-

Paper Information

- Next Paper

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Prevention and Treatment

2012; 1(2): 27-30

doi: 10.5923/j.ijpt.20120102.02

Preventing Occupational Ailments and Disorders Associated with Cassava Mash Dewatering Techniques

Kolawole O. P. 1, Agbetoye L. A. S 2, Ogunlowo A. S 2, Samuel T. M 3

1FMS International Institute of Tropical Agriculture (IITA), Ibadan, Nigeria

2Departmentof Agricultural Engineering, Federal University of Technology Akure. Nigeria

3Department of Agricultural & Mechanical Engineering, Olabisi Onabanjo University, Ogun State, Nigeria

Correspondence to: Kolawole O. P. , FMS International Institute of Tropical Agriculture (IITA), Ibadan, Nigeria.

| Email: |  |

Copyright © 2012 Scientific & Academic Publishing. All Rights Reserved.

Methods in use to reduce the cyanide level in cassava were found to be dangerous to the processors. To reduce occupational hazards, cassava processors sometimes wear protective coverings such as hand gloves, overall, mouth/nose hood, eye goggles which are not comfortable. Each of the steps in cassava processing stages exposes workers to various occupationally related ailments and disorders of ergonomic origin. The operators of dewatering tools are at the risks of suffering from different ailments.The traditional processors still depend on the old technique and resources. Workers are often exposed to cyanide and many are scared of the toxic effect of cassava juice. To prevent the occupational related ailment, mash process handling machine was developed and evaluated. The obtained result by use of the machine confirms the operators’ protection. The obtained mash cake was found to meet the stake holders’ requirement of 47-50% moisture content wet bases without human contact.

Keywords: Prevention, Cyanide, Cassava Mash, Dewatering , HQCF

Article Outline

1. Introduction

- Cassava (Manihot esculenta Crantz) is a perennial vegetative propagated shrub and is one of the most important food crops grown in Africa[1]. Good management practices could help in sustaining the high yielding capacity[2]. Cassava is grown for use as food in more than thirty nine African countries[3]. Food products from cassava include gari (fermented and roasted granules) fufu (fermented and steamed cooked), pupuru (fermented smoked dried balls and also gelatinized), lafun (fermented, sun dried flour and then gelatinized for the table) and Bread (from high quality cassava unfermented flour (HQCF)[4]. Cassava has been found to be a great giant that fights hunger and provides earnings for the farmer especially HQCF. It is the cheapest food used to combat hunger[5]. Aside from improving farmers’ income, value addition to the harvested roots could address unemployment and turn around the fortunes of farmers[6].The processing of cassava into any products has hazards to the environment, the processors, and even the consumers. For example, littering of the environment with cassava peels can destroy the freshness, cleanliness and aesthetic value of such environment. The environment responds to this negative effect in form of stenches and microbial load, which may be injurious to man's health[5]. Cassava tubers are traditionally processed by a wide range of methods, to reduce the toxicity of cyanide, improve palatability and converting the perishable root into stable product.The issue of hydrocyanic acid in the fresh roots is a limitation on the processing[7].Cyanide within cassava mash can harm the processor[8]. It is a poison, the reaction with human skin causes pain at the site of contact, the pain normally delayed between 15 to 30 minutes, and other signs include erythema. This is because cyanide can stop the cells of the body from being able to use oxygen. Prolonged contacts of human skin with cassava mash normally can lead to contact-dermatitis[9] All cassava tissues with the exception of seeds contain the cyanogenic glycosides. Several authors have reported the toxicity of cassava. The cyanide in cassava mash exists in three forms: (i) the glucosides (linamarin and lotaustralin), (ii) the cyanohydrin and (iii) the free hydrocyanic acid (HCN). Cyanide potential of less than 100 mg/kg is safe for human consumption[10]. Exposure to lower levels of cyanide over a long period can result in weakness and a variety of symptoms, including permanent paralysis[10]. Cassava processors sometimes wear protective coverings such as hand gloves, overall, mouth/nose hood, eye goggles which are not comfortable as a way of reducing occupational hazards[11]. Each of the steps in cassava processing exposes worker to various occupationally related ailments and disorders of ergonomic origin. The operators of dewatering tools are at the risks of suffering from different ailments; skin making contact with the cassava toxins, backache for standing and bending,prolonged bending of the vertebral column and uncomfortable sitting posture during manual sifting.[8] The traditional technique has not been able to address these health constraints. Many processors are scared of the toxic effect of cassava juice. The mash contains about 70% water with dangerous toxic substances. In literatures, it was discovered that cassava mash dewatering is mainly carried out manually under rural conditions[8]. So many methods are in use for cassava mash dewatering. This includes boulders or logs, sticks, parallel board method, tree stumps method, chain or string and screw jack. Cassava mash dewatering mechanism that was improved upon is the hydraulic jack[13]. All machines fabricated to solve this dewatering did not put preventing of skin contact[14][15] into consideration.This work was carried out to prevent occupational related ailments among the cassava mash processors. The objective of this work is to develop a mash process handling machine that will reduce the level of contact.

2. Methodology

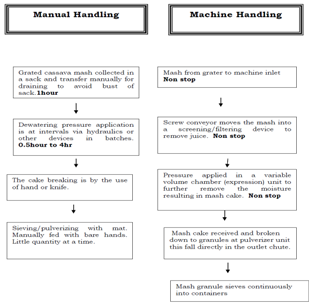

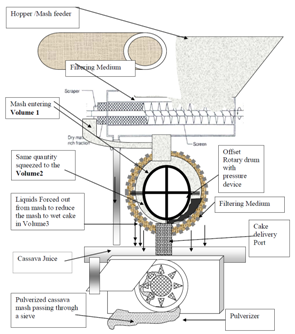

- Traditional methods of process handling was observed and the translated into processing machine method as shown in figure 1. This was later modified into mash process as shown in figure 2 and 3. The inlet chute allows the delivery of wet wash from grater at about 70±10% moisture content wet basis into the U trough. Without human hand screw (auger) adequately convey the mash to the screen for filtration dewatering. The pitch tolerance of the auger is important in minimizing the choking problems envisaged. Screw press dewatering method of fibrous material was used for this because of very low power requirement and low friction within the casing at horizontal position. This combines filtration with conveying. These actions make filtering medium to experience solid blinding of the perforations. The screw encased in dual steel tube with cloth as filtering medium between the casings assists the filter and prevents failure as a result of the exerted pressure and the blinded filter. The perforated steel casing is in the form of a basket, permeable to liquids. The filter is expected to retain starch grains of about 60 microns in size as well as the fibre solids. Accumulated mash cake is expected to naturally hold the starch grain by preventing the escape of starch particles. The inner screen with fine perforations collects the liquid, along the outer screen into the collection tray via a duct that takes away the water. Cassava mash is a bulk granular material with internal angle, the density, surface area, and coefficient of friction are mechanical properties needed in the design. The task of moving cassava mash within the machine requires some characteristics changes. Search for the physical and mechanical properties was carried out in literatures for the machine design. The bulk properties used were function of the geometry, size and surfacecharacteristics of the mash particles. Angle of friction as well as cohesion, flowability and compressibility were needed for inlet and discharge chute, other properties not found in literature were selected or assumed while attempts were made to determine some in the laboratory.

3. Result

- Since the machine was designed to replace human contact it has to perform four unit operations of conveying, dewatering, pulverization and sifting. Its performance evaluation was conducted in terms of effectiveness and in performing those operations. The movement of mash within the machine results in loss of juice, about 5 kg was expressed as juice containing water and starch. The data collected indicated that the machine can effectively replace human hand.

| Figure 1. Traditional and machine process flow chart for cassava mash |

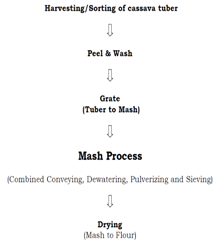

| Figure 2. Modified HQCF flow chart |

3.1. Mash Dewatering

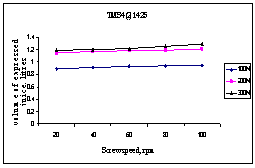

- The ideal moisture content of mash cake was given by the cake disintegration into granules without lumps. This was at 47 % to 50 % wb moisture content. With sufficient liquid removed during dewatering pulverization of the mash cake became so easy. The graphs of speed against the expelled volume of juice (Figure 4) revealed that speed of the machine affect the machine dewatering performance.The higher the machine speed the less was the moisture expelled. Cake made at screw speed of 100 rpm contained moisture more than those made at 40 rpm. This was confirmed with further experiment[12]. This may be due to spaces created within the mash at higher speed. Air is compressible and liquid is not, at higher speed the fluids moves away with the mash by so doing escape compression due to sponging behaviour of mash. Dewatering process is pressure dependent operation.

| Figure 3. Proposed cassava mash process handling machine |

| Figure 4. Moisture removed during the processing of mash |

4. Discussions

- The data of juice collected over the time (Figure 4) show that the rate of juice removal is proportional to the amount of force applied. The volume of juice also varied proportionally to the amount of force applied during dewatering. This shows that more juice can be removed using a relatively stronger spring force over a short period of time.

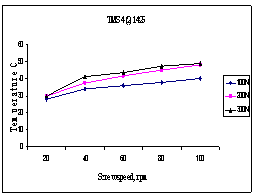

| Figure 5. Influence of machine speed on mash temperature |

5. Conclusions

- The overall machine performance shows a significant improvement over that of traditional method in production capacity. The pulverized materials came out very clean, free from foreign materials, and the machine operates with minimum human contact, a reduction in the risk of cyanide exposure. The choice of machine speed may be compromised between capacity and quality. The results obtained indicated that the product from the machine met the requirement of the stake holders.

ACKNOWLEDGEMENTS

- I wish to acknowledge STEP-B World Bank assisted Grant for Innovators of tomorrow 2008

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-Text HTML

Full-Text HTML