-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Materials Engineering

p-ISSN: 2166-5389 e-ISSN: 2166-5400

2017; 7(5): 93-99

doi:10.5923/j.ijme.20170705.03

Timber Use in Truss Structures for Roof (“Howe” Type – 8 to 18 Meters)

Danielle F. Palludo1, Roberto V. Pinheiro1, Diego H. Almeida2, Felipe N. Arroyo2, Tiago H. Almeida3, Marcelo de Castro Takeda2, André L. Christoforo2, Francisco A. R. Lahr4

1Department of Civil Engineering, University of Mato Grosso State (UNEMAT), Sinop, Brazil

2Department of Civil Engineering (DECiv), Federal University of São Carlos (UFSCar), São Carlos, Brazil

3Department of Materials Engineering (SMM), Engineering School of São Carlos (EESC), São Paulo University (USP), São Carlos, Brazil

4Department of Structures Engineering (SET), Engineering School of São Carlos (EESC), São Paulo University (USP), São Carlos, Brazil

Correspondence to: André L. Christoforo, Department of Civil Engineering (DECiv), Federal University of São Carlos (UFSCar), São Carlos, Brazil.

| Email: |  |

Copyright © 2017 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

The wood is a material widely used for several purposes, especially in the construction industry. There are many factors that this is due, between them the versatility and abundant availability of the material. However, the intensive use of some species might cause shortages. The lack of information about the wood behavior when it is exposed to various conditions, as well as projects not supported by regulatory rules, may imply in its inappropriate use, compromising in the safety of the structure. In this context, it was proposed the elaboration of roofing structures projects with the following characteristics: lattice type buildings Howe (10° slope - cement tile); span of 8, 10, 12, 14, 16 and 18 meters (geometrical proportion, in design, surrounding a 1: 3); typology of the lateral side of the building openings - relations 1:1, 2:1, 6:1 and open (coverage of small dimensions’ support) preservative treatment. Then, was determined the ratio of the wood amount (m³) and the built area (in design) to woods of C20 and C30 classes, following the requirements of NBR 7190: 1997. Front of the analysis of results was evidenced that it is possible to use unconventional woods applied in triangle framework structure in big spans, obeying a well elaborated conception of project.

Keywords: Wood, Roof asbestos cement, Covering structures

Cite this paper: Danielle F. Palludo, Roberto V. Pinheiro, Diego H. Almeida, Felipe N. Arroyo, Tiago H. Almeida, Marcelo de Castro Takeda, André L. Christoforo, Francisco A. R. Lahr, Timber Use in Truss Structures for Roof (“Howe” Type – 8 to 18 Meters), International Journal of Materials Engineering , Vol. 7 No. 5, 2017, pp. 93-99. doi: 10.5923/j.ijme.20170705.03.

Article Outline

1. Introduction

- Wood has always been present in human daily life, since the humanity beginnings to the present day. As a material, it presents a wide application variety and, particularly, in structures, can be used for roofs (residential, commercial, and industrial), works of art (bridges, footbridges) and storage (silo) [1].Being of vegetal origin, wood will be susceptible to biological deterioration, occasioned by the attacks of xylophage’s organisms. However, according to ABNT NBR 16143 [2], the preservative treatment should be adopted to improve the wood natural resistance and, consequently, increase the structure durability.Brazil has about 19% of the world's flora, being recognized as a country with enormous diversity [3]. However, when used in an uncontrolled way may cause its scarcity. Currently, the commercial reduction of some wood species is evident, and yet few actions are taken to combat this situation, as well as to encourage the characterization study of new species [4]. This fact is also the responsibility of higher education institutions, regarding the theme dissemination. Consequently, wood structure activities are devoid of professionals with sufficient training to disseminate the application in a sustainable manner and, evidently, do not allow the properly reasoned projects elaboration, causing the inadequate wood use and compromising the structure safety [5].It is worth noting that North and West regions of Mato Grosso State have a significant source of this resource, making it commercially competitive. In general, they are used in civil construction, mainly in panels, formwork and reinforced concrete structures shoring and lattice structures for roofing [1].Due to this, the work main objective was to present the low-traded wood species applicability in trusses structures for roof, through the structural projects elaboration.

2. Theoretical Foundation

2.1. Wood in Construction

- Wood is a natural material and that has always existed in the environment, has always been available to man. And may be used to meet their basic.Historically wood is one of the first materials used in houses construction, especially in roof structures case. In this context, it was necessary increase the knowledge about the wood properties in order to facilitate their use as a structural element [6].In Brazil, there are major deficiencies in some fields related to wood use in construction, mainly in terms of its structural applicability. This fact is related to traditionalist wood use in roofing structures, as evidenced by the triangular geometric forms and construction techniques commonly used by carpenters [4]. Another factor that discourages the wood use is the society pre-concept, understanding that it is a short-lived material. However, using appropriate preservative treatment and carrying out the planned maintenance, its useful life can be prolonged. It is noteworthy that, from view economic point, the initial wood costs are competitive in relation to other materials, making it advantageous in the long term [7].The construction industry must be aware that quality and wood costs are important, but also their origin. Wood is one of the few building materials that have a renewable character. When supplied, accompanied by documents that guarantee its legal origin, it can be clearly classified as a sustainable product [7].

2.2. Wood Properties

- According to Gesualdo [8] and Pigozzo et al. [9], knowledge and understanding the wood physical and mechanical properties are indispensable for a better design and consequent material use. These properties are influenced by several factors, such as: different temperature conditions, soil composition and humidity at the tree growth spot, stocking density and management employed type; as well as the tree position on the plot and rainfall incidence [10]. From these properties, density, strength/stiffness (strength classes - ABNT NBR 7190 [11]) and moisture, are the most relevant for wood structural elements dimensioning [12]. Jesus [13], in order to subsidize the region's engineers in their wood structures designs, through the strength class analysis of wood species, stand out some non-conventional species for Mato Grosso State. Among the species studied, the Cedar Rose (Cedrela odorata L.) and Marupá (Simarouba amara Aubl.) C20 restrength classes are mentioned, and Angelim Araroba (Dinizia excelsa) is cited for strength class C30.

2.3. Wood Structures

2.3.1. Structural Design

- Traditionally in Brazil, trusses are used in "Howe" wood and, to a lesser extent, "Pratt" trusses [14]. The main elements that make up the trusses are: upper and lower plinth, uprights and diagonals. The outer bars continuity (upper and lower bars) is considered, while the inner bars (uprights and diagonals) are hinged on the outer bars. In this way, bending moment, shear stress and normal shear forces will be generated in bump bars and only normal stress in inner bars. For a fibro-cement and steel roof, the third is the main structural covering element, being supported on two successive scissors, receiving actions directly from the tiles. In Brazil, in general, connections with metallic pins (nails and screws) are used [8].

2.3.2. Sizing

- The sizing procedure of a truss, in a succinct way, is: (i) roof definition; (ii) truss: geometry definition; (iii) purlim: actions definition; (iv) truss: spacing - with purlim sizing; (v) trellis: actions definition, internal efforts, loading and dimensioning; (vi) bracing system: sizing; (vii) drawings/detailing; (viii) material list. In accordance with NBR 7190 [11], the truss structures safety occurs through the following checks: (i) Last Limit States (structural elements - strength, local and global stability; (ii) Service Limits of Service/Utilization (structural elements - excessive displacement and vibration). In addition to the above considerations, following evaluations should be carried out: wood pieces classification (ABNT NBR 7190 [11] - item 10.6); proceed with preventive treatments (ABNT NBR 7190 [11] - item 10.7) to avoid piece deterioration; guarantee the water disposal; and structure aeration.

2.4. Art State

- Performance over the wood frame life is one of the designer's major concerns as well as meeting consumer aspirations. Pinheiro and Lázaro [15], observing the partial ruin of a wood truss structure with ceramic roof. The causes observed were mainly due to the organisms’ xylophages attack (termites and rotting fungi) and by periodic maintenance absence and lack of structures preservatives.Ribeiro and Pinheiro [16] carried out the consumption comparison of wood used (m³madeira/m²area) in Forest Park of Sinop/MT building, with a project proposed by them, with the same characteristics, strength class C30. It was evidenced the use of 0,032 m³madeira/m²building for building construction, and with the proposed project, the consumption of 0,025 m³madeira/m²edificio was obtained, a material reduction about 21%.Pinheiro and Danelichen Jr. [17] demonstrated the wood use feasibility, through the projects elaboration of "Howe" buildings (10° inclination - steel tile); span six, seven and eight meters (geometric ratio, in plan, of 1:3); lateral openings typology of the building - ratios 1:1, 2:1, 6:1 and open (coverage on small supports); condom treatment. The results analysis showed that the ratio m³/m² is greater than the 6:1 ratio, whereas for 1:1 they are the smallest, and the 2:1 and open ratios are approximately equal. Therefore, it is possible to conclude that a structural design is feasible, since the mean obtained was 0.0086 m³/m², while for structure executed without a structural design it is around 0.020 to 0.025 m³/m² (60% reduction).For truss systems "Howe" and "Pratt", Miotto and Nuernberg Junior [18]) observed that the connectors number and the total wood volume for "Howe" truss was lower.Sector [19] addresses the wood bridges typologies currently used on back roads in the Cuiabá/MT municipality. He also comments specifically on wooden bridges in Pratt trusses, applying tropical lumber, encouraging employment and neutralizing prejudice regarding the wood use in bridges.Garcia and Leão [20], using trusses arches for pedestrian walkways, investigated the medium-strength wood applicability, proving the application, quality and structure safety.Desiring to demonstrate the wood potential, Cavalheiro et al. [21] showed that wood Paricá (Schizolobium amazonicum), strength class C20, has good strength properties and therefore has great potential for use in timber structures.Tomczyk [22] carried out the comparative study in two trusses use (one built with empirical criteria and other technical criteria) the profitability generated with the trusses construction with technical base, based on material savings and market gain, evidenced mainly due to the material quality in the study site.Thus, it is concluded that such information validates the proposed study, mainly regarding the profitable applicability verification in trusses roof structures, from species of unconventional dicotyledonous woods.

3. Materials and Methods

- Activities were divided into five stages of design: i) the building geometric parameters were determined; ii) the structural design was determined; iii) the actions and shipments were determined, defining the internal efforts and displacements, with the aid of Ftool software; iv) the design and structural elements verification and connections were carried out, following the technical requirements of ABNT NBR 7190 [11]; v) quantitated the wood volume required and determined the ratio m³/m², presenting them in the graphs and tables form.

3.1. Step 1 – Geometrical Parameters

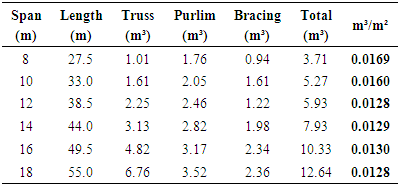

- The study buildings have the following parameters:a. Building, in plan, with geometric relation around 1:3:Ÿ Type 1 - 8,0x27,5m (five spans of 5,50 meters - ranges from "A" to "E");Ÿ Type 2 - 10,0x33,0m (six spans of 5,50 meters - tracks from "A" to "F");Ÿ Type 3 - 12,0x38,5m (seven spans of 5,50 meters - tracks "A" through "G");Ÿ Type 4 - 14.0x44.0m (eight spans of 5.50 meters - ranges from "A" to "H");Ÿ Type 5 - 16,0x49,5m (nine spans of 5,50 meters - ranges from "A" to "I");Ÿ Type 6 - 18,0x55,0m (ten spans of 5,50 meters - tracks "A" through "J").b. Height (clearence): 5.0 meters;c. Steel roof;d. Buildings side opening: 1: 1, 2: 1, 6: 1 and open faces.

3.2. Step 2 – Structural Design

- The following structural concepts were adopted:a. Trellises: isostatic, "Howe" type (inclination of 10°), considering the bars continuity of the top/bottom, while the internal bars (diagonals/uprights), hinged at their ends, in the flanges bars; free spans: 8, 10, 12, 14, 16 and 18 meters;b. Rectangular purlim: isostatic beam (with relation to "x" axis), supported on truss knots; (with relation to "y" axis), with end supports on truss knots and, internal support, given through chain lines (metal rods), located in the span middle;c. Bracing system (Fig. 1): upper flange plane - composed of purlim and steel cables (with tensioners) arranged in "X"; lower flange plane - composed of "T" beams (top table - 2.5x15cm, core - 2.5x15cm) locked transversely at the midpoint (piece of 5x6cm), fixed at nodes ends of lower flange and positioned in the spans in this way:Ÿ Type 1 - tracks "A", "C", "E";Ÿ Type 2 - tracks "A", "C", "D", "F";Ÿ Type 3 - tracks "A", "D", "G";Ÿ Type 4 - tracks "A", "D", "E", "H";Ÿ Type 5 - tracks "A", "D", "F", "I";Ÿ Type 6 - tracks "A", "D", "G", "J" (Figure 1).

| Figure 1. Bands transverse schematic plan for 18 meters span |

3.3. Step 3 – Actions, Loads and Internal Forces/ Displacements in the Structure

- Permanent actions (structural and non-structural) and variables (wind) were considered. For permanent actions (structural and non-structural) determination, ABNT NBR 7190 [11] and ABNT NBR 6120 [23] were used. The following permanent structural actions were considered: truss bars (spans: 8 and 10 meters - strength class C20; spans: 12, 14, 16 and 18 meters - strength class C30); (strength class C30); (3% increase on structural weight) and bracing system (strength class C20). The non-structural permanent action considered was the fiber cement roof, with its own weight equal to 0.20 kN/m². As for the variable actions, due to the wind, the requirements contained in ABNT NBR 6123 [24] were adopted, considering that the study building is located in basic wind velocity regions (V0) equal to 30m/s. The actions (loading) combinations were performed based on ABNT NBR 8681 [25] and ABNT NBR 7190 [11] recommendations, with the following combinations: State Limit Last (last normal) and State Service Limit (long duration). With the help of Ftool software, were calculated the truss bars internal stresses (normal tensile and compressive stresses), in the purlim (shear stress and bending moment), as well as the structures displacements.

3.4. Step 4 – Sizing and Verification

- For structural elements dimensioning and stability analysis of the truss and bracing system, the tensile and compression situations parallel to the fibers were considered and, for the purlim, oblique composite bending situation was considered. As for the connections, consideration was given to pin bending and the wood inlay. For these procedures, the Ultimate Limit State was adopted, according to ABNT NBR 7190 [11] and ABNT NBR 8681 [25]. For vertical displacements (sags) verifications and vibrations, they were calculated based on the State of Use (Service), with backing of ABNT NBR 7190 [11] and ABNT NBR 8681 [25].

3.5. Step 5 – Materials Quantification

- Finally, the total wood consumption (truss, purlim and bracing) was determined for all cases studied and represented by the relation "m³madeira/m²area". To facilitate the quantification and data comparison, it was organized in spreadsheets (tables and graphs).

4. Results and Discussion

4.1. Displacement Analysis

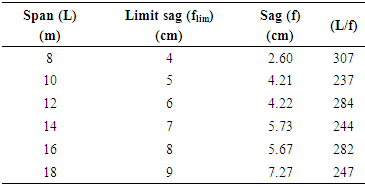

- The safety check against the deformation limit is given by the L/200 ratio. For all cases, according to ABNT NBR 7190 [11], the sags performed well, as evidenced in Table 1.

|

4.2. Wood Volume Analysis

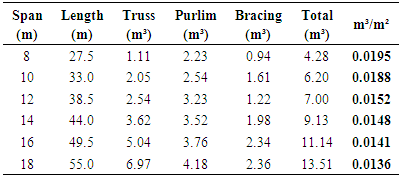

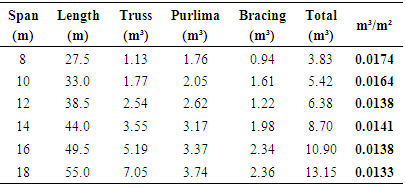

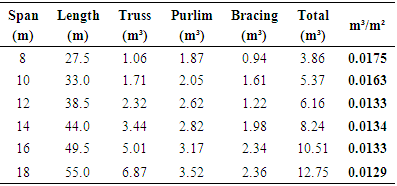

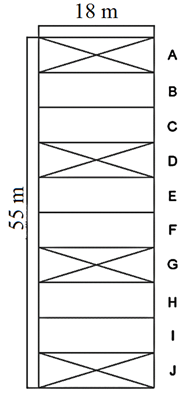

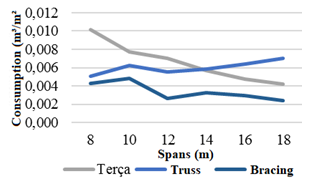

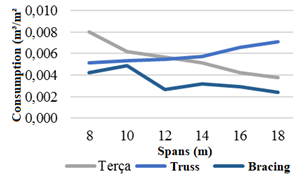

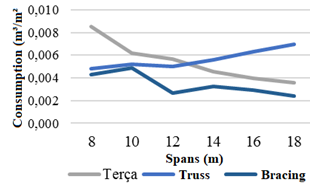

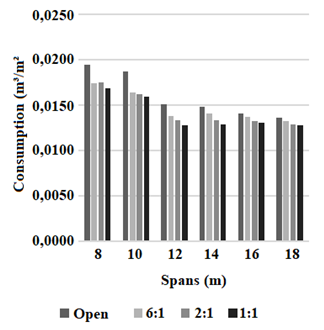

- Tables 2 to 5 and Figures 2 to 6 show the wood volumes per opening and spans, considering the trusses volume sum, purlim and the bracing system.

|

| Figure 2. Opening ratio – Open |

|

| Figure 3. Opening ratio – 6:1 |

|

| Figure 4. Opening ratio – 2:1 |

|

| Figure 5. Opening ratio – 1:1 |

| Figure 6. Total wood consumption by area |

5. Conclusions

- After the elaboration of this work, we conclude that:a) The technical feasibility of non-conventional wood (strength classes: C20 and C30) has been proven through well-designed project design, according to current normative prescriptions. This fact will allow the commercialization of these species, adding value to them and, consequently, will reduce the pressure of traditional species use;b) The structural scheme adopted (triangular trusses - rectangular sheds) for the studied spans (8 m to 18 m) was more adequate, generating consumption around 0.0123 to 0.0194 m³madeira/m²área, or approximately 40% lower than practiced;c) There was a considerable increase in wood consumption for 8 m and 10 m spans, in relation to the other cases. This was due to the initial design considerations and configurations and the truss strength class was lower than the one used for other structures, thus, implied the pieces use with larger cross sections;d) The structural scheme and span adopted for purlim (5.50 m), proved to be extremely advantageous when compared to the current process used in technical environment (spacing between trusses 2.5 m and 3.5 mm). This will reduce, by 50%, the inputs cost from the pillars and foundations;e) The bracing system wood consumption is around 20% to 30% if compared to the total volume. This information is extremely relevant because it shows the importance of the same in structural safety. It is worth mentioning that, in general, the structures commonly executed, do not have bracing or is executed in an erroneous way;f) For spans studied all (8 m to 18 m), the relation between building openings generates differentiated values in wood consumption and, therefore, it is suggested, whenever possible, the use of the relation between openings, equal to 1:1.

ACKNOWLEDGMENTS

- Authors thank to Wood and Timber Structures Laboratory (LaMEM), Structural Engineering Department (SET), São Carlos Engineering School (EESC), São Paulo University, by the materials and resources used in this research.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML