-

Paper Information

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Materials Engineering

p-ISSN: 2166-5389 e-ISSN: 2166-5400

2018; 8(5): 128-133

doi:10.5923/j.ijme.20180805.07

Adobe Soil-Lime Bricks Reinforced with Kraft Paper Fibers

Iury Bispo dos Santos1, Raul Tadeu Lobato Ferreira1, Greyce Bernardes de Mello Rezende1, Vinicius Borges de Moura Aquino2, André Luis Christoforo2, Francisco Antonio Rocco Lahr3

1Earth and Exacts Sciences Institute (ICET), Federal University of Mato Grosso, Barra do Garças, Mato Grosso, Brazil

2Centre for Innovation and Technology in Composites – CITeC, Department of Civil Engineering (DECiv), Federal University of São Carlos, São Carlos, Brazil

3Department of Structural Engineering (SET), University of Sao Paulo, São Carlos, Brazil

Correspondence to: André Luis Christoforo, Centre for Innovation and Technology in Composites – CITeC, Department of Civil Engineering (DECiv), Federal University of São Carlos, São Carlos, Brazil.

| Email: |  |

Copyright © 2018 The Author(s). Published by Scientific & Academic Publishing.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Residue generation causes significant environmental damages, mainly when there on technology for its treatment and several times end up discarded inappropriately. Several industries sectors have developed management programs aiming to destiny adequately solid residues produced on their activities. An alternative to solve this problem is the recycling process, which treats the residues as a potential matter to produce new products, focusing to reduce environmental impacts and inappropriate residue discard. In this context, ecological bricks emerge as a great opportunity to recycle, permitting residue incorporation. The present research analyzed compressive strength, retraction and water absorption on adobe bricks, made of soil-lime mixture and reinforced with Kraft paper fibers. Blocks were made with 7% lime content and with 0%, 8%, 10% e 12% fiber addiction. The results demonstrated that soil-lime-fiber blocks, with indicated lime content and fiber addiction, did not presented results that satisfy normative criteria to be used as a innovative material.

Keywords: Adobe, Soil-Lime, Civil Construction Residue, Kraft Paper, Sustainability

Cite this paper: Iury Bispo dos Santos, Raul Tadeu Lobato Ferreira, Greyce Bernardes de Mello Rezende, Vinicius Borges de Moura Aquino, André Luis Christoforo, Francisco Antonio Rocco Lahr, Adobe Soil-Lime Bricks Reinforced with Kraft Paper Fibers, International Journal of Materials Engineering , Vol. 8 No. 5, 2018, pp. 128-133. doi: 10.5923/j.ijme.20180805.07.

Article Outline

1. Introduction

- The advance on industrialization has caused the urbanization process, leading to great environmental impacts in cities this process occurred with greater intensity. With the rural exodus, towns have been more populous, demanding more infrastructure investments. However, the industrialization process had been occurring on distant places from big cities, with great engineering works, such as hydroelectric dams, thermoelectric and nuclear plants, mineral exploitation, railway and highway constructions, always motivated by the industrialization process [1]. The indiscriminate use of natural resources, unconscious energy use allied to inadequate production of residues are the causes of environmental impacts. Solid residues management permit to minimize caused on feedstock exploitation, such as sand, rock and other materials, avoiding soil and water table pollution, well as healthcare damages and unnecessary public spending [2].According Langanke [3], by definition, residue is all which is not used on human activities, provided by industries, commerce and households, on other words, everything that are useless on any process. As a residue there are garbage, produced on several ways, and toxic garbage. Solid and liquid residues can be classified on two types, based on their chemical composition: organic residue, provided from live matter, as rest of food, and inorganic residue, derived from glass, metals, etc.Civil Construction Residues come from civil construction activities and according Brazilian National Environment Council (CONAMA) Resolution [4], they are provided from constructions, reforms, repairs, demolitions and from land excavation. On Construction and Demolition Residue (CDR), the most common residues are from bricks, ceramic blocks, soil, rocks, metal, glues, inks, wood, mortar, electric cables. The resolution also establishes guidelines, criteria and procedure that must be employed on CCR management, specifying measures and procedures to be adopted to minimize environment impacts and classify the residues according reuse possibilities. CONAMA Resolution [4] divides CCR on four classes:1. Class A (Recyclable or Reusable): (a) Coming from construction, demolition, reforms and pavement repairs and other infrastructure work, including soils from earthmoving; (b) Coming from construction, demolition, reforms: Ceramic components (bricks, blocks, coverings, etc), mortar and concrete; (c) Pre cast concrete structures;2. Class B (Recyclable with other destination): plastics, paper, cardboard, metals, glass, wood and plaster;3. Class C (Not recyclable residues): sandpaper, glass mass, spackling, etc;4. Class D (Dangerous) Inks, solvents, oils and other residues provided from radiologic clinics reform or demolition, materials which contain asbestos and other toxic components.The residue classification is executed to ease materials separation with more probability to be reused and separate those materials which can harm population health.According Thiesen [5] residue recycling, mostly, is the best solution, due to its reuse as feedstock for other product, reducing production costs. He success of recycling depends on three factors: the ability to reuse the material for manufacturing another material; the ability of reusing it as a extern or intern feedstock; the ability to segregate recoverable and valuable materials.To utilize residue on new products manufacturing, the material must reach traditional material properties. It is necessary to maintain identical and favorable quality standards for the material to be considered a good alternative. Generally, the recycled material is cheaper or maintain the same cost of the traditional material. In these cases, marketing can solve material acceptance, presenting to clients the benefits for using a recyclable material [6].The enormous CCR production implies the need for residue reuse policies. Management process of CCR, demolition process sophistication and CCR reuse are demonstrating to a respectable civil engineer industry the demand for using finite resources in a economic manner and do not overload nature with unnecessary residues [7].Batista [8] affirms that some residue utilizations have been well widespread, such as its use on pavement base and subbase, non structural concrete, concrete block production, drainage projects, among other projects. The use of recycled aggregates on pavement construction have been intensified throughout last years. Although researches indicates good potential for their use, their use is relative small, due to lack of material variability, one of their major difficulties [9].It is important highlight that recycling presents a huge environmental, economic and social relevance, with many ramifications which unfold on population, conservation, energy economy and rational use of natural resources, products development, wealth generation and waste reduction [10].According Brasileiro and Mattos [11], the rapid urbanization, large natural resources exploitation led to terrible material waste indexes on civil construction. These residues represent, approximately, 20% to 30% of solid residue flow produced on cities of developed countries. In addition, Civil Construction Industry (CCI) is one of the sectors that more consumes natural resources, among 14% and 50% of extracted resources on Earth [12].Then, it is realized that recycling several CCRs is the best choice, due to scarce resources, which increases the demand to alert society the further need to reuse even more materials before discarding them.Thus, studies about constructive methods, alternative materials or the reuse of own residue have gained space and varnished the mistrust with alternative materials. Complex and difficult methods to be executed disturb the dissemination process of CCR management. Therefore, the present study intend to reconcile the employment of simple constructive techniques with residue recycling.Hence, this study aims to evaluate: (i) mechanical behavior of soil-lime blocks reinforced with Kraft paper fibers, analyzing the blocks with 0%, 8%, 10% and 12% Kraft paper fiber addition; (ii) the interference of Kraft fiber addition on compressive strength at 28 days and 40 days curing; (iii) Water absorption on blocks and; (iv) Mixtures retraction.

2. Material and Methods

2.1. Utilized Soil

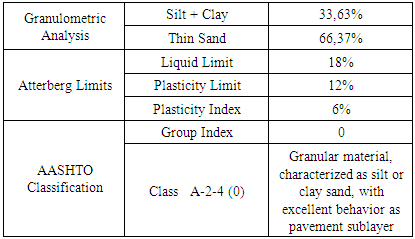

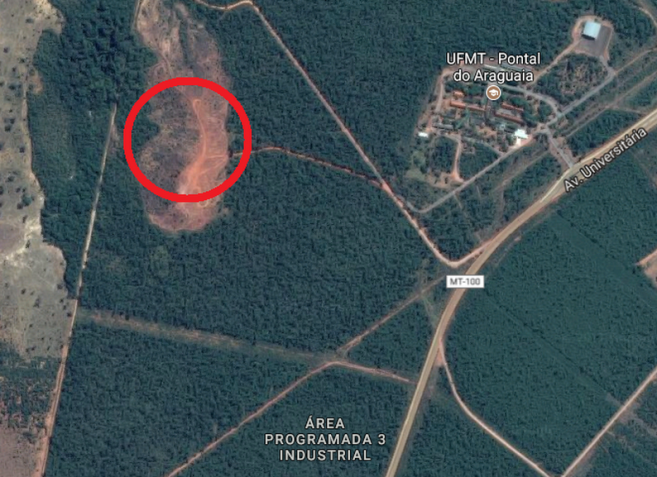

- The soil used on this research was harvested in 2017 on road ring which connects BR-070 and BR-158 highways, where there is a road construction on Pontal do Araguaia city, Brazilian state of Mato Grosso (Figure 1).

| Figure 1. Place of soil harvest. (Source: Author) |

|

2.2. Lime

- On block confection, it was used hydrated lime classified as CH-III according Brazilian Association of Technical Standard [13]. It was added a 7% lime content in relation to dry soil mass. The lime content was determined to compare with Schweig research [14], who evaluated the soil-cement adobe blocks with Kraft fiber addition with 7% Portland cement content in relation to dry soil mass.

2.3. Kraft Paper Fibers

- Portland cement bags were collected from a concrete company located in Barra do Garças city, Brazilian state of Mato Grosso, disposed on construction site after use, representing a considerable volume and according the company, these bags would be incinerated. Kraft paper recycling was executed following the forthcoming steps:1. Package cleaning, to withdraw any cement residue, avoiding interferences on the results (Figure 2);

| Figure 2. Cement bag cleaning |

| Figure 3. Primary Fragmentation |

| Figure 4. Cellulose pulp |

| Figure 5. Water excess withdrawal |

| Figure 6. Disperse Fibers |

2.4. Adobe Blocks Confection

2.4.1. Mixtures Preparation

- Mixture prepare process followed the proposed by Buson [14] on Krafterra manufacturing process. The script was adapted to laboratory conditions. The stages consist on humidify concrete mixer wall, add Kraft paper fiber, then add fraction of soil; add lime and mix until reach plastic consistence.

2.4.2. Brick Modeling

- Brick modeling was made manually, adobe style, on a plane surface lined with canvas and with cast forms (Figure 7) with dimensions of 24 cm length, 12 cm width and 7 cm height.

| Figure 7. Modeling Form |

2.4.3. Blocks Cure

- Blocks were maintained on improvised humid chamber made of canvas covering all bricks to not lose humidity for environment, reserved on fresh place and without direct incidence of sunshine or excessive heat.The blocks were submitted to cure periods of 28 and 40 days. It was opted to work with long periods of cure due to many researches indicates that cure of soil-lime mixture is a slow process when compared to soil-cement mixture cure.

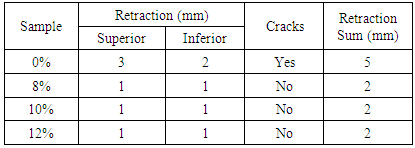

2.5. Retraction Test

- The Search and Development Centre [16] suggest the linear retraction test aiming to evaluate how the composition will behave face to climate conditions and Buson [15] adapted the process of Krafterra study, with the composite should not present cracks or retraction higher than 2 cm.In this test, soil-lime mixtures without fiber addiction and with 8, 10 e 12% fiber addiction were prepared with plastic consistence, and then, placed on a wood box with 60 cm x 8,5 cm x 3,5 cm dimensions, previously lubricated with oil. For retraction verification, after manual densification, material lies at rest on shade for 7 days and then, it is measured the retraction along proof test length. The material is considerable viable for block confection only if, after 7 days, the retraction is inferior or equal to 20 mm and present no cracks. The measures were made with a ruler with precision of 1 mm.

2.6. Compressive Strength Test

- The compressive strength test was executed according the Brazilian Code ABNT NBR 8492 [17], which rules this procedure for soil-cement blocks. The test was performed evaluating the strength of 10 blocks for each mixture and each cure period.

2.7. Water Absorption Test

- The water absorption test followed the Brazilian Standard ABNT NBR 8492 [17], with 3 determinations for each mixture on each cure period. For the test, blocks are dried on chamber, with temperature between 105°C and 110°C until mass consistence. Next, block on room temperature are weighted, obtaining the dry block mass.After this, blocks are immersed on water tank for 24 hours. Then, blocks are withdrawn from tank and dried superficially with a cloth. Then, blocks are weighted again, expressing the humid block mass.Absorption values for each block are expressed and calculated, according ABNT NBR 8492 [17] by:

| (1) |

3. Results and Discussion

3.1. Mixture Composition

- Blocks were confectioned and tested on Civil Engineer Laboratory of Federal University of Mato Grosso, Araguaia campus. In total, 52 blocks were made for each cure period, being 13 blocks for each fiber content:- 13 blocks without fiber addiction, also called testimony samples;- 13 blocks with 8% fiber content;- 13 blocks with 10% fiber content;- 13 blocks with 12% fiber content;Moisture content was determined empirically, focusing on a mixture with great workability with no water excess. Water amount was around 19% for testimony samples, 30% for 8% fiber content, 39% for 10% fiber content and 43% for 12% fiber content. It is noted the increase on fiber content leads to a non proportional increase on water content, due to fibers absorbs a considerable water amount.

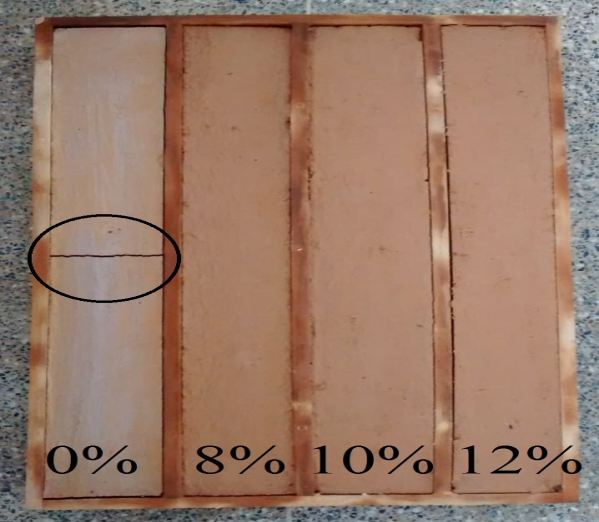

3.2. Retraction Analysis

- On retraction test all samples met with the maximum retraction criteria proposed on literature, i.e., retraction measurement on any case resulted superior to 20 mm. But, the testimony sample presented a crack of considerable dimensions (Figure 8), presenting inferior performance when compared with fiber reinforced mixtures.

| Figure 8. Retraction test results |

|

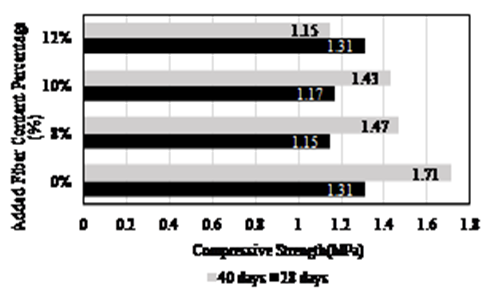

3.3. Compressive Strength Analysis

- On compressive strength analysis, fiber addition presented itself harmful to block mechanical performance, reducing compressive strength on two cure periods. Standard ABNT NBR 8492 [17] establishes a minimum compressive strength of 2 MPa. On Figure 9 is demonstrated the average values of compressive strength and none of samples presented minimal strength demanded.

| Figure 9. Average values of compressive strength |

3.4. Water Absorption Analysis

- Figure 10 displays obtained values for water absorption analysis. Only testimony sample and *% fiber content on 40 days cure obtained satisfactory results, i.e., values above 20% for absorption, as diposed on Brazilian Standard ABNT NBR 8492 [17]. Other samples did not reached code criterion.

| Figure 10. Absorption Test Results |

4. Conclusions

- The results of box test demonstrated that fiber addiction contributes to reduce retraction and crack formation on soil-lime mixtures. None of samples reinforced with Kraft fibers presented cracks, while testimony sample presented cracks and elevated retraction.On compressive strength, any mixture attended the minimum compressive strength of 2 MPa. Fiber addictions affected mechanical performance of soil-lime mixture, displaying strength values inferior to the testimony sample, also affected strength gain throughout time.Cure process favored the reduction on water absorption, considering that at 40 days cure blocks presented absorption values less than 28 days cure blocks.Unsatisfactory results can be attributed to the fact that lime reacts better with clay soils and the soil used was a sand soil, characteristic from Barra do Garças city region.Another factor might be the lime content utilized, since 7% lime content was adopted to compare with results of Schweig [13], who used the same cement content (7%) to confect adobe blocks with soil-cement blocks reinforced with Kraft fibers. Then, the pH method or Lime Fixation Point (LFP), which are lime dosage methods on soils, would be ideal for lime content determination with more accuracy.On compressive strength tests, it was occurred the block crash, phenomenon also verified on Buson [15], Mogrovejo [18] and Schweig [13] researches. Most part of obtained reading correspond to the maximum allowed deformation, i.e., even deforming and presenting cracks, block had been gaining strength until it reached machine limit, representing material toughness.Then, soil-lime-fiber brick confectioned with 7% lime content does not display properties to be released as a innovative construction material, due to its non attendance with Standard prescriptions. However, even not attending normative criteria, soil-lime criteria displays great potential on Civil Construction Industry.

ACKNOWLEDGMENTS

- For all the provided support, the authors thanks the Coordenação de Aperfeiçoamento de Nível Superior (CAPES) and the Conselho Nacional de Desenvolvimento Científico e Tecnológico (CNPq).

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML