Figure 5) shows that the geometric dimensions of its connections and components can determine the absolute displacement of the centers of gravity of the masses considered necessary to set up the equations of the kinetic and potential energy of the system. Thus, the absolute movement of driving rod weight of the axes ОХ, ОУ, OZ. determined by the algebraic addition of the relative displacement:

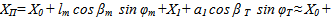

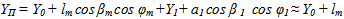

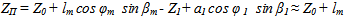

the potential energy of the system;Q – generalized force;q – generalized coordinate.Analysis of the physical model (Figure 5) shows that the geometric dimensions of its connections and components can determine the absolute displacement of the centers of gravity of the masses considered necessary to set up the equations of the kinetic and potential energy of the system. Thus, the absolute movement of driving rod weight of the axes ОХ, ОУ, OZ. determined by the algebraic addition of the relative displacement:

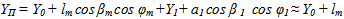

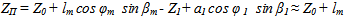

In the final form of these equations are written based on the fact that for small angles, βТ cos βТ ≈ 1, and sin βТ ≈ βТ (similarly for φT , φ1 , β1 ).In view of the assumptions made on the basis of [8,9-12] in planes ZОУ, ZОХ and УОХ taking into account the resistance forces in_ the kinematic pairs of equations derived energy: 1. Kinetic -

In the final form of these equations are written based on the fact that for small angles, βТ cos βТ ≈ 1, and sin βТ ≈ βТ (similarly for φT , φ1 , β1 ).In view of the assumptions made on the basis of [8,9-12] in planes ZОУ, ZОХ and УОХ taking into account the resistance forces in_ the kinematic pairs of equations derived energy: 1. Kinetic - | (3) |

2. Potential - | (4) |

3. The work of external forces on virtual displacements - | (5) |

Substituting equation (3), (4) and (5) in the Lagrange equation (2) and considering that the second term of the equation  , zero, we obtain the system 5 second order differential equations (6):

, zero, we obtain the system 5 second order differential equations (6):  | (6) |

By grouping the members of whose derivatives are of the same order, we obtain the following system of equations (7): | (7) |

Transforming the equation (7), we obtain the system in the form (8): | (8) |

In matrix form, these equations are of the form: | (9) |

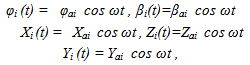

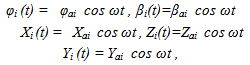

For simplicity we assume that in the course of its mass movement trains make the forced oscillation with a fixed angular frequency ω. The solution of the system of differential equations (9) describing the longitudinal and longitudinal angular oscillations of the masses train, look in the form of: | (10) |

when, φai , Xai , Yai , βai , Zai – amplitude of mass train.After substituting the solutions (10) in the system of differential equations (9) we obtain a system of linear algebraic equations | (11) |

The numerical values of inertia and stiffness coefficients aij and bij included in Equations (11) calculated by the following relationships (12).From the above dynamic models and systems of differential equations shows that the system with five degrees of freedom can make five independent harmonic oscillations, each of which corresponds to a specific value of the natural frequency. It is known that the maxima of the amplitude-frequency characteristics are close to the natural frequencies[1-4] Therefore, the presence of the spectrum of natural frequencies allows to predict the location of the maxima values of the amplitudes, and vice versa, can be determined from the maxima ¬ share the natural frequencies of the system. In the wild fluctuations at the wabling train in such a system is contained almost as many frequencies as the maximum value of the generalized coordinates is shown in all their ranges. It follows the method of their determination. Let the system operates on the frequency of the harmonic force ω1 and this frequency coincides with one of the frequencies natural oscillations. | (12) |

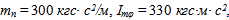

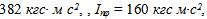

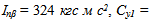

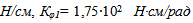

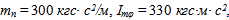

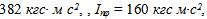

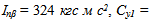

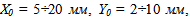

Then the amplitude of the oscillations increase indefinitely, and there is a phenomenon of resonance. When the frequency ω1 close to one of the natural frequencies, the corresponding amplitude is much greater than all the others. The system of equations (12) using the Gauss[12], with pivoting.In order to computing the error was minimal when the transformation matrix, the division by the maximum modulus of the matrix element. This took into account the possibility of changing the coefficients of stiffness equivalent to the serial model the trailer-truck modernized and equipped with a device for damping vibrations which is a torsion bar located on the dolly, as well as assignments in a wide range of kinematic coordinates approximate calculation scheme to the conditions close to operational. Knowing the geometric and stiffness parameters of the model (Fig. 1) and wondering frequency forced oscillation system ranging from 0 to 50 rad / s, and the amplitudes of the kinematic coordinates[2-4] on a computer using the software package Maple 9.5 calculated values of dynamic components forces and moments acting on a given mass model. In the calculations, the following initial data[12]:

(spring in the draw hook the car),

(spring in the draw hook the car),

(without torsion bar),

(without torsion bar),

(with torsion bar),

(with torsion bar),

(diameter torsion bar),

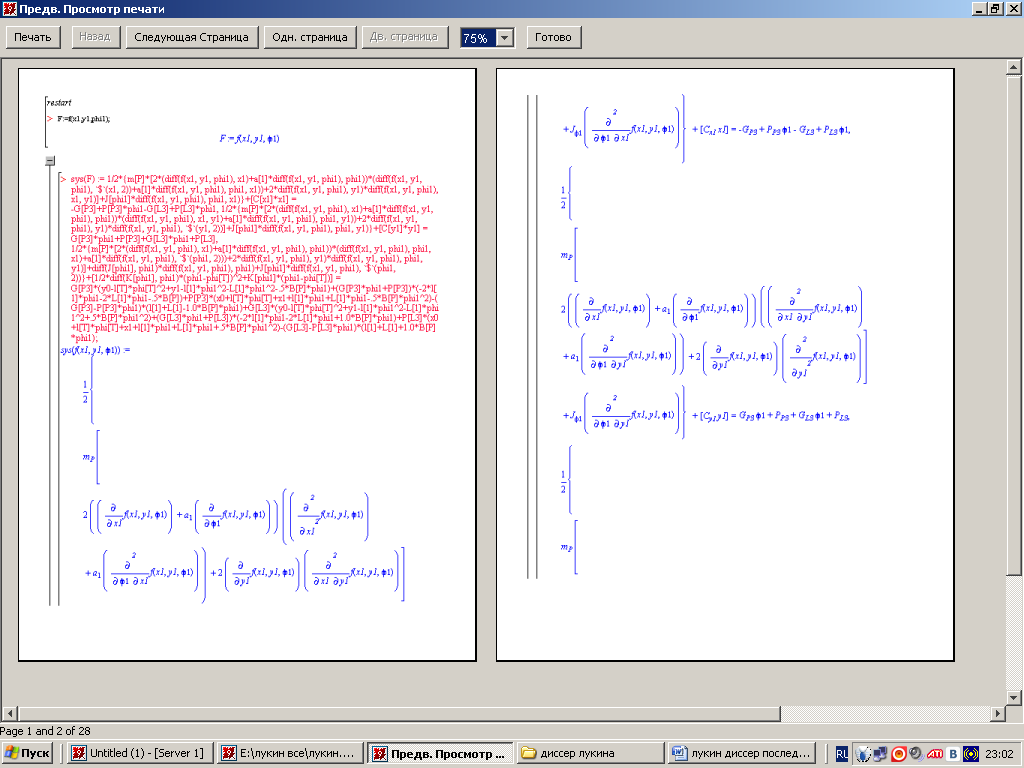

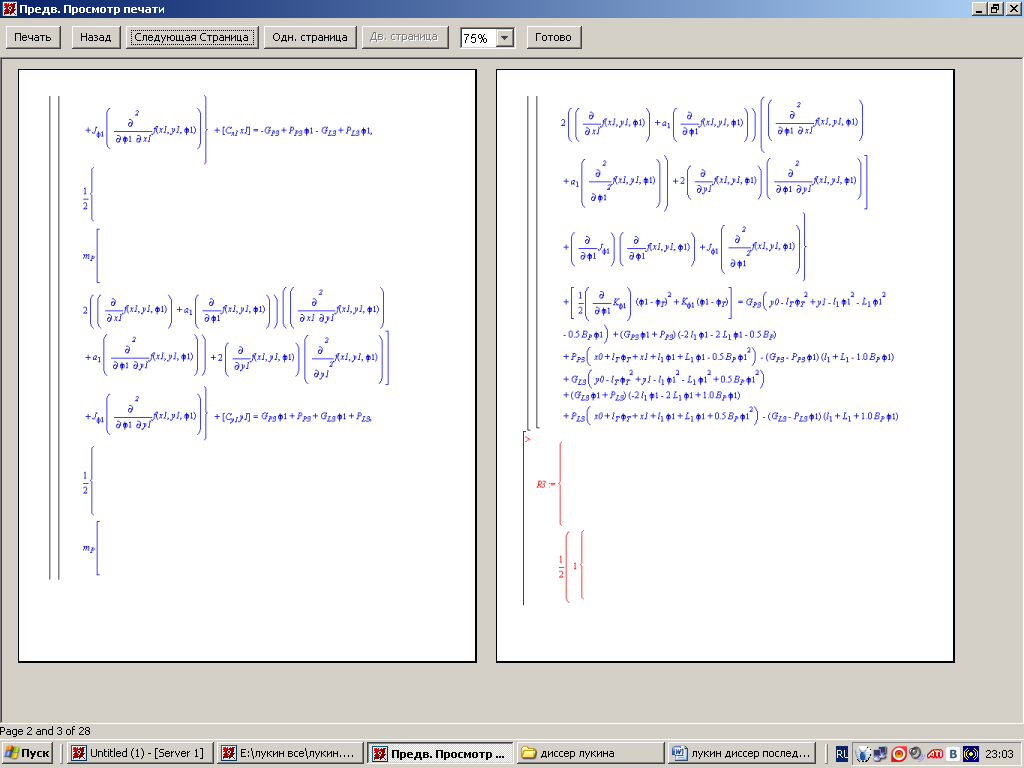

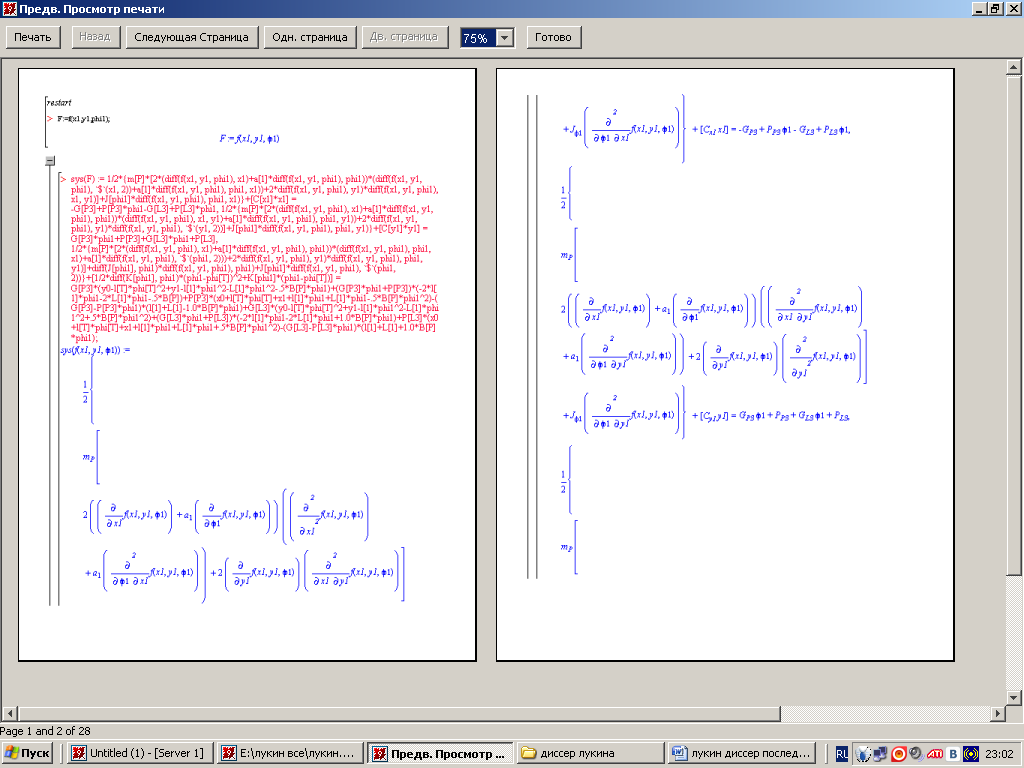

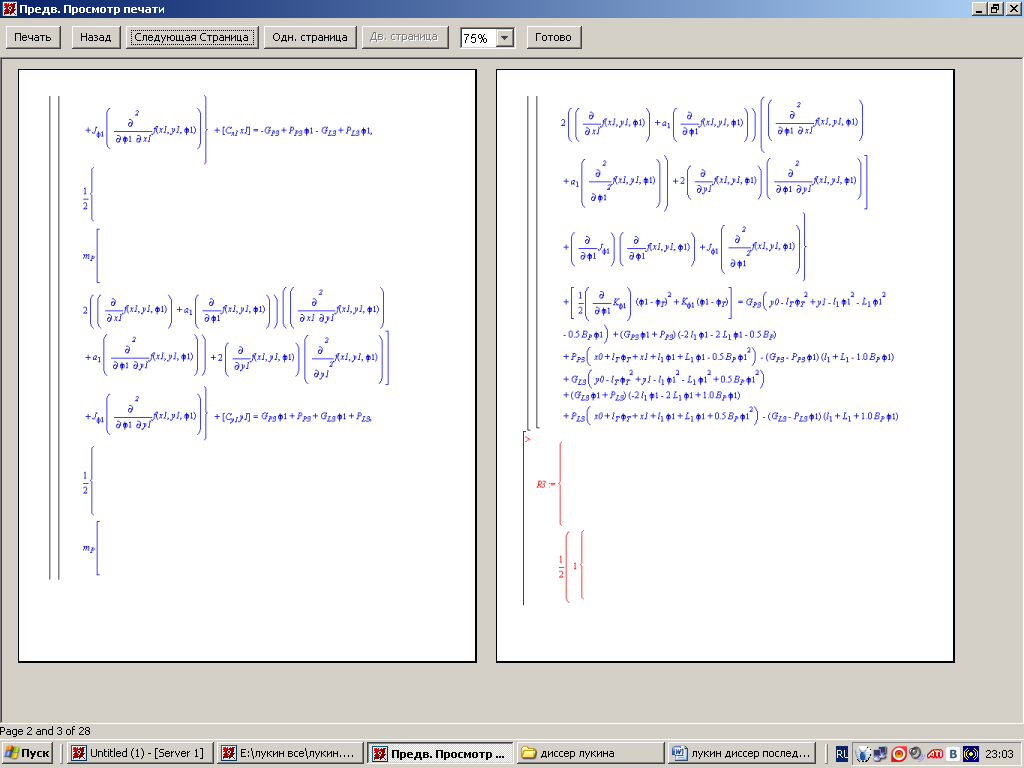

(diameter torsion bar),  (the length of torsion bar).To calculate the most important parameters characterizing the stability of the trailer truck moves as the associated safety and reliability of its construction elements, such as a twitching у1, wabling φ1 and lateral drift х1 used program Maple 9.5. To do this, the studied equations are written in the form shown in the windows of the program (Figure 6 and Figure 7), and then in the end, the new system, which is solved by a known method of substitutions (Figure 8 and Figure 9): Specifying the forced vibration frequency of the system in the range of from 0 to 50

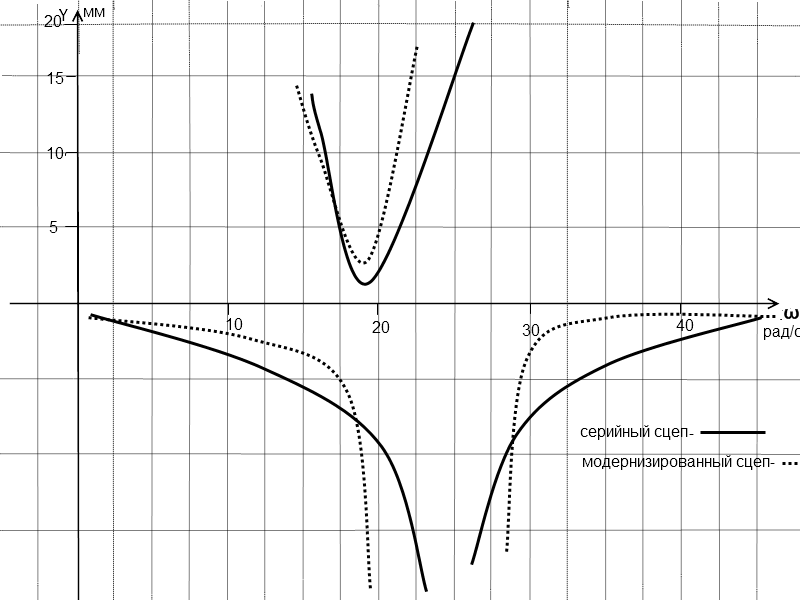

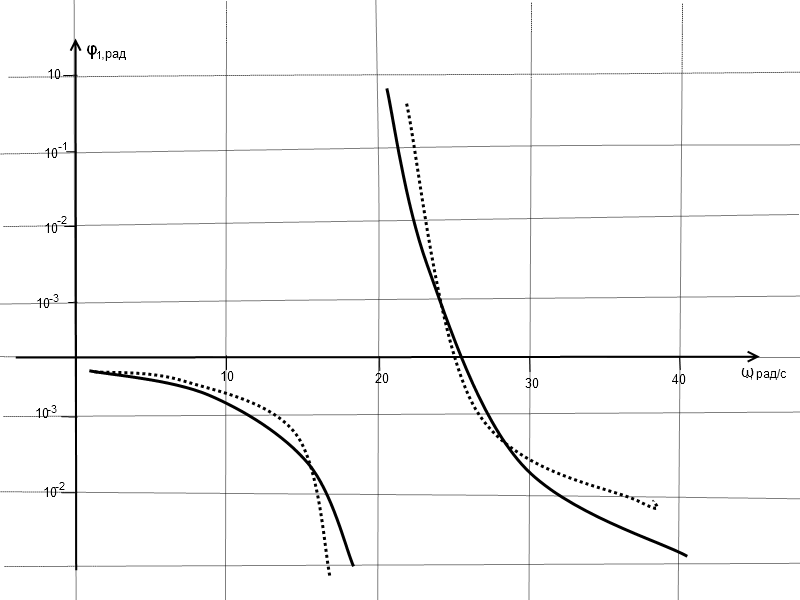

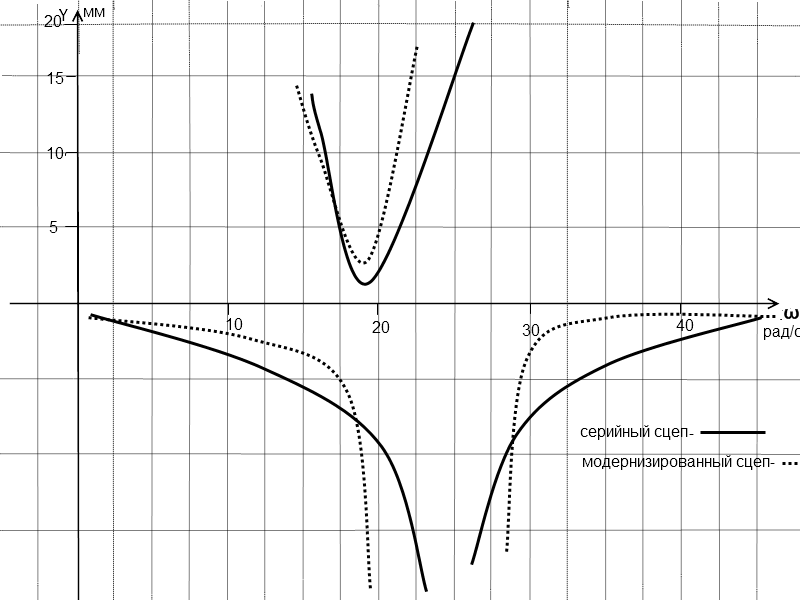

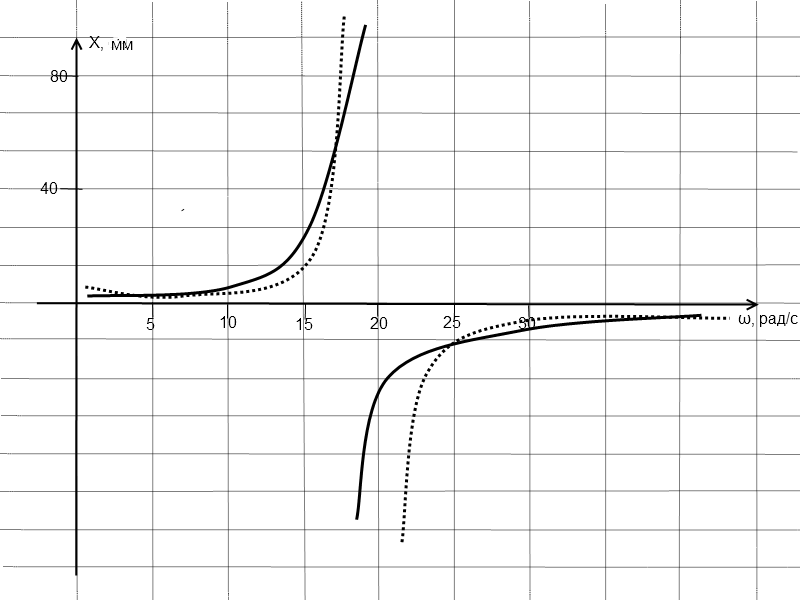

(the length of torsion bar).To calculate the most important parameters characterizing the stability of the trailer truck moves as the associated safety and reliability of its construction elements, such as a twitching у1, wabling φ1 and lateral drift х1 used program Maple 9.5. To do this, the studied equations are written in the form shown in the windows of the program (Figure 6 and Figure 7), and then in the end, the new system, which is solved by a known method of substitutions (Figure 8 and Figure 9): Specifying the forced vibration frequency of the system in the range of from 0 to 50  and amplitudes kinematic coordinates using the program Maple 9.5, built amplitude frequency graphs illustrating ¬ Glare forced vibrations and resonance mass settlement of the study of the mathematical model. Since the graphs Figure 10, Figure 11 and Figure 12 shows the most typical moving trailer in its tractive connection accordingly without damper and damper having a cross-angular oscillations in the horizontal plane (φ1), transverse vibrations in the horizontal plane (Х1), longitudinal oscillations (Y1). So in Figure 10 presents the amplitude-frequency graph describing the longitudinal axis travel Y1 both standard and upgraded the trailer-truck with the device increases the resistance movement of the last (RU2338658) where in the frequency range 18,8

and amplitudes kinematic coordinates using the program Maple 9.5, built amplitude frequency graphs illustrating ¬ Glare forced vibrations and resonance mass settlement of the study of the mathematical model. Since the graphs Figure 10, Figure 11 and Figure 12 shows the most typical moving trailer in its tractive connection accordingly without damper and damper having a cross-angular oscillations in the horizontal plane (φ1), transverse vibrations in the horizontal plane (Х1), longitudinal oscillations (Y1). So in Figure 10 presents the amplitude-frequency graph describing the longitudinal axis travel Y1 both standard and upgraded the trailer-truck with the device increases the resistance movement of the last (RU2338658) where in the frequency range 18,8  there is a significant increase in the amplitude and resonance observed twice, with wide display so you may experience considerable largest loads in the dynamic components hitch train.

there is a significant increase in the amplitude and resonance observed twice, with wide display so you may experience considerable largest loads in the dynamic components hitch train. | Figure 6. Window program 1, Figure 7. Window program 2 |

| Figure 8. Window program 3, Figure 9. Window program 4 |

| Figure 10. The amplitude-frequency plot 1 |

| Figure 11. The amplitude-frequency plot 2 |

| Figure 12. The amplitude-frequency plot 3 |

When using the device for damping yaw manifestation resonance zone somewhat higher than the mass, however, in the frequency range  amplitude trailer average 1.5-2.2 times lower. Such a reduction in the amplitude leads to the conclusion that the relationship of longitudinal vibrations with the vibrations of the trailer-truck yaw and lateral stability, though weak, but there is. Therefore, we can conclude some efficiency device eliminates wobble trailers fitted to the latter, as tractive connection to the place, and in the area of the turntable podkatnyh their carts.Figure 11 presents the amplitude-frequency graph showing the angular movements of the coordinate φ1 both standard and upgraded the trailer-truck with the device increases the resistance movement of the last (RU2338658) where in the frequency range

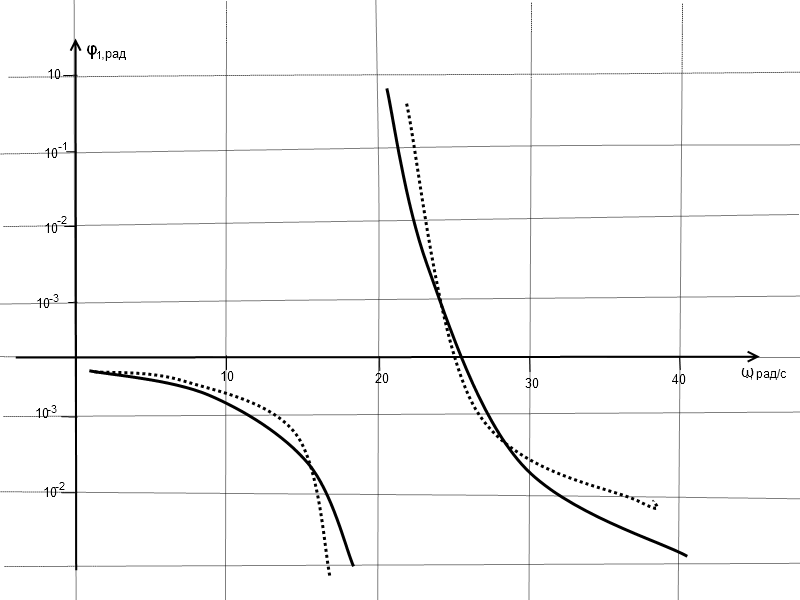

amplitude trailer average 1.5-2.2 times lower. Such a reduction in the amplitude leads to the conclusion that the relationship of longitudinal vibrations with the vibrations of the trailer-truck yaw and lateral stability, though weak, but there is. Therefore, we can conclude some efficiency device eliminates wobble trailers fitted to the latter, as tractive connection to the place, and in the area of the turntable podkatnyh their carts.Figure 11 presents the amplitude-frequency graph showing the angular movements of the coordinate φ1 both standard and upgraded the trailer-truck with the device increases the resistance movement of the last (RU2338658) where in the frequency range  exhibits a broad resonance region in the range of operating frequencies of oscillations is of the order

exhibits a broad resonance region in the range of operating frequencies of oscillations is of the order  thus, the angle φ, the deviation of the trailer-truck relative to the longitudinal axis of symmetry of the train is about 0.085 rad, which corresponds to the cross-trailer 185 мм. When you use the same device for damping yaw made under the patent RU2338658 such amplitude of the order below, in the order 111 мм.Figure 12 presents the amplitude-frequency graph showing the lateral displacements in the coordinate Х1 both standard and upgraded the trailer-truck with the device increases the resistance movement of the last (RU2338658) where in the frequency range

thus, the angle φ, the deviation of the trailer-truck relative to the longitudinal axis of symmetry of the train is about 0.085 rad, which corresponds to the cross-trailer 185 мм. When you use the same device for damping yaw made under the patent RU2338658 such amplitude of the order below, in the order 111 мм.Figure 12 presents the amplitude-frequency graph showing the lateral displacements in the coordinate Х1 both standard and upgraded the trailer-truck with the device increases the resistance movement of the last (RU2338658) where in the frequency range well as in the previous cases the resonance region in_ operating range of the oscillation frequencies of the order of the components

well as in the previous cases the resonance region in_ operating range of the oscillation frequencies of the order of the components  thus, the amplitude characterizing the lateral drift relative to the trailer-truck longitudinal axis of symmetry of the order of train 60,0 мм. When you use the same device for damping yaw made under the patent RU2338658 such amplitude is not much lower than in the order of 43,0- 52,0 мм.The resulting amplitude-frequency plots on the developed physical and mathematical models of trains has shown that the most significant components of the dynamic loads occur predominantly at the wabling twitching and the trailer truck. Such pressures undermine attachment mounted on the frame and dolly structural components and assemblies, and incapacitate the support structure forces the wear of the mating parts hitch, and generally worsens the stability of motion of the trailer truck.At the same time, the analysis of the results of the analytical study shows that the installation of the proposed technical solutions made under the patent RU2338658 on Motor and trailers family 2PTS-4 allows a positive trend in_ terms of improving the stability of motion of the trailer-truck as a whole, which will ultimately achieve performance under GOST 2349 - GOST 13377-67 54 and used in the art.

thus, the amplitude characterizing the lateral drift relative to the trailer-truck longitudinal axis of symmetry of the order of train 60,0 мм. When you use the same device for damping yaw made under the patent RU2338658 such amplitude is not much lower than in the order of 43,0- 52,0 мм.The resulting amplitude-frequency plots on the developed physical and mathematical models of trains has shown that the most significant components of the dynamic loads occur predominantly at the wabling twitching and the trailer truck. Such pressures undermine attachment mounted on the frame and dolly structural components and assemblies, and incapacitate the support structure forces the wear of the mating parts hitch, and generally worsens the stability of motion of the trailer truck.At the same time, the analysis of the results of the analytical study shows that the installation of the proposed technical solutions made under the patent RU2338658 on Motor and trailers family 2PTS-4 allows a positive trend in_ terms of improving the stability of motion of the trailer-truck as a whole, which will ultimately achieve performance under GOST 2349 - GOST 13377-67 54 and used in the art.

4. Results of the Study

Based on the above, the following conclusions and suggestions :1. The analysis of both domestic and foreign construction trucks shows that the latter have a significant disadvantage that at different speeds trailers have a high propensity to wagging, that is, the transverse vibrations of recent relative to the longitudinal axis of symmetry of the train. This phenomenon is dangerous not only for the trains, but also for other vehicles moving in the direction of overtaking or meet it. Experience in operation of motor trains shows that the consequences of accidents that occur on the roads for this reason, is more than 8% of all accidents recorded by the world practice.Given the above as inventions (RU500086, RU521152, RU2232099, RU2258018, RU2284942, RU2268824, RU2341400, RU2341401, RU2337850, RU2339534, RU2372242, RU2397906, RU2397904, RU2464197, RU2457141, RU2465165, etc.) to develop technical solutions devices allowing prevent wagging trailer units train as it moves at different speeds.2. To establish a rational geometric and kinematic parameters of one of these devices are made under the patent RU2338658 developed a physical model and proposed a method for their calculation. Thus, our calculations as applied to train consisting of the towing vehicle consisting of a vehicle pick up GAZ-53A and trailer-truck 2PTS-4-793A showed that as such a yaw dampers can be used vertically oriented torsion bar mounted on the dolly the trailer-truck, made of steel bar diameter steel 602S2A 25 мм. Analytical studies have shown that the use of this design reduces vibration damper the trailer-truck in the transverse plane of motion train an average of 1.8 times, which provides up in_ get indicators regulated by GOST 2349-54 and GOST 13377-67. To automate the calculations used Maple 9.5 program for computers that allows you to calculate these parameters for different designs trains.3. Results of the study are recommended to domestic and foreign transport companies, automobile industry, research and design units operating in the automotive industry for the study and analysis of the proposed designs for possible further put them into practice.

References

| [1] | A short car handbook. 10-е ed. reworked and added – М.: Transport, 1983. – 220p. |

| [2] | Vysotsky М.S. and etc. Automobile and tractor trailers. М.: Mashgiz, 1962. – 161p. |

| [3] | Zakin Ya.H. Car trains, development of vehicle design, Proceedings of the U.S., is. 12. Mashgiz, 1955. |

| [4] | Chudakov Е.А. The theory of the car. М.: Mashgiz. 1950.-272p. |

| [5] | Theory and design of the car. Tutorial for motor colleges. V.А. Ilarionov and etc. – М.: Engineering, 1985. – 368p. |

| [6] | Shchukin М.М. Hitches cars and trucks. М-L.: Маshgiz, 1961.-207p. |

| [7] | Smirnov G.А. The theory of the movement of wheeled vehicles. Textbook for students of mechanical engineering specials universities – 2ое ed. reworked and added – М.: Enginering, 1990. – 352p. |

| [8] | Allis D.R. Handling. М.: Enginering. 1975 – 216p. |

| [9] | Glushchenko А.D., Slivinskiy Е.V. Dynamics and strength of the transport system for the transport of freight cars. publishing house Phan, Tashkent. 1988. – 116p. |

| [10] | Ponamarev S.D., Andreeva L.Е. The calculation of the elastic elements of machines and devices. М.: Enginering 1980. – 326p. |

| [11] | Zakin Ya.Ch. Applied theory of train movement. М.: Transport 1967. – 215 p. |

| [12] | Slivinskiy Е. V. The study of vibrations and force loading tractor trailers 2PTS-4-793A. Author. dis. Candidate. tehn. Science. Alma-Ata: SAN, 1977. 165 p. |

| [13] | Glushenko А. D., Grokhovskiy U. V., Slivinskiy Е. V. The study of vibrations and force loading tractor trailer-truck 2PTS-4-793A / / Tractors and farm machinery, 1980. № 4. P. 8—11. |

| [14] | Glushenko А. D., Slivinskiy Е. V. and etc. The damping device for damping vibrations of the trailer truck. Auth. USSR certificate number 500086 / / Bulletin of inventions, 1976. № 3. |

| [15] | Glushenko А. D., Slivinskiy Е. V. and etc. A device for damping, vibration trailers. Auth. auth. Number 521152 / / Bulletin of inventions. 1976. № 26. |

| [16] | Slivinskiy Е. V., Glushenko А. D. and etc. The apparatus for testing automotive trains. Auth. auth. USSR number 511529 / / Bulletin of inventions. 1976. Number 15. |

| [17] | Slivinskiy Е. V. Research of power loading and vibration trailer 2PTS-4-793 Transport it in a tractor / train / mechanization of cotton growing. 1975. №2. P. 15. |

| [18] | The study and research of best practices for the organization and technology of repair of tractor trailers. Report VTSNTI. № st. reg. 71014439, inv. № Б2472. М., 1973. 318 p. |

| [19] | Slivinskiy Е.V., Zaitsev А.А. Increase traffic safety devices trucks. Monthly theoretical and scientific journal Automotive Industry М.: Engineering, №12, 2006.-31p. |

| [20] | Pharonov V.V. Delphi. Programming in a high level language. – SPt.: Peter, 2004. – 75p. |

| [21] | Slivinskiy Е.V., Zaitsev А.А. Improving the design of devices and components of automotive trains: monograph. – Yelets: ESU name I.А. Bunin, 2009. – 236p. |

| [22] | Slivinskiy Е.V., Lukin А.А. The long-term structure of the device to avoid whipping automotive trailers. Actual Problems of Engineering[Text]: collection of scientific - Lipeck: LGTU, 2009.- 286p. |

rotation about the axes of pick up Z, X, Y.As a result of the assumed model using the Lagrange equation of the second kind (1) deciding which known methods allows you to set the resonant oscillation of the mass units train and develop as a result of practical recommendations on the modernization of trains running parts.

rotation about the axes of pick up Z, X, Y.As a result of the assumed model using the Lagrange equation of the second kind (1) deciding which known methods allows you to set the resonant oscillation of the mass units train and develop as a result of practical recommendations on the modernization of trains running parts.

,when γ – twist angle of the elastic rod 9 (torsion bar), which is defined by the formula

,when γ – twist angle of the elastic rod 9 (torsion bar), which is defined by the formula  .Therefore it is clear the higher the twist angle of torsion bar γ generated torque Мкр attached to the dolly 5, the higher the damping capacity of the elastic rod 9. Picking up the rational dimensions d – diameter of the elastic rod and its working length ℓ can effectively extinguish not only wagging vibrations trailer vehicle, but also to provide angular rotation dolly 5 in a steep maneuvering of Automotive pick up.Let us first consider the ability to install the proposed technical solutions for automotive tractor trailer 2PTS-4-793A own weight

.Therefore it is clear the higher the twist angle of torsion bar γ generated torque Мкр attached to the dolly 5, the higher the damping capacity of the elastic rod 9. Picking up the rational dimensions d – diameter of the elastic rod and its working length ℓ can effectively extinguish not only wagging vibrations trailer vehicle, but also to provide angular rotation dolly 5 in a steep maneuvering of Automotive pick up.Let us first consider the ability to install the proposed technical solutions for automotive tractor trailer 2PTS-4-793A own weight  of mounted with the truck GAZ-53A own weight

of mounted with the truck GAZ-53A own weight  The masses of units train in this case are, respectively, will be

The masses of units train in this case are, respectively, will be

and the weight ratio of the characteristics of its reach

and the weight ratio of the characteristics of its reach

,when

,when  - коэффициент dynamism into account the effect of gaps in strip and equal 1,5;

- коэффициент dynamism into account the effect of gaps in strip and equal 1,5; - dynamic factor in the resonant vibrations of the system and equal 1,25;q0 - height of the bumps in the road, which is equal 6см;L – wave length roughness 2,5м.Assume that the trailer-truck tongue wagging in the trailer-truck with the dolly under the influence

- dynamic factor in the resonant vibrations of the system and equal 1,25;q0 - height of the bumps in the road, which is equal 6см;L – wave length roughness 2,5м.Assume that the trailer-truck tongue wagging in the trailer-truck with the dolly under the influence  turned at an angle 50 and then the shear force in its tractive connection with the hitch of the tractor is defined as

turned at an angle 50 and then the shear force in its tractive connection with the hitch of the tractor is defined as

In this case, at the time of dolly caused an angular rotation will be equal

In this case, at the time of dolly caused an angular rotation will be equal

(when

(when  drawbar length equal 1,8 м). Consequently, the angular rotation of the moment of resistance of an elastic rod Т an angle 50 should be slightly smaller than the moment М with the intention that after the disappearance of a specific point dolly back to the starting position straight-ahead the trailer-truck. Define the diameter of an elastic rod d the stabilizing device from the fact that Т = 2500 Н∙м well-known formula:

drawbar length equal 1,8 м). Consequently, the angular rotation of the moment of resistance of an elastic rod Т an angle 50 should be slightly smaller than the moment М with the intention that after the disappearance of a specific point dolly back to the starting position straight-ahead the trailer-truck. Define the diameter of an elastic rod d the stabilizing device from the fact that Т = 2500 Н∙м well-known formula: ,

, – allowable shear stress for steels 60С2А .We define the length of the working part of an elastic rod (torsion bar) based on the fact that the truck turned at the wabling an angle

– allowable shear stress for steels 60С2А .We define the length of the working part of an elastic rod (torsion bar) based on the fact that the truck turned at the wabling an angle  which corresponds to the lateral drift of the order of the trailer-truck body 200 мм recorded during tests the trailer-truck 2PTS-4-793A in the operating conditions, and consequently, for the same angle of twist has occurred, and it depends on:

which corresponds to the lateral drift of the order of the trailer-truck body 200 мм recorded during tests the trailer-truck 2PTS-4-793A in the operating conditions, and consequently, for the same angle of twist has occurred, and it depends on: ,when G – shear modulus,

,when G – shear modulus,  For the analytical study of vibrations and force loading of structures, both standard automobile and tractor trailer-truck 2PTS-4-793A, as well as the trailer-truck with the device performed by Pat RU2338658, developed the design scheme of Automotive train (Fig. 5), the equivalent full-scale train consisting of a car pick up GAZ -53A and trailer-truck 2PTS-4-793A.On the design scheme of the geometric dimensions as follows by train: ат — distance from the axis of the driven wheels of the car to pick up's center of gravity; Lт — base vehicle pick up; lT — distance from the axis of the driven wheels of the car pick up it to the point of tractive connection with drawbar the trailer-truck; dт — distance from the center of gravity of the car pick up to the horizontal plane of tractive connection; Вр and Вк— its front wheels of the car pick up and the trailer-truck

For the analytical study of vibrations and force loading of structures, both standard automobile and tractor trailer-truck 2PTS-4-793A, as well as the trailer-truck with the device performed by Pat RU2338658, developed the design scheme of Automotive train (Fig. 5), the equivalent full-scale train consisting of a car pick up GAZ -53A and trailer-truck 2PTS-4-793A.On the design scheme of the geometric dimensions as follows by train: ат — distance from the axis of the driven wheels of the car to pick up's center of gravity; Lт — base vehicle pick up; lT — distance from the axis of the driven wheels of the car pick up it to the point of tractive connection with drawbar the trailer-truck; dт — distance from the center of gravity of the car pick up to the horizontal plane of tractive connection; Вр and Вк— its front wheels of the car pick up and the trailer-truck  — its rear wheels of the tractor and trailer-truck; а1 — distance from the center of gravity of the trailer truck to his seat mate with a car towing pick up; l1,— distance from the center of the turntable to the place of tractive connection with the car bogie pick up; L1 — distance from the rear axle of the trailer truck to the turntable; dк — distance from the center of gravity and the plane dolly driving rod connection with dolly;

— its rear wheels of the tractor and trailer-truck; а1 — distance from the center of gravity of the trailer truck to his seat mate with a car towing pick up; l1,— distance from the center of the turntable to the place of tractive connection with the car bogie pick up; L1 — distance from the rear axle of the trailer truck to the turntable; dк — distance from the center of gravity and the plane dolly driving rod connection with dolly;  — distance from the center of gravity of the trailer truck to the plane of the vehicle tractive connection pick up and trailer truck.The adopted model consists of

— distance from the center of gravity of the trailer truck to the plane of the vehicle tractive connection pick up and trailer truck.The adopted model consists of  which respectively mean: weight of the vehicle pick up , reduced to its center of gravity, the mass of the trailer truck frame platform, with the axes of the wheels and spring group.To these masses in process of moving tractor train accompanied by the following external loads: РТ – traction vehicle pick up;

which respectively mean: weight of the vehicle pick up , reduced to its center of gravity, the mass of the trailer truck frame platform, with the axes of the wheels and spring group.To these masses in process of moving tractor train accompanied by the following external loads: РТ – traction vehicle pick up;  horizontal longitudinal rolling resistance of steering and driving wheels attached at the point of contact with the road and causing spatial variation vehicle pick up;

horizontal longitudinal rolling resistance of steering and driving wheels attached at the point of contact with the road and causing spatial variation vehicle pick up;  horizontal shear forces that cause side pull the wheels and attached at the point of contact wheels of the car pick up to the road;

horizontal shear forces that cause side pull the wheels and attached at the point of contact wheels of the car pick up to the road;  horizontal longitudinal force of rolling resistance and steering the driven wheels and the trailer-truck attached in_ the contact points of the wheels and cause spatial variation the trailer-truck;

horizontal longitudinal force of rolling resistance and steering the driven wheels and the trailer-truck attached in_ the contact points of the wheels and cause spatial variation the trailer-truck;  and

and  horizontal shear forces that cause side pull the wheels and attached to the contact point of the trailer wheels and the road.

horizontal shear forces that cause side pull the wheels and attached to the contact point of the trailer wheels and the road.

- absolute displacement of mass m1 the trailer-truck characterizing wagging the trailer-truck;

- absolute displacement of mass m1 the trailer-truck characterizing wagging the trailer-truck;  - absolute displacement of mass m1 the trailer-truck, which characterizes the twitching the trailer-truck;

- absolute displacement of mass m1 the trailer-truck, which characterizes the twitching the trailer-truck;  - absolute displacement of mass m1, which characterizes the bouncing the trailer-truck; The relative elastic deformation dolly the trailer-truck characterized by the following notation:

- absolute displacement of mass m1, which characterizes the bouncing the trailer-truck; The relative elastic deformation dolly the trailer-truck characterized by the following notation:  - angle mass

- angle mass  determines its displacement in the horizontal transverse plane of motion;

determines its displacement in the horizontal transverse plane of motion;  - mass transfer

- mass transfer  determining its displacement in the horizontal transverse plane of motion;

determining its displacement in the horizontal transverse plane of motion;  - mass transfer

- mass transfer  determine its displacement in the horizontal plane of the longitudinal motion;

determine its displacement in the horizontal plane of the longitudinal motion;  - angles weight

- angles weight  determining its displacement in the longitudinal vertical plane of motion;

determining its displacement in the longitudinal vertical plane of motion;  - mass transfer

- mass transfer  determining its displacement in the longitudinal vertical plane of motion;Vibrational excitation of the dynamic model is carried out following kinematic coordinates:

determining its displacement in the longitudinal vertical plane of motion;Vibrational excitation of the dynamic model is carried out following kinematic coordinates:  - the yaw angle in pick up_ the plane of

- the yaw angle in pick up_ the plane of  , causing the wobble the trailer-truck; х0 – move the car pick up along the axis of

, causing the wobble the trailer-truck; х0 – move the car pick up along the axis of  , contributing to the development and yaw twitch the trailer-truck;

, contributing to the development and yaw twitch the trailer-truck;  - move the car pick up along the axis of

- move the car pick up along the axis of  , contributing to the emergence twitching the trailer-truck;

, contributing to the emergence twitching the trailer-truck;  - the yaw angle in pick up_ the plane of

- the yaw angle in pick up_ the plane of  causing the trailer-truck bouncing;

causing the trailer-truck bouncing;  - roughness height of micro and macro and micro Profile roads causing fluctuations on the trailer-truck axle

- roughness height of micro and macro and micro Profile roads causing fluctuations on the trailer-truck axle  ;In developing the design scheme following assumptions. The coefficients of friction in the kinematic pairs are constant, linear characteristics of the suspension, the gaps in the kinematic pairs replaced by an equivalent stiffness, bending vibrations of the frame and the base platform are ignored, side-slip tires does not adopted by the XYZ coordinate system is located at the level of conventional road and moves along it at a constant speed.A general equation of motion of trains, using the well-known Lagrange equation:

;In developing the design scheme following assumptions. The coefficients of friction in the kinematic pairs are constant, linear characteristics of the suspension, the gaps in the kinematic pairs replaced by an equivalent stiffness, bending vibrations of the frame and the base platform are ignored, side-slip tires does not adopted by the XYZ coordinate system is located at the level of conventional road and moves along it at a constant speed.A general equation of motion of trains, using the well-known Lagrange equation:

the potential energy of the system;Q – generalized force;q – generalized coordinate.Analysis of the physical model (Figure 5) shows that the geometric dimensions of its connections and components can determine the absolute displacement of the centers of gravity of the masses considered necessary to set up the equations of the kinetic and potential energy of the system. Thus, the absolute movement of driving rod weight of the axes ОХ, ОУ, OZ. determined by the algebraic addition of the relative displacement:

the potential energy of the system;Q – generalized force;q – generalized coordinate.Analysis of the physical model (Figure 5) shows that the geometric dimensions of its connections and components can determine the absolute displacement of the centers of gravity of the masses considered necessary to set up the equations of the kinetic and potential energy of the system. Thus, the absolute movement of driving rod weight of the axes ОХ, ОУ, OZ. determined by the algebraic addition of the relative displacement:

In the final form of these equations are written based on the fact that for small angles, βТ cos βТ ≈ 1, and sin βТ ≈ βТ (similarly for φT , φ1 , β1 ).In view of the assumptions made on the basis of [8,9-12] in planes ZОУ, ZОХ and УОХ taking into account the resistance forces in_ the kinematic pairs of equations derived energy: 1. Kinetic -

In the final form of these equations are written based on the fact that for small angles, βТ cos βТ ≈ 1, and sin βТ ≈ βТ (similarly for φT , φ1 , β1 ).In view of the assumptions made on the basis of [8,9-12] in planes ZОУ, ZОХ and УОХ taking into account the resistance forces in_ the kinematic pairs of equations derived energy: 1. Kinetic -

, zero, we obtain the system 5 second order differential equations (6):

, zero, we obtain the system 5 second order differential equations (6):

(spring in the draw hook the car),

(spring in the draw hook the car),

(without torsion bar),

(without torsion bar),

(with torsion bar),

(with torsion bar),

(diameter torsion bar),

(diameter torsion bar),  (the length of torsion bar).To calculate the most important parameters characterizing the stability of the trailer truck moves as the associated safety and reliability of its construction elements, such as a twitching у1, wabling φ1 and lateral drift х1 used program Maple 9.5. To do this, the studied equations are written in the form shown in the windows of the program (Figure 6 and Figure 7), and then in the end, the new system, which is solved by a known method of substitutions (Figure 8 and Figure 9): Specifying the forced vibration frequency of the system in the range of from 0 to 50

(the length of torsion bar).To calculate the most important parameters characterizing the stability of the trailer truck moves as the associated safety and reliability of its construction elements, such as a twitching у1, wabling φ1 and lateral drift х1 used program Maple 9.5. To do this, the studied equations are written in the form shown in the windows of the program (Figure 6 and Figure 7), and then in the end, the new system, which is solved by a known method of substitutions (Figure 8 and Figure 9): Specifying the forced vibration frequency of the system in the range of from 0 to 50  and amplitudes kinematic coordinates using the program Maple 9.5, built amplitude frequency graphs illustrating ¬ Glare forced vibrations and resonance mass settlement of the study of the mathematical model. Since the graphs Figure 10, Figure 11 and Figure 12 shows the most typical moving trailer in its tractive connection accordingly without damper and damper having a cross-angular oscillations in the horizontal plane (φ1), transverse vibrations in the horizontal plane (Х1), longitudinal oscillations (Y1). So in Figure 10 presents the amplitude-frequency graph describing the longitudinal axis travel Y1 both standard and upgraded the trailer-truck with the device increases the resistance movement of the last (RU2338658) where in the frequency range 18,8

and amplitudes kinematic coordinates using the program Maple 9.5, built amplitude frequency graphs illustrating ¬ Glare forced vibrations and resonance mass settlement of the study of the mathematical model. Since the graphs Figure 10, Figure 11 and Figure 12 shows the most typical moving trailer in its tractive connection accordingly without damper and damper having a cross-angular oscillations in the horizontal plane (φ1), transverse vibrations in the horizontal plane (Х1), longitudinal oscillations (Y1). So in Figure 10 presents the amplitude-frequency graph describing the longitudinal axis travel Y1 both standard and upgraded the trailer-truck with the device increases the resistance movement of the last (RU2338658) where in the frequency range 18,8  there is a significant increase in the amplitude and resonance observed twice, with wide display so you may experience considerable largest loads in the dynamic components hitch train.

there is a significant increase in the amplitude and resonance observed twice, with wide display so you may experience considerable largest loads in the dynamic components hitch train.

amplitude trailer average 1.5-2.2 times lower. Such a reduction in the amplitude leads to the conclusion that the relationship of longitudinal vibrations with the vibrations of the trailer-truck yaw and lateral stability, though weak, but there is. Therefore, we can conclude some efficiency device eliminates wobble trailers fitted to the latter, as tractive connection to the place, and in the area of the turntable podkatnyh their carts.Figure 11 presents the amplitude-frequency graph showing the angular movements of the coordinate φ1 both standard and upgraded the trailer-truck with the device increases the resistance movement of the last (RU2338658) where in the frequency range

amplitude trailer average 1.5-2.2 times lower. Such a reduction in the amplitude leads to the conclusion that the relationship of longitudinal vibrations with the vibrations of the trailer-truck yaw and lateral stability, though weak, but there is. Therefore, we can conclude some efficiency device eliminates wobble trailers fitted to the latter, as tractive connection to the place, and in the area of the turntable podkatnyh their carts.Figure 11 presents the amplitude-frequency graph showing the angular movements of the coordinate φ1 both standard and upgraded the trailer-truck with the device increases the resistance movement of the last (RU2338658) where in the frequency range  exhibits a broad resonance region in the range of operating frequencies of oscillations is of the order

exhibits a broad resonance region in the range of operating frequencies of oscillations is of the order  thus, the angle φ, the deviation of the trailer-truck relative to the longitudinal axis of symmetry of the train is about 0.085 rad, which corresponds to the cross-trailer 185 мм. When you use the same device for damping yaw made under the patent RU2338658 such amplitude of the order below, in the order 111 мм.Figure 12 presents the amplitude-frequency graph showing the lateral displacements in the coordinate Х1 both standard and upgraded the trailer-truck with the device increases the resistance movement of the last (RU2338658) where in the frequency range

thus, the angle φ, the deviation of the trailer-truck relative to the longitudinal axis of symmetry of the train is about 0.085 rad, which corresponds to the cross-trailer 185 мм. When you use the same device for damping yaw made under the patent RU2338658 such amplitude of the order below, in the order 111 мм.Figure 12 presents the amplitude-frequency graph showing the lateral displacements in the coordinate Х1 both standard and upgraded the trailer-truck with the device increases the resistance movement of the last (RU2338658) where in the frequency range well as in the previous cases the resonance region in_ operating range of the oscillation frequencies of the order of the components

well as in the previous cases the resonance region in_ operating range of the oscillation frequencies of the order of the components  thus, the amplitude characterizing the lateral drift relative to the trailer-truck longitudinal axis of symmetry of the order of train 60,0 мм. When you use the same device for damping yaw made under the patent RU2338658 such amplitude is not much lower than in the order of 43,0- 52,0 мм.The resulting amplitude-frequency plots on the developed physical and mathematical models of trains has shown that the most significant components of the dynamic loads occur predominantly at the wabling twitching and the trailer truck. Such pressures undermine attachment mounted on the frame and dolly structural components and assemblies, and incapacitate the support structure forces the wear of the mating parts hitch, and generally worsens the stability of motion of the trailer truck.At the same time, the analysis of the results of the analytical study shows that the installation of the proposed technical solutions made under the patent RU2338658 on Motor and trailers family 2PTS-4 allows a positive trend in_ terms of improving the stability of motion of the trailer-truck as a whole, which will ultimately achieve performance under GOST 2349 - GOST 13377-67 54 and used in the art.

thus, the amplitude characterizing the lateral drift relative to the trailer-truck longitudinal axis of symmetry of the order of train 60,0 мм. When you use the same device for damping yaw made under the patent RU2338658 such amplitude is not much lower than in the order of 43,0- 52,0 мм.The resulting amplitude-frequency plots on the developed physical and mathematical models of trains has shown that the most significant components of the dynamic loads occur predominantly at the wabling twitching and the trailer truck. Such pressures undermine attachment mounted on the frame and dolly structural components and assemblies, and incapacitate the support structure forces the wear of the mating parts hitch, and generally worsens the stability of motion of the trailer truck.At the same time, the analysis of the results of the analytical study shows that the installation of the proposed technical solutions made under the patent RU2338658 on Motor and trailers family 2PTS-4 allows a positive trend in_ terms of improving the stability of motion of the trailer-truck as a whole, which will ultimately achieve performance under GOST 2349 - GOST 13377-67 54 and used in the art. Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML