-

Paper Information

- Next Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Metallurgical Engineering

p-ISSN: 2167-700X e-ISSN: 2167-7018

2013; 2(1): 1-9

doi:10.5923/j.ijmee.20130201.01

Predicting the Occurrence of Dynamic Transformation and Rolling Mill Loads Drops by Hot Torsion and Compression Testing

John J. Jonas, Chiradeep Ghosh, Xavier Quelennec, Vladimir V. Basabe

Materials Engineering, McGill University, 3610 University St., Montreal, H3A 2B2, Canada

Correspondence to: John J. Jonas, Materials Engineering, McGill University, 3610 University St., Montreal, H3A 2B2, Canada.

| Email: |  |

Copyright © 2012 Scientific & Academic Publishing. All Rights Reserved.

Flow curves were determined in hot compression and hot torsion at a series of temperatures on eight C steels of increasing C concentration. The critical strains for the initiation of dynamic transformation (DT) as well as of dynamic recrystallization were determined by the double differentiation method. It is shown that dynamic transformation is initiated well before dynamic recrystallization under industrial conditions of rolling. The mean flow stresses (MFS’s) pertaining to each experimental condition were then calculated from the flow curves by integration. These are plotted against inverse absolute temperature in the form of Boratto diagrams. The stress drop temperatures, normally defined as the upper critical temperature applicable to rolling Ar3*, were determined from these diagrams. These are shown to be about 40°C above the paraequilibrium and about 20-30℃ above the orthoequilibrium upper critical transformation temperatures. This type of behavior is ascribed to the occurrence of dynamic transformation during deformation. The general characteristics of the dynamic transformation of austenite to ferrite are reviewed. It is suggested that some of the unexpectedly low rolling loads, as well as the load drops that have been reported to take place above the Ae3 temperature in strip mills, may be attributable to this phenomenon.

Keywords: Rolling Load, Mean Flow Stress, Dynamic Transformation, Dynamic Recrystallization, Critical Strain, Mechanical Testing

Cite this paper: John J. Jonas, Chiradeep Ghosh, Xavier Quelennec, Vladimir V. Basabe, Predicting the Occurrence of Dynamic Transformation and Rolling Mill Loads Drops by Hot Torsion and Compression Testing, International Journal of Metallurgical Engineering, Vol. 2 No. 1, 2013, pp. 1-9. doi: 10.5923/j.ijmee.20130201.01.

Article Outline

1. Introduction

- The dynamic transformation (DT) of austenite to ferrite during rolling above the Ae3 was first demonstrated by Yada and co-workers in the 1980’s[1,2]. They were able to produce this kind of transformation as much as 166°C above the orthoequilibrium Ae3. On holding after deformation, the DT ferrite was shown to re-transform to austenite, as required by equilibrium thermodynamics. Later, the occurrence of this phenomenon was verified by in-situ x-ray methods[3] as well as by laser dilatometry[4,5] and considerable modeling work has also been carried out[6,7]. More recently, the double differentiation method has been employed to determine the critical strains for DT[8,9]. These have been shown to be well below the critical strains required for the initiation of dynamic recrystallization, so that DT is generally underway well before DRX under the usual conditions of industrial rolling.Although DT is generally initiated during finish rolling, it does not produce readily detectable effects for a number of reasons. One is that the grains produced in this way are less than a micron in size and so are not readily observable using optical microscopy[10-15]. Another is that the rate of production of DT ferrite is quite low, ½ to 1% volume fraction per 1% strain[16], so that its initiation does not produce dramatic effects or sudden decreases in rolling load. However, because DT ferrite is softer than the austenite from which it has formed (at a given temperature), at the stage in rolling where significant volume fractions of DT ferrite have formed, they can have a measurable softening influence on the load. This is an effect that can be detected under appropriate conditions.One way of predicting the occurrence and magnitude of the load drops due to DT is by carrying out hot compression and hot torsion experiments at the appropriate temperatures and then calculating the mean flow stress (MFS) by integration of the area under the curve. Such calculations can also be used to determine the effect of the accumulated strain below the Tnr on the magnitude of the load drop. Experiments of this type are described below and it is shown that load drops of 10 to 50 MPa can be readily produced in this way. It therefore appears that one of the possible causes of unexpected reductions in rolling load in the austenite phase field as well as rolling loads that are lower than predicted in the absence of strain accumulation may well be dynamic transformation. The calculations also explain why the values of the dynamic upper critical Ar3* temperature derived using the Boratto[17] method can actually be higher than the equilibrium Ae3 temperature.

2. Experimental Procedure

2.1. Materials

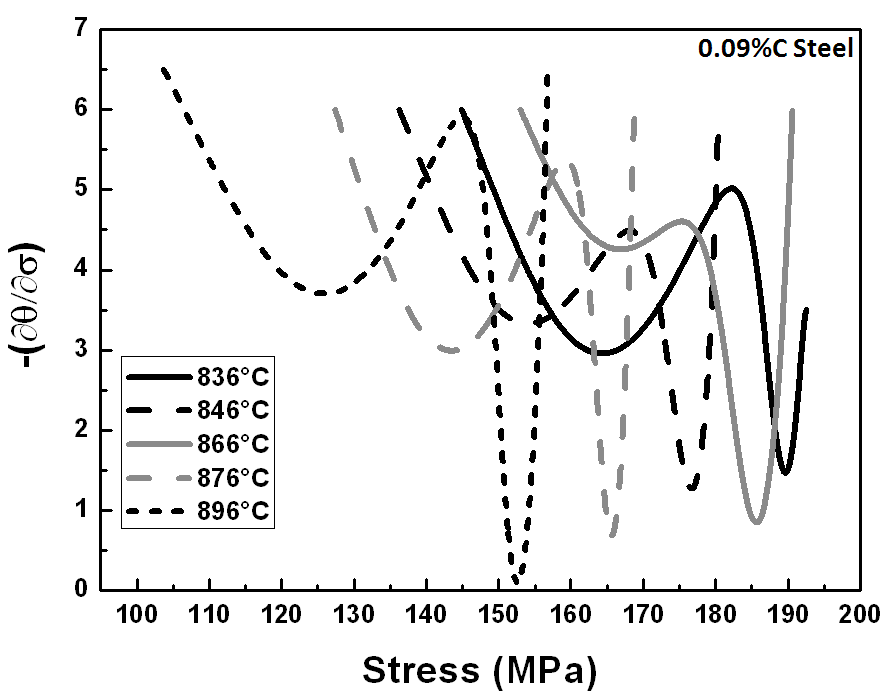

- The flow behaviors of an ultralow 0.019%C, a 0.11%C-0.038%Nb microalloyed, and a 0.22%C-0.045%Nb steel were determined by means of hot compression testing. A further five steels, containing 0.06%C, 0.09%C-0.036%Nb, 0.21%C, 0.45%C, and 0.79%C were tested in hot torsion. Their detailed compositions and equilibrium transformation temperatures are presented in Table 1.

2.2. Test Procedure

- The hot compression tests were carried out on an MTS test frame with the aid of a Research Incorporated radiation furnace and superalloy tooling. The TestStar software was employed for test programming and data acquisition and conversion. Details of the heating and cooling procedure followed are given in Refs. 18-20. The torsion tests were performed on an MTS-based hydraulic torsion machine, again using a Research Incorporated radiation furnace and superalloy tooling. Test programming and data acquisition and conversion were again accomplished using the TestStar software. Details regarding the austenite conditioning as well as the heating, cooling and quench schedule are provided in Refs. 10-15. Metallographic examinations of the quenched samples were carried out on a Philips XL-30 FE-SEM.

|

3. Results

3.1. Flow Curves

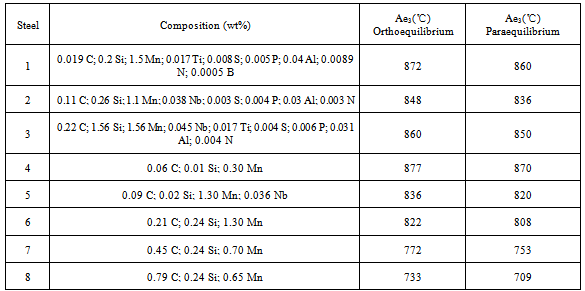

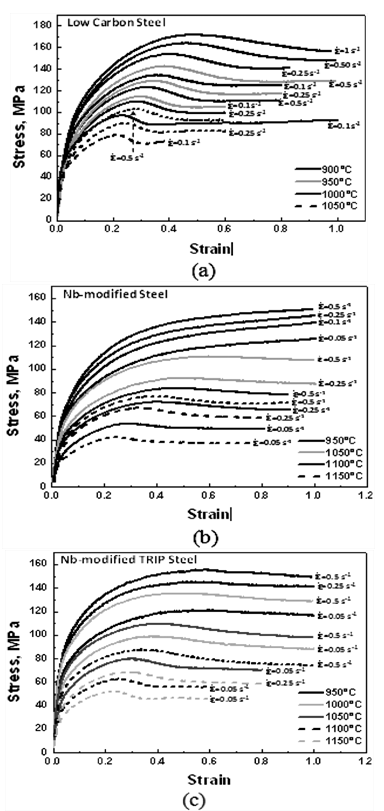

- Some typical flow curves determined in compression are presented in Fig. 1. In the ultralow C steel, Fig. 1a), flow softening took place under all the experimental conditions, while in the Nb-modified plain C steel, Fig. 1b), there was net work hardening at the lower temperatures and flow softening at the higher temperatures. In the Nb-modified TRIP steel, the flow stress nearly saturates at the lowest temperature, while there is clear evidence of flow softening, usually attributed to dynamic recrystallization (DRX) at the higher temperatures. Some typical flow curves determined in torsion are illustrated in Fig. 2. Only the low C (0.06%C) steel exhibits the conventional ‘single peak’ behavior, while the four remaining steels display work hardening, leading to saturation in three of the steels.

| Figure 1. Hot compression flow curves determined on the: a) 0.019%C ultralow C; b) 0.11%C Nb-modified; and c) Nb- modified TRIP steels[19] |

| Figure 2. Hot torsion flow curves determined on the: a) 0.06%C[10]; b) 0.09%C-0.036%Nb[11]; c) 0.21%C[15]; d) 0.45%C[16] and e) 0.79%C[15] steels |

3.2. Critical Strains

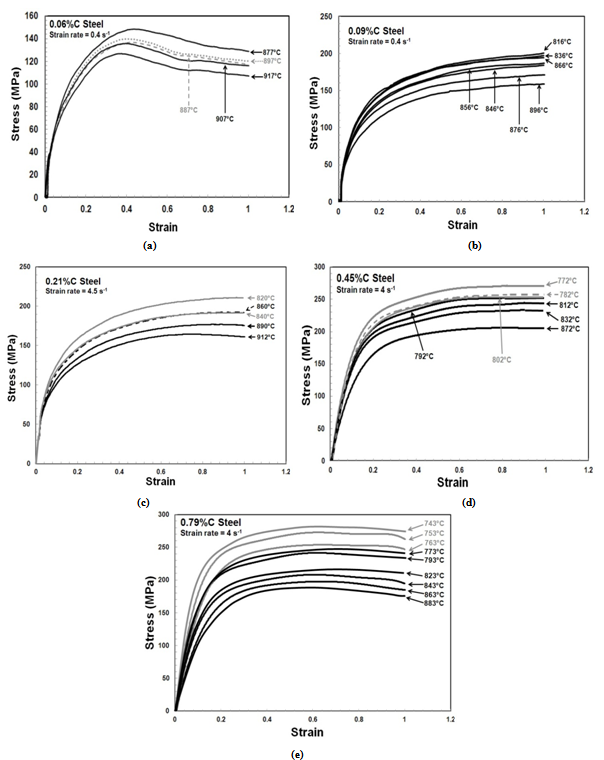

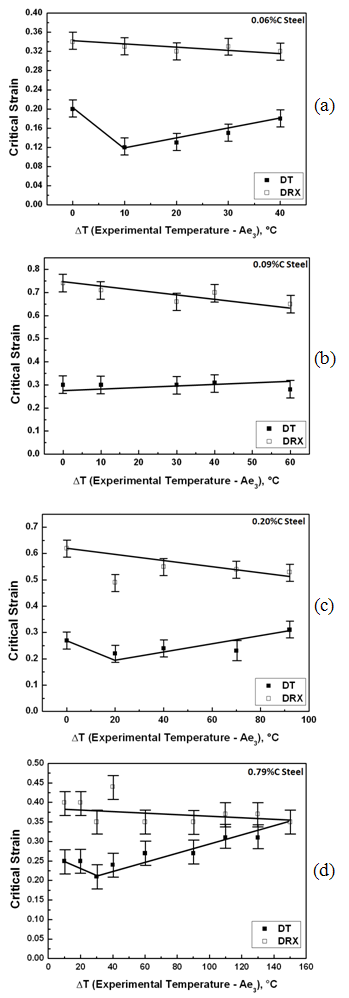

- The double derivative procedure[21] was employed In order to determine the critical strains for the initiation of dynamic transformation (DT) as well as of DRX. This required the fitting of polynomials to the rising portion of each stress-strain curve. Polynomials of order 8 to 10 were used, as described in more detail in Ref. 22. Examples of the second-derivative plots determined on the 0.09%C-0.036%Nb steel are provided in Fig. 3, where θ is the slope of the stress-strain curve (first derivative) and ∂θ/∂σ is the second derivative. Here it can be seen that there are two local minima on each plot, the first of which is associated with the initiation of DT and the second with the start of DRX. Similar results were obtained on the other steels[15].The critical strains determined on four of the steels tested in torsion are illustrated in Fig. 4. Here it can be seen that the critical strains for the initiation of DT are quite low (about 0.1 to 0.25) and relatively insensitive to temperature and strain rate. They are always lower than those associated with DRX. The latter decrease with increasing temperature and decreasing strain rate in the manner normally associated with DRX[23]. The DT critical strains are in good agreement with the metallographic observations of ferrite formation during testing[10-15]. Similar results were obtained on the materials tested in compression[22], although the compression critical strains were always somewhat lower than those determined in torsion under comparable conditions.

3.3. Mean Flow Stresses

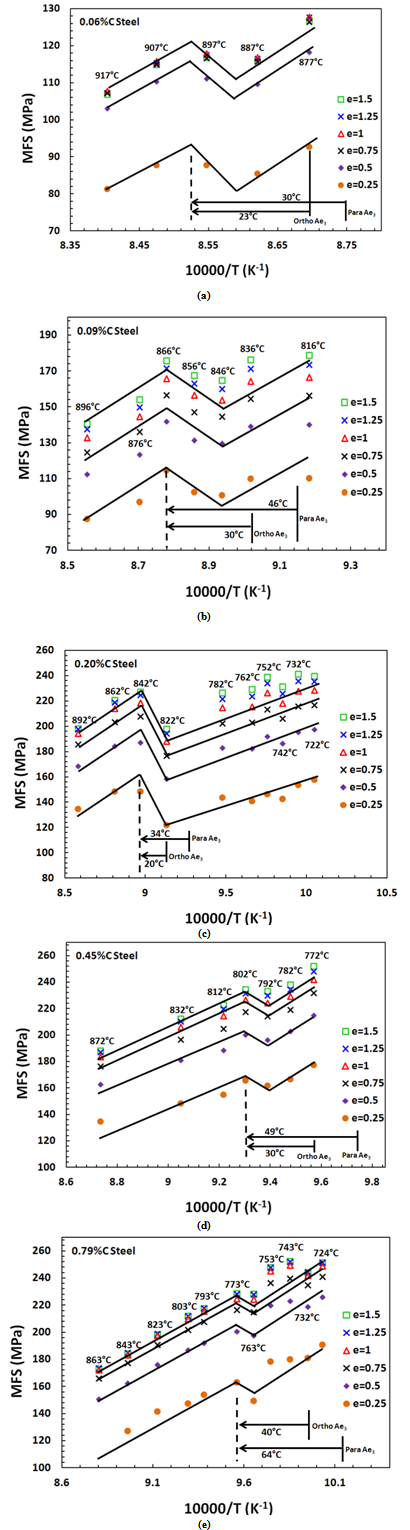

- The mean flow stresses (MFS values) were determined from the flow curves by simple integration. These calculations were carried out using the Excel™ and Origin™ software programs. The results obtained were then plotted against inverse absolute temperature following the Boratto[17] procedure. The dependences observed are shown in Fig. 5 for the five steels tested in torsion.

| Figure 3. -(∂θ/∂σ) vs. σ plots derived from the flow curves of the 0.09%C-0.036%Nb steel[15] |

4. Discussion

4.1. Mean Flow Stresses

- Several features of these plots are of interest. First of all, it should be noted that all of the plots exhibit an Ar3*, i.e. a point at which the MFS suddenly drops, even though the temperature is decreasing, so that the MFS is expected to rise. This is because the ferrite being formed by DT is softer than austenite at the temperature of interest. Of particular interest is the observation that in every case, the drop temperature is well above the equilibrium upper critical Ae3 temperature normally associated with phase transformation. Both the orthoequilibrium as well as paraequilibrium temperatures are indicated on the diagrams, from which it can be seen that the dynamic Ar3*’s are something like 20-40 degrees above the ortho Ae3 and as much as 30-60 degrees above the para Ae3.

| Figure 4. Critical strain determined by means of torsion testing: a) 0.06%C steel; b) 0.09%C steel; c) 0.21%C steel; and d) 0.79%C steel[15] |

| Figure 5. Mean flow stresses (MFS’s) determined from the torsion testing flow curves |

4.2. Critical Strains and Softening Mechanisms

- The conventional ‘single peak’ austenite flow curves of Fig. 1a) and 2a) are usually associated with the occurrence of DRX; their iconic shapes are thus generally attributed to the motion of the recrystallizing austenite grain boundaries, which remove dislocations and cause flow softening. However, it is clear from the critical strains presented in Fig. 4 that two flow softening mechanisms are acting concurrently during the high temperature deformation of austenite (in addition to dynamic recovery). That is, that the flow softening of austenite is actually caused by dynamic transformation as well as by dynamic recrystallization. This effect of DT has not been recognized to date for a number of reasons: i) one is that the DT ferrite plates produced in this way are so fine (under a micron in size) that they are not readily observable by optical microscopy; ii) the second is that the polygonal grains resulting from the coalescence and growth of the plates are usually considered to have formed statically, i.e. during cooling to room temperature (and not dynamically); and iii) finally the rate of formation of such DT ferrite is quite low, so that it does not generally produce any dramatic effects.

5. Conclusions

- 1. Hot torsion and hot compression testing can be used to determine the critical strains for dynamic transformation as well as the mean flow stresses applicable to rolling.2. The double differentiation method is readily adaptable to calculating the critical strain for DT.3. The DT critical strains are well below those associated with the initiation of DRX and indicate that, up to fairly high temperatures, the flow softening taking place during the high temperature deformation of austenite is generally caused by these two flow softening mechanisms occurring simultaneously.4. As a result of DT, the Ar3* temperatures determined by the Boratto method are generally higher than the ortho or para equilibrium Ae3’s.5. Ferrite formation at such high temperatures is brought about by the increase in free energy of the deformed austenite associated with the presence of the dislocations introduced by straining.

ACKNOWLEDGEMENTS

- The authors are indebted to the Natural Sciences and Engineering Research Council of Canada for financial support.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML