-

Paper Information

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Materials Engineering

p-ISSN: 2166-5389 e-ISSN: 2166-5400

2017; 7(6): 117-120

doi:10.5923/j.ijme.20170706.03

Analysis of Impact and Tensile Properties of Recycled Polypropylene

Luiz Gustavo Barbosa, Matheus Piaia, Gustavo Henrique Ceni

Instituto Federal de Educação, Ciência e Tecnologia do Rio Grande do Sul – Campus Erechim, Erechim, Brazil

Correspondence to: Luiz Gustavo Barbosa, Instituto Federal de Educação, Ciência e Tecnologia do Rio Grande do Sul – Campus Erechim, Erechim, Brazil.

| Email: |  |

Copyright © 2017 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

The present research proposed to evaluate the tensile and impact properties of polypropylene originating from secondary recycling. The polymer chosen for the studies was polypropylene (PP) for its high application and availability. The tensile and impact tests were performed on virgin polypropylene, recycled polypropylene and mixtures of different proportions of both. Thus, for each sample, values of yield strength, elastic modulus, yield elongation and impact strength were obtained. The results of the averages obtained demonstrated that the tensile properties of virgin PP and recycled PP are similar, as well as those of the mixtures between both. Regarding the impact properties, it was observed that the energy absorbed by the recycled polymers is lower than that of the virgin polypropylene. Consequently, recycled polypropylene can replace virgin polypropylene in applications which are subjected to tension stress but not in those subjected it to impact.

Keywords: Polymers, Recycled Polypropylene, Tensile Properties, Impact Properties

Cite this paper: Luiz Gustavo Barbosa, Matheus Piaia, Gustavo Henrique Ceni, Analysis of Impact and Tensile Properties of Recycled Polypropylene, International Journal of Materials Engineering , Vol. 7 No. 6, 2017, pp. 117-120. doi: 10.5923/j.ijme.20170706.03.

Article Outline

1. Introduction

- Nowadays, all action related to the disposal of any material should be considered based on the strategy of the four R's: reduction (combating waste generation), reuse (of materials), recycle (use of discarded material in new products) and recover (energy extraction from discarded waste) [1, 2]. Plastic recycling programs have been boosted in the last decade due to growing concern about the environment, the lack of space for the construction of landfills, and even the pressure not only from legislation but also from the society about this disposal [3], since these materials take thousands of years to spontaneously degradate [4]. Beyond keeping the planet clean, recycling offers the potential to reduce fossil fuel consumption, since recycled plastic can compete directly with virgin plastic produced from refined fossil fuels, and the electrical energy needed to process recycled plastics is notably lower than for virgin material [5].The main application of PP is in the food sector, representing 32% in products such as: packaging, lids, tupperwares, jars, bottles and gallons. In the consumer goods sector PP represents 17% of the market and is applied in packaging and boxes. In civil construction represents 3% of the market and, among others, it replaces asbestos in fibre cement tiles and water tanks, and it serves as a partial substitute of concrete in slabs with the use of BubbleDeck. Also, it is a raw material for the Pack Less, a plastic pallet. In the automotive sector it represents 9% of the market, being used in dashboards, door panels, bumpers, grilles, for example. [6]. Therefore, all this material when discarded can be recycled and originate new products. In Brazil, about 8.2% of the post-consumer polypropylene is recycled, which is processed into pellets through mechanical recycling and subsequently produces packaging, automobile components and other recycled products [7].However, few studies have been to verify if the properties of the recycled polymers are similar to those of the virgin polymers. Fernandes and Domingues [8] compared the mechanical properties between virgin high impact polypropylene, injected, and the recycled one. With the purpose of applying the recycled polypropylene in the automotive industry, two mixtures were tested, one composed of 30% recycled PP and 70% virgin PP, and other one of 50% recycled PP and 50% virgin PP. They observed that the mechanical properties under tensile strength (ultimate tensile strength, yield strength and strain) did not vary, however, the impact resistance only for samples with up to 30% recycled PP was acceptable for automotive use. Samples above this percentage (50% and 100% recycled PP) showed a large reduction in impact strength. For comparative purposes the virgin PP had an impact resistance of 78,7 kJ / m² and the PP 100% recycled 19,7 kJ / m².Likewise, Raj et al [9] tested the tensile and impact mixtures of injected virgin and recycled polypropylene in different proportions and have not obtained significant variation in yield strength and elastic modulus. However for the impact resistance, as the percentage of recycled PP increased, such property decreased, having a value of 55,9 kJ / m² for the 100% virgin PP and 45,3 kJ / m² for the mixture of 60% virgin PP and 40% recycled PP.Such decrease in some properties can be justified in many cases by the uncertainty of the composition of the samples, since the raw material comes from secondary recycling, having artifacts discarded from different materials [10]. Still the loss of impact property can occur due to the reduction of the molecular weight that the recycling promotes. Such reduction increases the mobility of the chains, allowing the formation of thinner lamellae and a higher degree of crystallization. Furthermore, the degradation suffered by the polypropylene material leads to a shearing of the main chain and consequently reduces the viscosity, directly affecting its mechanical properties [4]. However, all the previous works demonstrate that for certain percentages of recycled PP in a mixture with virgin PP the mechanical properties generally suffer few reductions, reinforcing the technical and economic viability of the recycling.Therefore, the present work tested if the tensile and impact properties of recycled polypropylene are the same of virgin polypropylene. Such recycled PP is used by Cavaletti S.A, leading office chair manufacturer in the Brazilian market.

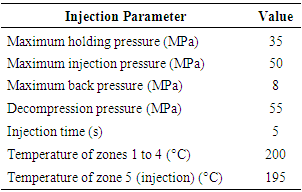

2. Materials and Methods

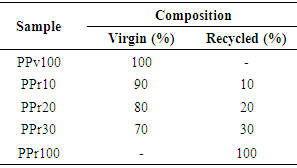

- Virgin polypropylene (PPv) type CP442XP produced by the company Braskem S.A. with yield strength of 24MPa and polypropylene from secondary recycling (PPr) supplied by the company Coplast were used. The materials were blended in the proportions shown in Table 1.

|

|

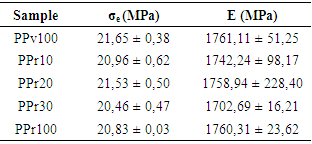

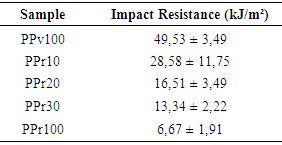

3. Results and Discussions

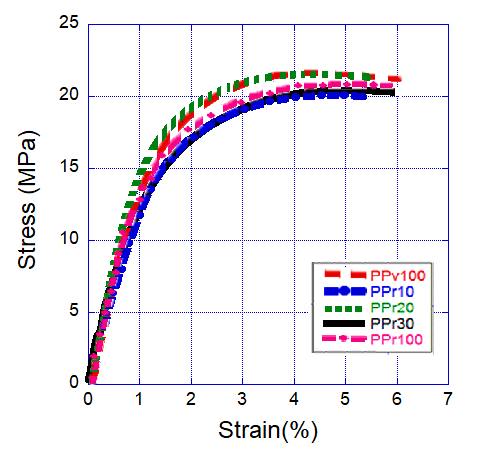

- From the values collected from the software WinWDW, which controls the universal testing machine, the graphs of Figure 1 were obtained. The stress-strain curves for the PPv100, PPr10, PPr20, PPr30 and PPr100 samples are shown in it.

| Figure 1. Stress Versus Strain Comportment of PPv100, PPr10, PPr20, PPr30 and PPr100 Samples |

|

|

4. Conclusions

- Analysing the results obtained, it can be concluded that the properties under tensile stress (yield strength and elastic modulus) are little affected by the usage of either 100% recycled polymer or its mixture with virgin polymer. However, recycling causes PP embrittlement, which is confirmed by the reduction in impact strength. Such results are in agreement with those obtained by Fernandes and Domingues [8] and Raj et.al. [9], which also obtained constancy for the yield strength and elastic modulus and a decrease in impact strength as the percentage of recycled PP in the blend with virgin PP increased.Therefore, the PP obtained by disposable and potentially recyclable objects, that is, PPr100, can be applied in situations that require tensile resistance without impact susceptibility. The low cost, when compared to the virgin, promotes competitive advantage for the plastic artifacts industries, which, by using recyclable materials, are contributing to the environment, reducing the final price of the product and/or increasing the profit margin, without changing the quality of the supplied object. For applications which undergo impact loads, virgin PP should be used, since the mixtures with recycled PP demonstrated a lower impact strength.

ACKNOWLEDGEMENTS

- First of all, we would like to thank Professor Fabio Knewitz for his attention in teaching how to operate the universal testing machine for tensile tests. Professor Luciano Aparecido Kempski, as well as the laboratory technicians Arthur and Emerson, for the idea and assistance in the preparation of the sample holder for the execution of the notch in the specimens of the impact test. Professor Douglas Simon of the IFRS - Campus Farroupilha for providing his time for the execution of the impact tests. And, finally, thank the company Cavaletti S.A., for supplying the samples for the experimental tests.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML