-

Paper Information

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Materials Engineering

p-ISSN: 2166-5389 e-ISSN: 2166-5400

2018; 8(4): 66-69

doi:10.5923/j.ijme.20180804.02

Using Alternative Timber in Parallel Flanges Truss Structures for Steel Roof - Slope 20º, with Spans between 16 to 26 Meters

Hyago Maurício Bremm Muller1, Roberto Vasconcelos Pinheiro1, Jennifer Mayara Vilas Boas da Silva2, João Paulo Boff Almeida1, Natalia Garcia Couto3, André Luis Christoforo3, Francisco A. Rocco Lahr4

1Department of Civil Engineering, University of Mato Grosso State (UNEMAT), Sinop, Brazil

2Department of Architecture and Urbanism, University of Cuiabá (UNIC), Sinop, Brazil

3Department of Civil Engineering (DECiv), Federal University of São Carlos (UFSCar), São Carlos, Brazil

4Department of Structural Engineering (SET), São Carlos Engineering School, São Paulo University (EESC/USP), São Carlos, Brazil

Correspondence to: André Luis Christoforo, Department of Civil Engineering (DECiv), Federal University of São Carlos (UFSCar), São Carlos, Brazil.

| Email: |  |

Copyright © 2018 The Author(s). Published by Scientific & Academic Publishing.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Timber is part of society’s evolutionary process. It presents several utilities because it is versatile and easy to apply. However, it is often extracted incorrectly from nature and used in inappropriate ways. In civil construction it is predominantly applied temporarily and, when it has structural purpose, it is used without knowledge about its properties and absence of structural projects. Thus, this research aims to assess the viability of employing not so usual species, with class resistance C-20 and C-30, in its usage as component structural element of industrial sheds with truss structures for roof (parallel flange) “Howe” type (20º inclination - steel roof tile); span 16, 18, 20, 22, 24 and 26 meters; typologies of edification lateral openings - 1:1, 2:1, 6:1 and opened. Therefore, it was determined the ratio between timber volume (m³) and constructed area (m²) according to NBR 7190:1997 standards, making it possible to verify the applicability of C-20 and C-30 species to industrial sheds typology determined in this research.

Keywords: Timber, Steel roof, Cover structure, Sustainability

Cite this paper: Hyago Maurício Bremm Muller, Roberto Vasconcelos Pinheiro, Jennifer Mayara Vilas Boas da Silva, João Paulo Boff Almeida, Natalia Garcia Couto, André Luis Christoforo, Francisco A. Rocco Lahr, Using Alternative Timber in Parallel Flanges Truss Structures for Steel Roof - Slope 20º, with Spans between 16 to 26 Meters, International Journal of Materials Engineering , Vol. 8 No. 4, 2018, pp. 66-69. doi: 10.5923/j.ijme.20180804.02.

Article Outline

1. Introduction

- Timber, a natural, renewable, and easily obtained material, presents a good ratio between resistance and density when compared to other civil construction materials such as steel and concrete [1].Due to its versatility and malleability, timber has been used by humanity for many years, meeting several purposes. In civil construction, it is verified the temporary employment of timber in forms for concrete, scaffolding, and shoring. For definitive use, it is employed in frames, ceilings, floors, bridges, footbridges, residential roofs, industrial sheds and others [2].Like the United States and Japan, which apply timber on a large scale, reaching, respectively, 85% and 95% of homes, other countries in Europe, Asia, America and Oceania have been using it intensely in civil construction [3]. However, in Brazil, despite being a world highlight in the timber industrial sector due to its diversity of native forests and productive capacity of planted forests, the use of timber is still victim of prejudice about its quality and performance, mainly due to lack of knowledge and technological advances in the sector [4, 3].Because of the scarcity of scientific studies about traditional timbers characteristics and exploration, the market has become restricted to few species, putting some of them in risk of extinction [5]. Thus, it is necessary to know new timber species, with the potential to replace the ones traditionally used in civil construction [6].In Brazil, the NBR 7190 (1997) standard “Timber Structures Project” [7] establishes the premises and calculation methods for structural measurement. It also establishes the test methods to obtain the physical and mechanical properties of timber.Timber species are gathered in classes of resistance, according to the characteristic value of resistance to compression parallel to fibers (fc0,k). Among the classes of resistance covered in the normative reference (C20, C30, C40 and C60), there are classes which are predominantly destined to temporary use, such as C20 and C30, due to lack of knowledge about the physical/mechanical properties and the lack of specific projects that prove their efficiency when employed in roof structures.Intending to contribute to the use of not so usual timber species and to minimize the prejudice that surrounds the employment of timber for structural purposes, this research aimed to present the applicability of species which belong to classes of resistance C20 and C30 in truss structures for roof through the elaboration of structural projects.

2. Material and Methods

- This research was performed in five steps: (i) Setting of construction geometrical parameters; (ii) Definition of the structural conception; (iii) Definition of actions and loadings; (iv) Measurement and verification of structural elements and connections according to ABNT NBR 7190 (1997) Brazilian standard prescriptions [7]; (v) Material gathering, ratio volume per construction square meter.

2.1. Step 1 - Geometrical and Structural Parameters

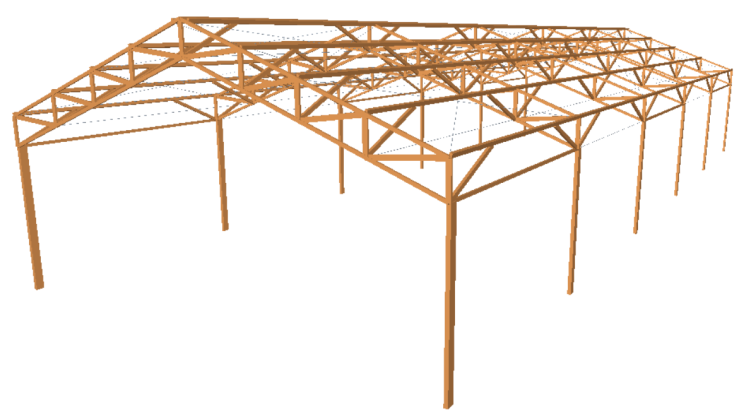

- The projected edifications have the following characteristics: Howe type Isostatic truss with parallel flanges, with spans of 16, 18, 20, 22, 24 and 26 meters; Steel roof with 20º inclination; Ceiling height 5 meters; Proportion in the design around 1:3; Lateral openings (relation between the predominant one and the others): 1:1, 2:1, 6:1 and opened. In Figure 1 it is possible to observe the 3D model of the pre-set geometrical parameters.

| Figure 1. Representative model of industrial shed typology proposed in the research |

2.2. Step 2 - Actions Definition

- To the development of this project, structural, non-structural and variable permanent actions (due to the wind) were considered. Permanent actions were established according to ABNT NBR 7190 (1997) [7] and ABNT NBR 6120 (1980) [8]. In permanent structural actions there are truss bars and brackets (class of resistance C-20) and purlins (class of resistance C-30). The steel roof tile weighing 0,05 kN/m² was considered as a non-structural permanent action.

2.3. Step 3 - Measurement and Verification

- Measurement and analysis of stability in truss structural elements (flanges, uprights and diagonals) and bracing system were considered compression situations and parallel traction to timber fibers (short piece, fairly thin and thin). The situation adopted to purlins was oblique simple flexion. After measuring all structural elements, the comparison between initial estimation and the project real situation was performed, accepting a 10% difference in the structure’s own weight, according to ABNT NBR 7190 (1997) prescription [7].

3. Results and Discussion

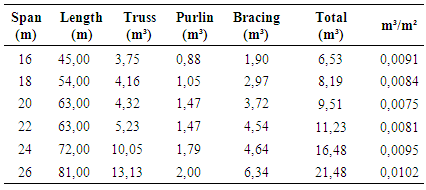

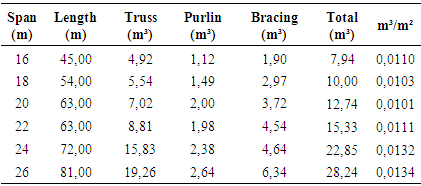

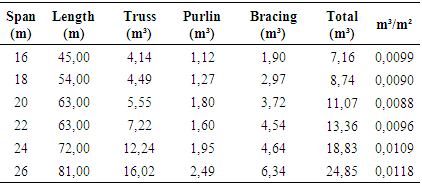

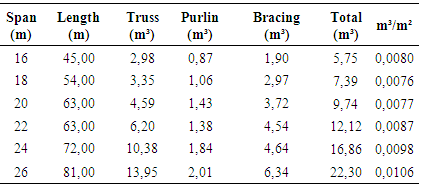

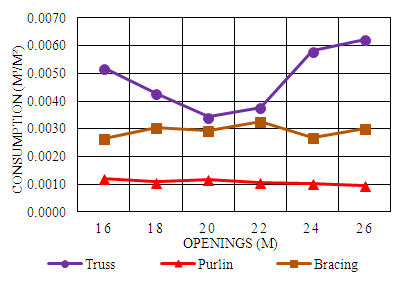

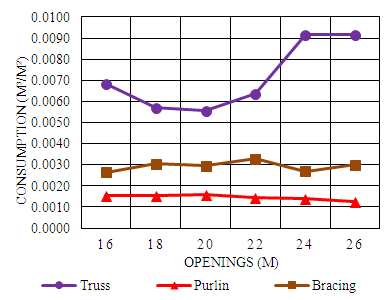

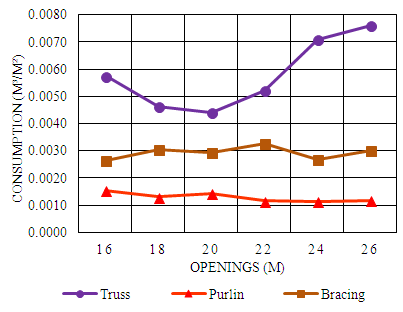

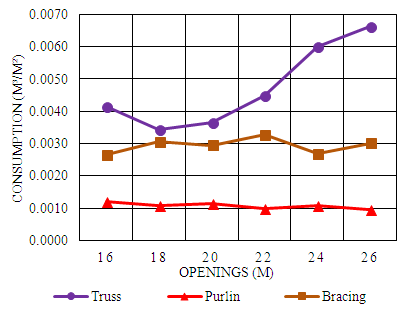

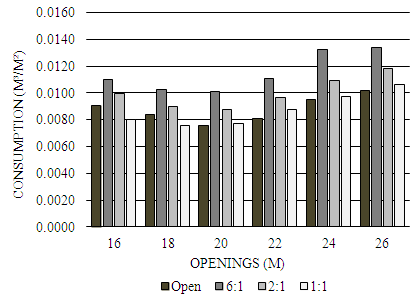

- After all the calculations were performed, it was possible to analyze the results, which are represented through figures 2 to 6 and tables 1 to 4. In order to optimize the dimensioning, technical and constructive and aspects were taken into consideration, analyzing independently each structural element.

|

|

|

|

| Figure 2. Timber consumption m³/m² for opening ratio – Open |

| Figure 3. Timber consumption m³/m² for opening ratio – 6:1 |

| Figure 4. Timber consumption m³/m² for opening ratio – 2:1 |

| Figure 5. Timber consumption m³/m² for opening ratio – 1:1 |

| Figure 6. Total timber consumption m³/m² for all openings |

4. Conclusions

- Through the results obtained in the present research, it was possible to conclude:- The technical viability of using non-conventional timbers (class of resistance C20 and C30) in parallel flanges truss structures for roof was proved through the elaboration of a project in accordance to the current standard prescriptions. Such fact contributed to valorization and commercialization of these species, consequently reducing the consumption of traditional species that may go extinct.- The structural scheme (parallel flanges truss structures for roof) adopted for the studied spans (16 to 26m) generated timber consumption around 0,0075 to 0,0134 m³/m², approximately 60% lower than what is practiced.- Bracing system timber consumption represented around 20 to 40% of total volume. This information is extremely relevant because it evidences the importance of bracing in securing the structure. It is worth mentioning that, in general, structures are usually made without the bracing system.- For all studied spans (16 to 26m) the opening ratios (open, 1:1, 2:1 and 6:1) generated different values of timber consumption per constructed area. Therefore, it is suggested the use of opening ratio 1:1 whenever it is possible, since this ratio led to lower material consumption.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML