E.V. Slivinsky, S.Y. Radin, O.A. Silchenko

Mechanical Technological Faculty, Elets State University I.A. Bunin, Elets, 399770, Russia

Correspondence to: E.V. Slivinsky, Mechanical Technological Faculty, Elets State University I.A. Bunin, Elets, 399770, Russia.

| Email: |  |

Copyright © 2012 Scientific & Academic Publishing. All Rights Reserved.

Abstract

This article presents materials concerning the development of perspective design of the heavy duty truck which possesses the ability to exclude a traumatism with a fatal outcome in the case when the catching-up of its vehicles on the big speed bump in the stern part. This is facilitated by the damping design mounted on podkatny cart automobile semi-trailer. Calculated basic kinematic parameters of such a design. Is recommended to research and industrial structures in the automotive industry with the purpose of its further study and possible introduction in practice.

Keywords:

Rama, Podkatny Cart, Guide, Spring, Skid Plate, Finger

Cite this paper: E.V. Slivinsky, S.Y. Radin, O.A. Silchenko, To Reduce Injury of the People of Fatal Injuries in the Operation of Motor Transport, International Journal of Traffic and Transportation Engineering, Vol. 2 No. 2, 2013, pp. 14-21. doi: 10.5923/j.ijtte.20130202.02.

1. Introduction

At the present time, both in our country and abroad in the conditions of market economy a special role is played by the automobile transport. High mobility, reliability, comparative simplicity in maintenance and management allows to use it as on others, and on long-haul transportation. It is known[2,3,6], that the main objectives of the further development of the motor transport is fuel economy, increase its life, reduction of metal consumption, ensuring high reliability, increase of dynamic and driving qualities, improve traffic safety and maintenance standards, reduction of the harmful impact on the environment, improvement of working conditions of drivers, etc. All of these tasks cannot be solved without the introduction of achievements of scientific and technological progress not only in the field of new technology, but also in the field of operation of rolling stock. Given the importance of such problems, in Elets state University I.A. Bunin at the Department of applied mechanics is the budgetary research work on a theme «Dynamics, strength and reliability of transport, road construction and agricultural machines, as well as the industrial standard and non-standard equipment in relation to Black-earth region of the Russian Federation». On the basis of this research work is being done and in the line of scientific research work, is also closely associated with the activities of the student design bureau University. One of the sections of this research is devoted to the following development aimed at the modernization of automobile semi-trailers, included in the ladder of heavy-duty trucks,and such, which would have increased the safety of their operation in road conditions and, if possible, would exclude injuries of people with a fatal outcome.

2. The Aim of the Research

It is known[10,13], that at the present time, in many countries of the world work is underway, aimed at further improvement of road transport. One of the important directions in this field is the reduction of metal consumption of cars due to the use of light alloys, plastics, etc.; automation of control transmission; use of drives гидропередач; improvement of the suspension and a safe tire on the basis of tubeless tires with more elastic properties and high durability; modernization of brake systems and devices, providing their dynamics using anti-lock systems, etc. And, of course, the most important point is the development of technical measures to ensure the safety of the driver and passengers. The most dangerous emergency situation is the collision of the car with the aft part of the semi-trailers, moving in the road-trains. So the main direction for the exclusion of fatal injuries is used, for example, the creation of bodies of passenger cars of various hardness, i.e. the front part of their less rigid in the longitudinal their plane than the average and rear. With this the purpose use, for example, elastic front buffers, filled with water, and etc. Of the patent sources are different by design technical solutions that reduce the impact energy in the process of collision of passenger cars with trailer. For example, one of these devices is described in А.С.СССР №1614838, representing a movable spring-loaded relative to the frame semi-trailer disc covered with friction material. Such a disk replaces safety Board semitrailer and in the case of a collision with a combination of catch-up of his car at the expense of eccentric application shock load on the last disk rotates on its axis, and the automobile is dropped into the side of the road. Several such a device described in the patent RU2255019. In this case, use spare wheels of the train, which is usually installed in the aft part of semi-trailers. Spare wheel mounted to the frame and covered by an elastic band, with the axles of the wheels are equipped with castors, which at the time of collision come in contact with the spinning wheels of the rear suspension semi-trailer. The rotation of the rollers contributes to the translational motion of an elastic tape and ensures that side of the demolition of a passenger car in the side of the curb or edge of the street. However, an analysis of such structures shows that they still cannot solve the main task - preservation of the life of the people, as well as the car, “discarded”, for example, on the road, may be faced with a moving vehicle.Given the importance of the problem - the preservation of life of people in emergency situations, when drivers were asleep and steer their cars meta-with leading-reaching trailer, the purpose of this research is the design of the semi-trailer, which has led the wheels are placed on podkatny cart, associated with the main frame semi-trailer with the help of elastic elements, and this cart can do move in the longitudinal plane of the semi-trailer, lifting his back part. Such a construction allows to exclude injuries of people with a fatal outcome due to the above reason, and this device must be bound to a different designs of semi-trailers, aggregated with seat cars-trucks.To achieve this purpose it is necessary to solve the following tasks:1. To develop the computational scheme of the above devices, tied to articulated truck in its interaction with catching up cars, allowing to produce analytical studies of two colliding masses and carried out with the help of the mathematical model calculations of main kinematic and geometric parameters.2. To use of the software with the use of language Delphi on the computer, taking into account the diversity of structures and semi-allows you to make calculations of rational parameters of devices intended to reduce the injury of the people of fatal injuries in the operation of vehicles.

3. Methods

It is known[6-8], the driver of the vehicle, including heavy-duty truck, takes a significant place in the system «driver-car-road-environment» (DCRE). He was the only one inherent in the conflicting properties and the factors that have a direct bearing on road safety and professional activities. The main task of the driver is the management of a single passenger or cargo vehicle and controlling the work of its main units, units and details. Tendencies of development of the cars are such that physical labor for their management becomes less, and in the first place put forward higher requirements to the perception, thinking, managing influences, the reliability of professional activity of the driver under the conditions of high nervous and emotional tension. Have to reckon with the fact that out of all kinds of automobile transport is considered to be the most dangerous. This is explained by several reasons, among which the most important are: the constant interaction with the elements of DCRE in traffic and a great scattering of personal qualities and the status of the drivers, as compared with the pilots or engineers. Statistics of losses from road and transport incidents (road accident) shows that, in General, it would seem, the loss of them are small, however they need to be considered. Thus, according to the countries of Western Europe accidents occur every 30 seconds, fatal crashes every 5 minutes, and the number of wounded in the world - millions of[8]. It follows from this that road traffic accidents should be seen as a single failure, due to the fact that the driver gets in the extreme situation, and this situation is based on three main issues DCRE.At the present time the practice of the automotive industry pays considerable attention to the protection of man, located in the vehicle. This and the airbag, the creation of car bodies such as to deformation of the past accompanied with damping shock loads, etc. It is clear that the design of such construction is necessary to use the collision theory. It is known that the shock phenomena[9,10] in mechanical systems are typical of the following common features: kinematic features that characterize the shortness of the instrument strike, during which there are abrupt changes velocities of the points of the system, and dynamic features, associated with the creation, and then and with the disappearance of large impact forces. Usually developing during the impact force is not known and to be determined. In many cases, the blow is characterized not only by the law changes force P(t) as the integral value - shock pulse: Or

Or In the mentioned equations S is called instantaneous shock pulse, and obtained in the transition from t0 to t1 force is called the instantaneous shock force and is determined by:

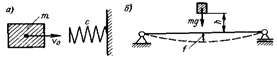

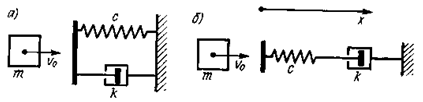

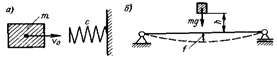

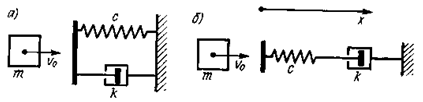

In the mentioned equations S is called instantaneous shock pulse, and obtained in the transition from t0 to t1 force is called the instantaneous shock force and is determined by: where δ is the Dirac Delta function.If, on the condition of the problem, the strike force set explicit function of time P(t) or momentary impulse S, then the problem is reduced to the study of forced vibrations of mechanical systems and can be solved known methods of the theory of oscillations[1,9]. Consider the case of a collision, the mass m with the account of the rigidity C another body (figure 1).

where δ is the Dirac Delta function.If, on the condition of the problem, the strike force set explicit function of time P(t) or momentary impulse S, then the problem is reduced to the study of forced vibrations of mechanical systems and can be solved known methods of the theory of oscillations[1,9]. Consider the case of a collision, the mass m with the account of the rigidity C another body (figure 1). | Figure 1. Scheme of dynamic loading of structural element |

In the first case (fig.1.а) the equation of motion of the body is written in the form  , i.e., using a normal differential equation of free oscillations, which decision has the form

, i.e., using a normal differential equation of free oscillations, which decision has the form  , where

, where  .Hence it follows, that the greatest deformation of an elastic connection rigidity C is determined by:

.Hence it follows, that the greatest deformation of an elastic connection rigidity C is determined by:  , in this case the maximum force of compression will be

, in this case the maximum force of compression will be  .In the second case the determination of the deformation of the system, shown in fig.1b, produce, using the equation of energy. As a result of the deflection of the beam can be determined depending on:

.In the second case the determination of the deformation of the system, shown in fig.1b, produce, using the equation of energy. As a result of the deflection of the beam can be determined depending on: .To determine the value of the coefficient of the speakers in this case, use the equation:

.To determine the value of the coefficient of the speakers in this case, use the equation: .In practice, in a study of the impact of physical bodies can be used design, and, consequently, the models without the inertial elastic and viscous elements (figure 2).Movement of the mass m after the beginning of the shock of the contact is described by the differential equation:

.In practice, in a study of the impact of physical bodies can be used design, and, consequently, the models without the inertial elastic and viscous elements (figure 2).Movement of the mass m after the beginning of the shock of the contact is described by the differential equation:  . Assuming the initial conditions of the form

. Assuming the initial conditions of the form  , and

, and  , get the solution

, get the solution  , where

, where  . The force of compression of a deformable element will be

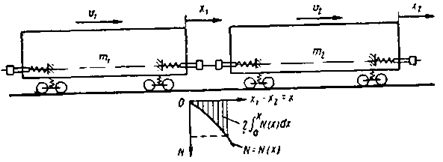

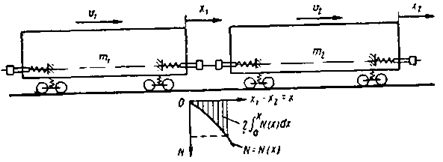

. The force of compression of a deformable element will be  .In the end, you can define a dimensionless the duration of the strike pt.To determine the force of collision of bodies also use the method of solving problems of collisions with the recovery rate. This method is widely used, for example, for the analytical study of the collision, the rail cars, as a result of which make characteristics of friction-absorbing devices[4]. Let us consider the scheme of collision of two cars, as shown in figure 3. The diagram shows two moving with velocities V1 and V2 of the car and then on the basis of the law of conservation of energy equation for their impact can be written as:

.In the end, you can define a dimensionless the duration of the strike pt.To determine the force of collision of bodies also use the method of solving problems of collisions with the recovery rate. This method is widely used, for example, for the analytical study of the collision, the rail cars, as a result of which make characteristics of friction-absorbing devices[4]. Let us consider the scheme of collision of two cars, as shown in figure 3. The diagram shows two moving with velocities V1 and V2 of the car and then on the basis of the law of conservation of energy equation for their impact can be written as: | (1) |

where  - the energy required for compression of their cushioning devices.

- the energy required for compression of their cushioning devices. | Figure 2. Scheme for calculation of a shock load and the damping |

| Figure 3. The Calculation scheme of the dynamics of the collision of cars |

Solving equation (1) is widely known way, you can define the efforts of the collision N, showing the effort of compression of a friction unit N1 and effort of compression Nm, when the cars are connected rigidly, respectively, to the dependencies: | (2) |

| (3) |

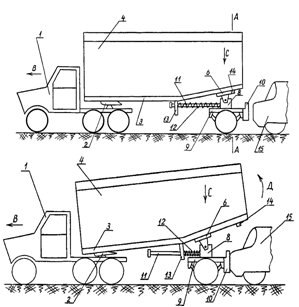

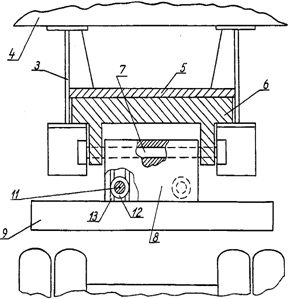

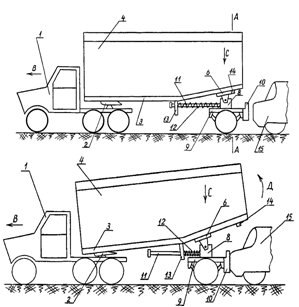

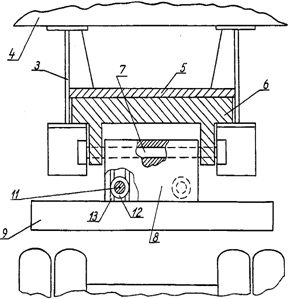

where, Спр - the hardness of friction devices;ψ - transfer coefficient compression;i - coefficient taking into account the amount of compression springs;k - the coefficient taking into account the additional absorption of energy;N0, V0 - respectively strength and speed in the interaction of cars, the relevant time the complete compression devices;Cn - dynamic rigidity of cars with the elastic deformation of their frames.Analyzing the above, it is evident that for the study of force loading of bodies of passenger cars in emergency situations, when the last bump in the stern of the road-trains, as well as the development of technical means to save the life of the people, who are in passenger cars and caught in such a situation, there are methods of analytical research, which are widely used in practice. It is clear that some methods of calculation, which would help establish a rational parameters of rigidity characteristics of bodies, is not enough. Apparently, the necessary constructive elaboration of devices, to prevent such situations, accompanied by a fatal outcome.At the present time, both in our country and abroad are widely used various purpose and design of the automobile semi-trailers of this, for example, a model ОДАЗ-885, MAZ-5205А, MAZ-9389, MAZ-5232В, ОДАЗ-9925, РЗ-ВЦП-11, TC-6, УМЗАП-9399, ОДАЗ-935, НАМИ-790, Volvo-А89-32, etc. However, all these design of the semi-trailers have no devices to eliminate the death of the people in cars, moving at high speed in the moment of collision of the past, especially at night, with the aft part of the moving ahead heavy-duty truck.Analysis of numerous literary and patent sources allowed to develop a perspective of technical solutions with regard to the structure of heavy-duty automobile trailers, which allows in case of emergency reduce the likelihood of injury drivers and car passengers with a fatal outcome.Such technical decision as the invention of the RU 2240249С1 and consists of a number of components of the structural elements, as shown in figure 4 and figure 5.So to car-tow truck 1 with the tractor unit 2, which contains a frame 3 semi-4. In the back of the frame 3 is located reference sheet 5, contact with the base plate 6, which with the help of a finger 7 hinged mounted on the bracket 8 cart frame 9. The frame 9 rigidly fixed safety Board 10, and on the bracket 8 fixed rods 11 with the springs of compression 12, which are in contact with both the surface of the bracket 8, as well as with the napravitel 13, rigidly fixed on the frame 3 of semi trailer 4. On the frame 3 of semi trailer 4 also rigidly fixed limiter 14 movement of trolley 9, and with safety bar 10 contacts passenger car 15. | Figure 4. General view of the train before and after the collision with the car |

| Figure 5. Section cart semi-trailer rear view |

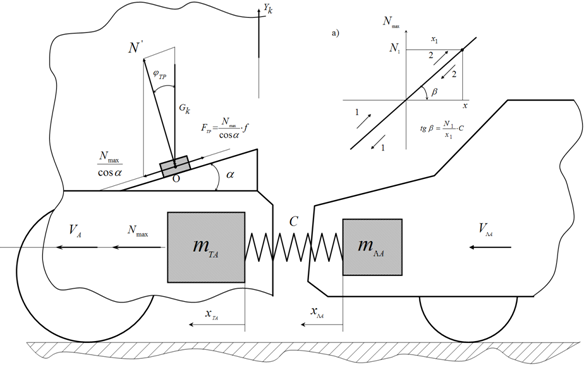

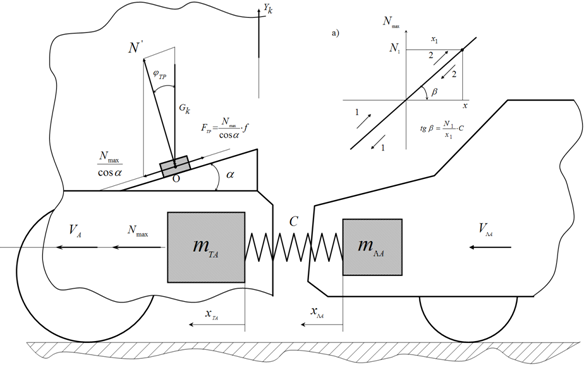

The work of the train is as follows. In the process of its movement by the arrow B (figure 4) semi-trailer 4 is located in the situation, when Dolly 9 is located in the far right position, and the base plate 6 resting on the limiter 14 frame 3 semi-4. The springs 12 with some predefined effort of the act on the brackets 8, and, hence, and on the base plate 6 through his finger 7, which creates a fixed position carts 9 in this division frame 3. In the case when the passenger car 15 of the causes of slumber or sleep driver, as well as other reasons for the significant speed of catching up with the train and goes in safety Board 10 carts 9 (fig. 4), the latter with the acceleration of moves on the arrow B, slipping base plate 6 for reference sheet 5 of the frame 3 semi-4, and compresses the spring 12. Depending on the size of a shock load the last will be limited to the cart 9 in the direction of the arrow B the daytime it will be at the expense of compression springs 12, frictional force arising in the contact zone of the base plate 6 and a reference sheet 5, as well as overcoming its own weight of semitrailer 4, which acts on the cart 9 on the arrow С. As Rama 3 semi-4 in its rear part has a sloping surface, then when moving the cart 9 in the direction of the arrow B take place simultaneously and the angular rotation of the semitrailer 4 on the arrow Д at a saddle-vehicle-truck, and it further excludes interaction of the upper part of the body of the passenger car 15 with semi-4, which protects against injury of the people in it. After the investigation of the accident train move the arrow В, and under the action of compressed spring 12 Dolly 9 returns to the initial transport position is, as it is shown in Fig.4. If such a return is difficult, then, smoothly wheels of the trolley 9 and moving car-tractor on the arrow В, you can reach the movement of reference sheet 5 on the base plate 6, and the semi-trailer 4 and Dolly 9 will take the position shown in figure 4.To study the interaction of the power of a passenger car at the time of collision him with a stern part of the semi-trailer is designed scheme, as shown in fig.6. It concentrated masses mта (mass of the cart of a semi-trailer truck) and mла (weight of the car) connected between an elastic coupling rigidity С (spring damping device, see figure 4.). The mass of the mта and mла move with the translational velocity VА and VЛА, and VЛА > VА. The collision of these forces arise Nmax, contributing to the relative movement xта and xла. On the semi-trailer is a force of its own body weight Gк. Under the action of forces Nmax at the point O contact of the body of a semi-trailer with a cart, with inclined planes pairing under the angle of a relative to the horizon, there are progressive force  , the force of friction

, the force of friction  and the normal component

and the normal component  of ensuring the progressive movement

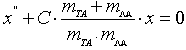

of ensuring the progressive movement  of the body of a semi-trailer in the vertical plane of motion of the train. For the us the case of the differential equation of motion of the train and a passenger car is of the form:

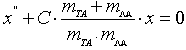

of the body of a semi-trailer in the vertical plane of motion of the train. For the us the case of the differential equation of motion of the train and a passenger car is of the form:  or, marking

or, marking  , we obtain the equation:

, we obtain the equation: | (4) |

where  - the relative movement of vehicles;

- the relative movement of vehicles;  and

and  - absolute movement of two colliding masses.

- absolute movement of two colliding masses.  | Figure 6. Calculation scheme |

The solution of equation (4) we are looking for in the form of:  , where С1 and С2 are constants of integration.Using the initial conditions

, where С1 and С2 are constants of integration.Using the initial conditions  ,

,  and

and  , where

, where  - the relative speed of colliding masses, receive

- the relative speed of colliding masses, receive  and

and  . Then the decision will take the form:

. Then the decision will take the form:  .We believe that the elastic properties of rigidity C have a linear response (see fig.6a), the force, resulting in the equivalent of spring, of changes under the same law, and that its deformation, so the fair will be the following entry:

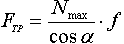

.We believe that the elastic properties of rigidity C have a linear response (see fig.6a), the force, resulting in the equivalent of spring, of changes under the same law, and that its deformation, so the fair will be the following entry: . The greatest same value of the effort Nmax get in

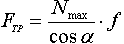

. The greatest same value of the effort Nmax get in  , when the sinetreats of the unit, therefore:

, when the sinetreats of the unit, therefore: | (5) |

Spend an example of numerical calculation by definition Nmax on the example of the collision, the car model VAZ-2107 of full weight  kg[17] when it is moving with a speed

kg[17] when it is moving with a speed  km/h (33,3 m/s), with a cart of automobile semi-trailer models of MAZ-5205А, which has many of the body with the burden attributable to the cart, is 18,0 t[17], and the mass of the cart is 786 kg also moving in the train with a speed

km/h (33,3 m/s), with a cart of automobile semi-trailer models of MAZ-5205А, which has many of the body with the burden attributable to the cart, is 18,0 t[17], and the mass of the cart is 786 kg also moving in the train with a speed  km/h (11.1 m/s). Pre-let's hardness equivalent elastic connection C = 3.8 t/m. Using the formula (5), we obtain:

km/h (11.1 m/s). Pre-let's hardness equivalent elastic connection C = 3.8 t/m. Using the formula (5), we obtain: Check, what would be equal to the residual deformation of the body VAZ-2107 under the influence of a shock load 9.1 tons. For this, we first define the longitudinal rigidity of the car Ск taking into account the location in his under hood part of the motor depending on[16]:

Check, what would be equal to the residual deformation of the body VAZ-2107 under the influence of a shock load 9.1 tons. For this, we first define the longitudinal rigidity of the car Ск taking into account the location in his under hood part of the motor depending on[16]: where E – the modulus of elasticity for steel, kg/cm2;F1 – the average living area of the cross section of a passenger car, F1≈190 cm2[17];L1 – the length of a body VAZ-2107, 390 cm[17];F2 – average living area of cross-section подкатной cart semi-trailer, F2≈150 cm2[17];L2 – length подкатной cart semi-trailer, 270 cm[17].Then, with this value of the Ск, the deformation of the body will be

where E – the modulus of elasticity for steel, kg/cm2;F1 – the average living area of the cross section of a passenger car, F1≈190 cm2[17];L1 – the length of a body VAZ-2107, 390 cm[17];F2 – average living area of cross-section подкатной cart semi-trailer, F2≈150 cm2[17];L2 – length подкатной cart semi-trailer, 270 cm[17].Then, with this value of the Ск, the deformation of the body will be  .It is seen that the described parameters of collision, will residual deformation of the front of the car VAZ-2107 at a value of about 900 mm. Given that cars are equipped with airbags, they will at this stage of the collision, the deformation of the body 0.9 m save the life of the driver and the one sitting, for example, near the passenger. According to the scheme (figure 6) shows that under the action of forces

.It is seen that the described parameters of collision, will residual deformation of the front of the car VAZ-2107 at a value of about 900 mm. Given that cars are equipped with airbags, they will at this stage of the collision, the deformation of the body 0.9 m save the life of the driver and the one sitting, for example, near the passenger. According to the scheme (figure 6) shows that under the action of forces  in the zone of contact of the cart with a frame semi-trailer, which is at an angle

in the zone of contact of the cart with a frame semi-trailer, which is at an angle  to the horizon, there will be a force

to the horizon, there will be a force  . In this case, the normal force

. In this case, the normal force  , which will move the body of the semi-trailer in the vertical plane of motion of the train, to decide

, which will move the body of the semi-trailer in the vertical plane of motion of the train, to decide  . The obtained result shows that

. The obtained result shows that  (19,6 > 19,3), therefore, the movement of the body of a semi-trailer in this direction will be provided. Since the length of trolley semi-trailer

(19,6 > 19,3), therefore, the movement of the body of a semi-trailer in this direction will be provided. Since the length of trolley semi-trailer  , then you can specify a value

, then you can specify a value  (figure 7), showing in which value can raise up the body of the semi-trailer

(figure 7), showing in which value can raise up the body of the semi-trailer  . The movement of the body in this direction will allow to accommodate the roof of the car VAZ-2107 of the latter and thereby eliminate the deformation of her, that in the end will save the life of the people in the car already in the back seat. Knowing linear movement подкатной cart equal to 2.3 m, install the geometric dimensions of the spring stiffness С (see figure 4), using the reference data on the screw springs of compression[19]. As in the proposed design (figure 4) semi-trailer installed on the rods, placed parallel to each other, the two springs of compression, the total hardness define C = C1+C2 and then the stiffness of each of them will be equal to С1 = С2 = 1,9 t/m, diameter of bar d = 8 mm, step turns t = 40 mm, the length of the free state l = 2.2 m, the length of the full compression l1 = 460 mm, outer diameter dн = 120 mm, internal diameter dв = 100 mm and material rod - steel 60С2[t] = 75 kg/mm2.

. The movement of the body in this direction will allow to accommodate the roof of the car VAZ-2107 of the latter and thereby eliminate the deformation of her, that in the end will save the life of the people in the car already in the back seat. Knowing linear movement подкатной cart equal to 2.3 m, install the geometric dimensions of the spring stiffness С (see figure 4), using the reference data on the screw springs of compression[19]. As in the proposed design (figure 4) semi-trailer installed on the rods, placed parallel to each other, the two springs of compression, the total hardness define C = C1+C2 and then the stiffness of each of them will be equal to С1 = С2 = 1,9 t/m, diameter of bar d = 8 mm, step turns t = 40 mm, the length of the free state l = 2.2 m, the length of the full compression l1 = 460 mm, outer diameter dн = 120 mm, internal diameter dв = 100 mm and material rod - steel 60С2[t] = 75 kg/mm2.  | Figure 7. The results of the calculation of the stiffness of springs for different car models |

4. Results

It is known that at present the domestic automotive industry large-scale production produces various models of passenger cars, total weight of which does not exceed on average of 1.5-2.0 tons, and also foreign models of this class and previously sold models of the domestic production, widely used in practice. Therefore, given the diversity of the Park, which is the legal and physical persons, and the possibility of emergency situations described above, as well as establishing a rational geometric parameters of elastic elements, included in the design of the trolleys semi-trailers, aggregated in the ladder of trains, used a computer program using a language Delphi, an example of the window, which is shown in figure 7.As a result of the performed calculations found that the rational value stiffness of the elastic elements, placed on the rods of the on podkatny carts semi-trailers, excluding the injury of the people of fatal injuries from collision of passenger cars with rear parts of them, should be the value of the order 3,95-4,23 t/m at the cart equal to not less than of 2.45 m and a slope angle α reference sheet frame semi-trailer of no more than 320.

5. Discussion and Conclusions

On the basis of the above we can make the following conclusions and recommendations:1. Analysis of bibliographic sources, dedicated to traffic safety of motor transport, including in the operation of heavy-duty trucks, both in our country and abroad shows, one of the types of injury of people with a fatal outcome, located in the passenger cars, moving at high speed, especially in the night time, are those when the driver, located in the Sandman or short-term dream, is faced with the back of the trailer. Such interaction colliding vehicles contributes to the fact that a car of “comes” under the semi-trailer, and his frame cuts off the roof of a car, as a result of which within it, people instantly die. Therefore, the development of technical means, preventing such injuries, is very urgent.2. The analysis of domestic and foreign patent sources allowed to develop at the level of the invention of perspective construction of heavy-duty automobile semi-trailer (patent RU2240249С1),in which, through the use of mobile of his cart, when impact occurs last in the longitudinal plane of the motion with the subsequent rise of the rear part of semitrailer, which ensures unimpeded entry of a passenger car with the last.3. Conducted analytical research on the basis of the developed design scheme are allowed to justify rational geometrical characteristics of the end part of the heavy duty semitrailer and, in particular, to recommend to the total stiffness of the two screw springs of compression С = 3,95-4,23 t/m, the course of the carts of 2.45 m and a tilt angle of the reference sheet frame α = 320. Such parameters are acceptable for passenger cars, total weight of which lies in the range of 1.0 to 2.0 tons.4. In the calculations of these parameters has been developed and used a computer program in Delphi, which allows to solve such problems for studying the interaction of different types of passenger cars with trailers in emergency situations.5. The results of the study recommended the scientific-research and design units of the automobile industry of the Russian Federation, as well as enterprises, producing heavy-duty automobile semi-trailers, as in our country and abroad with a view to the possible implementation of the proposed development in practice.

References

| [1] | Babakov I.M. Theory of oscillations. - M.: Nauka, 1989. – 554 p. |

| [2] | Babkov V.F. Road conditions and traffic safety. - M.: Transport, 1982. - 288 p. |

| [3] | Vasiljev A.P. The condition of the roads and safety of cars in difficult weather conditions. - M.: Transport, 1986. – 244 p. |

| [4] | Vershinsky S.V. etc. Dynamics of the car. - M.: Transport, 1982. - 304 p. |

| [5] | Vysotsky М.S., etc. Automobile and tractor trailers. - M.: Машгиз, 1982. - 162 p. |

| [6] | Indikt E.A. Chernyakin V.A. The operational reliability of freight cars. - M.: WE, 1987. - 92 p. |

| [7] | Lobanov EM. Design of roads and organization of the movement with regard psychophysiology of the driver. - M.: Transport, 1980. - 311 p. |

| [8] | Nemtsov YU.M., Mayboroda O.V. The performance of the vehicles regulated by the requirements of traffic safety. - M.: Transport, 1997. - 141 p. |

| [9] | Fundamentals of applied theory of vibrations and shock / Ya.G. Panovko. 4-th Izd., pererab. I dop. - L.: Polytechnic, 1990. - 272 p. |

| [10] | Ostrovtsev A.N. and others. Criteria of quality assessment and management of motor vehicles at the design stage of production and operation. - M.: MADI, 1991. - 95 p. |

| [11] | Rotenberg R.V. Roads and reliability of the driver// Designing of motor roads and the database. - M.: MADI, 1992. p. 28-35. |

| [12] | Rotenberg R.V. The basics of system reliability “driver-car-road-environment”. - M.: “Mechanical engineering”, 1986. - 216 p. |

| [13] | Trikozyuk V.A. Increase of reliability of the car. - M.: Mechanical engineering. - 1987. - 88 p. |

| [14] | Fedotov V.V. etc. Problems and experience of the medical-technical prevention of road accidents. - M.: Transport, 1987. - 77 p. |

| [15] | Wolkov I.G., etc. Directory of mechanization experts of a sea port. - M.: Sea transport, 1989. – 450 p. |

| [16] | Gold B.V., etc. The foundations of strength and durability of the car. - M.: Machinery, 1987. - 212 p. |

| [17] | A summary of the automobile reference book. - 10-e Izd., pererab. I DOP. - M.: Transport, 1983. - 220 p. |

| [18] | Fundamentals of the theory and calculation of agricultural machinery on the strength and reliability of/ under ed. P.M. Volkov, M.M. Tanenbaum. - M.: Machinery, 1977. - 310 p. |

| [19] | Ponomarev S.D., Andreeva L.E. The calculation of the elastic elements of machines and devices. - M.: Machinery, 1980. – 326 p. |

| [20] | Slivinsky E.V., Bykova O.S. Road train patent RU 2240249С1 from 20.11.04. |

| [21] | Slivinsky E.V., Bykova O.S. For calculation of the main parameters of safety devices with the help of a computer for the exception of fatal injuries in the operation of the cars. Informatics: concepts, modern condition, prospects of development. Materials of interuniversity scientific-practical conference. - Voronezh, 2006. - p. 135-137. |

| [22] | Theory and design of the vehicle: Ucheb. For motor colleges / V.A. Ilarionov, etc. 3-e Izd., pererab. I DOP. - M.: Machinery, 2002. - 375 p. |

Or

Or In the mentioned equations S is called instantaneous shock pulse, and obtained in the transition from t0 to t1 force is called the instantaneous shock force and is determined by:

In the mentioned equations S is called instantaneous shock pulse, and obtained in the transition from t0 to t1 force is called the instantaneous shock force and is determined by: where δ is the Dirac Delta function.If, on the condition of the problem, the strike force set explicit function of time P(t) or momentary impulse S, then the problem is reduced to the study of forced vibrations of mechanical systems and can be solved known methods of the theory of oscillations[1,9]. Consider the case of a collision, the mass m with the account of the rigidity C another body (figure 1).

where δ is the Dirac Delta function.If, on the condition of the problem, the strike force set explicit function of time P(t) or momentary impulse S, then the problem is reduced to the study of forced vibrations of mechanical systems and can be solved known methods of the theory of oscillations[1,9]. Consider the case of a collision, the mass m with the account of the rigidity C another body (figure 1).

, i.e., using a normal differential equation of free oscillations, which decision has the form

, i.e., using a normal differential equation of free oscillations, which decision has the form  , where

, where  .Hence it follows, that the greatest deformation of an elastic connection rigidity C is determined by:

.Hence it follows, that the greatest deformation of an elastic connection rigidity C is determined by:  , in this case the maximum force of compression will be

, in this case the maximum force of compression will be  .In the second case the determination of the deformation of the system, shown in fig.1b, produce, using the equation of energy. As a result of the deflection of the beam can be determined depending on:

.In the second case the determination of the deformation of the system, shown in fig.1b, produce, using the equation of energy. As a result of the deflection of the beam can be determined depending on: .To determine the value of the coefficient of the speakers in this case, use the equation:

.To determine the value of the coefficient of the speakers in this case, use the equation: .In practice, in a study of the impact of physical bodies can be used design, and, consequently, the models without the inertial elastic and viscous elements (figure 2).Movement of the mass m after the beginning of the shock of the contact is described by the differential equation:

.In practice, in a study of the impact of physical bodies can be used design, and, consequently, the models without the inertial elastic and viscous elements (figure 2).Movement of the mass m after the beginning of the shock of the contact is described by the differential equation:  . Assuming the initial conditions of the form

. Assuming the initial conditions of the form  , and

, and  , get the solution

, get the solution  , where

, where  . The force of compression of a deformable element will be

. The force of compression of a deformable element will be  .In the end, you can define a dimensionless the duration of the strike pt.To determine the force of collision of bodies also use the method of solving problems of collisions with the recovery rate. This method is widely used, for example, for the analytical study of the collision, the rail cars, as a result of which make characteristics of friction-absorbing devices[4]. Let us consider the scheme of collision of two cars, as shown in figure 3. The diagram shows two moving with velocities V1 and V2 of the car and then on the basis of the law of conservation of energy equation for their impact can be written as:

.In the end, you can define a dimensionless the duration of the strike pt.To determine the force of collision of bodies also use the method of solving problems of collisions with the recovery rate. This method is widely used, for example, for the analytical study of the collision, the rail cars, as a result of which make characteristics of friction-absorbing devices[4]. Let us consider the scheme of collision of two cars, as shown in figure 3. The diagram shows two moving with velocities V1 and V2 of the car and then on the basis of the law of conservation of energy equation for their impact can be written as:

- the energy required for compression of their cushioning devices.

- the energy required for compression of their cushioning devices.

, the force of friction

, the force of friction  and the normal component

and the normal component  of ensuring the progressive movement

of ensuring the progressive movement  of the body of a semi-trailer in the vertical plane of motion of the train. For the us the case of the differential equation of motion of the train and a passenger car is of the form:

of the body of a semi-trailer in the vertical plane of motion of the train. For the us the case of the differential equation of motion of the train and a passenger car is of the form:  or, marking

or, marking  , we obtain the equation:

, we obtain the equation:

- the relative movement of vehicles;

- the relative movement of vehicles;  and

and  - absolute movement of two colliding masses.

- absolute movement of two colliding masses.

, where С1 and С2 are constants of integration.Using the initial conditions

, where С1 and С2 are constants of integration.Using the initial conditions  ,

,  and

and  , where

, where  - the relative speed of colliding masses, receive

- the relative speed of colliding masses, receive  and

and  . Then the decision will take the form:

. Then the decision will take the form:  .We believe that the elastic properties of rigidity C have a linear response (see fig.6a), the force, resulting in the equivalent of spring, of changes under the same law, and that its deformation, so the fair will be the following entry:

.We believe that the elastic properties of rigidity C have a linear response (see fig.6a), the force, resulting in the equivalent of spring, of changes under the same law, and that its deformation, so the fair will be the following entry: . The greatest same value of the effort Nmax get in

. The greatest same value of the effort Nmax get in  , when the sinetreats of the unit, therefore:

, when the sinetreats of the unit, therefore:

kg[17] when it is moving with a speed

kg[17] when it is moving with a speed  km/h (33,3 m/s), with a cart of automobile semi-trailer models of MAZ-5205А, which has many of the body with the burden attributable to the cart, is 18,0 t[17], and the mass of the cart is 786 kg also moving in the train with a speed

km/h (33,3 m/s), with a cart of automobile semi-trailer models of MAZ-5205А, which has many of the body with the burden attributable to the cart, is 18,0 t[17], and the mass of the cart is 786 kg also moving in the train with a speed  km/h (11.1 m/s). Pre-let's hardness equivalent elastic connection C = 3.8 t/m. Using the formula (5), we obtain:

km/h (11.1 m/s). Pre-let's hardness equivalent elastic connection C = 3.8 t/m. Using the formula (5), we obtain: Check, what would be equal to the residual deformation of the body VAZ-2107 under the influence of a shock load 9.1 tons. For this, we first define the longitudinal rigidity of the car Ск taking into account the location in his under hood part of the motor depending on[16]:

Check, what would be equal to the residual deformation of the body VAZ-2107 under the influence of a shock load 9.1 tons. For this, we first define the longitudinal rigidity of the car Ск taking into account the location in his under hood part of the motor depending on[16]: where E – the modulus of elasticity for steel, kg/cm2;F1 – the average living area of the cross section of a passenger car, F1≈190 cm2[17];L1 – the length of a body VAZ-2107, 390 cm[17];F2 – average living area of cross-section подкатной cart semi-trailer, F2≈150 cm2[17];L2 – length подкатной cart semi-trailer, 270 cm[17].Then, with this value of the Ск, the deformation of the body will be

where E – the modulus of elasticity for steel, kg/cm2;F1 – the average living area of the cross section of a passenger car, F1≈190 cm2[17];L1 – the length of a body VAZ-2107, 390 cm[17];F2 – average living area of cross-section подкатной cart semi-trailer, F2≈150 cm2[17];L2 – length подкатной cart semi-trailer, 270 cm[17].Then, with this value of the Ск, the deformation of the body will be  .It is seen that the described parameters of collision, will residual deformation of the front of the car VAZ-2107 at a value of about 900 mm. Given that cars are equipped with airbags, they will at this stage of the collision, the deformation of the body 0.9 m save the life of the driver and the one sitting, for example, near the passenger. According to the scheme (figure 6) shows that under the action of forces

.It is seen that the described parameters of collision, will residual deformation of the front of the car VAZ-2107 at a value of about 900 mm. Given that cars are equipped with airbags, they will at this stage of the collision, the deformation of the body 0.9 m save the life of the driver and the one sitting, for example, near the passenger. According to the scheme (figure 6) shows that under the action of forces  in the zone of contact of the cart with a frame semi-trailer, which is at an angle

in the zone of contact of the cart with a frame semi-trailer, which is at an angle  to the horizon, there will be a force

to the horizon, there will be a force  . In this case, the normal force

. In this case, the normal force  , which will move the body of the semi-trailer in the vertical plane of motion of the train, to decide

, which will move the body of the semi-trailer in the vertical plane of motion of the train, to decide  . The obtained result shows that

. The obtained result shows that  (19,6 > 19,3), therefore, the movement of the body of a semi-trailer in this direction will be provided. Since the length of trolley semi-trailer

(19,6 > 19,3), therefore, the movement of the body of a semi-trailer in this direction will be provided. Since the length of trolley semi-trailer  , then you can specify a value

, then you can specify a value  (figure 7), showing in which value can raise up the body of the semi-trailer

(figure 7), showing in which value can raise up the body of the semi-trailer  . The movement of the body in this direction will allow to accommodate the roof of the car VAZ-2107 of the latter and thereby eliminate the deformation of her, that in the end will save the life of the people in the car already in the back seat. Knowing linear movement подкатной cart equal to 2.3 m, install the geometric dimensions of the spring stiffness С (see figure 4), using the reference data on the screw springs of compression[19]. As in the proposed design (figure 4) semi-trailer installed on the rods, placed parallel to each other, the two springs of compression, the total hardness define C = C1+C2 and then the stiffness of each of them will be equal to С1 = С2 = 1,9 t/m, diameter of bar d = 8 mm, step turns t = 40 mm, the length of the free state l = 2.2 m, the length of the full compression l1 = 460 mm, outer diameter dн = 120 mm, internal diameter dв = 100 mm and material rod - steel 60С2[t] = 75 kg/mm2.

. The movement of the body in this direction will allow to accommodate the roof of the car VAZ-2107 of the latter and thereby eliminate the deformation of her, that in the end will save the life of the people in the car already in the back seat. Knowing linear movement подкатной cart equal to 2.3 m, install the geometric dimensions of the spring stiffness С (see figure 4), using the reference data on the screw springs of compression[19]. As in the proposed design (figure 4) semi-trailer installed on the rods, placed parallel to each other, the two springs of compression, the total hardness define C = C1+C2 and then the stiffness of each of them will be equal to С1 = С2 = 1,9 t/m, diameter of bar d = 8 mm, step turns t = 40 mm, the length of the free state l = 2.2 m, the length of the full compression l1 = 460 mm, outer diameter dн = 120 mm, internal diameter dв = 100 mm and material rod - steel 60С2[t] = 75 kg/mm2.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML