-

Paper Information

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Materials Engineering

p-ISSN: 2166-5389 e-ISSN: 2166-5400

2018; 8(4): 76-84

doi:10.5923/j.ijme.20180804.04

Investigation on Influence of Halloysite Nanoclay and Carbon Nanotubes on Cement Nano Composites- A Critical Review

1Research Scholar, Civil Engineering, VTU Belgaum, India

2Professor and Director (R&D- Civil Engg.) Ghousia College of Engineering, Ramanagaram, Karnataka, India

Correspondence to: Ghazala Anjum, Research Scholar, Civil Engineering, VTU Belgaum, India.

| Email: |  |

Copyright © 2018 The Author(s). Published by Scientific & Academic Publishing.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

This paper aims to provide an insight into the various developments that have taken place since the introduction of nano materials into cement mortar. Earlier, cement and sand with aggregates were the basic materials used for construction. But as time passed by, there have been considerable advancements and many other materials whose structural stability have been studied upon as a means to move away from the conventional form and improve the performance of cement composites at the same time. It all began with the inclusion of plasticisers and then in present times, we have moved on to the use of nano materials as a substitute for strength gain. In this paper, various experiments conducted with the use of nano materials, especially halloysite nano clay and Multiwalled carbon nanotubes have been highlighted in order to provide an in depth knowledge of CNT and their individual effects on the strength of cement mortar.

Keywords: MWCNT, HNC, Compressive strength, Strength gain

Cite this paper: Ghazala Anjum, N. S. Kumar, Investigation on Influence of Halloysite Nanoclay and Carbon Nanotubes on Cement Nano Composites- A Critical Review, International Journal of Materials Engineering , Vol. 8 No. 4, 2018, pp. 76-84. doi: 10.5923/j.ijme.20180804.04.

1. Introduction

- Nanomaterials is the recent advancement in science and technology. The versatility of their use as well as their minimal quality is what makes these materials the most sought out ones in any industry. Although certain nanomaterials such as CNT’s have found to have an adverse effect on the environment yet some other materials such as HNC seem more eco-friendly. While CNTs need to be manufactured, HNC is a naturally occurring nanomaterial in the form of kaolinite. Apart from the general view, these nano materials are found to be the excellent addition to enhance the performance of concrete. The demand for structural stability has gone up since the standard of construction is raised from mere bricks and cement into composite buildings, due to which, there arises a need for multifunctional materials that appeal to both structural and functional aspects of construction. It is a well-known fact that the properties of cement are in direct correlation with the pore structure of the cement matrix which in turn depends on the materials used. Therefore, it clearly implies that more the material is advanced, more will be the strength of the cement matrix. This is achieved by the introduction of ultra-fine particles on the nano scale which fill the voids of CSH structure and provide uniform distribution of hydrated products. Carbon Nanotubes (CNT) are defined as tube like structures constructed of one or more layers of graphite sheets. When carbon atoms join in a hexagonal pattern, Graphite is formed. CNT’s are basically classified into single-walled CNT’s (SWCNT) and Multiwalled CNT’s (MWCNT). SWCNT’s have diameter of 1 to 3 nm, while MWCNT’s have a diameter somewhere between 10 to 100 nm. The length of both CNT’s varies from 0.5μm to 50 μm. CNT’s have small diameters and high aspect ratios that range from 1,000:1 to 2,500:1. CNT’s make for excellent reinforcements in cementitious composites due to their excellent mechanical properties and aspect ratio. Compared to traditional reinforcing fibers, CNT’s can be dispersed in the cement matrix at a much finer scale due to their Nano dimensions. [4] The advent of CNTs have paved way for their application as reinforcing agents. Because of their high strength, low density, high aspect ratio, they are much suitable in structural applications. They produce noticeable stronger composites than their other counterparts such as glass fibres. Due to their fineness, they provide efficient crack bridging at the earliest stages of crack formation. Coming to Halloysite nanoclay, the greatest advantage of HNC is the fact that it is naturally occurring thereby eliminating the need for manufacture which is the cause for its cost effectiveness. Halloysite Nanoclay (HNC) is an Aluminosilicate clay Al2Si2O5(OH)4.H2O) with Nano tubular and hollow micro structure. Its theoretical composition is of 13.96% H2O, 39.5% Al2O3 and 46.54% SiO2. HNT’s have an outer diameter of 10-15nm and inner diameter of 5-10 nm with 2-40 mm in length. [19] They are non toxic in nature and hence eco-friendly. Their usage as reinforcing material is considerably new, but they are considered the next best thing apart from nano silica. The main difference between use of nano silica and HNC lies in quantity. A small quantity of HNC provides a better performing cement composite. In terms of aspect ratio, CNT is similar to HNC but HNC has more advantages in terms of availability, cost and safety.

2. Materials and Methods

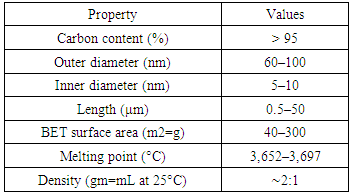

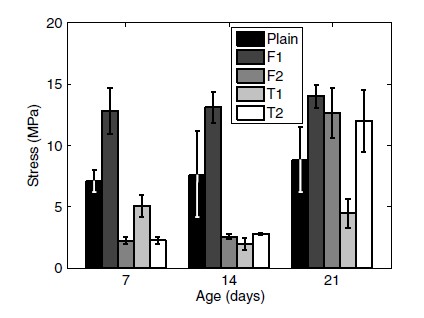

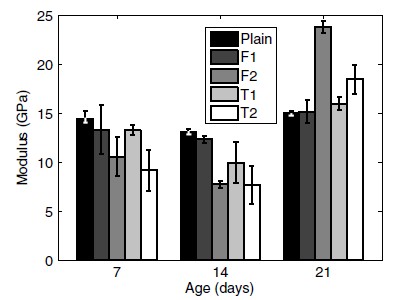

- A study conducted by Simone Musso [1] et al in 2009 on influence of carbon nanotubes structure on the mechanical behaviour of cement composites, used 0.5wt% of MWCNT in plain cement mortar to study the physical and chemical properties of nanotubes on the mechanical behaviour of cement composite. Three point bending tests were conducted on prism of length 100mm and compression tests were conducted on specimens of dimensions 40x40x60mm with load applied uniaxially at the rate of 0.1mm/min for both tests. The results obtained were compared with the compressive and flexural strength of unreinforced cement mortar. Further, characterization of composites was done using Thermo Gravimetric Analysis coupled with mass spectroscopy and minerology and microstructure characterization took place by means of R-ray diffractometer and Scanning Electron Microscopy. Similar tests were conducted using functionalized MWCNT’s. Bryan M. Tyson, [2] in 2011 used untreated and treated CNT’s and CNF’s for their study of carbon nanotubes and carbon nanofibers for enhancing the mechanical properties of nanocomposite cementitious materials in the proportions of 0.1wt% and 0.2wt% each, added to cement matrix. W/c ratio of 0.4 and a plasticizer to cement ratio of 0.005 was adopted. Five batches of cement paste were produced of which two batches had added CNT, two batches had added CNF and one batch had plain cement mortar. The specimens of size 6.5x6.5mm c/s area were tested at 7, 14 and 21 days for flexure using three point bending tests to determine the Young’s modulus, flexural strength, ultimate strain capacity and fracture toughness. SEM was conducted to detect the difference between crack bridging and fibre pull-out. In order to investigate the effect of carbon nanotubes and carbon fibres on the behaviour of plain cement mortar composite round bars under direct tension, A. M. Hunashyal [3] and his team in 2011 used reinforced cement composite with 0.5wt% MWCNT and 2.25wt% CF (carbon fibres) to determine ultimate load, deflection and stress-strain behaviour. The results were compared with that of plain cement round bars. The w/c ratio was fixed at 0.4% which was acceptable for mixing and workability of the mortar including the introduction of fibres. UTM was used to perform the tensile tests and the ultimate load and maximum deflection were noted down.Another similar experiments by A.M Hunashyal [4] on experimental investigation on the effect of multiwalled carbon nanotubes and nano-SiO2 addition on mechanical properties of hardened cement paste in 2014 revolved around the behaviour of hardened cement paste reinforced with 0.75wt% of MWCNT and 0.5wt% Nano-SiO2 (NS). Specimens of size 20mmx20mmx80mm were tested under a load frame of capacity 10kN at the loading rate of 0.1kN/s after 28 days curing. For uniform distribution of load, specimen was sandwiched between two steel plates of 5mm thickness. The tests were conducted to determine the mechanical properties such as compressive strength, flexural strength, toughness and ductility. The results were then compared with plain cement mortar beams. SEM was conducted to study the relation between MWCNT and cement matrix.The properties of MWCNT used by Sanjeev Kumar [5], et al is as shown in table (1).

|

3. Results

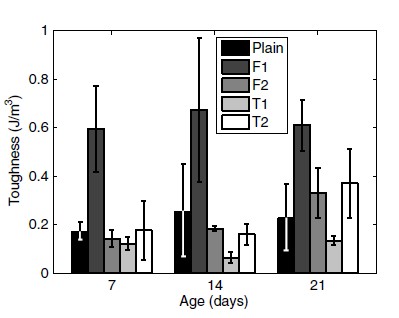

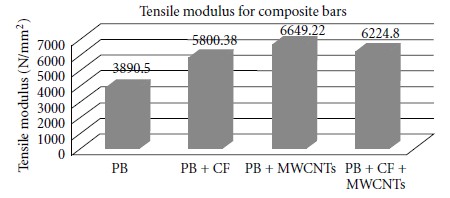

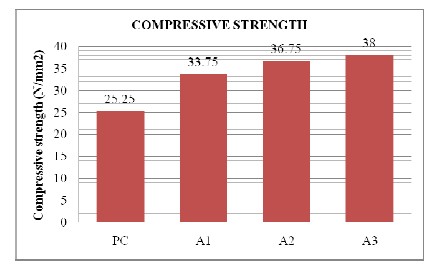

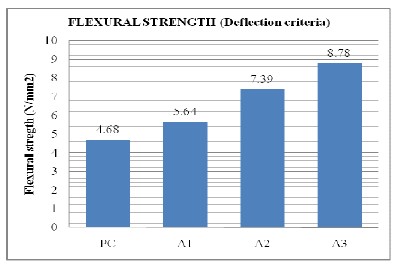

- 1. The studies by Simone Musso revealed that the mechanical strength of cement composite was greatly affected due to the presence of MWCNTs’. The comparison of the results between the two showed that f-MWCNT were hydrophilic leading to a faulty hydration product, however there was considerable increase in strength of cement composite with both functional and pristine MWCNT. However, by increasing the w/c ratio from 0.4 to 0.56, suitable hydration of the products could be obtained. Although, a more favourable dispersion of CNT is preferable to lower the degree of interference with surrounding CNT. It was found that the properties of cement paste can be increased by adding small amounts of CNT or CNF. [1]2. Bryan M. Tyson’s study of untreated and treated CNT’s and CNF’s for enhancing the mechanical properties of nanocomposite yielded the following graphs.

| Figure (1). Stress variation |

| Figure (2). Variation of modulus |

| Figure (3). Toughness variation |

| Figure (4). Variation of tensile modulus |

| Figure (5). Compressive strength |

| Figure (6). Flexural strength |

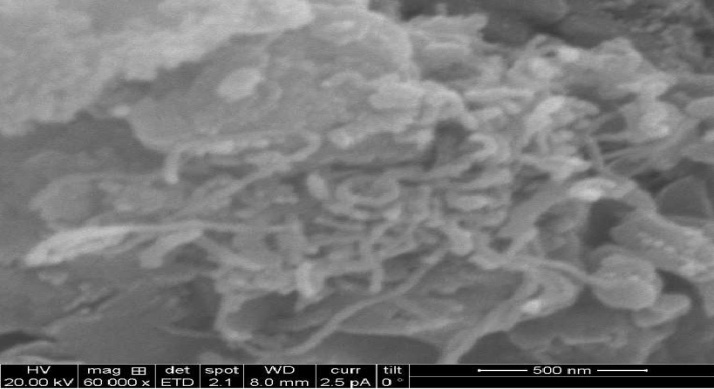

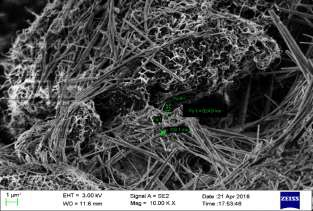

| Figure (7). SEM image of hybrid composite with MWCNT and nanosilica |

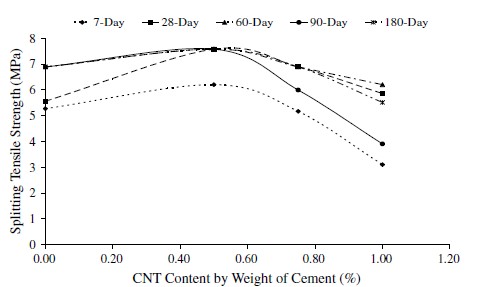

| Figure (8). Splitting tensile strength |

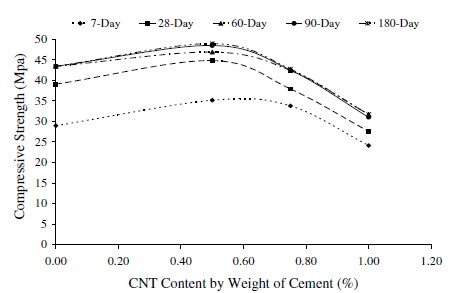

| Figure (9). Compressive strength |

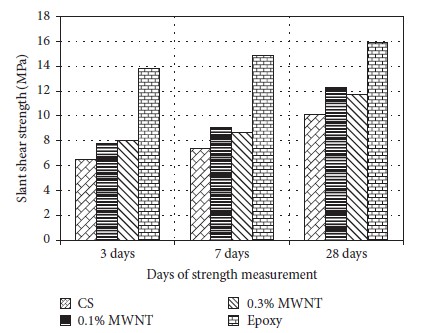

| Figure (10). Slant shear strength at various curing days |

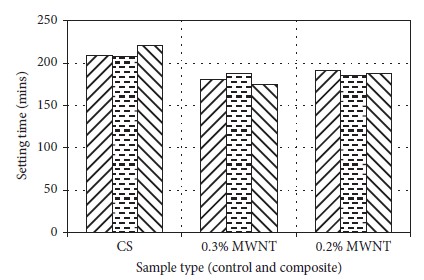

| Figure (11). Setting time of control and composites |

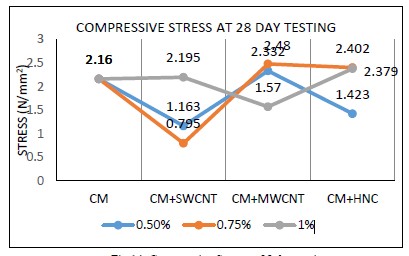

| Figure (12). Compressive stress at 28 day |

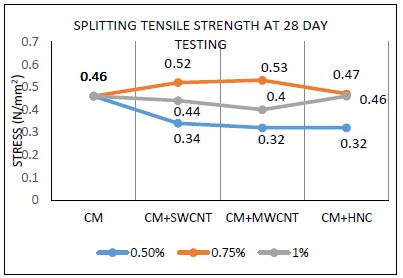

| Figure (13). Splitting tensile strength at 28 day |

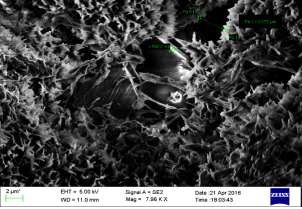

| Figure (14). SEM image of MWCNT in cement composite after testing |

| Figure (15). SEM image of MWCNT in cement composite before testing |

4. Conclusions

- Based on the above results following conclusions could be drawn from each of the studies conducted-1. The study conducted by Brian M Tyson proved that the addition of CNFs and CNTs increased the strength higher than plain cement paste. The strength, ductility and toughness gain was seen after 14 days and this delay can be attributed to easy separation of nano-filaments at the early stages. However, the bonding seem to harden at later stages which is seen by the increase in strength.2. CNFs have an improved performance because of their higher aspect ratio than CNTs. 3. The second study of CF’s and MWCNT in round cement bars under tension showed that there was 54% increase in load capacity when both the fibres were included. There was also a considerable increase in the tensile modulus values with 0.5wt% MWCNT showing the maximum value of tensile modulus. 4. The addition of nanotubes to the bars, will increase tensile properties in terms of strength, strength to weight ratio. This proves their ability to become an ideal reinforcing material and it can be used for the construction of structures subjected to seismic, impact, dynamic, and so forth, loadings.5. Increase in compressive and splitting-tensile strength was seen at 0.5wt% CNT by 15% and 36% respectively at 28 days curing. However, at 0.75wt% CNT, the compressive and split tensile strength was almost equal to plain cement mortar. The rate of change of compressive and splitting-tensile of all cement-CNT composites with respect to curing age was seen to be very similar to that of the control mix. This indicates that the strength gain of composites is primarily because of cement hydration and the fact that CNTs are not reacting with cement compounds.6. The experiments on MWCNT in comparison to nano silica (NS) showed that a mix proportion including both MWCNT and NS was provided optimum strength gain and flexural resistance. MWCNT reinforced the cement matrix on a nanoscale while NS provided the strength gain due to formation of additional CSH gel, almost doubling the flexural strength in comparison to PC.7. The SEM study by Anand Hunshyal et al. indicated at the non-uniform dispersion of MWCNTs. It was concluded that it is difficult to establish any chemical bond between MWCNT and cement matrix by SEM, the presence of a physical bonding can be verified. 8. From the study of addition of CNT to cement composites with embedded steel bars, it was found that CNT does not significantly affect the bending strength (less than 6%) or the compressive strength (less than 7%), at 28 days curing time.The addition of CNT to the cement matrix could imply the development of higher levels of corrosion in aggressive conditions, such as carbonation and contamination by chloride ions.9. The nano cement testing involving PPC and the PCC showed that PPC had a moderate increase in strength at the earlier ages with 40% substitution being a turning point for the change in strength gain for both cements. The optimum substitution of nano material content was found to be at 40% to 80%.10. The use of MWCNT composite as repair material was exhibited by the studies conducted by Tanvir Manzur in which it was concluded that MWCNT composites showed 26%, 21%, 15%, and 14% higher compressive strength at 3, 7, 28, and 100 days respectively. 11. The setting time, bleeding and slant shear tests were conducted showing that MWCNT composite hardened faster than conventional mortar which is an important characteristic of a repair material. Also, it showed no signs of bleeding as bleeding can affect the overall strength and durability of repair material. They also exhibited lower slant shear strength at early ages of 3 and 7 days when compared to epoxy however slant shear strength of MWCNT was more than conventional mortar.12. The optimum dosage of nanotubes compression testing was found to be 1wt% for HNC and 0.5wt% for both CNT’s whereas for splitting tensile strength, optimum dosage was found to be 0.75wt% for all the nanotubes.13. The SEM and EDX analysis conducted showed that the testing on a specimen with reinforced nanomaterials only change the bonding nature of the materials used by the introduction of a fracture surface. It does not alter the composition of the specimen.14. From the above survey, it can be concluded that while MWCNT have a greater potential as structural and repair material in cement industry, a lot of tests needs to be conducted in order to determine the inclusion of nano materials on a large scale basis. The use of MWCNT on a large scale is a future dream but use of HNC can be looked forward to as it holds similar properties as MWCNT with an added bonus of being environment friendly and cost effective.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML