S. K. Shukla1, Santosh Kumar1, Saikat De1, A. K. Bhakat1, Atul Saxena1, B. K. Jha1, Basudeb Mishra2, Alok Verma2, A. K. Singh2

1Research and Development Centre for Iron and Steel (RDCIS), Steel Authority of India Ltd. (SAIL), Ranchi, India

2Bokaro Steel Limited (BSL), SAIL, Bokaro, India

Correspondence to: S. K. Shukla, Research and Development Centre for Iron and Steel (RDCIS), Steel Authority of India Ltd. (SAIL), Ranchi, India.

| Email: |  |

Copyright © 2016 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Abstract

In this paper, efforts made at BSL, SAIL towards developmental of API X70 grade HR coils intended for SW pipes, have been presented. Two trial heats with Nb-Cr-V and Nb-Cr-V-Mo based chemistry aiming (a) ferrite-pearlite and (b) ferrite-pearlite-bainite microstructures respectively were made and cast into 1400 x 210 mm slabs. These trial slabs were processed under suitably designed process variables. Acicular ferrite microstructure engineered through Nb-V-Cr-Mo alloy design has been found more suitable to achieve requisite strength level (in 45° direction) and impact toughness properties consistently in API X70 HR coils. All the properties requirements like, Yield Strength (YS): 515-536 MPa, Ultimate Tensile Strength (UTS): 590-610 MPa, Percentage elongation (%El) in 50mm GL: 25-35%, YS/UTS: 0.86-0.88, Hardness: 184-218 HV10 and Impact toughness (at -5°C): 305-328 J were successfully achieved in HR coils of Nb-V-Cr-Mo heat. Performance trial for three number of coils of Nb-V-Cr-Mo heat were conducted at customer’s end. The coils were rolled into 28 mm OD x 7.1 mm thick Helical Submerged Arc Welded (HSAW) pipes and forty numbers of pipes were successfully made. Mechanical properties requirements like YS : 511-550 MPa, UTS: 589-646 MPa, %El: 34-38%, YS/UTS: 0.84-0.87), impact toughness in base (280-296 J), weld (184-196 J) and HAZ (184-236 J) and 100% shear area in Drop Weight Tear Test (DWTT) at 0°C were successfully met in all the pipes. Surface of the rolled pipes were found free from any defect. All the pipes passed the hydraulic, ultrasonic and radiography tests.

Keywords:

APIX70 grade, Acicular microstructure, Spiral welded pipes

Cite this paper: S. K. Shukla, Santosh Kumar, Saikat De, A. K. Bhakat, Atul Saxena, B. K. Jha, Basudeb Mishra, Alok Verma, A. K. Singh, Development of API X70 Grade Hot Rolled (HR) Coils for Spiral Welded (SW) Pipes, International Journal of Metallurgical Engineering, Vol. 5 No. 1, 2016, pp. 9-14. doi: 10.5923/j.ijmee.20160501.02.

1. Introduction

The ever increasing demand for energy word wide requires the construction of high-pressure gas transmission lines with the greatest possible transport efficiency, so that the cost of pipeline construction and gas transportation is minimized. Therefore there is a trend towards using line pipe of larger diameter and/or increasing the operation pressure of the pipeline. This, in turn, necessitates the use of higher strength steel grades (API X70 and above) to avoid a large wall thickness that would otherwise be needed. Large pipeline systems that are installed on land with operating pressures in the range of 70-100 bars are typically constructed from API X65 or X70 grades. However, if the operating pressure requirement is more, higher strength grades like API X80 and above are used for pipeline construction [1]. These steels combine high strength, high impact toughness and outstanding weldability. There are basically two different processes to produce pipes from hot strips i.e Longitudinally Electric Resistance welded (ERW) pipes and Helically or spirally welded pipes. Production of ERW pipes is carried out in a continuous forming and longitudinal welding operation. The most common welding process is the High Frequency Induction (HFI) welding. A major advantage is the high productivity attainable due to the high welding velocities of HFI process. The pipe diameter depends critically on the strip width and very tight tolerances apply. Spiral pipes are produced from forming and welding of strip. Some pipe producers may use a tack welding operation, whereby the pipes are formed and tack welded in one step and the submerged arc welding is done in another operation. A major advantage of spiral pipe production is its high versatility. Various pipe diameters can be produced from the same strip width by changing the forming angle. The forming angle is defined as the angle between the incoming strip and the leaving pipes [2]. Thermomechanically processed hot strip displays anisotropic mechanical properties. This phenomenon can be explained by the elongated grain structure in the austenitic phase that transforms into a textured ferritic phase. Therefore, thermo mechanically rolled material possess long grain boundaries in rolling direction. Pipes are usually tested with samples from the circumference of the pipe. These specimens, transverse to the pipe axis, correspond to a completely different location within the strip material depending on the pipe production process used. A transverse or longitudinal sample in a ERW pipe corresponds with the transverse or longitudinal sample in the strip. However, the location of a transverse sample in a spirally welded pipe compared to the hot strip depends on the forming angle and the pipe diameter. In the hot strip a transverse sample in the pipe is located approximately in a 30 to 45° angle from rolling direction. A pipe made from the same strip material will show different properties depending on the production process. The ERW pipe will display higher YS compare to spiral welded pipe, as the YS values are lowest in this angle range.In the recent past [3], API X70 grade HR coils for ERW pipes were successfully developed at BSL based on ferrite-pearlite microstructure having Nb-V-Cr based steel chemistry, where the required tensile properties need to be achieved in transverse direction (at 90°) of the strip. Since the demand of API X70 grade HR coils for making SW pipes in India is also quite substantial, it was felt worthwhile to initiate efforts for making API X70 HR coils for SW pipes, keeping in view that properties requirements (YS values required to be achieved in 45° direction) for this application shall be different as explained above. Keeping above factors in mind, two different microstructures i.e (i) ferrite-pearlite and (ii) ferrite-pearlite-bainite having Nb-V-Cr and Nb-V-Cr-Mo steel chemistry respectively were targeted in the present work to achieve requisite properties in the API X70 grade HR coils (intended for SW pipes). The objective was to examine effect of different microstructures on the properties of API X70 grade HR coils as well as on pipes.

2. Alloy Design & Processing Considerations

Alloy design considerations for production of defect free slabs involved control of C ≤ 0.06% and N ≤ 50 ppm and addition of higher (~0.018%) Ti addition to avoid chances of peritectic reaction and to improve hot ductility of steel [4]. Mn content was kept in the range of 1.4 - 1.5% keeping in view the customer specification, strength requirement of API X70 grade and solid solution strengthening on one hand and the strong tendency of Mn to segregate on the other. S & P was restricted below 0.010% and 0.020%, respectively for enhancing impact toughness and DWTT results. Nb addition was made to achieve refinement of ferrite grains. Addition of V aimed at engineering precipitation hardening without increasing the mill load. Further, small amount of Mo was also added to achieve bainitic microstructure in HR coils [5]. Mo alloying helps to promote a continuous yielding curve and avoid the so-called Bauschinger effect, which is important when strain-based design codes are specified [6].Concept of thermo-mechanically controlled processing (TMCP) has long been employed for high strength micro-alloyed line-pipe steels. In order to control grain refinement and fine dispersion of precipitates, dissolution of coarse primary carbides and carbo-nitrides present in the slab needs to be ensured. Accordingly, the temperature of soaking in reheating furnace was selected on the basis of the temperature of dissolution (Tsol.) of primary Nb(CN) precipitates. Sufficient holding time at temperatures above Tsol. ensured Nb & V in solution. Austenite grains undergo two processes during rough rolling, viz. (a) grain refinement through the process of recrystallisation after each pass, and (b) grain coarsening during inter-stand time or any holding on the roller table. Temperature control and distribution of draft during each rough rolling pass was adjusted accordingly for austenite conditioning in order to obtain a fine-grained microstructure. Finish rolling was carried out by processing austenite below the temperature of non-recrystallisation (Tnr). High deformation (~70%) during finish rolling was ensured to achieve enhanced number of nucleation during γ to α transformation which in turn results in a very fine, homogeneous ferrite grain structure [7].

3. Experimental

Basic Oxygen Furnace (BOF) – Ladle Furnace (LF) – Continuous Casting (CC) Route was followed for making of API X-70 grade steel. Two trial heats were made and cast into 1400 x 210 mm slabs. Typical casting parameters comprised casting speed of 1.2 M/min., super heat < 200°C and soft secondary cooling practice. These slabs were stack cooled for 60 hours. Slabs were reheated to 1250°C (which was about 50°C above Tsol.). Soaking of a minimum period of 2 hours was ensured. The slabs were processed into 7.1 mm thick HR coils under suitably designed process variables. During hot rolling, thickness of slab was reduced from 200 mm to ~38 mm in 5 roughing-passes. Temperature at the end of roughing (R5 Temp.), finish rolling temperature (FRT) and coiling temperature (CT) varied in the range of 1016 – 1054°C, 834- 917°C, and 538– 679°C respectively.Samples were drawn from HR coils of two trial heats. Tensile properties, impact toughness, hardness and microstructure of these samples were evaluated. Tensile testing was carried out in a 100 kN capacity INSTRON, UK make 1195 model screw driven mechanical testing machine using flat test specimens of 50 mm gauge length (GL) and 12.5 mm gauge width as per ASTM A 370. The tests were carried out in accordance with ASTM E-8 specification while maintaining cross-head speed of 2 mm min-1 during the testing. Hardness measurements were carried out by Rockwell indentation method using an Instron Wolpert make (Model: Series R-Testor®600) hardness testing machine with 100 kg load.Charpy impact tests were conducted using V-notched (2 mm deep notch) with sub- size specimens of 55 x 10 x 5 mm size as per ASTM E - 23 specification. The tests were conducted at ambient and sub-zero (–5°C & –10°C) temperatures. Microstructural examination of the steel was conducted on longitudinal section in an Olympus make metallurgical microscope. The samples were ground and mechanically polished by conventional metallographic procedures. The polished samples were etched in 2% nital solution for microstructural examinations.Performance trial for three number of HR coils (of Nb-V-Cr-Mo heat) were conducted at customer’s end. All the pipes were subjected to hydraulic, ultrasonic and radiography tests. Samples from pipes corresponding to three coils were collected and tensile, hardness, impact & DWTT properties were evaluated.

4. Results & Discussion

4.1. Steel Chemistry

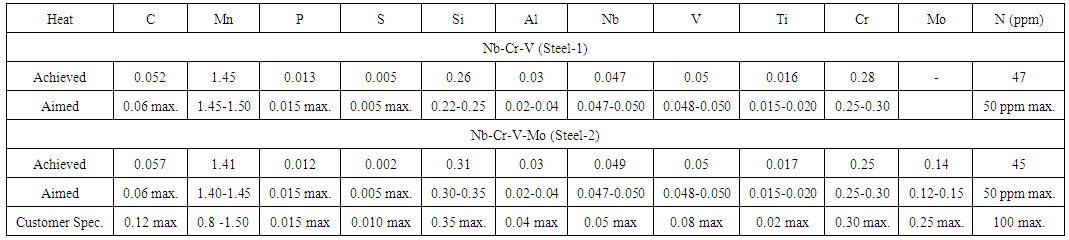

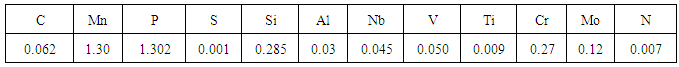

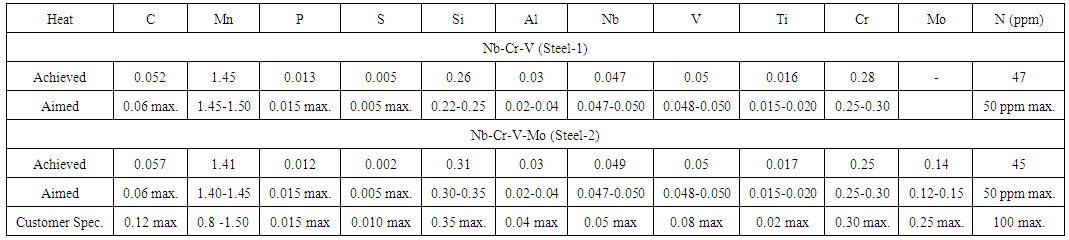

Chemistry of the two trial heats made against a customer specification is shown in Table 1. In order to achieve high Mn level (1.40-1.50%) along with low carbon content (0.06% max.), high purity Mn metal was added in the heat. Re-blows were avoided to achieve low N level in the steel. Nitrogen level was also controlled within 50 ppm in both the heats. Ti addition was targeted in the range of 0.015-0.020% to tie up any free nitrogen to improve hot ductility of steel. S and P were controlled within 0.005 and 0.015% respectively to improve ductility and impact toughness of steel. Nb and V were maintained as per customer specified limit of 0.05% max. and 0.08% max. respectively to achieve requisite strength level in HR coils. Cr addition was controlled in the range of 0.25-0.30% to achieve required YS/UTS ratio. Mo addition of 0.14% was made in steel-2 to achieve ferrite-pearlite-bainite structure in HR coil.

4.2. Properties of API X70 HR Coil

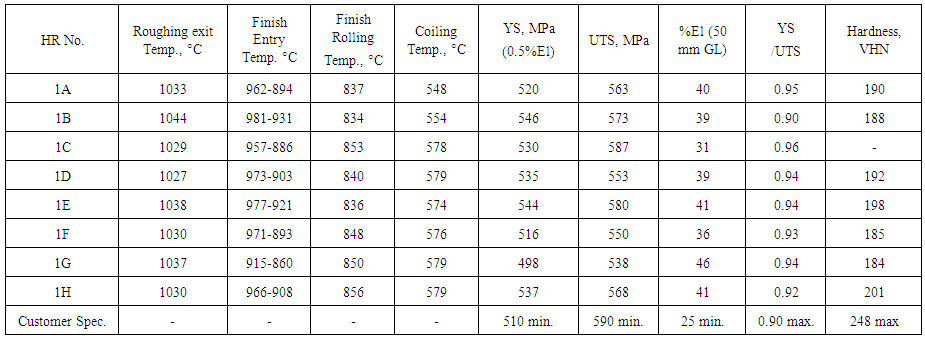

4.2.1. Tensile Properties & Hardness

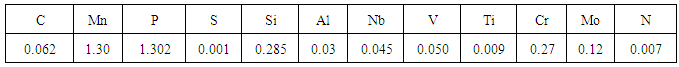

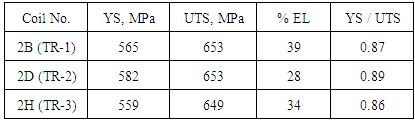

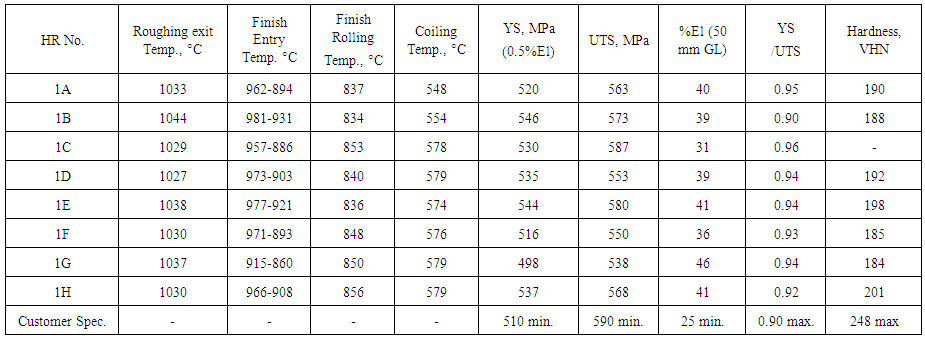

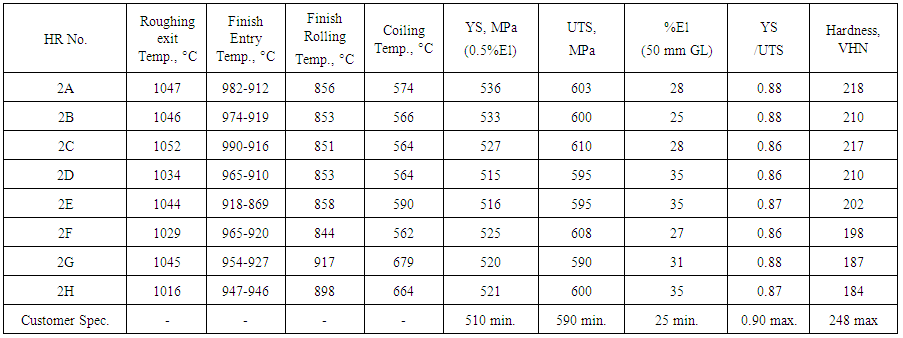

Details of processing parameters along with tensile properties and hardness achieved in the HR coils of two trial heats are shown in Table 2 & 3. It may be noted from the Table 1, that in case of Nb-V-Cr HR coils, YS (at 0.5% El), UTS and %El (G.L=50mm) varied in the range of 498-546 MPa, 538-587 MPa and 31-46%. Customer Specified YS value were achieved in all the coils (except one), however, UTS requirement could not be achieved in any of the coils for Nb-V-Cr HR coils. This may be attributed to insufficient solid solution strengthening and precipitation strengthening in case of Nb-V-Cr HR coils due to lower amount of Si, restricted Mn addition (1.5% max.) due to customer specification and absence of Mo. However, due to sufficient refinement of ferrite grain size, YS value of 510 MPa min. could be achieved in most of the coils. Hardness of the HR coils varied between 184-201 against the requirement of 248 max.In case of Nb-V-Cr-Mo HR coils (Table 2), YS (at 0.5% El), UTS and %El (G.L=50mm) varied in the range of 515-536 MPa, 590-610 MPa and 25-35% respectively. YS, UTS, %El and YS/UTS ratio could be achieved successfully in all the coils. In case of Nb-V-Cr-Mo HR coils, hardness varied in the range of 184-218 VHN. In most of the coils, it was on the higher side (202-218 VHN), except for last two coils (2G and 2H) which were processed at higher finishing (898-917°C) and coiling temperature (664-679oC) resulting in relatively coarser ferrite grain size (~ 5.6 µm). | Table 1. Steel chemistry (in wt.%) achieved in two trial heats |

| Table 2. Tensile properties of Nb-Cr-V HR coils |

| Table 3. Tensile properties of Nb-Cr-V-Mo HR coils |

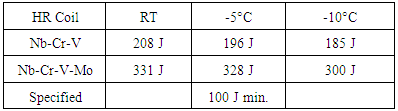

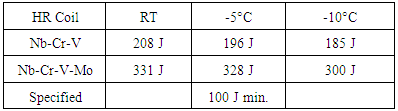

4.2.2. Impact Toughness

Impact toughness (shown in Table 4) of both Nb-V-Cr and Nb-V-Cr-Mo HR coils was found much superior to specified value of 100 J at -5°C. In case of Nb-V-Cr HR coils, it varied from 208 J at room temperature to 196 J at -5°C. Even at -10°C, drop in impact energy was marginal (~10 J). The superior impact toughness is attributed to formation of very and uniform ferrite grain structure (3.0-4.0 µm) in Nb-V-Cr HR coils due to their processing at lower roughing exit temperature (~1035°C) as well as lower finish rolling (~840°C) and coiling (~570°C) temperatures during hot rolling. Impact toughness of Nb-V-Cr-Mo was much superior to Nb-V-Cr HR coils owing to formation of acicular ferritic grain structure. It varied from 331 J at room temperature to 300 J at -10°C.Table 4. Impact toughness of Nb-V-Cr and Nb-V-Cr-Mo HR coils

|

| |

|

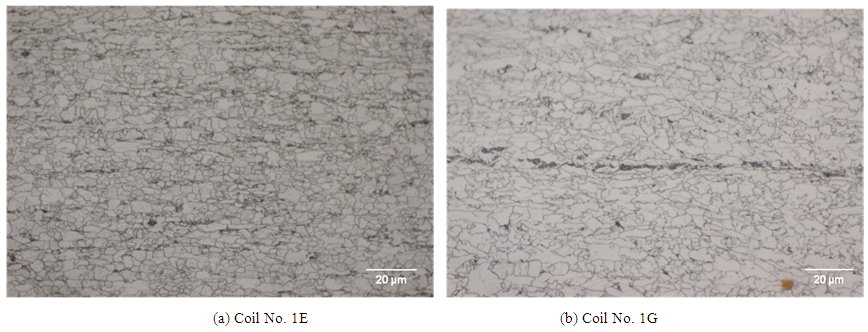

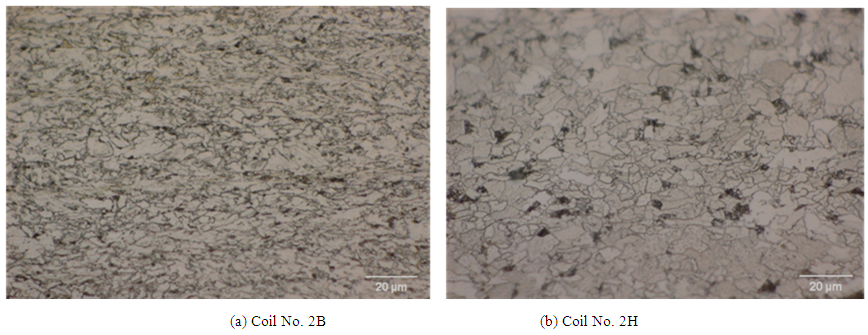

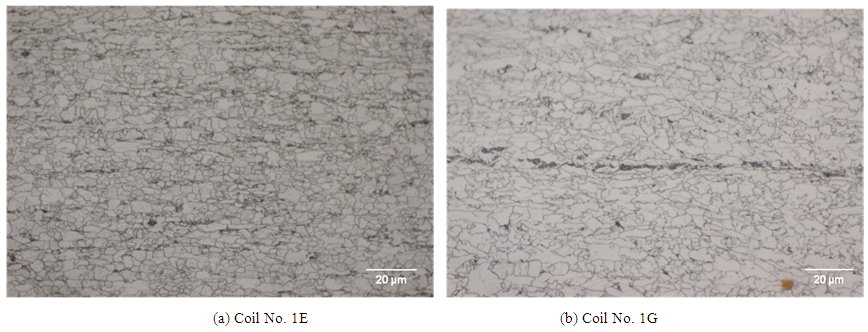

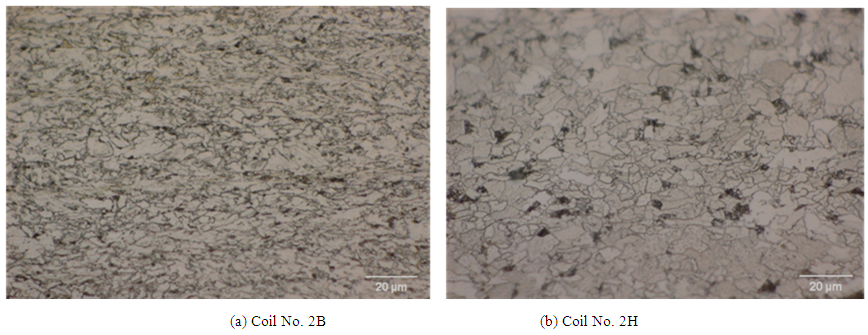

4.2.3. Microstructures

Microstructures of HR coils are shown in Fig 1 and 2. Typical ferrite-pearlite microstructure, with very fine ferrite grain size (3.0-4.0 µm) was observed in most of the Nb-V-Cr HR coils (Fig.1). Nb-V-Cr-Mo HR Coils mostly manifested acicular ferrite grain structure, as shown in Fig. 2a, however, coil processed at higher finishing (898°C) and coiling temperature (664°C) manifested typical ferrite-pearlite structure even in case of Mo added HR coils (Fig.2b). | Figure 1. Microstructures of Nb-V-Cr HR coils |

| Figure 2. Microstructures of Nb-V-Cr-Mo HR coils |

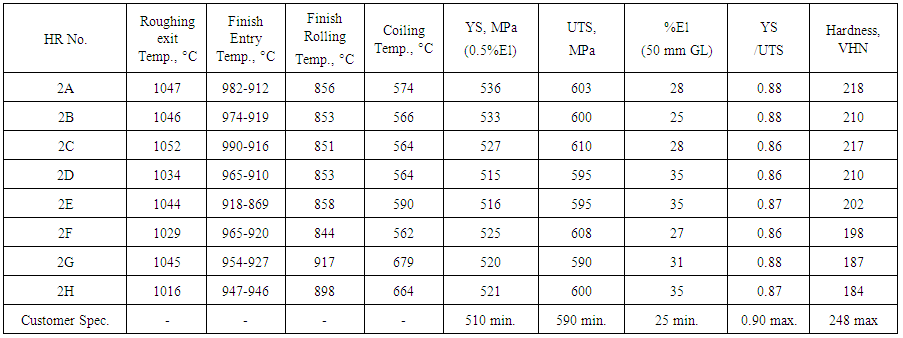

5. Performance Trial at Customer’s End

Three coils (Coil No. 2B, 2D and 2H) of Nb-V-Cr-Mo Heat were evaluated for HSAW pipe performance at customer’s end. Chemical analysis and properties evaluated for the these coils at customer’s end are shown in Table 5 and 6 respectively. The values were found acceptable.Table 5. Chemical analysis of HR coils

|

| |

|

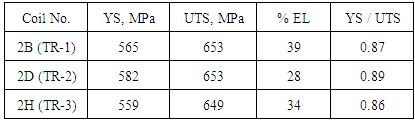

Table 6. HR coil Properties (in transverse direction)

|

| |

|

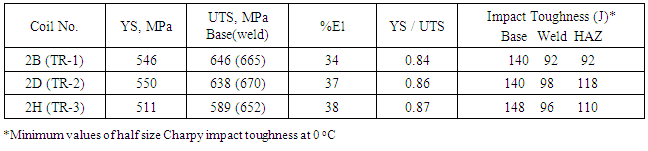

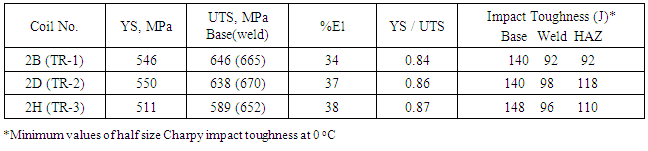

These three coils were rolled into 28 mm OD x 7.10 mm WT HSAW pipes of API 5L Gr X70 M PSL2. Forty numbers. (13 + 13 + 14) pipes were made from these three coils. Surface of the rolled pipes were found free from any defect. No incidence of edge lamination was observed. All the pipes passed hydraulic, ultrasonic and radiography tests. Samples from three pipes corresponding to above three coils were evaluated for tensile, hardness and impact properties. Properties achieved in pipes corresponding to three HR coils are given in Table 7 and Table 8. Bauschinger gain observed as tensile properties of pipes are comparable or better than those achieved in 45o angle in HR coils.Table 7. Tensile and impact toughness properties of pipes

|

| |

|

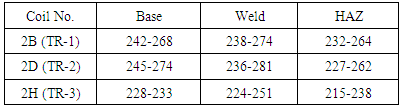

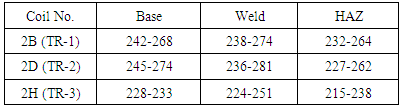

Table 8. Hardness (in VHN) after pipe forming

|

| |

|

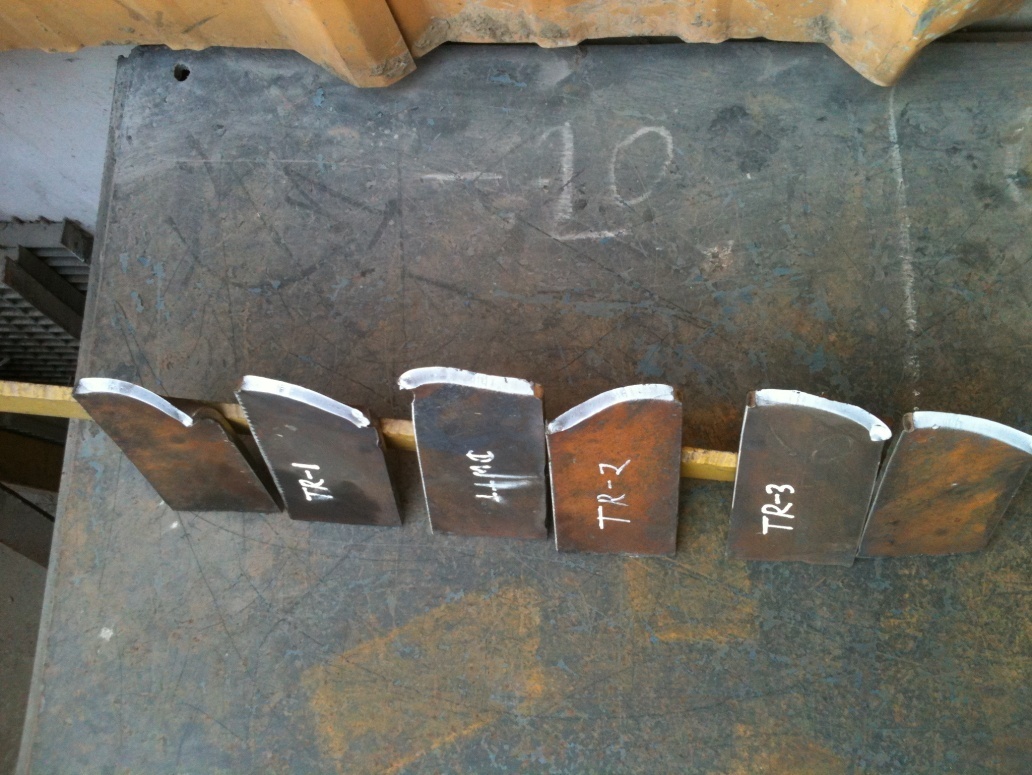

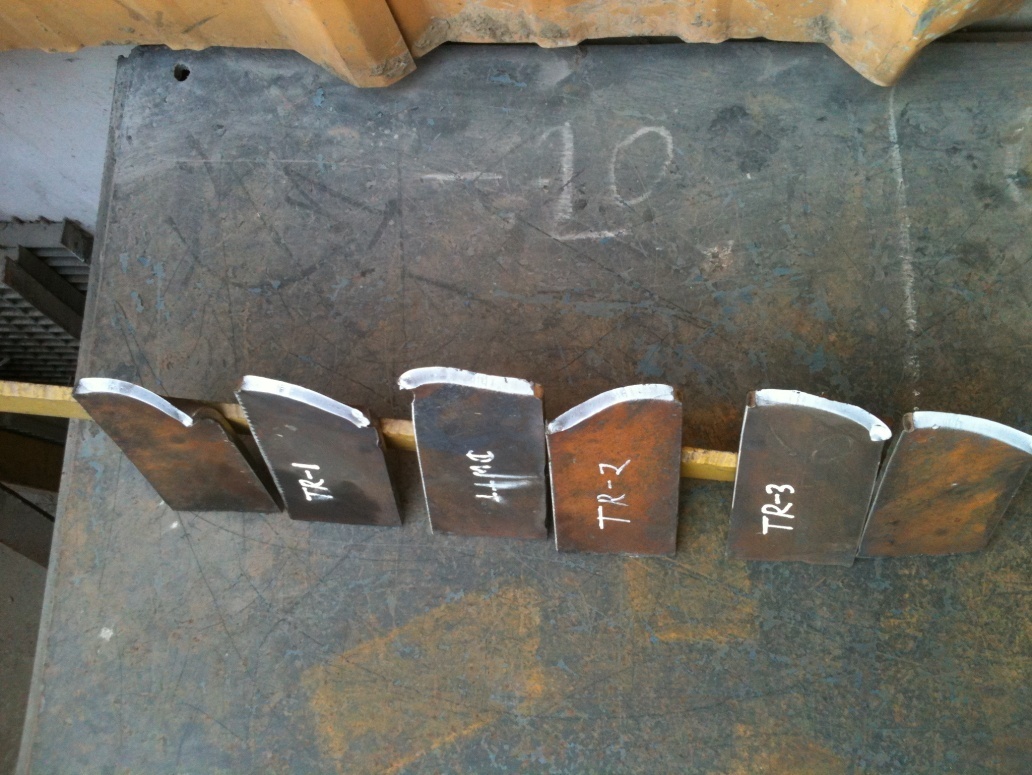

DWTT tests were carried out at 0oC. Percentage Shear Area of fractured surfaces was found 100% in all the three test-cases, as shown in Fig.3. 4t bend test (Mandrel dia.: 28 mm) results were also satisfactory in all cases. Pipes made from two coils (2B and 2D) manifested very high tensile properties which are close to the specified values of API X 80 i.e. YS: 555–705 MPa and UTS: 625–825 MPa. All the requirements of properties of formed pipes of API X70 grade have been met satisfactorily. As per trial results, Mo bearing HR coils of API X70 have been found suitable for making of HSAW pipes in every respect. | Figure 3. Fractured surfaces of DWTT tested specimens |

6. Conclusions

Ÿ Control of carbon (< 0.06%) and nitrogen (< 50 ppm) is must to produce defect free slabs of API X70 gradeŸ Nb-V-Cr-Mo alloy design is more suitable to achieve requisite strength level (in 45°) and toughness properties consistently in API X70 HR coils intended for SW-pipe making.Ÿ Control of R5 temperature, FRT and CT to less than 1040°C, 850°C and 600°C respectively results in achieving consistently very fine and uniform ferrite grain structure leading to superior impact toughness properties in HR coils of both Nb-V-Cr and Nb-V-Cr-Mo heats. Ÿ Performance trial results of 40 pipes made from 3 HR coils of low carbon Mo bearing API X70 grade supplied by BSL have been found satisfactory in terms of surface inspection, ultrasonic testing, hydraulic testing, radiography and all other metallurgical quality requirements of HSAW pipes of API X70 grade.

ACKNOWLEDGEMENTS

The authors are grateful to the management of RDCIS, Ranchi and BSL, Bokaro for their constant support and encouragement during the course of work accomplished under this project.

References

| [1] | J. Y. Koo, M. J. Luton, N. V. Bangaru, R. A. Petkovic et. al; “Metallurgical Design of Ultra-High Strength Steels for Gas Pipelines” Proceedings of The Thirteenth International Offshore and Polar Engineering Conference, Honolulu, Hawaii, USA, May 25–30, 2003. |

| [2] | Ronald Rittmann and Klaus Freier; “Niobium containing steels for spiral and electric resistance welded line pipe production”, Niobium, Science and Technology 01/2001. |

| [3] | Santosh Kumar, S.K. Shukla, S.K. De, Atul Saxena, B.K. Jha, B. Mishra, Alok Verma and S. Mallik “API X 70 grade HR coils for ERW pipes”, International Journal of Metallurgical Engineering, Vol.2, No.1, March 2013, p.173-181. |

| [4] | Nicolas Triolet, Kristof Poelmans, Pierre Mabelly and Yann Le Papillon, Technical paper on “PREVENTION OF CORNER CRACKS IN SLAB CONTINUOUS CASTING”, Arcelor Mittal Research Group, Private Communication. |

| [5] | Douglas G. Stalheim, Keith R. Barnes, Dennis B. McCutcheon, “ALLOY DESIGNS FOR HIGH STRENGTH OIL AND GAS TRANSMISSION LINEPIPE STEELS”, International Symposium on Microalloyed Steels for the Oil and Gas Industry, TMS, 2007. |

| [6] | Douglas G. Stalheim and J. Malcolm Gray, “Ferrite/Acicular Ferrite Alloy Designs for API X80 Gas Transmission Linepipe Steels” Proceedings and Presentation at Modern Steels for Gas and Oil Transmission Pipelines, Problems and Prospects, International Seminar, Moscow, Russia, March 2006. |

| [7] | Nishioka, K. et al.: Proc. Microalloying ‘88. Chicago, USA, 1988, ASM, p.597-605. |

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML