-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Materials Engineering

p-ISSN: 2166-5389 e-ISSN: 2166-5400

2016; 6(5): 151-154

doi:10.5923/j.ijme.20160605.02

Physical Properties of OSB Panels Manufactured with CCA and CCB Treated Schizolobium amazonicum and Bonded with Castor Oil Based Polyurethane Resin

Fabiane Salles Ferro1, Tiago Hendrigo de Almeida1, Diego Henrique de Almeida2, André Luis Christoforo3, Francisco Antonio Rocco Lahr4

1Department of Science and Material Engineering, Engineering School of São Carlos (SMM), São Carlos, Brazil

2Department of Engineering, College Pitágoras, Poços de Caldas, Brazil

3Centre for Innovation and Technology in Composites - CITeC, Department of Civil Engineering (DECiv), Federal University of São Carlos, São Carlos, Brazil

4Department of Structural Engineering (SET), São Paulo University (EESC/USP), São Carlos, Brazil

Correspondence to: André Luis Christoforo, Centre for Innovation and Technology in Composites - CITeC, Department of Civil Engineering (DECiv), Federal University of São Carlos, São Carlos, Brazil.

| Email: |  |

Copyright © 2016 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

This research aimed to evaluate the physical properties of OSB panels manufactured using Paricá (Schizolobium amazonicum) wood species particles, treated with CCA (chromated copper arsenate) and CCB (chromated copper borate) preservatives, and castor oil based polyurethane resin. Three resin contents were evaluated: 8, 10 and 12%. Results showed that OSB panels manufactured with CCA-treated wood particles did not meet the minimum requirements stipulated by EN 300Code, while OSB containing CCB treated wood particles reached the properties values required for structural applications in dry conditions. Therefore, it was demonstrated the feasibility of using CCB-treated Paricá wood and castor oil based polyurethane resin in OSB production.

Keywords: Schizolobium amazonicum, Oriented strand board (OSB), Treated wood

Cite this paper: Fabiane Salles Ferro, Tiago Hendrigo de Almeida, Diego Henrique de Almeida, André Luis Christoforo, Francisco Antonio Rocco Lahr, Physical Properties of OSB Panels Manufactured with CCA and CCB Treated Schizolobium amazonicum and Bonded with Castor Oil Based Polyurethane Resin, International Journal of Materials Engineering , Vol. 6 No. 5, 2016, pp. 151-154. doi: 10.5923/j.ijme.20160605.02.

1. Introduction

- Oriented Strand Board (OSB) is a wood particleboard of formed by "strands" in oriented layers, bonded with waterproof resin and consolidated under hot pressing. It is an engineered wood product used widely in construction materials such as coating, flooring and I-beams [1, 2].As other wood products, OSB is also subject to decomposition when exposed to favorable conditions do biological decay, imposed by microorganisms such as fungi. In general, OSB has been not used for applications where there is direct contact with moisture sources, such as ground or wet ambient [3].Preservative treatment application in structural composite panels, as OSB, could be an effective method to prolong their use, which are commonly made of with low natural durability wood. The traditional methods of treatment with water-based preservatives such CCA (chromated copper arsenate) and CCB (chromated copper borate), which are conducted under high pressure after panel production, has not proved to be effective enough for OSB treatment, because of water has an adverse effect on adhesive bond, resulting in higher thickness swelling and water absorption of these panels [4].To obtain desirable properties for OSB with preservative treatment, factors as the application stage of treatment, preservative type and their combination with the type of adhesive should be considered [5]. The good interaction between the mentioned factors was verified in studies with composite panels made with treated wood particles bonded with castor oil based polyurethane resin, as Bertolini et al. [6], with homogeneous particles panels manufactured with waste of CCB-treated Pinus sp., Ferro et al. [2] with OSB panels manufactured using CCA and CCB treated Schizolobium amazonicum wood species; Nascimento et al. [7] with high density particleboard manufactured with CCA and CCB- treated Eucalyptus sp.Considering the positive aspects of the current production of OSB and the need for studies that provide the use of preservative treatment in these panels, the present work aimed to evaluate the physical properties of OSB panels manufactured with CCA and CCB treated Schizolobium amazonicum strands and castor oil based polyurethane resin.

2. Material and Methods

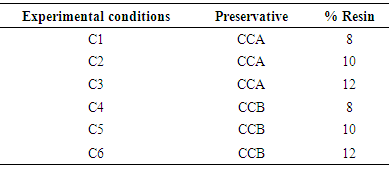

- Wood species chosen was Paricá (Schizolobium amazonicum), due it slow density (about 0.40 g/cm³) and good permeability. Paricá pieces came from a seven years old plantation, located in Paragominas City, Pará State, Brazil, and were treated with CCA salts and CCB oxides (Figure 1a). Retentions adopted were 6.5 and 9.6 kg of ingredients active/m³, respectively, as pointed out by several authors [2, 6].Strands were generated with nominal dimensions under 90×35×0.7 mm (Figure 1c) and dried to achieve moisture content between 10 and 12%, based on dry weight of strands (compatible for convenient bonding reactions). Strands were glued with bi-component castor oil based polyurethane resin, with 100% solid content, composed by a polyol (component derived from vegetable oil) and a prepolymer (Figure 1b). The ratio of prepolymer and polyol used was 1:1 [2, 8].Three resin contents were evaluated, providing six different experimental conditions, as shown in Table 1. For each experimental condition, four OSB panels were produced with nominal dimensions 40× 40×1 cm and nominal density 0.70 g /cm³, totaling 24 panels [2, 8, 9].

|

| Figure 1. OSB manufacture process |

3. Results and Discussion

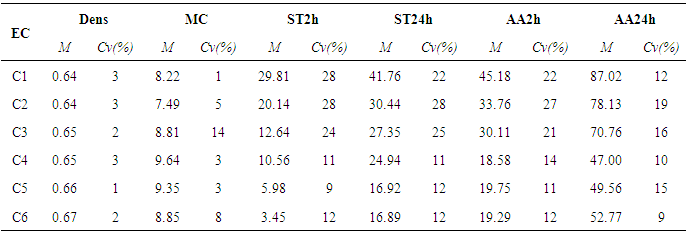

- Table 2 present mean (M) results and coefficients of variation (Cv) obtained for each treatment investigated.

|

|

|

4. Conclusions

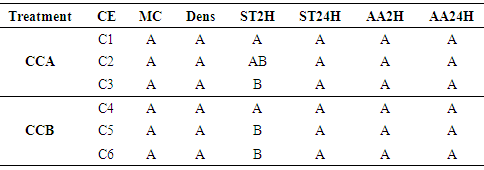

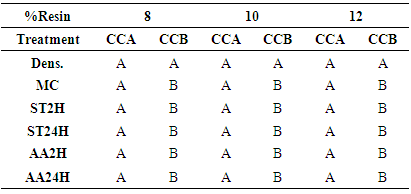

- It is possible to conclude that CCB preservative is more feasible in treatment of wood for OSB manufactured, once panels reached consistent physical performance required by EN 300 for structural applications in dry environments, while CCA treated panels did not reach the minimum usage requirements stipulated by the mentioned Code.Tukey’s test for resin content showed that only thickness swelling after 2 hours of water immersion was influenced by this factor, and that increasing resin content provided reduction in the values of this property. Tukey’s test for preservative treatment type showed that only density was not influenced by this factor and CCB treated panels presented better performance.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML