| [1] | Alimov V. N. Research of durability and durability of valves of the gas-distributing mechanism forced transport дизеля.//the Messenger of mechanical engineering. - 2001. - No. 12. |

| [2] | Anfinogenov M. A. Research of wear process of valves and the details of the diesel engine interfaced to it. Дисс. Cand.Tech.Sci.: - Novosibirsk. 1972. - p. |

| [3] | Balabin V. N. Mechanisms and bodies of a gazoraspredeleniye of transport internal combustion engines. Manual. M: MIIT, 2004,-61 page. |

| [4] | Balyuk B. K., Vakhtel V. Yu., Ermenko B. S. Increase of durability of the valve//Tractors and agricultural cars.-1966. - No. 11. |

| [5] | Betekhtin V. I., Zhurkov S. N. Temporary and temperature dependence of durability//durability Problems. – 1971.-№2. |

| [6] | Vakhtel V. Yu., Balyuk B. K. Determination of speed of a habit клапана.//Tractors and agricultural cars.-1963.-№8. - page 22-24. |

| [7] | Gas exchange in internal combustion engines: Uchebn. Grant / Century of G. Dyachenko. – To.: UMK IN, 1989.-204 pages. |

| [8] | Galgovsky Century of River, Karakulin I.F. About perfection of a design of final channels дизелей.//the Internal combustion engine. |

| [9] | Pigeon fanciers of Page. M. Grigoriev N. I. Dobrynin D. K., etc. Diknamika of modern domestic locomotives. M, 1964.123с. |

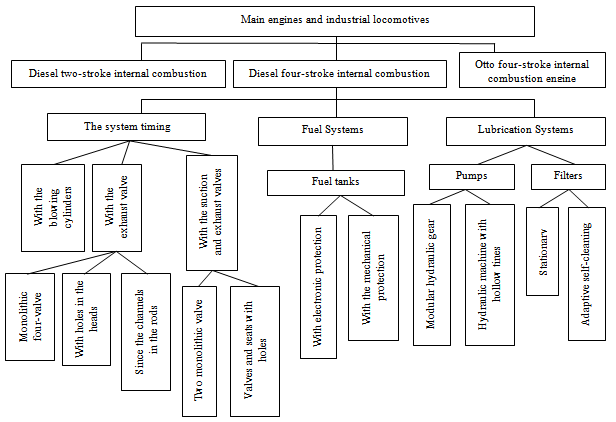

| [10] | Zubarev O. V., Brewers O.A.Modernizatsiya of four-cycle diesel DVS. Actual problems of technical science: Сб. научн. – Lipetsk: LGTU, 2009. – 286 pages. |

| [11] | Slivinsky E.V., Zubarev O. V., Brewers of the Lake. And. To synthesis of the perspective gas-distributing mechanism for duple and four-cycle diesel DVS. Control systems, technical systems: ways and research methods. Materials of interuniversity scientific and practical conference. EGU of I.A.Bunin. Yelets. Вып.3, 2011-230s. |

| [12] | Brewer O.A., Sirayev R. O. To a question of increase of efficiency of four-cycle diesel engines of industrial locomotives. Control systems, technical systems: ways and research methods. Materials of interuniversity scientific and practical conference. EGU of I.A.Bunin. Yelets. Вып.2, 2010 - 230с. |

| [13] | Slivinsky E.V., Savin L.A., Brewers of the Lake. And. Gas-distributing mechanism. Patent Russian Federation No. 2390638 from 27.05.10. |

| [14] | Slivinsky E.V., Savin L.A., Brewers О.А.К to a question of expansion of functionality of the perspective gas-distributing mechanism of four-cycle and duple diesel engines of locomotives. Control systems, technical systems: ways and research methods. Materials of interuniversity scientific and practical conference. EGU of I.A.Bunin. Yelets. Вып.3, 2011-230s. |

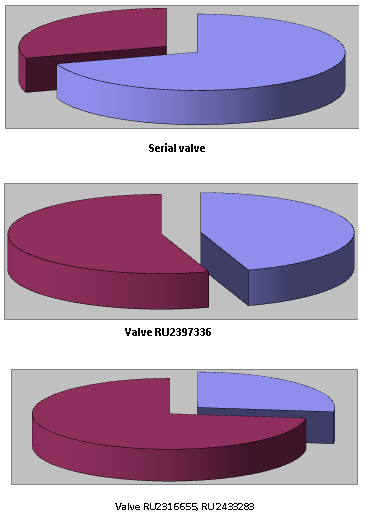

| [15] | Slivinsky E.V., Savin L.A., Brewers O.A.Mekhanizm of a gazoraspredeleniye of a diesel engine. Patent Russian Federation No. 2397336 from 20.08.10. |

| [16] | Slivinsky E.V., Savin L.A., Brewers of the Lake. And the Assessment of efficiency of use of the perspective gas-distributing mechanism of a four-cycle diesel engine тепловоза.ΙΙ the All-Russia scientific and methodical conference «Bases of design and a detail of cars – ΧΧΙ a century – the Eagle: ОрёлГТУ, 2010.-365с. |

| [17] | Slivinsky E.V., Brewers of the Lake. And. To a question of increase of efficiency of DVS at the expense of modernization of its gas-distributing mechanism. Control systems, technical systems: ways and research methods. Materials of interuniversity scientific and practical conference. EGU of I.A.Bunin. Yelets 2008-96s. |

| [18] | Brewers O.A.Razrabotka of the perspective gas-distributing mechanism for duple and four-cycle diesel DVS. Youth in a science: problems and prospects: the collection of materials of interregional congress of young scientists of Russia – Lipetsk: LGTU. 2008. – 351 pages. |

| [19] | Brewers O.A.Rasshireniye of functionality of diesel diesel engines at the expense of modernization of gas-distributing mechanisms of the [Text] / Lake. A.Pivovarov, L.A.Savin, E.V.Slivinsky//Izvestiya ORELGTU. World of transport and technological cars. – An eagle, 2012 No. 1 – page 48-52. |

| [20] | Brewers O.A.Sovershenstvovaniye of function of operation of the DVS gas-distributing mechanism by use of valves with a difficult gazodinamichesky path. Shock and vibrating systems, cars and tekhnologii./under the editorship of the Dr.Sci.Tech., the professor of H.p. Ushakov. – Eagle: ОрелГТУ, 2010-384 pages. |

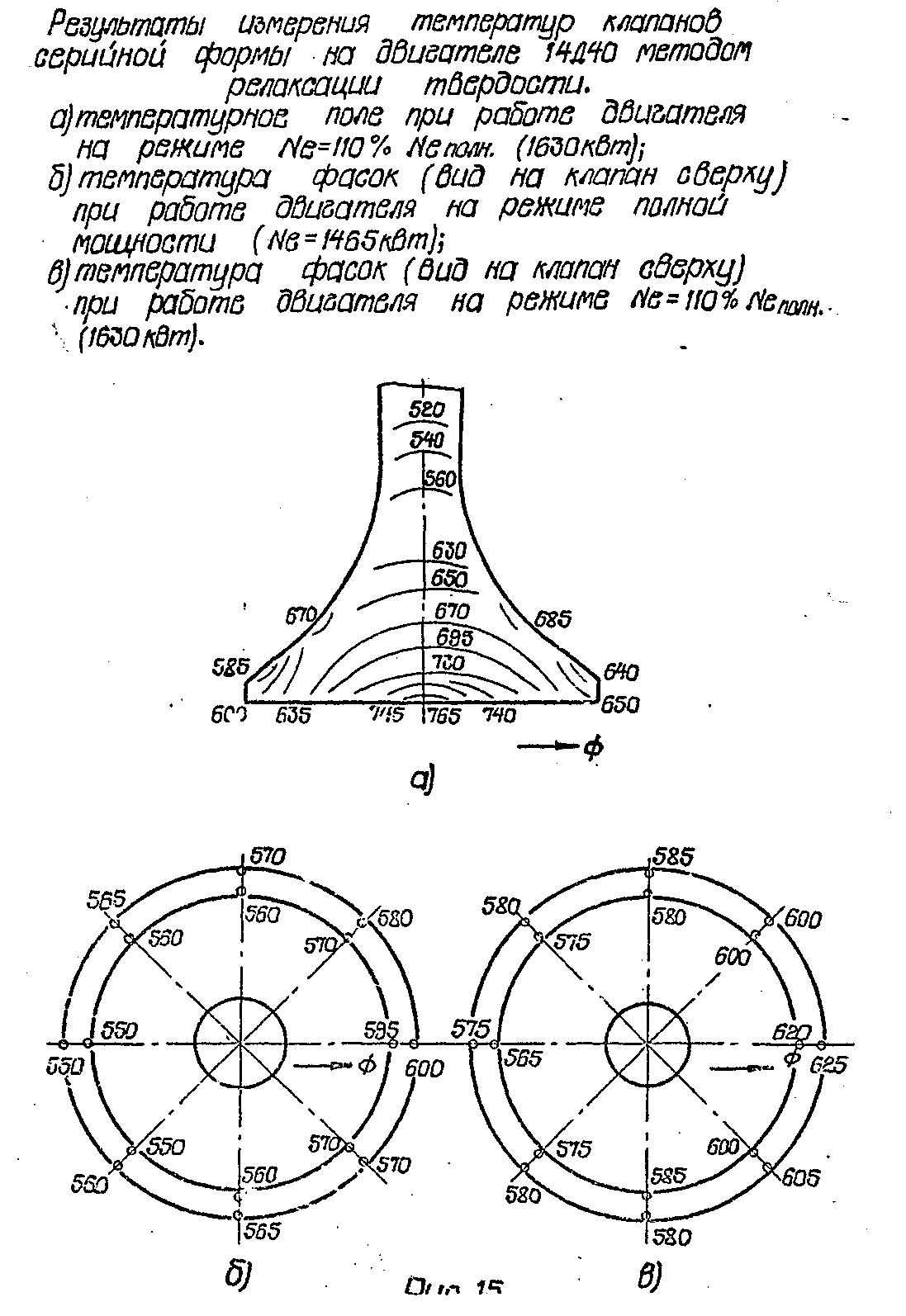

| [21] | Brewers of the Lake. And. Pilot studies of capacity of the punched final valves of the gas-distributing mechanism of a diesel engine 14Д40 the [Text] / Lake.A.Pivovarov//Izvestiya ORELGTU. World of transport and technological cars. – An eagle, 2012 No. 2 – page 32-38. |

| [22] | Slivinsky E.V.Pivovarov O.A.Mekhanizm of a gazoraspredeleniye. The patent RU 2268373 C1 from 20. 01.06. Bulletin No. 02 |

| [23] | Slivinsky E.V., Savin L.A., Brewer O.A., Increase of efficiency of use of constructional elements of diesel DVS. The collection of works of total scientific conference «About scientific potential and ways of its further development» - Lipetsk, LGTU, 2008. – 370 pages. |

| [24] | Slivinsky E.V., Savin L.A., Brewers O.A.Modernizatsiya of element base of gas-distributing mechanisms of diesel engines of the main and industrial locomotives. Engineering 2009: сб. works of a regional scientific and practical conference / edition stake.: L.A.Savin, P. G. Antonov, etc. Eagle: »Publishing house «The Oryol literature and a publishing house» and To», 2009. - 284с. |

| [25] | Slivinsky E.V., Brewers of the Lake. And. To a question of increase of efficiency of duple and four-cycle diesel diesel engines. Theory and practice of production of sheet hire [Text]: Сб. научн. тр. Part 2. - Lipetsk: LGTU, 2008. - 305с. |

| [26] | Slivinsky E.V., Brewers of the Lake. And. To a question of increase of efficiency of a diesel diesel engine at the expense of modernization of its gas-distributing mechanism. Materials of interuniversity scientific and practical conference. EGU of I.A.Bunin. Yelets, 2008-289s. |

| [27] | Slivinsky E.V of Brewers of O.A.Modernizatsiya of the perspective gas-distributing mechanism for duple and four-cycle diesel DVS. Actual problems of technical science [Text]: Сб. научн. - Lipetsk: LGTU, 2010. - 150с. |

| [28] | Slivinsky E.V., Brewers O.A.Rasshireniye of functionality of the gas-distributing mechanism of diesel engines of locomotives. Actual problems of technical science: Сб. научн. - Lipetsk: LGTU, 2009. - 286с. |

| [29] | Slivinsky E.V., Brewers O.A.Sovershenstvovaniye of gas-distributing mechanisms of diesel diesel engines. ΙΧ International scientific and technical conference «Vibration 2010. Operated vibrating technologies and cars» - Kursk: Kurskgta, 2010. - 58с. |

| [30] | Functional elements of diesel engines of locomotives. Constructional decisions. Design procedures: monograph / Lake. A.Pivovarov, L.A.Savin, Е. Century Slivinsky. - Eagle: ORLIK and K publishing House, 2010.-124 pages. |

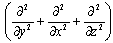

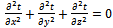

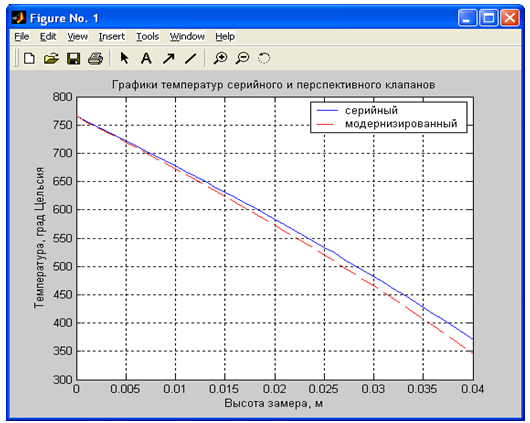

- the Laplace operator

- the Laplace operator

.Assuming that the internal heat sources are not available

.Assuming that the internal heat sources are not available  , then equation can be written in final form:

, then equation can be written in final form:

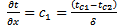

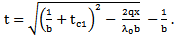

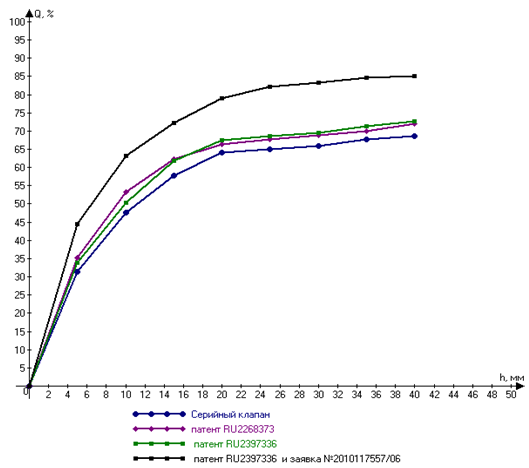

, after substituting

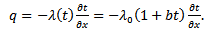

, after substituting  the values in the expression of Fourier's law we obtain the following relationship:

the values in the expression of Fourier's law we obtain the following relationship:

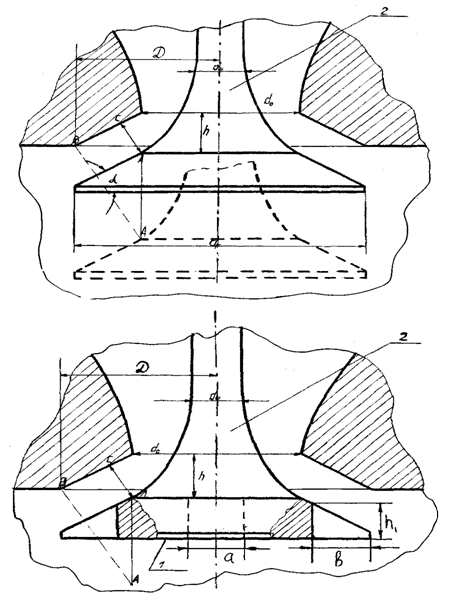

- the temperature of the valve is installed at its height, ℃tin -temperature end of the valve head, ℃;

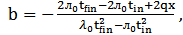

- the temperature of the valve is installed at its height, ℃tin -temperature end of the valve head, ℃;  - thermal conductivity of steel W / m ·℃.As calculated data distribution of the thermal field at a height of the valve taken the initial parameters obtained by Shiryaev[19] and is shown in fig. 4.

- thermal conductivity of steel W / m ·℃.As calculated data distribution of the thermal field at a height of the valve taken the initial parameters obtained by Shiryaev[19] and is shown in fig. 4.

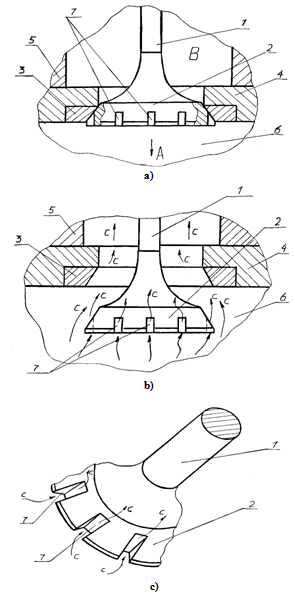

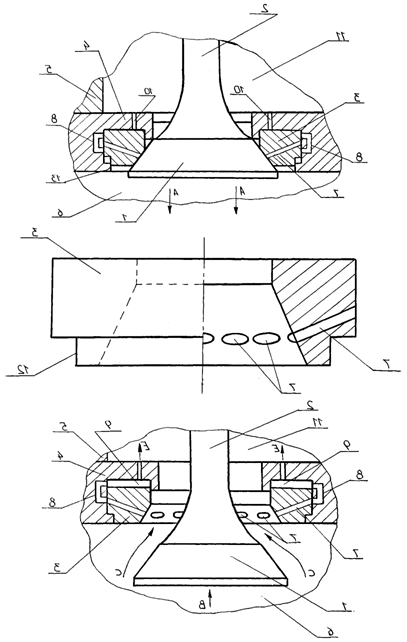

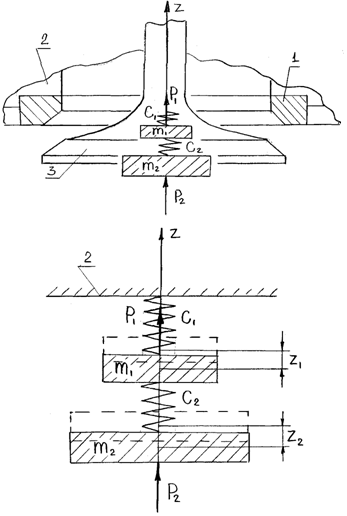

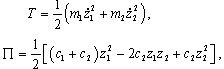

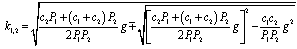

Analysis of the structure of the proposed technical solution demonstrates that the presence of inductors in the saddle can dampen shock loads applied to the saddle as well as to the valve plate in the modes of closing it. Therefore, determining the mass flow of gas traversed by a W on the dependence of the throttle:

Analysis of the structure of the proposed technical solution demonstrates that the presence of inductors in the saddle can dampen shock loads applied to the saddle as well as to the valve plate in the modes of closing it. Therefore, determining the mass flow of gas traversed by a W on the dependence of the throttle:

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-Text HTML

Full-Text HTML