Saikat Kumar De , S. Srikanth , A. K. Bhakat , Atul Saxena , B. K. Jha

RDCIS, SAIL, Ranchi, India

Correspondence to: A. K. Bhakat , RDCIS, SAIL, Ranchi, India.

| Email: |  |

Copyright © 2016 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Abstract

Steel Authority of India Limited (SAIL) has developed a number of economical, value added hot and cold rolled steels which has satisfied the material requirements for a variety of critical applications. Keeping in view the development in infrastructure, automobile, transport and power sector in India there is huge potential for increase in per capita consumption of steel from the present level of 60kg. Construction and infrastructure will continue to be the dominant steel consuming segment. To meet the requirement of corrosion resistant property for the steels to be used in these two segments, SAIL has successfully developed a number of special quality steel grades with copper such as SAILCOR for Railways and BHEL, HCR variety TMT rebars, IS 2062 Cu bearing structural & plates and copper containing Stainless Steel. Further, a lot of application engineering efforts have been put in to establish these grades in the market by improving product quality, suiting the process at the customers’ end and thus ensuring greater acceptability of products. These grades possess superior corrosion resistance and high strength combined with good workability, excellent welding properties and other superior mechanical properties. Such characteristics make these steels a natural candidate for use in a number of segments like transport, construction, power and other engineering sector, agriculture and mining.

Keywords:

Copper bearing, Structural steel, Corrosion resistant

Cite this paper: Saikat Kumar De , S. Srikanth , A. K. Bhakat , Atul Saxena , B. K. Jha , Copper Bearing Steels from SAIL and Its Application, International Journal of Metallurgical Engineering, Vol. 5 No. 1, 2016, pp. 1-8. doi: 10.5923/j.ijmee.20160501.01.

1. Introduction

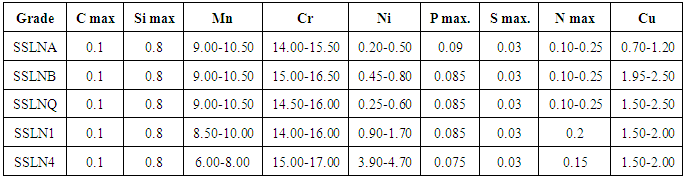

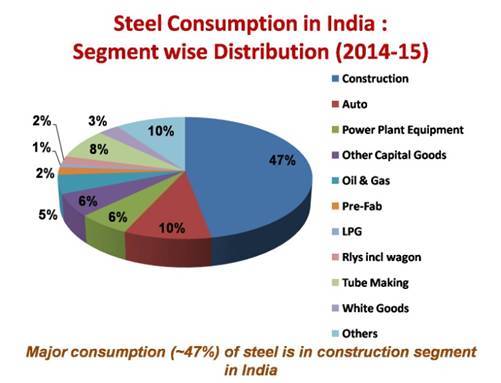

Copper (Cu) is added to steel mainly to increase corrosion resistance. Experimentation with the addition of Cu to structural steels for its ability to impart good atmospheric corrosion resistance properties began in the year 1916 in the USA [1, 2]. The first commercial use of Cu bearing steel as atmospheric corrosion resistant steel was during the period 1933 to 1935. Cu also increases strength through precipitation hardening if present in concentrations greater than 0.75%. In the present market scenario, customers are constantly looking for cost effective, customized products with enhanced intrinsic quality and improved performance in service. Meeting this demand could be made possible by modernizing steel making & processing technology by introducing secondary refining, continuous casting and thermo-mechanical processing etc. Application engineering efforts also assumes a vital role through backward integration of material performance with respect to fabrication and service life of finished component. Adhering to such customer centric product development approach, Steel Authority of India Limited (SAIL) has successfully developed a number of special quality steel grades with copper such as SAILCOR for Railways and BHEL, HCR variety TMT rebars for construction sector, IS 2062 Cu bearing structurals & plates for engineering sector and copper containing Stainless Steel mostly to meet the requirement of corrosion resistant property. Further, a lot of application engineering efforts have been put in to establish these grades in the market by improving product quality, suiting the process at the customers’ end and thus ensuring greater acceptability of products.India has immense potential for development in infrastructure, automobile, transport and power sector as growth in GDP is expected to continue at around 7.5%. Per capita consumption of steel in India now is merely 60kg as compared to world’s average of 217kg [3]. This indicates that there is huge potential for increase in consumption of steel in India. Presently, a major portion of this demand emanates from the construction and Engineering segment, which roughly constitutes 47% of the total market requirements (Figure 1) [4]. | Figure 1. Segment wise demand of steels |

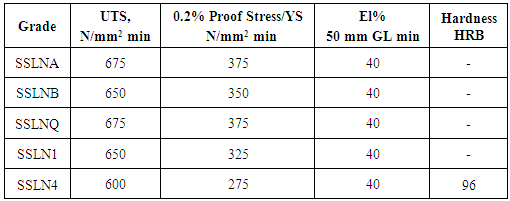

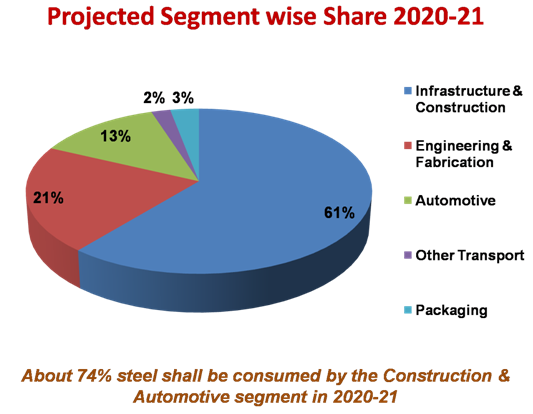

Projected demand for steel in India is around 80 million ton in 2015 and 180 million ton by 2020. Construction and infrastructure will continue to be the dominant consuming segment with an increase of 50 million tonnes emerging by 2020 compared to current consumption (Figure 2). In line with this SAIL is also enhancing capacity and modernizing its plants in order to meet future requirement of the nation in terms of ordinary as well as special grades of steel products. | Figure 2. Projected Segment wise demand of steels |

2. Copper Bearing Steels from SAIL

To meet the requirement of corrosion resistant property, several Cu bearing new products has been developed and commercialised in recent past. - Weather resistant steel i.e. SAILCOR specially to cater to the special needs of Railways, BHEL and other industries- IS 2062 grade Cu bearing structural, sheets and plates for weather resistant application- HCR TMT rebars for construction sector mainly in coastal areas- Copper containing Stainless Steel

2.1. Weather Resistant Steels (SAILCOR)

2.1.1. SAILCOR Steel for Railways-IRSM 41

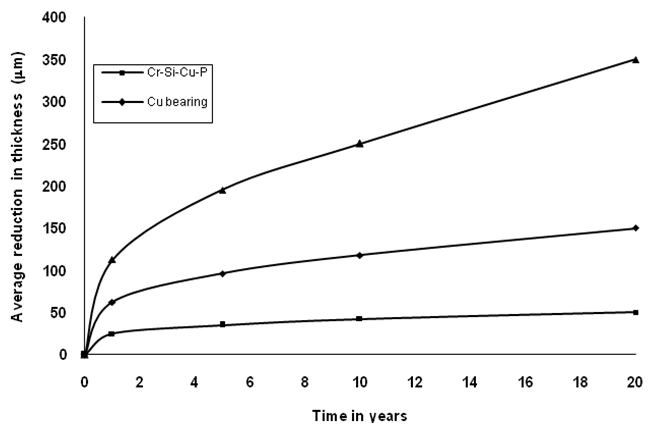

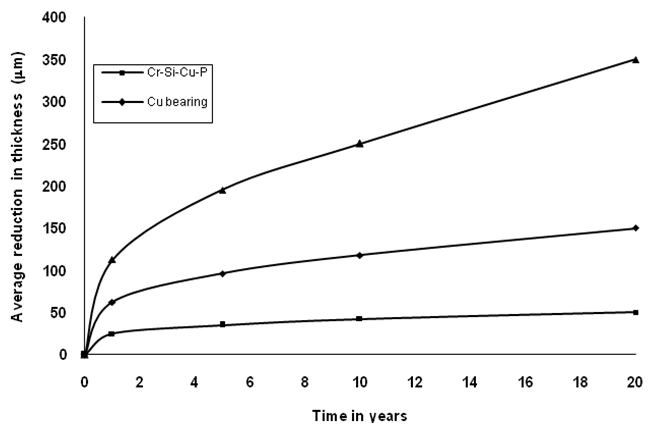

Weather resistant steels conforming to Railways specifications IRSM 41 is a weldable quality, multi alloy steel with superior atmospheric corrosion resistance. In this steel combined addition of copper along with nickel, chromium, phosphorous, silicon etc. enhances the atmospheric corrosion resistance property by 4 to 6 times greater than mild steel. Therefore, SAILCOR steel is potentially attractive materials for applications where both strength and weathering characteristics (Figure 3) are required. Some of the examples are railway rolling stocks, bridges, structural along the coast or in remote areas etc. | Figure 3. Comparative corrosion of steels of varying thickness, industrial atmosphere |

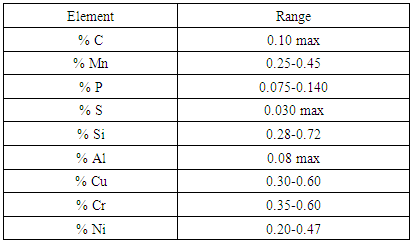

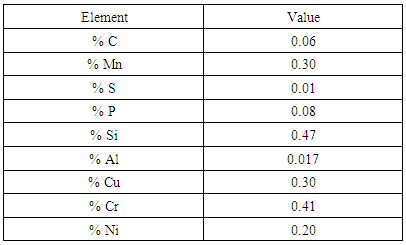

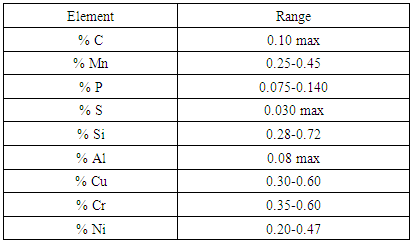

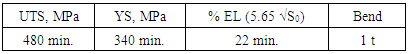

On the other hand, if the alloy addition is restricted to only copper (IS 2062 with Cu) then the improvement in corrosion resistance is around 2 times. It may be mentioned that IS 2062 Grade is produced either in semi-killed or in fully killed conditions but IRSM 41 steel need be processed not only as a killed steel but some extra addition of aluminium is required for grain refinement. This extra quantity of Al helps to accommodate large amounts of phosphorous in ferrite grains without segregations and simultaneously makes the steel more cleaner with better toughness properties. Specified chemical compositions and the mechanical properties [5] are illustrated in Table 1 and Table 2.Table 1. Chemical Composition of Weathering Steel IRSM 41 (By Weight %)

|

| |

|

Table 2. Mechanical Properties of Weathering Steels

|

| |

|

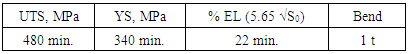

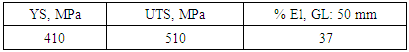

2.1.2. SAILCOR Steel for Regenerator

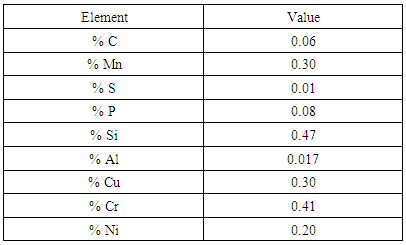

There was a requirement from BHEL, Ranipet for 1.21 × 300 mm slit coils of SAILCOR grade steel. The end applications was roll formed section for regenerator air-preheater elements for heat transfer purpose. Trial rolling of thinner gauge SAILCOR was carried out at Bokaro Steel Ltd (BSL). The typical chemical composition of SAILCOR from Alloy Steel Plant, ASP is given in Table 3.Table 3. Chemical Composition of SAILCOR (by Wt %)

|

| |

|

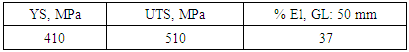

To meet the stringent thickness tolerance of +0.07 mm and - 0 mm, slabs (200×940 mm) from ASP were hot rolled into 2.8×940 mm size. Thickness of HR coils was opted to be equal to 2.8 mm to ensure less than 60% reduction. Hot rolled coils were further processed through Pickling Line II (PL II) - Tandem Mill II (TM II) – Annealing – Slitting route. For cold rolling of 1.2 mm thick CR coils of such a high strength, special measures were undertaken, such as, increasing inter stand tension by 20% more as compared to that of normal grade, introduction of suitable emulsion concentration in different strand. Equal amount of reduction was given to first four strands while fifth strand was used for only skin pass. The annealing cycle was suitably modified. The typical tensile properties of hot rolled (Table 4) and cold rolled coils (Table 5) along with drop in strength during annealing are given below. The CR coils were successfully used by M/s BHEL for heat exchanger application.Table 4. Mechanical Properties of Hot Rolled Coils of SAILCOR

|

| |

|

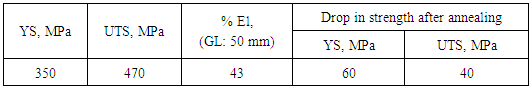

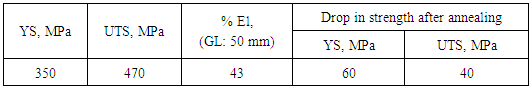

Table 5. Mechanical Properties of Cold Rolled Coils of SAILCOR

|

| |

|

2.2. Cu Bearing Structural Sheets and Plates (IS 2062)

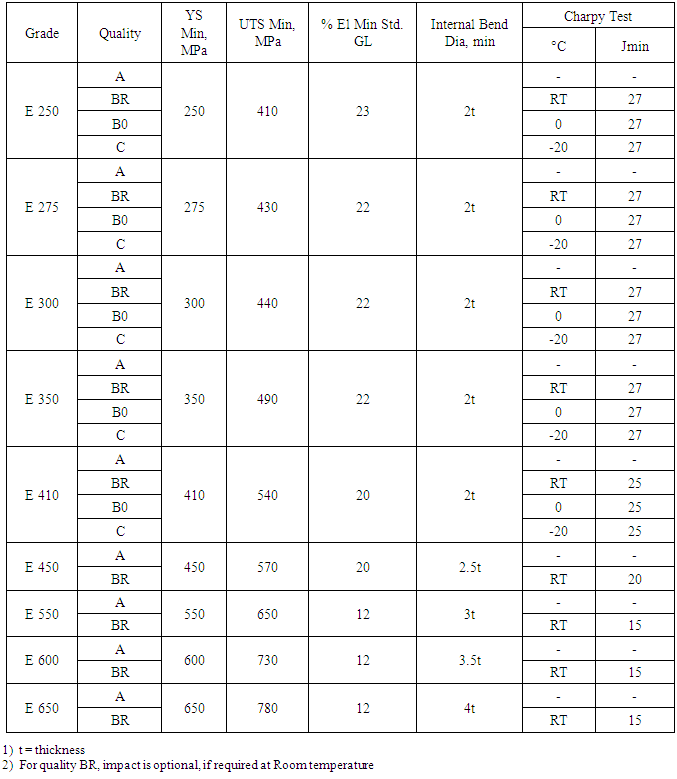

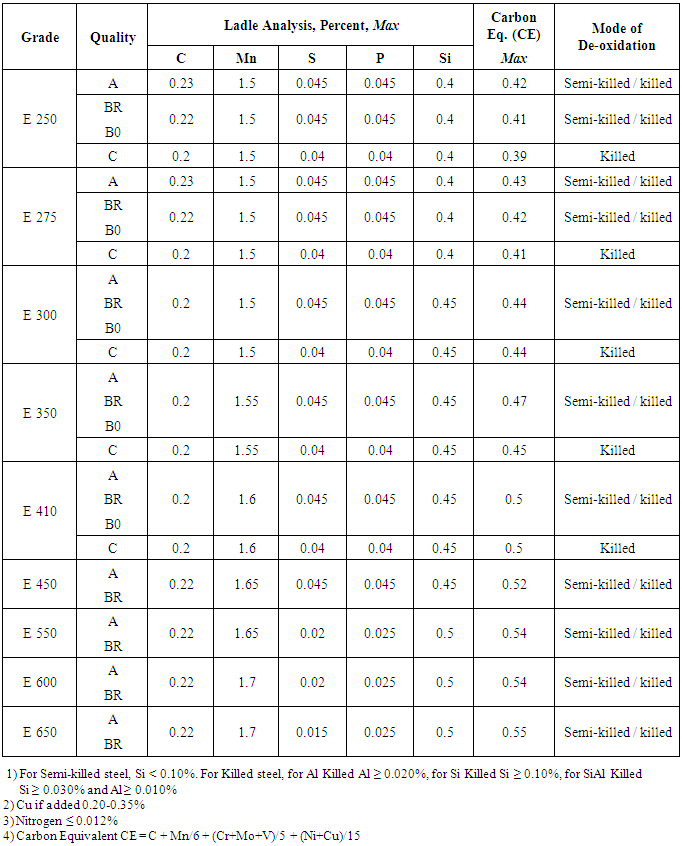

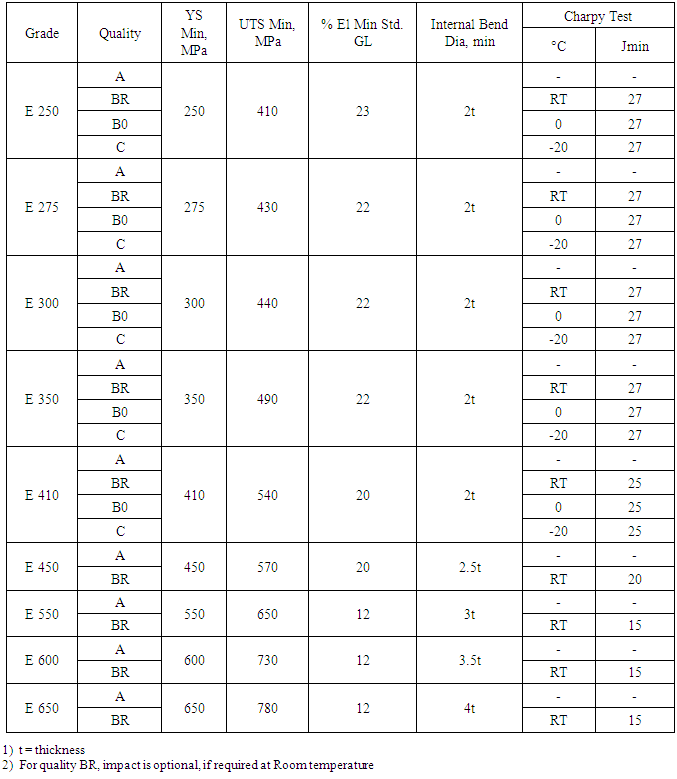

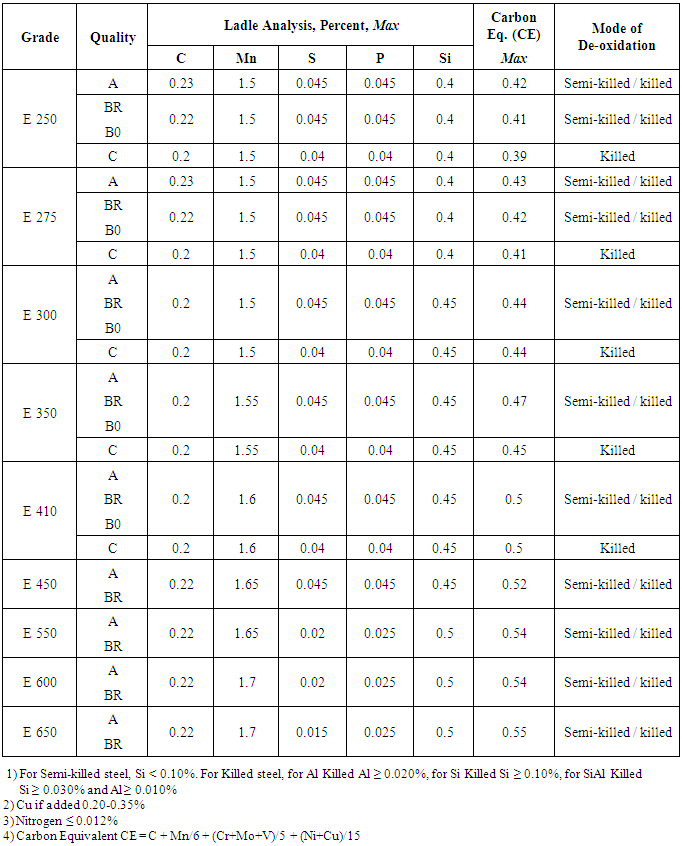

The Indian Standard for structural steels, IS 2062:2011 [6] has nine grades of steel with minimum yield strength vales ranging from 250 MPa to 650 MPa and is shown in Table 6. The number in the grade name signifies the minimum yield strength. For grades E 250 to E 410 there are 4 sub qualities (A, BR, B0 and C) and for grades E450 to E650, there are two sub-qualities (A and BR). Sub qualities A, BR, B0 and C indicate requirement of impact test and mode of de-oxidation as indicated below: A: Impact test not required, Semi-killed / KilledBR: Impact test optional; if required at room temperature; Semi-killed / KilledB0: Impact test mandatory at 0°C, Semi-killed / KilledC: Impact test mandatory at -20°C, KilledThese steels are for general engineering purposes and are also supplied in the copper bearing quality in which case the copper is present between 0.20 to 0.35 percent (product analysis, Cu 0.17 and 0.38 percent) to improve corrosion resistant property. The micro-alloying elements like Nb, V, and Ti may be added singly or in combination. Total micro-alloying elements is restricted below 0.25%. The chemistry of the various grades is shown in Table 7. Sheets, plate and structural materials produced in these grades are being widely used in railways, transport vehicles, agricultural, mining and construction sector.Research Designs and Standards Organisation (RDSO) of Indian Railways had designed BCNHL (Bogie covered wagon with air brake and heavy load) type all stainless steel covered wagon. However recently as per the new design of BCNHL wagon a new grade of steel with micro-alloying has been developed. Cost reduction took place due to use of thinner & higher strength material during manufacture of the wagons. The steel used was IS 2062 E450BR with Cu for corrosion resistance and having yield strength of 450 MPa minimum. The production of such high strength steel of thickness ranging from 1.6 mm to 10 mm was a challenge which was taken up at SAIL. These steels have been developed through innovative alloy chemistry by utilizing the concept of effective Nb.Table 6. Mechanical Properties of Various Grades as Per IS 2062:2011

|

| |

|

Table 7. Chemical Composition of various grades as per IS 2062:2011

|

| |

|

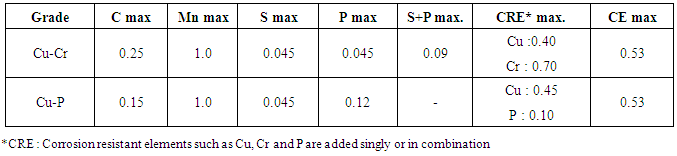

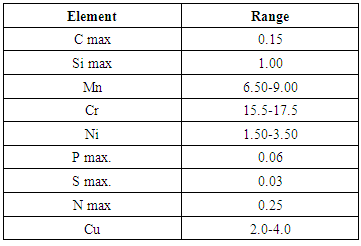

2.3. SAIL HCR TMT Rebars

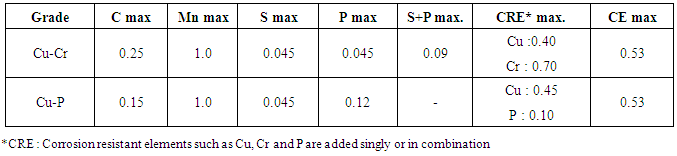

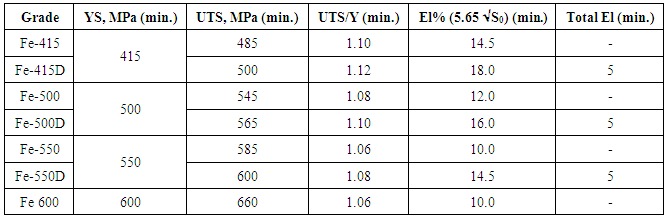

TMT rebars used in buildings and other infrastructures in coastal and other aggressive industrial atmospheric regions, are subjected to natural environmental degradation. To meet the requirements for such infrastructures, SAIL has introduced corrosion resistant TMT rebars. Corrosion process is generally classified into two categories according to its environment, namely, atmospheric corrosion and marine corrosion. The elements that improve atmospheric corrosion resistance of steel are Cu, Cr, P, Ni, Si and Mo. Copper is known to exhibit the highest atmospheric corrosion resistance followed by Cr and P. Similarly, studies involving alloy additions on the corrosion rate of steel structures under marine environments such as sea water or synthetic sea water solutions have shown that Cr possesses the highest marine corrosion resistance followed by Cu, Si and Mo. Based on the above findings, SAIL has introduced two types of corrosion resistant TMT rebars, namely, Cu-Cr and Cu-P in DSP (Durgapur), ISP (Burnpur) and BSP (Bhilai). The chemical composition and mechanical properties for Cu-Cr and Cu-P rebars are shown in Table 8 and 9.Table 8. Chemical composition of HCR-TMT rebars (wt.%)

|

| |

|

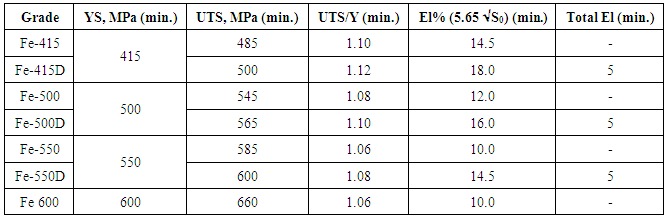

Table 9. Tensile Properties of HCR TMT rebars (IS 1786, 2008) [7]

|

| |

|

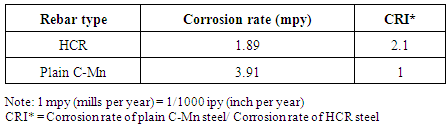

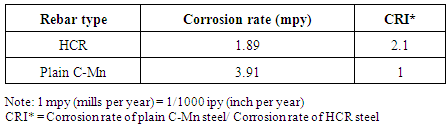

To achieve the targeted properties, certain rolling parameters like finish rolling temperature, mill speed, quenching water flow and equalization temperature were suitably controlled. The use of thermo mechanical treatment has helped to produce reinforcement bars of high strength, superior ductility, weldability, bendability and thermal resistance with superior corrosion resistance properties to suit all constructional applications and environments. The new generation HCR TMT rebars from SAIL when used for RCC structures in coastal, humid and industrial situations, provide superior longevity than conventional rebars. A further improved variety of TMT bar is now available as HCR-EQR which not only provide superior earth quake resistant property but also ensures high corrosion resistance in industrial/marine atmospheric conditions. The product is well received by the customers and requirement is increasing substantially at various regions and covers a size range from 8-40mm diameter.Comparative evaluation of corrosion properties of Cu-Cr rebars vis-à-vis plain carbon TMT rebars were carried out at RDCIS, SAIL. Rebars were subjected to potentio dynamic tests, and the corrosion resistance index (CRI), which is ratio of corrosion rate of plain C-TMT rebars to that of Cu-Cr HCR TMT rebars was determined. A higher CRI reflects superior corrosion resistance properties of the given steel with reference to plain C-Mn steel rebars. Corrosion resistance indices of HCR and Plain C-Mn TMT rebars as determined using Tafel polarization technique in 3.5% NaCl solution are in Table 10.Table 10. Corrosion resistance indices of HCR & plain C-Mn TMT rebars

|

| |

|

2.4. Copper Bearing Stainless Steel

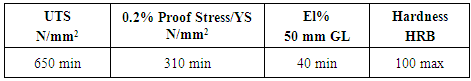

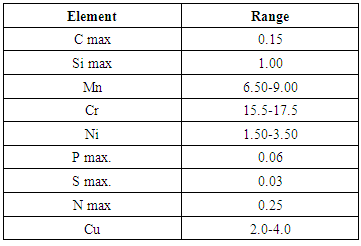

2.4.1. 204Cu

204Cu is a chrome-manganese stainless steel [8] belonging to 200 series of austenite stainless steel family with moderate amounts of nickel, copper and nitrogen. 204Cu is a new alloy that bridges the cost / property gap between 200 and 300 series stainless steel. It has better formability than 201 and 304 due to Cu addition which lowered the work hardening rate to provide cold working properties superior to 200 series stainless steel and similar to type 304. Copper improves corrosion resistance and stress corrosion cracking resistance in certain media. Nitrogen increases strength and pitting resistance of stainless steel. Manganese as austenite former replaces a part of nickel and has beneficial effect on weldability. Consequently 204Cu has a higher annealed strength, similar corrosion resistance in a variety of mild corrosive media and similar formability & weldability in comparison with 304. It can replace 304 in numerous applications where higher strength, high formability and lower cost are required. Copper containing stainless steels exhibit biocidal characteristics and 204Cu has been used for improved drawability and antibiosis for items such as thermos and kitchenware.Table 11. Chemical Composition of 204Cu (wt.%)

|

| |

|

Table 12. Mechanical Properties of 204Cu

|

| |

|

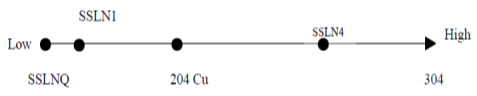

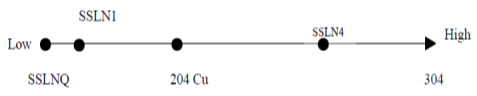

| Figure 4. Performance with respect to properties (indicative, not to the scale) |

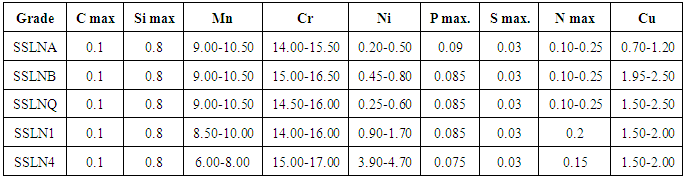

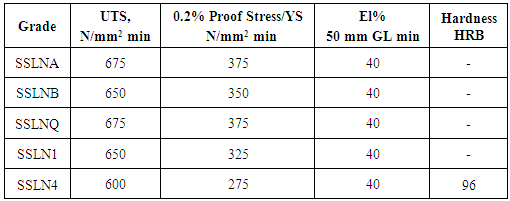

2.4.2. Low Nickel Austenitic Stainless Steel Grades

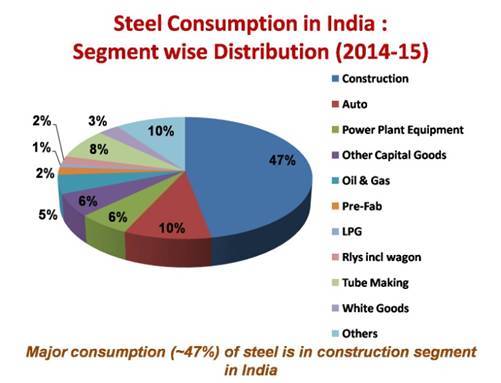

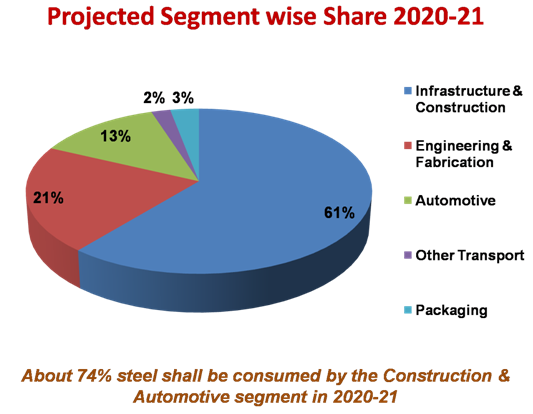

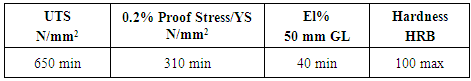

Low Ni austenitic stainless steel grades SSLNA, SSLNB, SSLNQ, SSLN1 and SSLN4 produced by Salem Steel Plant have sizeable market demand in thinner gauges (≤0.8 mm) as cold rolled coils. All these grades belong to low nickel Chrome Manganese stainless steels commonly referred to 200 series. The Nickel content is replaced with Manganese, Nitrogen & Copper. These alloys are non magnetic in annealed condition and like SS 304 becomes mildly magnetic after cold working. It is recommended for applications of stainless steels exposed to normal atmospheric conditions and moderate drawing requirement. Typical applications are utensils, appliances, consumable durables, transport, food processing, building & constructions etc. Performance with respect to formability, weldability and general corrosion resistance of these grades can be rated in common scale as depicted in Figure 4. Chemical composition & mechanical properties [8] are given in Table 13 & 14.Table 13. Chemical composition of SSLN grades (wt.%)

|

| |

|

Table 14. Mechanical properties of SSLN grades (wt.%)

|

| |

|

These stainless steels were prone to incidences of surface defects such as shells and slivers, which often led to rejections and diversions of hot rolled coils. Metallurgical investigations were performed to establish the genesis of defects and correlated with hot shortness resulting from enrichment and formation of low-melting Cu-rich phase (e-Cu, epsilon copper) at oxide scale-steel interface during reheating of slabs and the accompanying austenite grain boundary embrittlement. Process technology for the manufacture of defect-free hot rolled coils was formulated and implemented in the form of interventions involving the use of higher Ni:Cu ratio of 1:2.5 in steel chemistry, control of slab discharge temperatures within 1220°C, restriction of slab reheating times within 3.5-4 hr, regulation of furnace oxygen level within 0.4% and close control of coiling temperatures within 680-710°C leading to complete elimination of shells/slivers and overall improvement in surface quality of downstream cold rolled coils.

3. Application Areas of Cu Bearing Steel

Weather resistant steel finds extensive application in different segments. Following are the few potential areas of application:Transport: buses and trucks: all structural and body parts, accessories, cars, air brake reservoirs, all types of rail and mine cars, earth moving equipment: bulldozers, excavators, scrappers, railway rolling stocks: wagons, coaches, barges, boats, containers and military equipment, conveyors, gas and oil pipelines etc.Construction: buildings, bridges and flyovers, airports, ship building and ports infrastructures, farm warehouse and factory structures, concrete mixers, derricks, dredges, dams & locks, air conditioning ducts, filters, fans, pre heaters, etc.Power and other Engineering Sector: transmission line towers, power plant structures preheaters, heating equipment: stoves, furnace parts, machinery frames and HP and LP gas cylinders etc.Agriculture: Tractor and trailers, farm wagons, fertilizer spreaders (dry), grain elevators and threshers etc.Mining: mine equipment: cars, screens, ore boats, superstructures, jacks and lifts, various accessories, coal handling equipment: chutes, conveyors, hoppers, mine cars etc.

4. Conclusions

• IRSM 41 type low alloy steel (SAILCOR) possesses high strength and superior corrosion resistance combined with good workability, excellent welding properties and other superior mechanical properties. These characteristics make this steel a natural candidate for the manufacture of railway rolling stocks and other areas of corrosion resistant application. • Corrosion resistance of TMT rebars is 1.7 to 2.3 times more than Plain C-Mn TMT rebars. In SAIL the process technology for production of weather resistant variety of steel like SAILCOR, HCR-TMT rebars, IS 2062 (Cu) plates and structural & Copper containing Stainless Steel are well established and well accepted in market. • Huge potential in consumption of Cu bearing and other special grade of steel exists in India as robust growth is expected in coming years.• Realizing customization of product is the fundamental of market acceptability of product; the developmental efforts have been directed not only to meet the product specification but also to satisfy the intrinsic and extrinsic requirements for end applications.

ACKNOWLEDGEMENTS

The authors wish to express sincere thanks to the management of Research & Development Centre for Iron and Steel (RDCIS), Steel Authority of India Limited (SAIL) for giving permission to present this paper.

References

| [1] | F C Langenberg, The Influence of Copper on Steel, 1917, Defense Technical Information Center. |

| [2] | S K Sarna, Copper in Steels, www.ispatguru.com. |

| [3] | World Steel Association, www. worldsteel.org. |

| [4] | Internal Report by Market Analyst Group, SAIL. |

| [5] | Indian Railways Standard IRSM 41-97. |

| [6] | Indian Standard, IS 2062:2011. |

| [7] | Indian Standard, IS 1786:2008. |

| [8] | Steel Authority of India Limited, Product Brochure, www.sail.co.in. |

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML