-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Materials Engineering

p-ISSN: 2166-5389 e-ISSN: 2166-5400

2022; 12(1): 1-7

doi:10.5923/j.ijme.20221201.01

Received: Aug. 19, 2022; Accepted: Sep. 5, 2022; Published: Sep. 15, 2022

Investigating the Use of Crushed Macadamia Nutshells in the Manufacture of Interlocking Stabilized Soil Blocks

T. D. Bijugo

Research and Development, Aveo Materials Technology Limited, Wakiso, Uganda

Correspondence to: T. D. Bijugo, Research and Development, Aveo Materials Technology Limited, Wakiso, Uganda.

| Email: |  |

Copyright © 2022 The Author(s). Published by Scientific & Academic Publishing.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

The macadamia nutshell, a waste product of the macadamia nut kernel processing, is tough and has mechanical properties similar to aluminium. This research aims to study the possibility of reusing crushed macadamia nutshells in the manufacture of Interlocking Stabilised Soil Blocks (ISSBs) and analyse the impact of the crushed macadamia nutshells on the physical, mechanical and thermal performance of ISSBs. For this; preliminary tests were first conducted on soils stabilised with 9% cement and mixed with crushed macadamia nutshells at different percentages (0%, 5%, 10%, 15%, 20% and 25%) to determine the effect of crushed macadamia nutshells on the physical and mechanical properties of stabilised soils Thereafter, interlocking stabilised soil blocks specimens were made with 9% cement content and with 0%, 15% and 20% crushed macadamia nutshells addition. Mass comparisons, water absorption, compressive strength, weathering and thermal conductivity tests were then conducted on the stabilized soil block specimens. The study found that the crushed macadamia nutshells influence the performance of ISSBs positively by reducing the water absorption and weight of the ISSBs at the same time increasing both dry and wet compressive strength. However, the thermal conductivity of the ISSBs increases significantly with the addition of crushed macadamia nutshells and weathering resistance of the ISSBs reduces as more crushed macadamia nutshell are added.

Keywords: Macadamia nutshells, Interlocking Stabilised Soil Blocks

Cite this paper: T. D. Bijugo, Investigating the Use of Crushed Macadamia Nutshells in the Manufacture of Interlocking Stabilized Soil Blocks, International Journal of Materials Engineering , Vol. 12 No. 1, 2022, pp. 1-7. doi: 10.5923/j.ijme.20221201.01.

Article Outline

1. Introduction

- Originating from Australia, Macadamia nuts belong to the family of Proteaceae. Of the four known species, only Macadamia integrifolia and Macadamia tetraphylla nuts and their hybrids are cultivated for their edible kernels [1].The shell of macadamia nut displays astonishingly high strength and exhibits the same specific tensile yield and ultimate strength as that found in commercially pure annealed aluminium [2]. Macadamia nut shells require about 2000N to crack [3] and can achieve a strength of up to 338 MPa [4]. Several authors have researched the properties of macadamia nutshells. Wang et al. [5] found that macadamia nutshells show high isotropy and homogeneity, with random oriented 3D cells. Braga et al. [6] investigated the mechanical characterization of macadamia nutshells, aiming at maximizing industrial shelling processes while Sesana et al. [7] characterized mechanical properties, focusing mainly on the bending resistance of macadamia nutshells.The useful mechanical properties of macadamia nutshell make it an ideal material for waste valorisation, for example, as charges in structural composite materials as macadamia nutshell powder [8,9]. Macadamia nutshells have also been used to produce polyethylene and polypropylene composites [10,11]. Various authors have conducted research on the reuse of macadamia nutshells in particle boards [12] and furniture panels [13]. While many researchers have mechanically characterised macadamia nut shells and investigated their use in composite material, particle boards and furniture panels, research on the use of macadamia nutshells in the manufacture interlocking stabilized soil blocks is still limited. Interlocking Stabilized Soil Blocks (ISSBs) are an example of an eco-friendly building material that comprises 60 - 70% soil, 20 - 30% coarse sand and 8 - 10% cement. ISSBs are characterised by low embodied energy and low related emissions [14].Several studies have explored the concept of recycling waste in cementitious materials. For example, the reuse of inorganic waste such as plastic [15] and rubber [16] in sand concrete. Guendouz et al. [17,18] studied the reuse of organic compounds like coffee waste and floor tile waste in sand concrete while Boukhelkhal et al. [19] investigated the reuse of olive core waste in self compacting mortar. Studies by Mohamed et al. [20] investigated the use of brick waste in the manufacture of cement mortars. Finally, regarding macadamia nutshells, Muchangi [21] investigated the use of the nutshells in concrete as a partial replacement for aggregate.Incorporating waste macadamia nutshells into the production of ISSBs has the potential to not only improve the mechanical performance of the ISSBs but also increase their carbon storage capacity. ISSBs offer an alternative construction product which is typically biodegradable at the end-of-life helping to regenerate natural systems. From an economic standpoint, diverting macadamia nutshells from post agricultural waste streams to become resources in the production of new construction materials enhances the value chain of macadamia nuts, providing additional income streams and contributing to a circular economy. This study focuses on the possibility of using crushed macadamia nutshells in the manufacture of interlocking stabilized soil blocks and analyse the influence of the proportion of macadamia nutshells used on the physical, mechanical and thermal properties of the new material.

2. Materials and Sample Preparation

2.1. Macadamia Nutshells

- The Macadamia Nutshells (MNS) were supplied from Mr. Henry Ddamulira’s orchard; located in Wamala, Wakiso district, Uganda. The nutshells were washed, air dried and then hand crushed and sieved through a 6.3mm sieve as shown in Figure 1. The resulting material had a bulk density of 0.56g/cm3 and comprised of 42% gravel size particles, 58% sand size particles and 1% fines. The crushed nutshells had a coefficient of uniformity of 2.7 and a coefficient of gradation of 0.9.

| Figure 1. Crushed macadamia nutshells |

2.2. Soil Sample

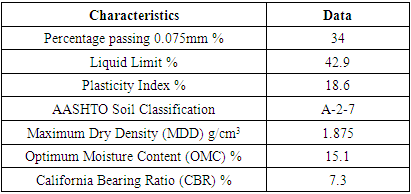

- The soil used for the study was sourced from a borrow pit located 3.4km off Nakawuka - Mayo Road in Nakawuka Town, coordinates E437194 N22051 (WGS84), Wakiso District, Uganda. The sampled soil was air-dried for 2 weeks and then sieved through a 4.75mm sieve. According to the AASHTO designation, the soil sample was classified as A-2-7 (clayey gravel with sand). It had a liquid limit of 42.9%, plastic index of 18.6%, linear shrinkage of 9.0%, Maximum dry density of 1.875g/cm3 and California bearing ratio of 7.3%. as shown in Table 1 below.

|

2.3. Cement

- Tororo Multipurpose Cement, a pozzolana cement, with fair strength characteristics, was used to stabilise the soils for this study. It is categorized as CEM-IV type cement of class 32.5N. The cement contains a natural pozzolana manufactured from Portland clinker.

2.4. Preparation of Blended Soil Samples

- The material used for preliminary laboratory tests was got by mixing the prepared soil sample with the crushed macadamia nut shells in increasing mass proportions of 0% (control), 5%, 10%, 15%, 20% and 25%. Each mix was stabilized with a constant measure of 9% cement and was mixed manually on a large tray in a dry state, ensuring a uniform mixing.

2.5. Casting and Curing of Stabilized Soil Block Samples

- Based on the observations in the preliminary laboratory tests on the blended soil samples, interlocking soil stabilized block specimen were prepared at Derocketch Investments Limited; located in Ssonde, Mukono District. The material used to make the block specimen was got by mixing the prepared soil with the crushed macadamia nut shells in selected mass proportions of 0% (control specimen), 15%, and 20%. Each mix was then stabilized with a constant measure of 9% cement and was mixed manually on a dry surface. After mixing, water was incrementally added until the optimum moisture for compaction was approximately achieved. The mixture was then compacted using a “Makiga” ISSB press machine. The ejected blocks were air-cured under a shade for up to 28 days, as shown in Figure 2 below.

| Figure 2. Air curing of Interlocking stabilised soil block samples |

3. Laboratory Tests

3.1. Blended Soil Samples

3.1.1. Compaction

- Compaction tests were conducted on the blended soil samples for each percentage addition of MNS. The samples were subjected to the standard proctor test (‘light’ compaction) in accordance to BS 1924 Part 2:1990 to determine the Maximum Dry Density (MDD) and the Optimum Moisture Content (OMC).

3.1.2. California Bearing Ratio

- The California Bearing Ratio (CBR) was determined for each percentage addition of MNS in accordance to BS 1924 Part 2:1990. Each sample was compacted with an effort similar to the standard proctor test (‘light’ compaction). After compaction, the sample was left to cure in an airtight bag for 3 days, after which it was soaked in water that was maintained at a temperature of 25±2°C for 4 days. At the end of the 4 days, the sample was penetrated to obtain the CBR.

3.1.3. Unconfined Compressive Strength

- The Unconfined Compressive Strength (UCS) test specimen were prepared using blended soil for each percentage addition of MNS. Each sample was compacted at maximum dry density and optimum moisture content in accordance with TMH1 1986. Two (2) curing regimes were adopted for each percentage of MNS i.e., two (2) specimens were cured in plastic bags for 7 days airtight curing and 7 days soaking in water that was maintained at 25±2°C and two (2) other specimens were cured in plastic bags for 14 days airtight curing. After 14 days, all specimens were loaded to failure using a compression testing machine at a uniform rate of 140kPa/s. The maximum load at failure was recorded. The average compressive strength of the two specimens was calculated and reported as the unconfined compressive strength.

3.2. Interlocking Stabilised Soil Blocks Samples

3.2.1. Mass Comparisons

- The prepared stabilized soil block samples from each percentage MNS were weighed to determine their mass. Precaution was taken to measure the samples that did not have any defects. The masses were then compared to determine the variation of weight with changing proportions of MNS.

3.2.2. Water Absorption

- For the water absorption test, two (2) stabilized soil blocks samples from each percentage of MNS were placed in a drying oven at 105±5°C for 24 hours. After oven drying, the blocks were left to cool at room temperature and then weighed to give the oven dry mass. The blocks were thereafter immersed in a soaking tank maintained at 25±2°C for 24 hours. After 24 hours elapsed, the blocks were removed from the soaking tank, wiped with a damp cloth and their mass after immersion in water was weighed. The water absorption was computed as the gain in mass as a percentage of the oven dried mass.

3.2.3. Compressive Strength

- Six (6) stabilized soil blocks samples from each percentage of MNS were first marked for easy identification. Three (3) would be soaked in water maintained at 25°C for 24 hours for wet compressive strength, while three (3) were tested immediately after curing for dry compressive strength. All blocks were weighed and dimensions were taken using a measuring tape. A sample block was placed between two wooden moulds so that the load could be distributed evenly across the top and bottom faces on the block. The sample was then carefully centered on the lower platen of the testing machine to ensure that the load is applied on the top and bottom sides of the block, as shown in Figure 3. The block sample was then loaded to failure at a uniform rate of 150kN/min in accordance with US 849:2011 - “Specification for stabilized soil blocks”. The maximum load at failure was recorded and the average compressive strength of the three samples was computed and reported as the compressive strength.

| Figure 3. Compressive strength test setup |

3.2.4. Weathering

- The weathering test of the stabilized soil block specimens was conducted in accordance with US 849:2011 - “Specification for stabilized soil blocks”. Blocks samples were subjected to repeated heating and cooling cycles coupled with the abrasive action of wire brush strokes. The loss in mass of the block specimen as a percentage of the original mass gave a measure of the resistance to weathering.

3.2.5. Thermal Conductivity

- Thermal conductivity measurements of the prepared stabilized soil block samples were conducted using the TLS-100 portable thermal conductivity meter by Thermtest in accordance with the ASTM D5334 as shown in Figure 4.

| Figure 4. Measurement of thermal properties |

4. Results and Discussions

4.1. Effect of Macadamia Nutshells on Dry Density of Cement Stabilized Soils

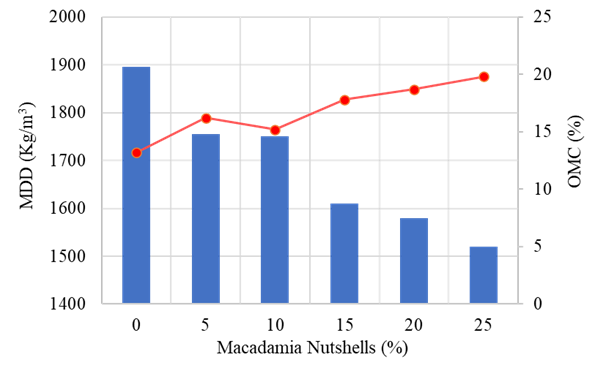

- As illustrated in Figure 5, the MDD decreased as the percentage of macadamia nutshells added to the soil increased. The stabilized soil with 0% MNS had a maximum dry density of 1895 kg/m3 which reduced to 1755 kg/m3 on addition of 5% MNS. At 10% MNS the MDD decreased slightly before dropping steeply to a value of 1610 kg/m3, at 15%. The MDD then gradually decreased to a low of 1520kg/m3 at 25% MNS. Figure 1 also shows the steady increase in Optimum Moisture Content (OMC) as the percentage of MNS increased.

| Figure 5. Variation of MDD with macadamia nutshell content |

4.2. Effect of Macadamia Nutshells on CBR of Cement Stabilized Soils

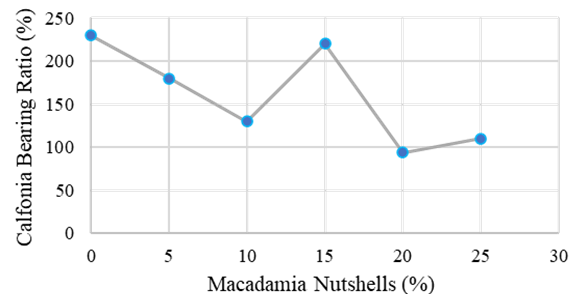

- Figure 6 depicts the relationship between CBR of cement stabilized soils and macadamia nutshells. From the figure, the general trend is that the CBR values decreased as the MNS content increased. The stabilized soil with 0% MNS initially had a CBR of 230% that gradually decreased to 180% and 130% on the addition of 5% and 10% MNS, respectively. At 15% MNS there was a sudden rise in the CBR value as it increased to 220% after which the CRB value plummeted to its lowest point of 94% at 20% MNS. A slight rise in CBR value was then observed at 25% MNS.

| Figure 6. Variation of CBR with macadamia nutshell content |

4.3. Effect of Macadamia Nutshells on Unconfined Compressive Strength of Cement Stabilized Soils

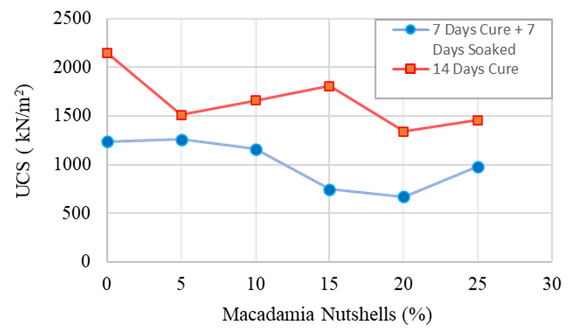

- In Figure 7, are presented the results of unconfined compressive strength as a function of MNS content. The results show that the mobilized UCS registered from the 14 days airtight cure first decreased from 2150 kN/m2 at 0% MNS to 1510 kN/m2 at 5% MNS; the values of UCS then increased gradually to an optimum value of 1810 kN/m2 at 15%, from which there was a decline to its lowest value of 1340 kN/m2 at 20% MNS. A slight rise in strength to 1460 kN/m2 at 25% MNS followed. Meanwhile, UCS values from the 7 days soaked & 7 days cure specimen initially increased slightly from 1240 kN/m2 at 0% MNS to 1260 kN/m2 at 5% MNS before gradually declining to a low of 670 kN/m2 at 20% MNS followed by a slight rise to a value of 980 kN/m2 at 25% MNS. The results show that the airtight curing regime yields a higher unconfined compressive strength.

| Figure 7. Relationship between UCS and macadamia nutshell content |

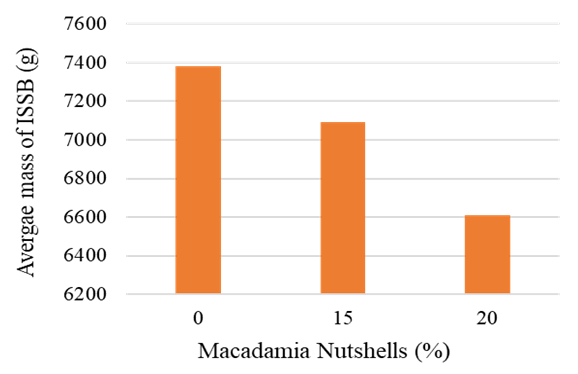

4.4. Mass of Stabilized Soil Blocks

- The mass of interlocking stabilized soil blocks was assessed for the different percentages of MNS. From Figure 8, it can be seen that the average mass of stabilized soil blocks gradually decreased as the percentage of macadamia nut shells added to the blocks increased. The control specimen had an average mass of 7380g which reduced by 3.9% to 7090g on addition of 15% MNS and by 20% the average mass of the blocks had decreased by 10.4% to 6610g. The reduction in mass is attributed to the volume-mass ratio of the macadamia nutshells that eventually reduces the mass and density of the blocks as the proportions of MNS are increased. These results agree with other researcher’s cement-based composites [15,16,17,19].

| Figure 8. Variation of average mass of ISSB specimen with macadamia nutshell content |

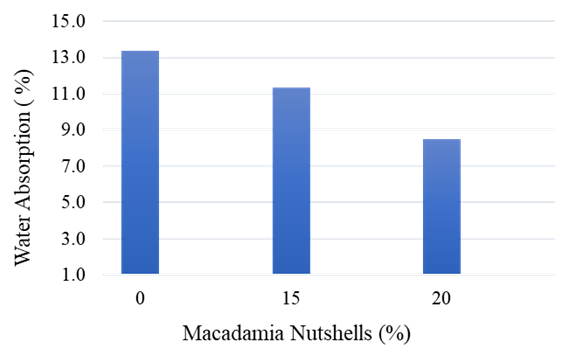

4.5. Water Absorption

- The results of the water absorption test on the ISSBs are summarized in “Figure 9”. This figure shows that ISSBs with macadamia nutshells absorb less water than the control specimen. This might be attributed to the higher absorbing capacity of the macadamia nutshell that slows down the ingress of water further into the core of the soil block. Observations from the study are in concordance with studies by Guendouz et al. [20].

| Figure 9. Variation of average mass of ISSB specimen with macadamia nutshell content |

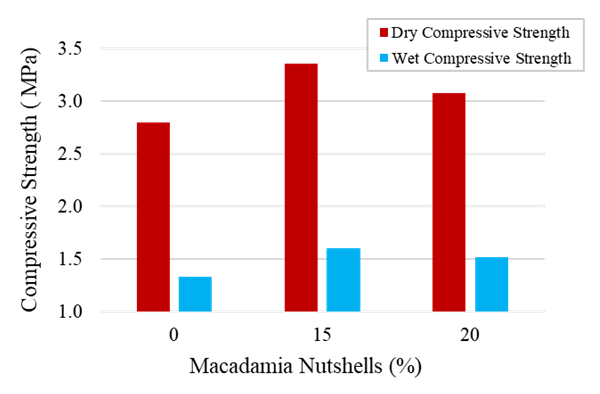

4.6. Compressive Strength

- Figure 10 depicts the variation of compressive strength of the ISSBs with increasing macadamia nutshell content. The control specimen had a dry compressive strength of 2.8MPa which increased by 20% to an optimum value of 3.4 MPa at 15% MNS and then declined slightly to 3.1 MPa at 20% MNS. A similar trend was observed in the wet compressive strength as the percentage of MNS increased. The wet compressive strength of the control specimen was 1.3 MPa which rose by 20% to a value of 1.6 MPa at 15% MNS and then dropping slightly to a value of 1.5 MPa at 20% MNS. These observations are in disagreement with some researchers [16,17,19,21] but in agreement with other authors [18,20]. This trend may be attributed to a better chemical compatibility between the macadamia nutshells and cement-soil mixture, which is likely to have contributed to a significant increase in strength.

| Figure 10. Compressive strength variation with macadamia nutshell content |

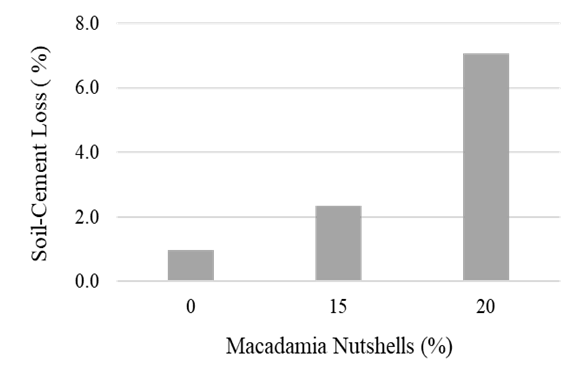

4.7. Weathering

- Figure 11 describes the variation in the percentage loss in mass due to weathering with increasing MNS in the interlocking stabilized soil blocks. The control specimen had a loss in mass (1.0%). Blocks with 15% and 20% MNS recorded a loss in mass of 2.3% and 7.1% respectively. This reflects a reduction in weathering resistance with increasing macadamia nutshell content in the stabilised soil blocks. This might be attributed to the uniform gradation of the crushed macadamia nutshells that inhibits the formation of a dense mass, especially at high dosages.

| Figure 11. Soil-cement loss variation with macadamia nut shell content |

4.8. Thermal Conductivity

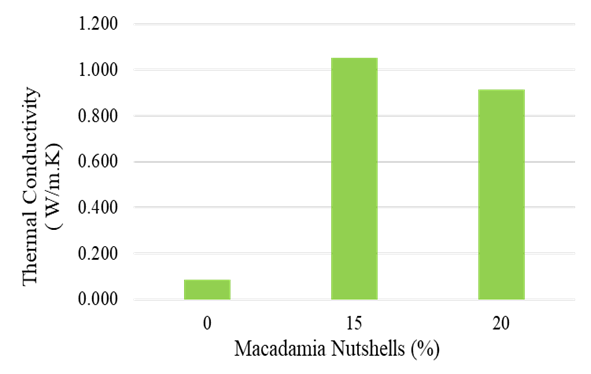

- The relationship between the thermal conductivity and the macadamia nut shell content of the interlocking stabilized soil blocks is in shown in Figure 12. From the figure, it can be observed that the control specimen had a thermal conductivity of 0.086W/m.k. There was a sharp rise in the value of thermal conductivity (1.054W/m.k) at 15% MNS that fell slightly at 20% MNS to a value of 0.913 W/m.k. This result disagrees with those observed by some authors [16,17,19].

| Figure 12. Relationship between thermal conductivity and macadamia nutshell content |

5. Conclusions

- The aim of this study was to evaluate the use of crushed macadamia nutshells in the manufacture of interlocking stabilised soil blocks. For this purpose, the study is based on the comparison of the behaviour of ordinary ISSBs with those of ISSBs based on crushed macadamia nutshells. Based on the results obtained through this study, the following conclusions have been drawn:• The results obtained show that macadamia nutshells can be used in the manufacture of ISSBs.• The macadamia nutshells contribute to the decrease in weight and density ISSBs by as much as 10.4% at 20% MNS content.• The addition of macadamia nutshells reduces the water absorption of ISSBs.• The increase in dry compressive strength of the ISSBs at 28 days of age was about 20% and 10% when 15% and 20% of macadamia nutshells are added, respectively. Wet compressive strength also saw a gain of 20% and 14% when 15% and 20% of macadamia nutshells are added, respectively.• The macadamia nutshells contribute to a decrease in the weathering resistance of ISSBs.• The addition of macadamia nutshells to ISSBs caused a significant increase in the values of thermal conductivity of the ISSBs.

ACKNOWLEDGEMENTS

- The author is grateful to Aveo Materials Technology Limited for funding this research. Gratitude also goes to the management and staff of Teclab Limited where most of the laboratory tests were conducted. The author is grateful to Mr Henry Ddamulira for the provision of the macadamia nutshells for the study.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML