-

Paper Information

- Next Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Traffic and Transportation Engineering

p-ISSN: 2325-0062 e-ISSN: 2325-0070

2013; 2(2): 9-13

doi:10.5923/j.ijtte.20130202.01

Tire Inflation Pressure Influence on a Vehicle Stopping Distances

Vladimír Rievaj, Ján Vrábel, Anton Hudák

University of Zilina, Faculty of Operation and Economics of Transport and Communications, Univerzitna 1, 010 26 Zilina, Slovakia

Correspondence to: Ján Vrábel, University of Zilina, Faculty of Operation and Economics of Transport and Communications, Univerzitna 1, 010 26 Zilina, Slovakia.

| Email: |  |

Copyright © 2012 Scientific & Academic Publishing. All Rights Reserved.

Health and ensure the safety of the road is now a priority in Europe. The authors deal with the adhesion problems of tires – ground contact under process of vehicle braking. The proper tire pressure is just part of many factors inflicting stopping distances of vehicle. The article describes the stopping distance dependence on tire pressure. It has been tested three probable options (e.g. overcrowding, under-inflation and adherence to the values specified by the manufacturer).

Keywords: Road Safety, Pressure, Stopping Distance

Cite this paper: Vladimír Rievaj, Ján Vrábel, Anton Hudák, Tire Inflation Pressure Influence on a Vehicle Stopping Distances, International Journal of Traffic and Transportation Engineering, Vol. 2 No. 2, 2013, pp. 9-13. doi: 10.5923/j.ijtte.20130202.01.

Article Outline

1. Introduction

- Road traffic safety regulation require vehicle to be able to stop within visibility distance. The reaction pathway depends on the driver´s speed of reaction, concentration, experience and immediate mental and physical condition. The driver does not change direction or speed of a vehicle during the phase from noticing obstacle to the stopping of the vehicle. The stopping distance of a vehicle is determined by several factors which affect tire grip such as weather conditions (e.g. rain, fog, lighting conditions), geography (e.g. slope traverse plane), speed, quality and type of tire.[1],[2] The driver scope is influenced by density of transport flux, the driver's view of traffic flow (e.g. saddle, peak), topography and environment. The driver is required to drive only at a speed to be able stop before an obstacle is suddenly revealed ahead. The distance travelled by the vehicle from the moment of the obstacle appearing to the vehicle standstill is called trajectory required to stop a vehicle. It is influenced by the driver's ability to respond to the technical and structural status of the braking system, driver´s speed and tire design. This distance can be calculated using the following formula:

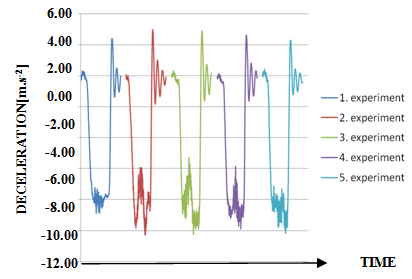

| (1) |

2. Tire Pressure

- Optimal value for a specific inflation pressure prescribed by the vehicle manufacturer to achieve the best performance of the vehicle, limiting the transmission of road surface irregularities on the vehicle, and of course to achieve the shortest stopping distance.[8]It has been perform comparative measurements at an initial speed of 50 km.h-1 to demonstrate the influence of pressure inflation on a braking distance of the vehicle. This speed has been determined based on the fact that most countries have set the speed limit in urban areas at 50 km.h-1. The reason is high traffic volume and always increasing number of mobility vulnerable road users (e.g. pedestrians, cyclists, drivers) in the village. Increased probability of collision is also caused by building-up areas as driver´s view is restricted.To eliminate random effects, the measurements are being repeating five times with the same initial speed for each tire pressure. Stopping distance measurements were performed at the airport in the village of Rosina. The passenger car used was a Citroen C6.[9]

2.1. Measurement Conditions

- Ø Used vehicle: Citroën C6Ø Road surface: dry asphaltØ Ambient temperature: 21°CØ Weather: cloudy, no wind, no rainØ Initial velocity: V0 = 50 km.h-1Ø Final velocity: V1 = 0 km.h-1Ø Deceleration:full average braking deceleration Ø Used tires:MICHELIN Primacy 245/45 R 18Ø Tires were heated by driving to operating temperatureof 60°C. This was measured with a special thermometer.Ø Inflation pressure:a) Saturation pressure 0.29 MPa (+20.83 %).b) The tire inflation pressure reached Alpha according the manufacturer specification 0.24 MPa.c) The tire inflation pressure underinflated 0.19 MPa (-20.83 %).Ø Measurement device: XL meter a) Sampling frequency XL meter was set to 200 Hz, the accuracy of the device is ± 0.1 m.s-2[10].b) Number of measurements: 15 measurements (5 for each inflation pressure)During the measurement, the vehicle and its part (e.g. tires) were not exposed to direct sunlight.

2.2. Measuring Device

- To measure the impact of tire inflation pressure for the transfer of longitudinal tangential forces between the tire and the substrate and recording the measured values, XL meter facility was used. This is capable of recording the following parameters:[11],[12]Ø Interval measurement[s]Ø Longitudinal acceleration[m.s-2]Ø Lateral acceleration[m.s-2]To eliminate random effects, the measurements are being repeating five times with the same initial speed for each tire pressure. Stopping distance measurements were performed at the airport in the village of Rosina. The passenger car used was a Citroen C6.There were measurements focused on further parameters:Ø Total stopping distance[m].Ø The initial speed of the vehicle before deceleration [km.h-1].Ø Braking time[s].Ø Full average braking deceleration[m.s-2].

3. Experiment

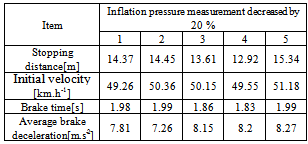

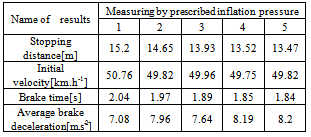

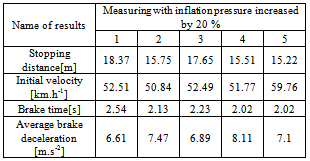

- The main intention was to run up the vehicle at a velocity of 50km.h-1 for any measurement. After reaching the interrupted transmission of torque from the engine to the wheels, the driver began work on the service brake control. Actuating force was set so as to activate the anti-lock braking system ABS.At the beginning of the measurements were tires inflated with pressure of 0.29 MPa, while the prescribed ideal inflation pressure is 0.24 MPa. Therefore the inflation pressure is 20% higher than recommended by a car producer. The inflation pressure was decreased in all tires to a level of 0.24 MPa after all the tests had been run. Then another series of measurements were done with the given inflation pressure. Another 5 measurements were executed. These 5 measurements were performed when the inflation pressure had been decreased to the level of 0.19 MPa. The changes in inflation pressure were done in the same conditions. There were no changes in ambient pressure or its temperature during the time of measurements. The tire inflation pressure was measured and tested before every single brake test.

3.1. Test Performance

|

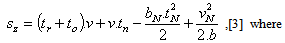

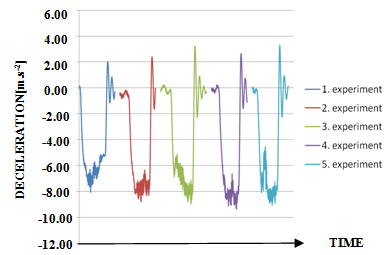

| Figure 1. The progress of acceleration of particular measurements with inflation pressure decreased by 20 % |

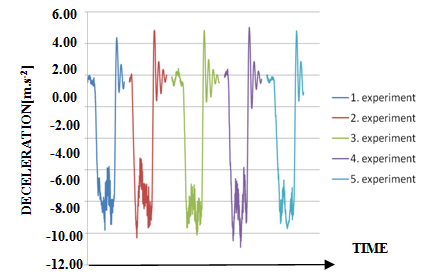

| Figure 2. The course of particular acceleration measurements when using tire pressure prescribed by car producer |

|

|

| Figure 3. The acceleration vehicle curve – tire pressure increased by 20 % |

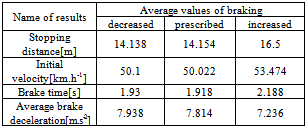

4. Conclusions

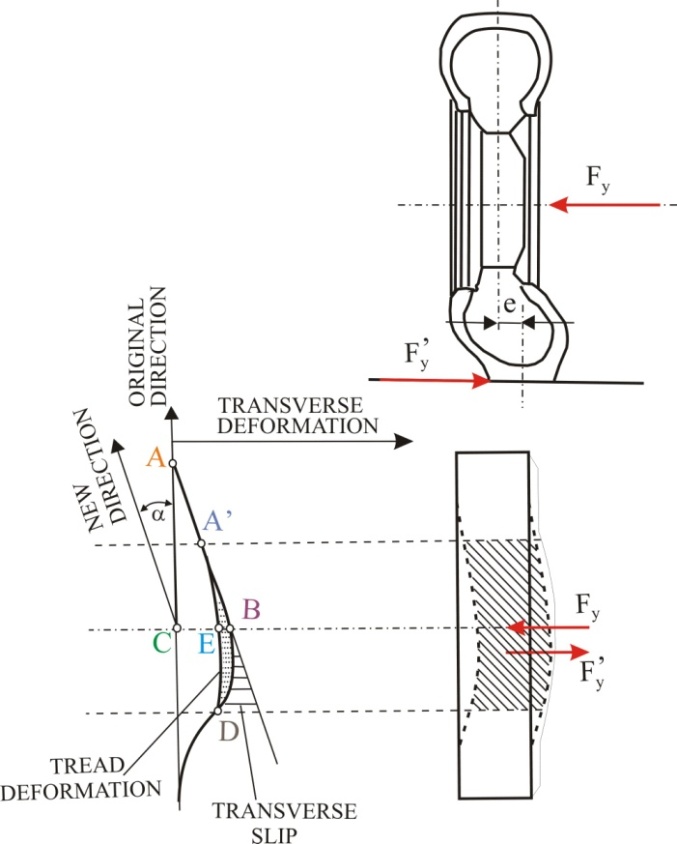

- From the results shown in Table 4, it would seem that driving on underinflated tires is beneficial in terms of stopping distance.The changes in the size of contact surface of tire with base influences the factor of hysteresis and abrasion of tread´s rubber. This is claimed to be a reason why under-inflated tire transfers greater brake forces and allows shorter stopping distance.

|

| Figure 5. Effect of lateral force on the transverse deformation of the tire Modified from[14] |

| Figure 6. Deformation of the underinflated tire |

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML