-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Prevention and Treatment

p-ISSN: 2167-728X e-ISSN: 2167-7298

2020; 9(1): 1-8

doi:10.5923/j.ijpt.20200901.01

Risk Factors Associated with Artisanal and Small-scale Gold Mining in Rosterman, Kakamega, Kenya

Winnie Rabera Makokha, Jackim Matara Nyamari, Isaac K. Makau

Department of Environmental and Occupational Health, Kenyatta University, Nairobi, Kenya

Correspondence to: Winnie Rabera Makokha, Department of Environmental and Occupational Health, Kenyatta University, Nairobi, Kenya.

| Email: |  |

Copyright © 2020 The Author(s). Published by Scientific & Academic Publishing.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

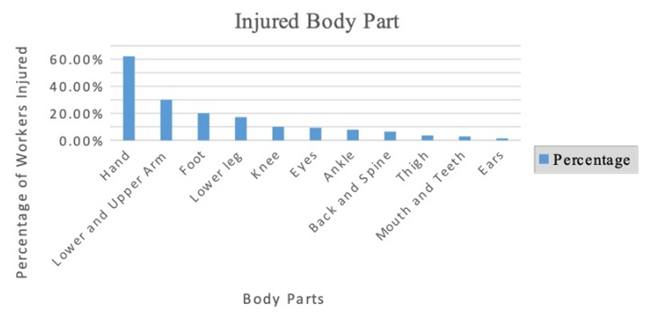

Occupational injuries, though preventable, have been described as a major public health problem. In artisanal and small-scale gold mining (ASGM), little is known about the risk factors to injuries. In 2018, we examined injuries and the potential risk factors among ASGM workers in Rosterman, Kakamega County, Kenya. A descriptive cross-sectional survey was conducted and three hundred and thirteen (313) ASGM workers were interviewed regarding their occupational injuries experiences over the preceding 1 year. Data was collected using structured interviewer administered questionnaires with the aid of open data kit (ODK) platform. Injury rates were estimated at 44.7 injuries per 100 person years. The most affected body parts were hands, upper and lower limbs at 62.14%, 30% respectively. The risk factors associated with injuries included; having an alternative source of income (p=0.027), an individual personal safety culture (p=0.021) and use of hammer or mallet as tools (p=0.022). In conclusion, injuries are prevalent among ASGM workers with several body parts being affected, the upper limbs being the most commonly affected. The study also demonstrated that there are various risk factors associated with injuries in ASGM. In view of those findings, the study recommends that injury prevention should be made a priority in ASGM intervention programs in order to reduce the burden of occupational injuries and also sensitize the workers on the risk factors they are exposed to.

Keywords: Artisanal small-scale gold mining, ASGM, ASM, Occupational injuries, Mining, Occupational health and safety, Rosterman, Kakamega

Cite this paper: Winnie Rabera Makokha, Jackim Matara Nyamari, Isaac K. Makau, Risk Factors Associated with Artisanal and Small-scale Gold Mining in Rosterman, Kakamega, Kenya, International Journal of Prevention and Treatment, Vol. 9 No. 1, 2020, pp. 1-8. doi: 10.5923/j.ijpt.20200901.01.

Article Outline

1. Introduction

- With an increasing demand for minerals and precious metals in growing economies, artisanal and small-scale mining (ASM) has proliferated worldwide, practiced in about 50 countries [1]. Close to 100 million people are dependent on it for their livelihood and in rural Africa it supports several hundred thousand households [1,2]. In Kenya, it is estimated that approximately 140,000 people are engaged in ASM and about 800,000 people depend on it for their livelihood [3]. In 2013, it was estimated that Kenya’s gold production was 3.6 tonnes with most of it originating from the artisanal and small-scale gold mining (ASGM) sector. In Rosterman, ASGM begun post 1952 after the colonial British mining company stopped their operations. The community in the area have since been mining the tailings of the abandoned sites as a source of livelihood [4]. The type of mining in Rosterman is both alluvial and hard rock mining [4]. The process of alluvial ASGM begins with digging ore from some sections of River Isiukhu where it is slow moving. The excavated ore is then processed through panning or sluicing. Hard rock mining on the other hand involves going underground through vertical or inclined narrow shafts in order to access the ore body. Using various tools such as picks, mallets, mattocks, chisels, hammers, shovels, the miners loosen the ore, excavate it, transport it through the shaft in sacks or buckets for further mechanical processing [4,5]. The ore is then grounded using hand held mortar and pestle, in some cases by mallet into smaller pieces or by generator powered grinding machines. The fine powder is then sifted over a piece of cloth while the big pieces are re-ground and re-sifted. Despite ASGM being a common economic activity, its casual nature of operations has often led to neglecting good occupational health and safety practices thus making it a source of accidents that result in injuries [6]. Other than the casual nature of operations, workers engaging in ASGM have been reported to be lacking in skills, training, knowledge and with limited resources to enable them to practice the trade safely [5,7]. Though not widely documented, the physical conditions, accompanied processes, and activities in ASGM are hazardous and are a concern for work-related injuries [5]. Some of the conditions that have led to injuries in ASGM include being struck by an object, falling, machinery and tools [5]. The International Labour Organization (ILO), estimated that non-fatal accidents are 6 to 7 times more common in small scale informal mines than in large scale organized mines [8]. In Kenya, ASGM has had a long standing illegal status up until 2016 when the repealed Mining Act CAP 306 of Kenyan laws that were in use since 1940 during the colonial period was replaced with the Mining Act no. 12 of 2016. In this new piece of legislation, ASGM is recognized and in section 98 sub-sections 2 and 3 there is a requirement that holders of artisanal mining permits observe good mining practices including health and safety in their operations [9]. Due to this long standing informal and illegal nature of ASGM there is paucity of information regarding occupational injuries, risk factors and hazards in ASGM. In addition, there is no adequate occupational injury surveillance systems in Kenya.Similarly, in other countries in Sub-Saharan Africa where ASGM is practiced there is underreporting on occupational injuries and hazards in ASGM and there is very little information in existence. A couple of studies have attempted to characterize injuries in ASGM. In Ghana’s upper east region an injury rate of 45.5 injuries per 100 person years was recorded in 2013 with legs and knees being the most common injured body parts [5]. In a different part of Ghana, Tarkwa area, ASGM workers reported an injury rate of 23.5 per 100 person years with 70% of the injuries being upper and lower limbs [10]. In Katanga province in the Democratic Republic of Congo (DRC), an injury prevalence of 72.2% was reported among artisanal miners [6]. Outside of Africa, countries like Philippines also had studies that reported 31.2% prevalence in injuries among small-scale miners [11]. Various activities in ASGM are injury prone including excavation and crushing [10], in other cases being male was a predictor to injury risk [5]; while in other studies having less years of experience, less than a year increased the frequency of injuries [10]. Given all these, this study aimed to better characterize occupational injuries and the risk factors in ASGM community in Rosterman, Kakamega County, Kenya.

2. Methods

- A cross-sectional study was conducted in August 2018 in Rosterman area which is administratively located in Bukhungu location, Shirere Ward in Kakamega County, Kenya.

2.1. The Research Participants

- Our study sample was (N=313) from a study population of 1325 miners as per the estimate from the office of natural resources and environment, Kakamega County. The workers were drawn from four registered associations with majority not belonging to any association. Stratified random sampling was used to determine the number of ASGM workers to take part in the study. These strata consisted of ASGM workers drawn from the four registered associations that operate in Rosterman area and those workers who are not registered with any association, thus making up five strata. The associations included Kakamega mineral mining group, Bukhungu gold mining group, Muungano gold miners, Kakamega Mwangaza Miners. The fifth stratum was the non-registered miners. To obtain a sample from each stratum, proportionate sampling was carried out, and within the stratum, systematic random sampling was used to come up with a number of ASGM workers per stratum to be interviewed. Yamane’s formula was used to obtain the desired sample size [12].

2.2. Research Instruments

- This study used interviewer administered questionnaire study as the main data collection tool. The questionnaire was digitally coded into the Open Data Kit (ODK) platform on Android mobile devices, they were then used by the field assistants to key in the respondents’ responses. Some of the questions in the questionnaire were an adaptation from the a study on occupational injuries in ASGM conducted in Tarkwa, Ghana [10]. The questionnaire was divided into several sections including demographic information, risk factors such as individual characteristics, work tools and equipment and a section on occupational injuries. The respondents were required to choose the most appropriate response as the questions were close-ended.

2.3. Data Analysis

- The completed and data cleaned electronic questionnaires were uploaded to the ODK server directly through an internet connection. The data was then downloaded into a Microsoft Excel spreadsheet and exported to the Statistical Package for Social Sciences (SPSS) (IBM Corp) version 22 for further analysis. Descriptive statistics such as frequencies, mean, mode and percentages were used to provide an overview of the demographic characteristics such as education levels, gender, age of respondents, years of work experience as a miner. Injury rate was estimated per person-year by dividing the number of miners surveyed who had experienced injury in the year preceding the study and the total number of miners surveyed multiplied by 100, resulting in a rate expressed in people injured/100 person years. Bivariate analysis was conducted and the Chi-square statistic test was used to test the association between the independent and dependent variable to get the p-values at 95% confidence interval. The P-values were considered significant if the values were less than 0.05. Finally all the independent variables that had significant associations to occupational injuries were subjected to logistic regression analysis and expressed as odds ratio. This analysis was used to identify those factors that are predictors of injury risk.

2.4. Ethical and Logistical Considerations

- Ethical approval for the study was obtained from the Kenyatta University Ethics Review Committee (KUERC); reference number PKU/773/1841. Research authorization was obtained from the National Commission for Science, Technology, and Innovation (NACOSTI) in Kenya, reference number (NACOSTI/P/18/76702/19932). From the local community, permission was sought from the Kakamega County administration including the County Commissioner, County Director of Education, County Director of Health Services and the area chief of Rosterman. Full disclosure on what the study is about including any potential risks and benefits that may be foreseen was provided to the respondents. The researcher ensured that the respondents were aware that their participation is voluntary and that they are free to terminate participation at any point if they so wish. They were also assured of confidentiality and anonymity. All participants who voluntarily participated in the study signed written consent forms that had all this information before they were interviewed. Permission to take photographs of the work area was also sought beforehand.

3. Findings

3.1. Demographics and Individual Characteristics of the Artisanal Miners

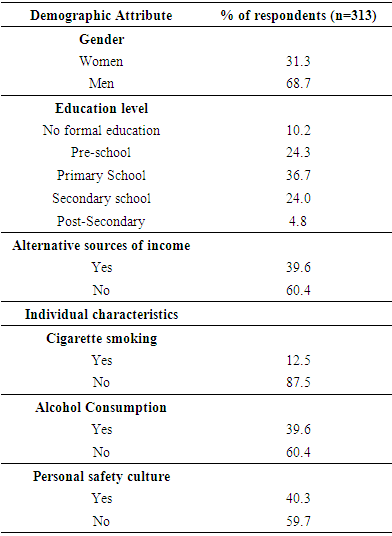

- Table 1 below outlines the distribution of respondents across various demographic factors and individual characteristics. The analysis used three hundred and thirteen questionnaires. In this study, 68.7% of those interviewed were men accounting for majority of the respondents. The majority of the miners (36.7%) had primary school education as their highest level education with only 4.8% having had a post-secondary education. It was also reported that 69.6% of the miners had alternative sources of income besides mining. Some of the alternative income sources the study documented included farming, running a business, casual labour and being a motorbike rider. The ages of the respondents was also documented with a mean age of 34.6 ± 10.7 years (range: 17-67 years). For years of work experience as a miner in general, the least amount of years worked was 1 year while the highest was 43 years with a mean of 6.4 ± 7.1 working years. With the knowledge of the transient nature of the ASGM work, the study also documented years worked as a miner in Rosterman specifically. The least amount of years worked in Rosterman was 1 year, while the highest number of years was 38 with a mean of 4.8 ± 6.3.To corroborate on the transient nature of ASGM workers the study reported on the other areas they had worked previously besides Rosterman and the corresponding counties around the country. Only 31.3% of the respondents indicated that they had worked elsewhere as miners. The areas were summarized in counties and the most common county being Migori at 48.94% followed by Kakamega county at 24.82%. The counties with the least number of respondents who worked there previously as artisanal miners were Homabay, Nandi, Taita Taveta, Turkana, and West Pokot all represented by 0.71% respectively. Other counties recorded were Siaya, Vihiga and Narok at 9.22%, 7.80% and 5.67% respectively.For individual characteristics, self-reported cigarette smoking, alcohol consumption and personal safety culture were used for analysis (Table 1). Personal safety culture among the miners was assessed by asking them if they have ever refused to carry out any work due to personal safety concerns. Majority (59.7%) of the respondents indicated that they have never refused to do work due to personal safety concerns (Table 1).

|

3.2. Injury Rates, Experience and Severity

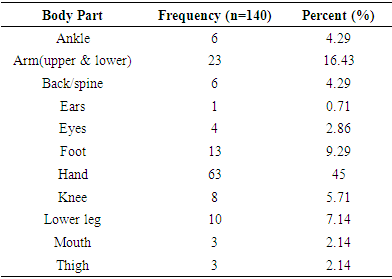

| Figure 1. Self-reported injured body parts |

|

3.3. Risk Factors Associated with Injuries

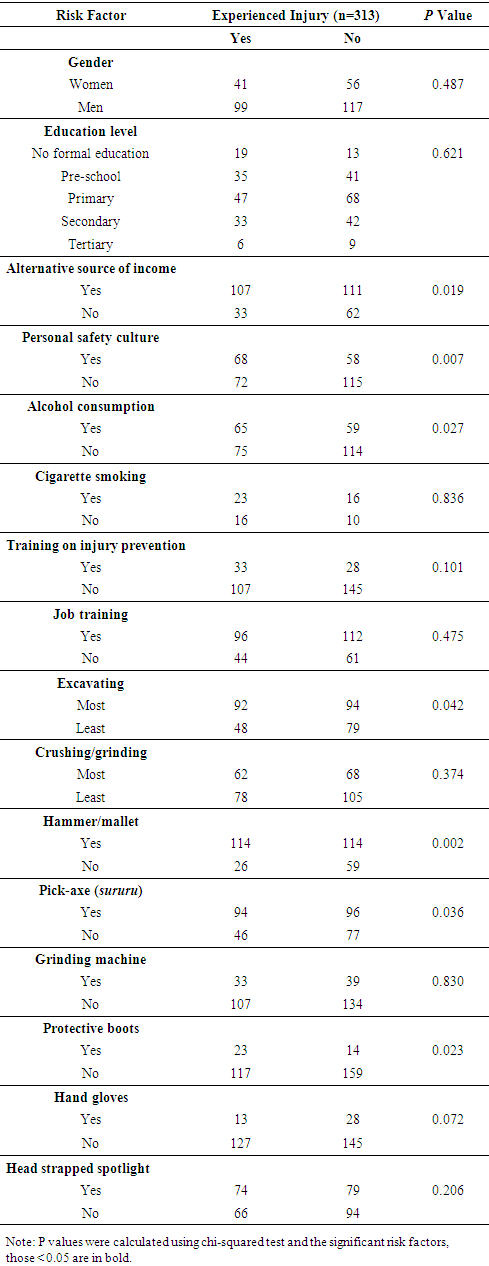

- Factors associated with injuries were put into several broad categories including demographics, individual worker characteristics, work tools and equipment, mining work processes and use of various personal protective equipment (PPE). By use of the Chi-square test of association, demographic factors including gender and education levels did not have a significant association with injuries (see Table 3). However, it was established that having an alternative source of income, a personal safety culture and alcohol use were significantly associated (p=0.019), (p=0.007) and (p=0.027) respectively with the occurrence of occupational injuries. The variables on self-reported cigarette smoking, job training and training on injury prevention were not statistically significant with regards to the occurrence of occupational injuries (Table 3). In terms of work processes, excavating had a significant association in relation to the occurrence of occupational injuries (p= 0.042) while crushing and grinding did not have a significant association. On work tools and equipment, the association between use of hammer/mallet, use of pick-axe (sururu) and injuries was found to be significant (p=0.002) and (p=0.036) respectively. The use of a grinding machine was however not found to have a significant association with injuries (Table 3). For PPE, use of protective boots had a significant association with occupational injuries (p=0.023) while the use of a head strapped spotlight and hand gloves did not have a significant association with injuries (Table 3).

|

3.4. Predictors to Injury Risk

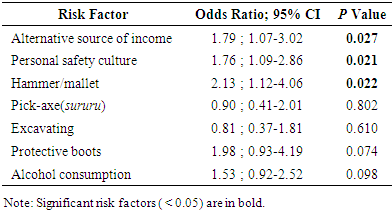

- The risk factors that had significant relationship (p<0.05) with injuries after a chi-squared test (Table 3) were subjected to further analysis. Logistic regression analysis was used to validate their predictive value to injuries. Occupational injuries were associated with having an alternative source of income (OR: 1.79, 95% CI: 1.07-3.02) and having a personal safety culture (OR: 1.76, 95% CI: 1.09-2.86). Using a hammer or mallet as a work tool in mining (OR: 2.13, 95% CI:1.12-4.06) was also shown to significantly predict occupational injuries (see Table 4). Other risk factors in this study that were not significant but had a potential relationship with injuries included alcohol consumption, the use of pickaxe, wearing protective boots as PPE and excavating as one of the work processes in ASGM. Those who used a pickaxe had 10% lower odds of suffering an injury while those who wore protective boots were 1.98 times likely to suffer an injury. Those whose most common activity was excavating in this study had 19% lower odds of experiencing an injury (Table 4).

|

3.5. Employee Welfare and Organizational Safety Culture

- All the respondents were asked to highlight about their welfare as workers and the general organizational safety culture. Majority of the respondents at 60.38% thought that sometimes the owner of the mine showed concern about the welfare and safety of the workers while a minority (16.93%) indicated that the mine owners never showed concern while the rest thought that the mine owner always showed concern for their welfare. With regards to discussing safety issues with workers, 57.51% of the respondents indicated that the mine owner sometimes discussed safety issues with workers. The minority (20.45%) indicated the mine owner never discusses safety issues with workers while the rest indicated that the mine always discussed safety issues with workers. On having safety issues acted upon by mine owner, a majority of the study participants (50.8%) reported that their safety complaints or issues were only sometimes acted upon. This was followed by 22.36% who agreed that the mine owner acted on their safety concerns and a minority at 13.42% indicated that they have never complained about a safety issue.

4. Discussion

4.1. Demographics and Individual Characteristics of the Artisanal Miners

- This study has documented findings on occupational injuries, associated risk factors and the predictors of injuries among artisanal gold miners in Rosterman, Kakamega county, Kenya. The study participants reported to be engaging in various mining activities over a number of years ranging from 1 year to 43 years. It is evident that despite this occupation being practiced for many years, there is limited information regarding injuries in ASGM and regrettably most of these injuries go unreported or undocumented due to the informal nature of the work. Numerous studies have been conducted on occupational injuries and diseases with background information highlighting that official figures are not available or only estimates are provided [15], an indicator of an information gap. In this study, the respondents’ age range of 17 to 67 years is almost similar to what a study on injury profiles in ASGM in Tarkwa, Ghana documented with an age range from 17 years to 72 years and a mean age of 33.8±10.6 [10]. From the results, it is evident that some ASGM processes though less remunerative [13] allows people older than 50 years of age to earn a living from it. The work that is less remunerative is also often work that doesn’t demand a lot of physical strength including crushing, grinding, washing, amalgamation, transportation [13] thus befitting workers who are older. Having one study participant, a boy, indicating that they are 17 years old was a signal of involvement of children in mining. This evidence is consistent with the International Labour Organization (ILO) report on children between 5-17 years involved in hazardous work in sub-Saharan Africa [14]. The report indicates that in 2012 there were 28.7 million children involved in hazardous work in sub-Saharan Africa and that globally boys were involved in child labour more than girls [14].

4.2. Injury Rates, Experience and Severity

- The findings in this study revealed an injury rate of 44.73 injuries per 100 person years taking into account at least an injury experienced in the cause of the 12 months preceding the study. This injury rate is close to what was reported by Long et al. from Ghana’s upper East region at 45.5 injuries per 100 person years among those who were ever gold miners in the year 2011 [5]. Though with a higher injury rate, a study on artisanal miners in Katanga province, DRC established that the respondents experienced at least two accidents in the study period (392 accidents) thus resulting in an injury rate of 217.8 injuries per person years [6]. A study in Philippines on ergonomic hazards and injuries among small scale miners reported that out of 93 respondents 29 of them had experienced accidents thus having an injury rate of 31.2 per 100 person years [11]. Evidence of injuries in ASGM and small scale mining in general exists across different countries, though the injury rates vary in each study. This could be because of the different study methodologies, for instance, the different sample sizes, period under study and also the interaction of other factors in the different work environments. The results in this study showed that the body parts with most injuries were hands at 62.14%. Among the injured respondents the majority at 45% also reported that the hand injuries they experienced were the most severe or bothered them the most, followed by injuries on the lower and upper arm at 16.43%. This is consistent with findings in a study on small scale gold mining in Siaya, Kenya where hand injuries were the most frequent at 41.1% [16], and a study by Calys-tagoe et al. in Tarkwa, Ghana reported that most common injuries affected the upper limbs at 38% [10]. Similarly in Katanga, DRC, Elenge et al. [6] reported that majority of injuries at 50.5% were on the upper limbs. The upper limb injuries could be common because of the widespread use of hand tools and manual equipment [4,17] and the low level of mechanization in ASGM.Missing work days after being injured as a measure of severity was also highlighted in the study with 62.14% of those who were injured having experienced injuries that made them miss some workdays. Missing workdays resulting from occupational injuries is a common phenomenon for example a study by Calys-tagoe et al. in Tarkwa, Ghana [10] all the miners with recorded occupational injuries had their lost work days classified as either mild, moderate, severe and severe enough. Relatedly, in a study in DRC by Elenge et al., 50.8% of the injured miners had to stop work for three or more days after an occupational accident. Other than severity, lost workdays due to occupational accidents have an economic and social cost attached to it and Takala et al. note that these costs are both direct and indirect, and the burden is borne by the employer, the worker and the community [18].

4.3. Predictors to Injury Risk

- In relation to the upper limb injuries and use of hand tools, this study highlighted that the use of hammer/mallet was significant in predicting injuries (OR:2.13, 95% CI:1.12-4.06), that is, a miner is 2.13 times likely to get an injury if they used a hammer or mallet. Without specifying the odds ratio, Elenge et al. in a study in Katanga, DRC report that the majority (51.5%) of miners’ accidents were as a result of handling tools such as hammers, shovels [6] and in a study in Ghana’s Upper East region, 25% of injuries were also caused by tools handling [5]. It is perhaps the frequent use of hammer or mallet in more than one process in ASGM (excavation, crushing) that could have brought about their use being a predictor of occupational injuries. Our study also demonstrates that having a personal safety culture was a predictor to injuries with those who have it being 1.76 times more likely to suffer an injury. In Tarkwa, Ghana though there was no report on statistical significance, 12.1% of the miners interviewed had reported that they had ever refused to do work due to concerns regarding their personal safety [10]. Though it is expected that those who refuse to do work due to concerns regarding their personal safety will have lower chances of experiencing an injury, the results of this study indicate otherwise. It could be a pointer towards other confounding factors such as, the work environment not changing including the ASGM organizational safety culture or lack of alternative sources of income resulting in them going back to the same work despite the apparent risks. This finding corroborates with the fact that 50.8% of the respondents in this study reported that when they expressed concerns on safety issues the employer did not always act upon them. Another predictor of injuries was having an alternative source of income (OR: 1.79, 95% CI: 1.07-3.02) which represented having another job in this study. A study in the United States (US) among the working population revealed multiple job holders had higher injury rate per 100 workers for work-related injuries (OR:4.2, 95% CI: 3.5-4.8) compared to the single job holders (OR:3.3, 95% CI: 3.1-3.5) [19]. While ASGM has been described as an attractive venture that provides employment to people [1,2,20] including in Rosterman [4] it may be that in Rosterman, the income from ASGM may not be sufficient for some thus the need to supplement. It was however evident in this study that using a pickaxe, wearing protective boots as PPE and excavating as one of the work processes in ASGM does not predict injuries. Additionally, there was no association between socio-demographic factors such as age, gender, educational level and marital status with occurrence of injuries.

5. Conclusions

- Occupational injuries are prevalent among artisanal and small-scale gold miners in Rosterman, Kakamega County, Kenya with a substantial injury rate of 44.73 per 100 person years. Taking into account that this study is one of the few that have focused on documenting occupational injuries and its risk factors in ASGM in Rosterman, Kakamega County, Kenya, the results help in addressing an information gap, which is important in adding to the existing literature on occupational health and safety in ASGM. The upper limbs consisting of the hand, lower and upper arm are the body parts that were most affected with injuries with the hand injuries being recorded as most severe. Various risk factors predicted the likelihood of injury occurrence including having an alternative source of income, having a personal safety culture, using a hammer or mallet as working tools. There is a possibility of more risk factors that predict injuries that could be explored in further research especially because this study did not document the exact causes of the various injuries including their clinical descriptions. The employee welfare and the overall organizational safety culture in ASGM was revealed to be lacklustre as it was clear from the miners that the mine owners only sometimes acted upon their safety concerns and also sometimes discussed safety issues.

6. Recommendations

- There is need to sensitize the ASGM workers on the injury risks they are exposed to while making injury prevention as a priority in ASGM intervention programs in order to reduce the burden of occupational injuries. In addition, due to the cross-sectional study design, the prevalence of injuries recorded in this study is likely to be an underestimation since the study did not capture people who were not at work as a result of injuries at the time of data collection. This also means that those who possibly suffered permanent disabilities from mining accidents were not captured hence the magnitude of the burden of occupational injuries was not clearly depicted. Thus, a longitudinal study is recommended to be able to effectively address this. Given that the employee welfare wasn’t adequately taken care of, there is need to put emphasis on implementing the Kenyan Mining Act no. 12 of 2016 where ASGM is recognized, thus making it a legal trade and outlines a requirement that holders of artisanal mining permits observe good mining practices including health and safety in their operations. Implementing the Act among other interventions such as health and safety trainings, emphasis on use of PPEs among others may be useful in reducing the burden of injuries in ASGM.

ACKNOWLEDGEMENTS

- We would like to acknowledge the miners in Rosterman for giving us permission to carry out the study in their community and for voluntarily agreeing to take part in the study. We wish to thank the leaders of the various artisanal gold mining associations in Rosterman, for their support during the process of data collection. We would also like to acknowledge the team of field assistants whose professionalism and skills ensured that the data was collected efficiently.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML