R. K. Tiwary, M. Kalet, D. Karmakar, Dr. A. K. Bhakat

RDCIS, SAIL, Ranchi, India

Correspondence to: Dr. A. K. Bhakat, RDCIS, SAIL, Ranchi, India.

| Email: |  |

Copyright © 2016 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Abstract

In an integrated steel plant coal and coke preparation units demand application of high performance hammers in coal crushing units to maintain high coal crushing index and heavy duty screen decks for maximizing yield of sized coke (25-80 mm fraction). These components work under severe wear due to the combined effects of fatigue and impact loadings. An attempt has been made to develop a suitable material for hammer heads of coal crushing units and screen decks for screening the -25 mm coke. In case of hammer, top portion of hammer head was synthetically prepared using an alloy powder of Fe-C (~3%), Cr (~18%), Mo (~1.5%), which was sintered, ensuring uniform through thickness hardness value of 60 HRC. The material used for the screen decks was 2-2.5 mm thick composite [Fe-C (~1%) – Cr (15-17%) alloy powder] deposited over mild steel plate of 8 mm thick by submerged arc welding. Such surface treatment process enabled to enhance hardness value in excess of 55 HRC and the material was found quite suitable to withstand higher fatigue stresses during screening operation due to good wear resistance property. The service lives of both hammers & screen decks improved significantly i.e. higher than 6000 hrs. and 27 months respectively as against earlier service life of 3000-3500 hrs. for hammers & 3-4 months for screen decks. Application of such advanced materials (both for hammer and screen decks) resulted in increased productivity of mills (by way of reduction in frequency in downtime), maintaining coal crushing index of ~82% and eliminating over size (+25 mm) fraction of coke in the screened materials.

Keywords:

Hammers, Screen decks, Carbides, Crushing, Hardness

Cite this paper: R. K. Tiwary, M. Kalet, D. Karmakar, Dr. A. K. Bhakat, Application of Improved Quality Abrasion Resistant Materials in Hammer Head and Screens for Coal and Coke Preparation Units of Integrated Steel Plant, International Journal of Metallurgical Engineering, Vol. 5 No. 2, 2016, pp. 25-30. doi: 10.5923/j.ijmee.20160502.02.

1. Introduction

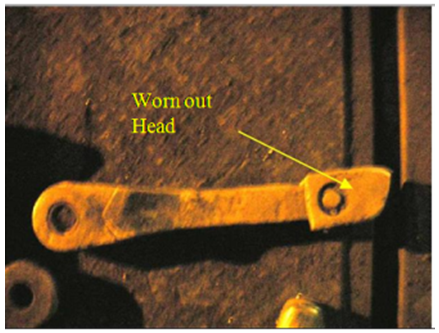

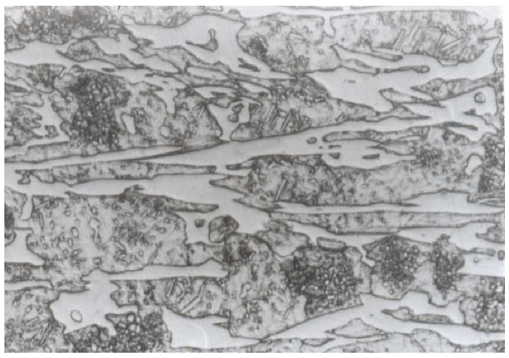

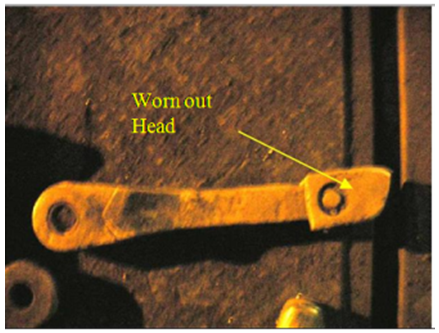

Coal crusher hammers & coke screen decks experience high impact and severe abrasion in coal mill, simultaneously. Optimal properties level in the materials from which these components are to be made, may not be achieved from single metal. Abrasion resistance is usually higher as the hardness of material is increased but often such materials are brittle. In case of high impact property material the wear resistance is low. Thus an optimal value of abrasion resistance and impact charpy energy may be achieved by combination of different metals to make an alloy. A representative alloy composition [1, 2] consisting 2.5-6 carbon and 10-40% chromium is known for its excellent wear resistance requirements. It consist of 20-40 vol. % of very hard MC3 type chromium carbides (1200-1400 VHN). Addition of Mo enhances the toughness of alloy at elevated temperatures. Coke preparation unit of an integrated steel plant uses hammers extensively for coal crushing to -3 mm size (80% min.) and screen decks for sizing the coke between 25-80 mm. The hammers are made from high manganese grade steel with initial hardness of ~280 BHN (~30 HRC). The hardness of these hammers increases to 390 BHN (~40 HRC) due to impact of coal on the hammer heads. Increase in hardness of hammer head during process helps in reducing the wear rate of hammer head. Such hammers have high toughness and also have high resistance to fracture during the use. But these hammers have lower life and worn out in 3000-3500 hrs. A typical photograph of worn out hammer has been shown in Fig. 1(a). | Figure 1(a). Photo of worn out Hammer |

Screen decks are made from high strength low alloy (HSLA) steel plates. Surface hardness of these plates varies between 150-200 BHN. Holes are made by die & punch and the edges of holes are parallel from Top to bottom surface. Such holes get clogged by the coke pieces during the operation as shown in Fig. 1(b). Thereby, screening efficiency is reduced within a short time. Though these screen decks can easily be fabricated at low cost but life achieved so far has been 3-4 months only. The lower life of these screen decks has been hampering the production of coke due to frequently shut down of mill for changing the worn out screens decks. | Figure 1(b). Photo of partially clogged screen |

In the present study, alloy compositions have been designed for hammers & screen decks. Modifications have been done in design of hammer head and in shape of holes of screens. Both hammers and screen decks have been fabricated and installed for direct use in mill. The performance has been monitored at frequent interval. Necessary modifications in design of screen decks were carried out based on its performance. As a result the life of hammer and screen has been achieved more than 6000 hrs. and 27 months as against earlier life of 3000-3500 hrs. & 3-4 months respectively.

2. Experimental

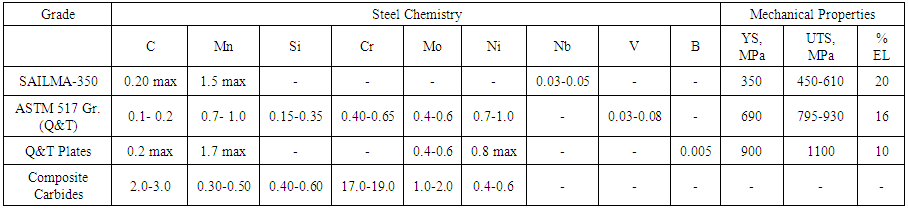

2.1. Screen Decks

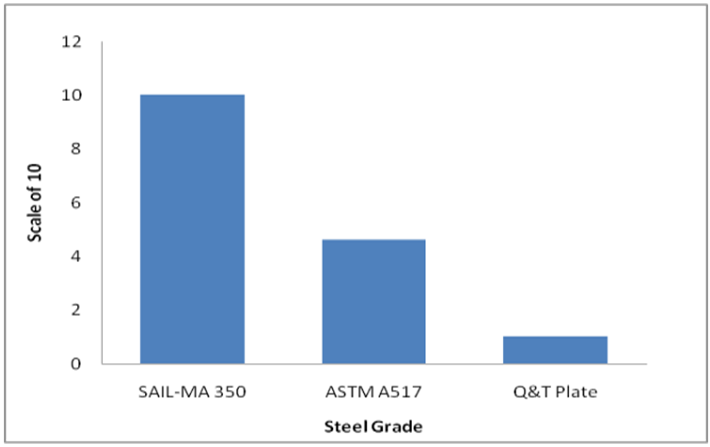

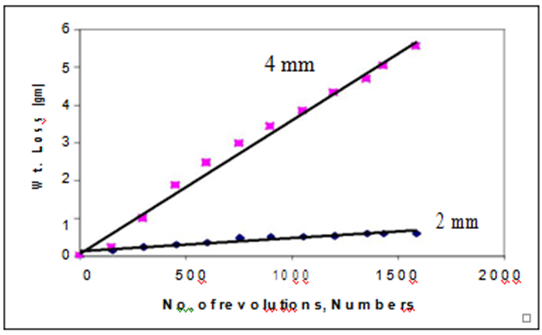

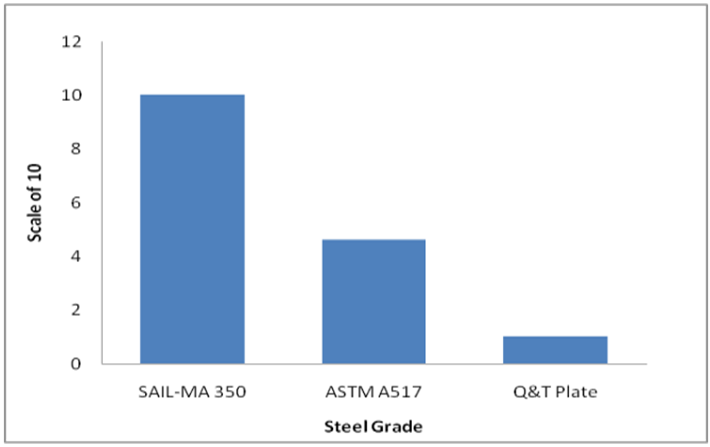

Three different steel products, whose composition and mechanical properties are given in Table-1, were selected for wear test. The wear properties of proposed steels were evaluated by pin and disk wear method. The pin was made from steel plate and rubbed against tungsten carbide disc. Weight loss in the sample was measured against number of revolutions. A comparative histogram has been plotted in Fig. 2. | Figure 2. Comparative wear resistance of different steel grades |

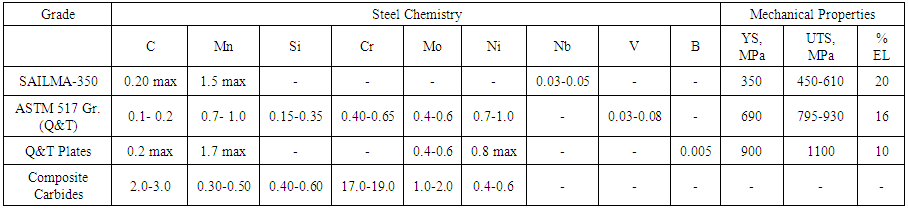

| Table 1. Steel Composition & mechanical properties |

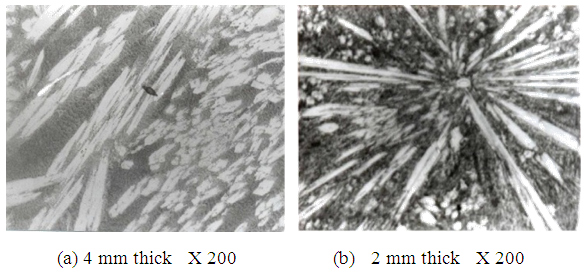

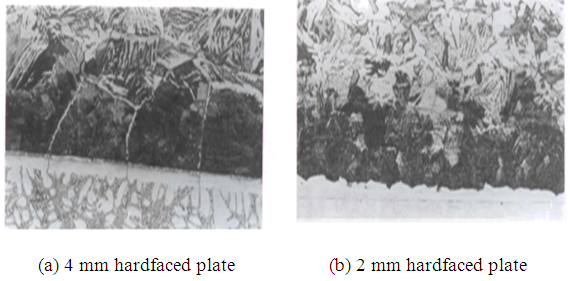

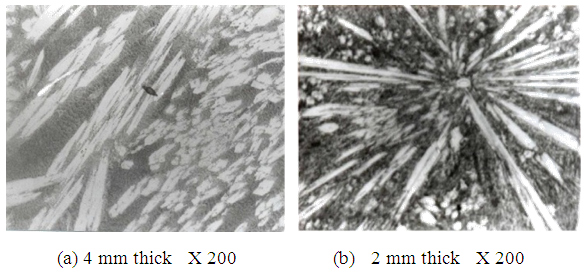

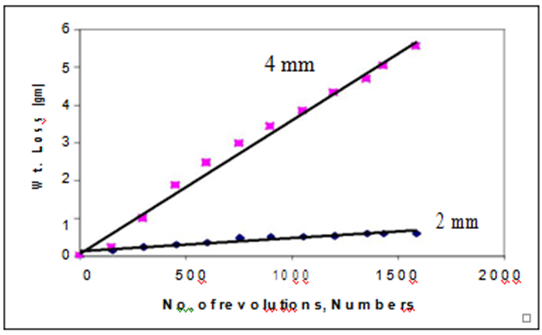

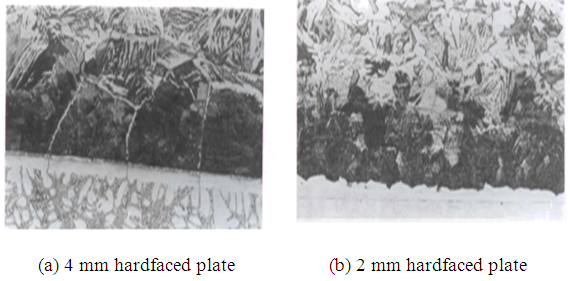

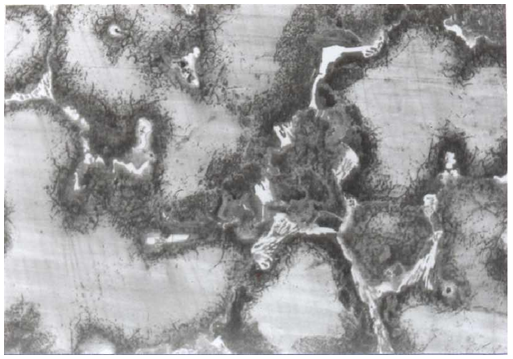

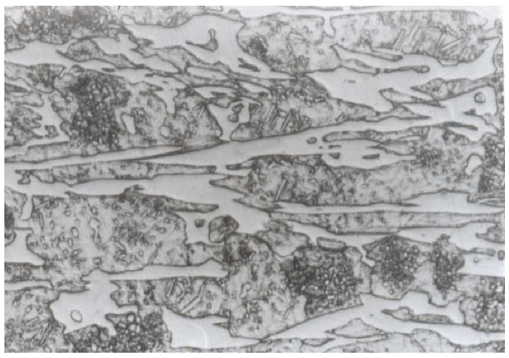

The quenched and tempered plates have highest (1:0.08) wear resistance. These plates were used [3] for manufacturing the screens and a significant improvement was observed in the screen deck life. But it was observed from plant operational studies that the quenched and tempered steel plates suffered from inconsistency in hardness across the width and length and flatness in screen plate which resulted in non uniform wear in the screens.Therefore, SAIL-MA-350 grade steel plates were preferred over Quenched & tempered plates. The screen decks, made from SAIL-MA-350 grade steel plates, had very low life (3-4 months only), but the experiments enlightened that the high hardness materials can solve the problem of high wear rate. Screen decks also experienced heavy vibrations during screening. High hardness materials are allergic to fatigue, therefore composite carbide plate was selected for making the screen decks. A layer of 2 & 4 mm thickness of Fe-Cr-Mo-Mn carbides was deposited over 8 mm thick mild steel plates. The carbide layer had 50-60 % carbide as shown in Fig. 3 (a & b) and the carbides are uniformly distributed along the thickness of carbide layer. As shown in micrographs there is significant difference in carbide morphology in 2 & 4 mm thick carbide deposed layers. The wear properties of carbide deposits were evaluated by dry sand/rubber wheel abrasion method. As shown in Fig. 4, the 4 mm thick carbide deposited sample had inferior wear resistance. Also 4 mm thick deposited layer had visible cracks as compared to 2 mm thick deposited carbide layer. Microstructure of both samples was studied across the interface of mild steel & carbide layers and it had been shown in Fig. 5 (a & b). | Figure 3. Distribution of carbides in defused layer |

| Figure 4. Wear loss measurements on hard faced material |

| Figure 5. Microphotographs of interface of carbide and steel plate (X 200) |

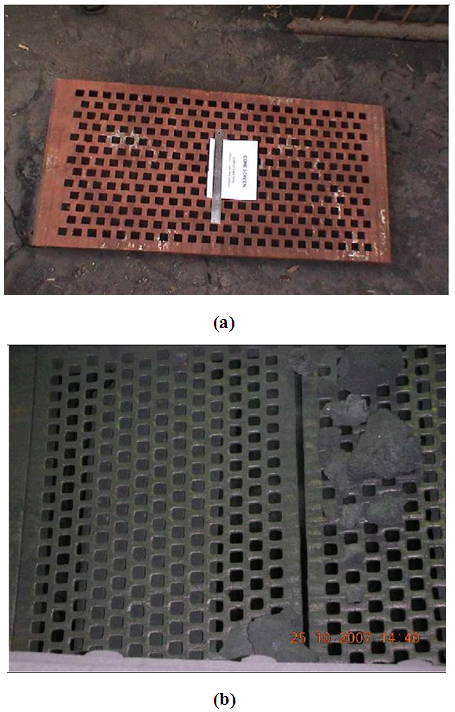

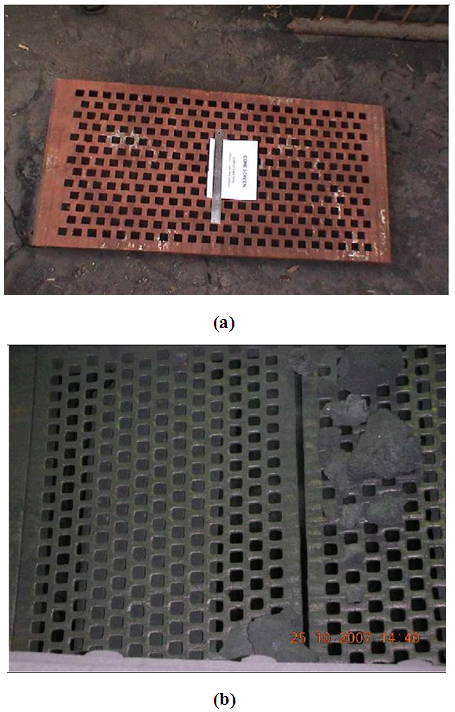

The cracks have penetrated to mild steel from 4 mm thick deposit carbide layer. It was apprehended that the cracks may propagate into base plate during the use.Therefore, 2 mm thick layer was preferred to deposit on 8 mm thick mild steel. Normally, the screens were made from die and punch and as the opening of a hole is parallel across the thickness of the plate so it suffers from frequent clogging with screening material. Therefore, tapered holes were made by plasma torch. The screens were put in use in a commercial coke mill where +25 to -80 mm size coke is screened and sent to Blast Furnace. Coke analysis was done at frequent intervals and +25 mm size coke in screened out coke was nil in all tests. Fig. 6 (a & b) shows the view of new & 20 month old and used composite layered screens. As shown in Fig. 6b, the screen is free from clogging and has insignificant wear even after 20 months of use. | Figure 6. Carbide layer deposited over mild steel plate (a) New screen & (b) 20 months used screen |

2.2. Hammers

40/50 Cr Mo grade steel billets are commonly used for manufacturing the hammers for crushing the coal, lime stone, dolomite etc. The steel billets are forged into the hammer profile and hardened between 900-950°C followed by oil quenching. Quenched hammers are quite brittle due to martensitic structure and have tendency to break under heavy impact during use. Therefore, hammer heads are tempered suitably to achieve surface hardness between 350-400 BHN. The hardness in such hammers decreases across the depth from surface. Due to drop in hardness, the wear rate is higher in these hammer heads. In order to achieve consistency in hardness across the depth, 12-14% Mn steel composition was preferred for manufacturing hammer heads for coal crushing mill at an integrated steel plant. The hammer heads were austenised at 1000-1050°C followed by oil quenching. Such hammer heads had austenitic structure all along the depth as shown in Fig. 7a. Some carbide was also precipitated at grain boundaries. These hammers had surface hardness ~290 BHN (~ 30 HRC). But during the operation under heavy impact on the surface, hardness of steel increased to 390-400 BHN (~ 40 HRC) due to austenite to martensitic transformation. These hammer heads had life to the tune of 3000-3500 hrs as against a life of ~1000 hrs in case of hammer heads made from 40/50 Cr-Mo steels. In order to propose any improvement in the life of hammers further, first the wear characteristic of 12-14% steel hammer was evaluated to compare with the wear characteristics of newly proposed material. A sample of 25X50 X10mm was prepared from hammer head material and weight loss was measured with respect to number of revolutions as per ASTM-65 using dry sand/ rubber wheel apparatus. A plot of weight loss V/s number of revolutions is shown in Fig. 8. | Figure 7a. Microphotograph of12-14% Mn Steel Hammer-1000X |

| Figure 7b. Microphotograph of new Hammer material-1000X |

| Figure 8. Wear test for Mn grade steel and Cr-C block |

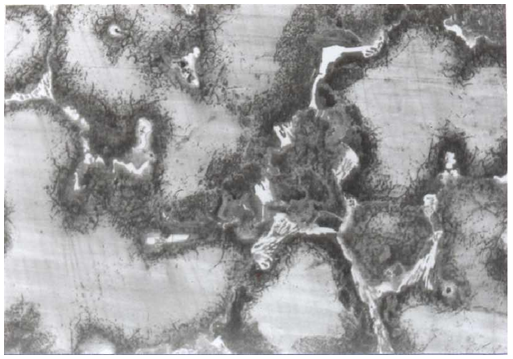

In order to enhance the life of hammer heads, further, a composition [4, 5] as shown in Table-1, was identified for manufacturing the hammer heads. Fine powders of C, Cr, Mo, Mn and Fe (balance) were mixed in a ball mill thoroughly to achieve uniform distribution of each metal particle. An organic binder (BP=200°C) was mixed and the powder was pressed in cuboids shape in a die. The pressed block was heated in a vacuum furnace @ 50-60°C/sec. upto 1250-1400°C and sintered for 5-6 hrs. 10-5 bar pressure was maintained in the furnace during the sintering. In sintering process metal & carbon, particles react with each other through inter particle diffusion process and form the stable phases. Microstructure of sintered block is shown in Fig. 7b. The microstructure shows the elongated carbides as well as carbides blocks. Hardness of blocks and elongated carbides was measured 740 & 1265 HV respectively and bulk hardness was measured 60-62 HRC. A sample of 25X50X10 mm size was machined from the block and tried to assess the wear properties by Dry sand & Rubber wheel apparatus as per ASTM G65. Practically there was no wear on carbide surface during the test as shown in Fig. 8, where as the wear of 12-14% Mn grade steel hammer head material was quite prominent.On the basis of results, derived from wear tests, rectangular blocks of Cr-Mo-Mn-Fe carbides were pressed as per design and sintered as per the procedure as mentioned earlier. The rectangular blocks were fixed over 12-14% Mn grade steels hammer head. The carbide block was protected by extending a collar in hammer head. Final shape of the hammer is shown in Fig. 9. Ninety six such hammers were fixed in universal reversal hammer coal crusher mill which crushes +10mm coal to <3 mm (> 80%) size @ 250ton/hr. The mill was opened after 2000 hr. of use to examine the hammer’s condition. Fig. 10a shows the close view of used hammer and Fig. 10b shows the hammers assembled in the mill. Practically, the wear has been 10-15% only. The hammers were in use at the rate of 12-14 hrs/day. The mill was again opened after the use of 6000 hrs for checking the condition of hammers. The hammers were found still usable for some period. | Figure 9. New hammer designed |

| Figure 10. New Hammers after use of 2000 hrs (a)- Close up view, (b)- Assembled in mill |

Coal crushing hammer mill have primary & secondary crushers. The coal is crushed in single or mixed mode of primary & secondary mills. Crushing index was recorded for Cr-Mo-Mn-Fe carbide & 12-14% Mn hammers. Data were collected on daily/monthly basis for various types of coals. It was found that in case of developed material the crushing index of coal had been > 80% in case of all coal combinations crushed.

3. Results and Discussions

Raw material handling units in sinter plants, coke ovens and blast furnaces in integrated Steel Plant use various equipments where sizable number of components in these equipments suffers from wear kind of cronical decease. Wear reduces the life of operating components of equipments and causes frequent shut down of the mills for changing the worn out components. As a result, the productivity of mills hampers. In the present work, attention has been given on enhancement in life of hammers & screens, those are being used in coke ovens for coal crushing (<3mm) and screening the coke between +25 and -80mm size for blast furnace. In screens and hammers, the wear occurred due to displacement and subsequent removal of comparatively soft material and grooving action by hard material. Therefore, hardness of under use material plays vital role in improvement of their life. In coke ovens the coke falls over the vibrating screen through conveyer and hopper and subsequently slides over the vibrating screen surface. In this process screens experienced the wear along with fatigue and impact. Four different types of materials were studied for optimizing the optimum combination of wear under fatigue & impact loading conditions. As shown in Fig. 2, the quenched & tempered low alloy steel plates have been ~8 times more wear resistant than high strength low alloy (SAIL-MA 350) steel. Practical experience revealed that surface hardness of quenched plate varied in wide range across the width and length of the plates. Wear properties of sintered carbide blocks have been shown in Fig. 4. Though the wear properties of carbide materials are better, but the carbides are brittle in nature and have tendency to develop cracks during fabrication, therefore, carbide plates cannot be used for making screens. Also fabrication of large size carbide plate, practically, not possible Therefore, screens were fabricated by deposition of a carbide layer over mild steel plates. Thickness of carbide layer is equally important. As the thickness of carbide layer increased, the morphology of carbide laths changed from coarse to fine as shown in Fig. 3a [5, 10]. This might had happened due to differential heat dissipation from the molten carbide pool. Though the hardness of 4 mm thick carbide layer is as high as the hardness of 2 mm thick carbide layer but the wear loss has been observed more in 4 mm thick carbide layer as shown in Fig. 4. Molten carbide pool also suffers from cracks during the cooling and the cracks are quite prominent if volume of molten pool is more. In case of 4 mm thick carbide layer the quantum of molten carbide is just double of 2 mm thick layer and the cracks in 4 mm thick carbide layer are quite prominent and had penetrated to the steel plate as shown in Fig. 5a. Effect of these cracks was observed when the immature failures occurred in the screens as shown in Fig. 11. It can be clearly seen that the screen plate had broken from different places without wear. As a result, the screens are to be examined at regular intervals. Fig. 6a & 6b showed a view of new and 20 months used screens. As appeared from Fig. 6b the wear on the surface of screen is insignificant. Enlargement of holes in screen is also unnoticeable. The analysis of screened coke was done at regular intervals for +25 mm size coke. +25mm size coke was nil in screened coke [6]. Actually the screen had given a life of 27 months in regular use. | Figure 11. Screen made from 4 mm thick carbide deposited layer |

Coal crushing unit of an integrated steel plant have three primary & three secondary mills. Depending upon the quality, the coal is crushed either by single or in combination of primary & secondary mills. Earlier, 40/50 Cr-Mo grade steel hammers were in use and the life of these hammers were ~1000 hrs. only. These hammers were replaced by Mn grade steels hammers which were austenitic in nature after solution annealing. These steels have lower hardness all across the thickness of hammer. The surface hardness of these hammers increased by transforming austenite into martensite under heavy impact conditions. The life of these hammers has been 3/4 times higher than that of 40/50 Cr-Mo steel grade hammers.Metal powder compaction & sintering process has been able to produce hard & tough carbide blocks and used for shaping into hammer heads [7-9]. In order to access their characteristic first, a block was made and its wear properties were evaluated along with Mn grade steel hammer material. As shown in Fig. 4, the weight loss was measured against number of revolutions and it was negligible as compared to Mn grade steel hammer material. Microstructures are shown in Fig. 7a & 7b. As shown in Fig. 7a the Mn grade steel hammers have austenitic structure as major phase. However, small amount of carbides have precipitated at grain boundaries. During crushing, austenite transform to martensite under impact. Martensite is quite hard and thus surface hardness increased to 390-400 BHN. Fig. 7b shows the microphotograph of sintered carbide sample, where carbides in bulk are present in elongated shape. The hardness of these carbides varied between 740-1265 HV and bulk hardness of carbide block has been measured 60-65 HRC (710-840 HV) [4, 11]. It can be inferred that that the sintered carbide block had Fe-Cr carbides as the major phase along with other lower carbides. These carbides in bulk resisted the impact and reduced the wear of material. A total ninety six hammers were installed in hammer mill and the coal was crushed @ 250 ton/hr. The hammer mill was opened after 2000 hrs of use. Condition of hammer has been shown in Fig. 10a & 10b. The wear rate had shown encouraging results and as a result all the hammers were changed with new materials. Prolonged life of hammers helped in maintaining the gap between hammer heads and the crushing mill cover, that resulted into the crushing index > 80% for <3.0 mm size coal. Uniform coal size improved the bulk density of coal in ovens and finally assists in improving the productivity and quality of coke in the coke ovens.

4. Conclusions

a) Life of screen deck increased by improvement in hardness through enriching steel chemistry or by heat treatment of plates. But a thin layer of Cr carbide over mild steel plates enhanced the screen deck life by many fold i.e. from 3-4 months to >27 months. b) Sintered blocks of Fe-Cr-carbides are very hard and able to absorb the impact of coal blocks in hammer mill. Wear of carbide blocks reduced drastically due to their high hardness across the thickness. Expected hammer life will be >3 times from the Mn grade steel hammers.c) Since the wear rate is too low in Fe-Cr-Carbide hammer heads, the gap between hammer head & hood cover remained unchanged for a long duration. It helped in maintaining crushing index of coal between (80-85%) for prolonged period.

ACKNOWLEDGEMENTS

The authors thankfully acknowledge the guidance and support with gratitude extended by the management of RDCIS during the course of this work.

References

| [1] | O.H, Hongsug, Lee, Sunghak J.A.E. Young Jung & A.H.N Sangho Metallurgical & Materials Trans. A Vol. 32A, March 2001, p.515. |

| [2] | K.H.Z. Gahr and D.V. Doane Metall. Trans. A. 1980 Vol. 11A, p.613. |

| [3] | ASTM Standard G 65-00, Standard Test Method for Measuring Abrasion Using the Dry Sand/Rubber Wheel Apparatus, Pennsylvania, USA: ASTM international, 2001. |

| [4] | R. Choteborsky, P. Hrabe M. Mulle, R. Valek, J. Savkova M. Jirka, Effect of of Carbide Size in hardfacing on abrasive wear, Res. Agr. Eng., 55, 2009(4):149-158. |

| [5] | S. Zic, I. Dzambas, M. Ikonic, Possibilities of implementing Bimetallic hammer castings in crushing industries, META 48(1) 51-54 (2009). |

| [6] | Improvement in designe of decks of cold sinter screens of blast furnace to reduce oversize fraction in return sinter: R&D Centre for Iron & Steel, R&D Report22:02:3308.01.2003. |

| [7] | V. Mason, C. M. Perrott, and I. R. Sare, Wear resistance materials for sugarcane shredder hammers. Int. Conf. on Wear of Materials, Dearborn, (1979), USA. |

| [8] | Key to total wear solutions, Imco Alloys Pvt. Ltd. 129, Damji Shamji Industrial Estate. LBS Marg Vikroli (W) Mumbai, 400083. |

| [9] | Enhancement in life of 25 & 80mm nets of coke screens at coke sorting plants of coke oven using composite wear resistant alloy: R&D Centre for Iron & Steel, R&D Report 22:02:3537.01.2006. |

| [10] | P. Yang Shoufan Rong, X. Zhao, Y. Zhu, Y.Wu & X. Li, New type of Bimetal Composite Casting and welding Connection Square Hammer, International Conference on Materials, Environmental and Biological Engineering (MEBE2015). |

| [11] | Branislav Nedeljkovic, Vukic Lazic, Srbislav Aleksandrvic B. Krstic, Milan Mutavdzic, D. Milosavljevic, & M. Dordevic., Influence of the Carbide type on Tribological properties of the hard faced layers, Association of Metallurgical Engineers of Sorbia, Scientific paper UDC:661.665.2. |

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML