-

Paper Information

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Metallurgical Engineering

2012; 1(3): 40-43

doi: 10.5923/j.ijmee.20120103.02

Effects of Melt Vibration During Solidification on the Mechanical Property of Mg-Al-Zn Alloy

Aramide Fatai Olufemi 1, Ibitoye Simeon Ademola 2

1Metallurgical ,Materials Engineering Department, Federal University of Technology, Akure, Ondo State, Nigeria

2Materials Science ,Engineering Department, Obafemi Awolowo University, Ile-Ife, Osun State, Nigeria

Correspondence to: Aramide Fatai Olufemi , Metallurgical ,Materials Engineering Department, Federal University of Technology, Akure, Ondo State, Nigeria.

| Email: |  |

Copyright © 2012 Scientific & Academic Publishing. All Rights Reserved.

The effect of mechanical mould vibration during melt solidification on the mechanical properties of an AZ91 magnesium alloy was investigated. This was tested in the frequency range from 0 to 24 Hz and at two vibration intensities; 5V-peak to peak and 10V-peak to peak. Mechanical tests such as tensile test, hardness test and impact test were carried out on the samples. Improvements were observed in the mechanical tests within the frequency threshold of 12 and 16 Hz. It was concluded that vibration of moulds during melt solidification have some refining effects on the grain structures of the alloy and improve the mechanical properties of the sample. The optimum frequency of mold vibration is between 12 and 16 Hz.

Keywords: Mould Vibration, AZ91 Magnesium Alloy, Solidification, Melt

Article Outline

1. Introduction

- Materials (metallic) whose microstructure have been subjected to grain-refinement possess many advantages which among others include, good mechanical properties[1, 2], thermal stability[3] and low temperature and/or high strain rate superplasticity[4]. This grain refinement can be achieved either when external forces are applied to induce fluid flow during solidification which include rotation of the mold, mechanical/electromagnetic stirring of melt and rheocasting[5, 6] or by imposing very large plastic strains through several techniques which include, multiaxial Forging[7], accumulative roll-bonding[8] and equal-channel angular pressing (ECAP)[9].Grain refinement is a spontaneous transition observed in many pure metals and alloys above a critical undercooling,

T*. The coarse columnar grain structure evident below

T*. The coarse columnar grain structure evident below  T* is replaced by a equiaxed structure. The transition is accompanied by a break in the growth velocity-undercooling curve and a change in the shape of the solid-liquid interface from angular to smooth[10].In most foundry in this country, alloys are normally subjected to annealing in order to impart workability in to them; this research endeavour is aimed at investigating the possibility of improving workability of these alloys during solidification, for all applications involving plastic deformation of the cast alloy without necessarily subjecting it to annealing.

T* is replaced by a equiaxed structure. The transition is accompanied by a break in the growth velocity-undercooling curve and a change in the shape of the solid-liquid interface from angular to smooth[10].In most foundry in this country, alloys are normally subjected to annealing in order to impart workability in to them; this research endeavour is aimed at investigating the possibility of improving workability of these alloys during solidification, for all applications involving plastic deformation of the cast alloy without necessarily subjecting it to annealing.2. Materials and Methods

- The materials used for this research are Magnesium alloy, Aluminum alloy (whose composition is shown in the Appendix) and Zinc metal of 99.98% purity. From these, the charge calculation was made to arrive at alloy composition 90% Mg, 9% Al and 0.6% Zn. Other materials used for this work are flux MgCl2.KCl. H2O and MgO used during melting to coagulate and separate the slag from the melt.A vibrator device which converts electrical signals to mechanical vibrations was coupled to the target moulds. This vibrator produced horizontal vibrations.The melt was produce in a cast iron crucible placed in an electric furnace, after charging it with 90% Magnesium sample, 9.2% Aluminum (6063) sample and 0.6% zinc sample. The salt based flux (MgCl2.KCl. H20 and Mg0) was added to it to coagulate slag and de-slag the melt. The electric furnace was set at 850℃and then switched on. The first melt was poured into non-vibrating permanent moulds. While the subsequent melt was poured into permanent moulds being vibrated at varied frequencies. (The vibration was brought about using two different vibration intensities of 5 volt peak to peak and 10 volts peak to peak).The cast rods were machined to standard dimensions for the impact and tensile test samples on a lathe machine.

2.1. Tensile Testing

- The tensile tests were performed on various samples using Monsanto tensometer. The fracture load for each sample was noted as well as the diameter at the point of fracture and the final gauge length. The initial diameter and initial gauge length for each sample was noted before uniaxial load. From the generated data the ultimate tensile strength and percentage elongation of each sample were calculated.

2.2. Impact Test

- The impact tests were performed on various sample determine the impact strengths by the “V-notch method using the Honsfield Balance Impact Testing Machine. Prior to mounting on the machine, the test sample is notched to a depth of 2mm with v-shaped hand file. The notched test sample was then mounted on the impact-testing machine, which was then operated to apply a (constant) impact force on the test sample. The impact strength (the amount of impact energy the specimen absorbed before yielding) was then read off the calibrated scale on the impact testing machine.

2.3. Hardness Test

- The hardness test was carried out on the various test sample using the Hounds Field Tensometer with a compression die and the Brinell ball bolster attached, having adjusted the mercury level to zero.Two samples each of the various test samples were initially grounded to 600 microns, and then polished using the Ecomet II machine to produce smooth and shining surfaces. The polished surface of each sample was held against the Brinell ball and the load was applied until the mercury level read 125KN, this was allowed to be in place for 15 seconds. The diameter of the impression left by the ball on the sample was measured using the Brinell calibrated hand lens and the corresponding Brinell hardness numeral was determined.

3. Results and Discussion

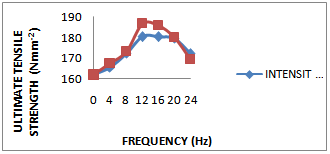

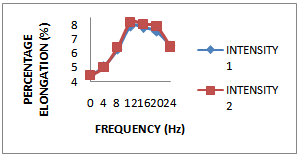

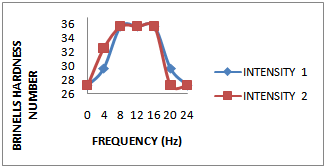

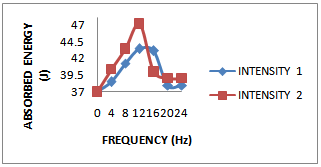

- Table 1 shows the results obtained from the various test carried out on various samples of the Mg-Al-Si alloy. While figures 1, 2, 3 and 4 depicts the relationship of the ultimate tensile strength, percentage elongation, Brinells hardness number and absorbed energy of the alloy respectively with the frequency of vibration of the mould contain the molten alloy until solidification was complete.

| Figure 1. Relation between the Frequency of vibration and Ultimate Tensile Strength of the samples |

| Figure 2. Effects of Frequency of vibration on the Percentage Elongation of the samples |

| Figure 3. Effects of Frequency of vibration on the Hardness of the samples |

| Figure 4. Effects of Frequency of vibration on the Impact Strength of the samples |

4. Conclusions

- Increased frequency of mould vibration during solidification causes refinement of the grain in the alloy. This refinement of the grains results in an increased ductility/ percentage elongation/UTS/impact strength and hardness of the said alloy samples. Increase in vibration intensities results in higher maximum values of these mechanical properties. The mechanical mould vibrations increasingly improve the mechanical properties of the alloy, with the optimum mechanical properties occurring at a frequency of 12Hz. A moderate application of this optimum frequency of mould vibration during alloy solidification in foundry will improve workability of the alloy for all applications involving plastic deformation of the cast alloy without necessarily subjecting it to annealing.

ACKNOWLEDGEMENTS

- The authors would like to acknowledge the assistance rendered by Mr Alo F.I., Mr Aminu, Mr Omolayo, Mr Olaoye and Mr Solanke, (all of the Department of Materials Science and Engineering, O.A.U., Ile-Ife) during the bench work of this research.

References

| [1] | Valiev, R.Z., Islamgaliev, R.K. and Alexandrov, I.V.,Bulk nanostructured materials from severe plastic deformation. Progress Mater. Sc. 45, 103-189, 2000. |

| [2] | Markushev, M.V., Bampton, C.C., Murashkin, M.Y. and Hardwick, D.A., Structure and properties of ultra-fine grained aluminum alloys produced by severe plastic deformation Mater. Sc. Eng. A234, 927-931, 1997. |

| [3] | S. Lee, M. Furukawa, Z. Horita and T.G. Langdon, “Developing a Superplastic Forming Capability in a Commercial Aluminum Alloy Without Scandium or Zirconium Additions,” Materials Science and Engineering A342, 294-301 (2003). |

| [4] | S. Komura, Z. Horita, M. Furukawa, M. Nemoto and T.G. Langdon: An Evaluation of the Flow Behavior during High Strain Rate Superplasticity in an Al-Mg-Sc Alloy, Metall. Mater. Trans. A 32A (2001) 707-716 |

| [5] | Flemings, M.C.; Behavior of Metal Alloys in the Semi-Solid State, Metall. Trans. B, 22B, 269, 1991. |

| [6] | Vives, C.; Elaboration of semisolid alloys by means of new rheocasting processes Metall. Trans. B, 24B, 493, 1993. |

| [7] | Belyakov, A., Miura, H. and Sakai, T.; Fine-Grained Structure Formation in Austenitic Stainless Steel under Multiple Deformation at 0.5 Tm, Materials Transaction. JIM 41 476-484, 2000. |

| [8] | Saito, Y., Utsunomiya, H., Tsuji, N. and Sakai, T. Novel Ultrahigh Straining Process for Bulk Materials-Development of the Accumulative Roll-Bonding (ARB)Process, Acta Mater., 47, 579-583, 1999. |

| [9] | Alexandre, G., Olegi, S., Taku, S., Rustam, K. and Hiromi, M.; “Grain Refinement in As-Cast 7475 Aluminium alloy under Hot Equal-Channel Angular Pressing Mater. Trans. 44(4), 766-774, 2003. |

| [10] | Dragnevski, K., Cochrane, R.F. and Mullis, A.M., Experimental Evidence for Dendritic Tip Splitting in Deeply Undercooled, Ultra-High Purity Cu. Physical Review Letters, 89, 215502, 2002. |

| [11] | Vives, C.; Grain Refinement in Aluminium Alloys by means of Electromagnetic Vibrations including Cavitation Phenomena, JOM-e, 50 (2), 1-9, 1998. |

| [12] | Mollard, F.R., Flemings, M.C. and Niyama, E.F. ; “Alumium Fluidity in Casting”, J. Met., 39 (11), 34, 1987. |

| [13] | Abramov, O.; Ultrasound in Liquid and Solid Metals, CRC Press, Boca Raton, 289, 1994. |

| [14] | Higgins, R.A.; Engineering Metallurgy Part 1: Applied Physical Metallurgy, 5th Edition, ELBS with Edward Arnold, Kent, Pp261, 376, 1991. |

| [15] | Vives, C.; Elaboration of semisolid alloys by means of new rheocasting processes", Met. and Mat. Trans. B 23B, 189-206, 1992. |

| [16] | Goryany, V. and Mauk, P.J.; Intermetallic Compounds and Choice of Alloying Elements for the Manufacture of Thixomolded Creep resistant Magnesium Alloys; Journal of Mining and Metallurgy, 43 B, Pp 85 – 97, 2007. |

| [17] | Nikulin, L.V., Lip?in, T.N. and Zaslavskij, M.L.; Die casting of magnesium alloys. Mašinostroenie, Moscow, (in Russian), 1978. |

| [18] | Pettersen, K., Bakke, P., Skar, J.I., Tian, Ch. and Albright, D.; Druckguss-Praxis 4, str, pp. 115-121 (in German), 2004. |

| [19] | Dargusch, M.S. Pettersen, K. and Dunlop, G.L.; The Microstructure and Creep Behaviour of Die Cast Magnesium AZ91 and AS21 Alloys. Proc. 19th Int. Die Casting Congress, Minneapolis, USA, pp131-137, Nov, 1997. |

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-Text HTML

Full-Text HTML