-

Paper Information

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Materials Engineering

p-ISSN: 2166-5389 e-ISSN: 2166-5400

2016; 6(3): 97-102

doi:10.5923/j.ijme.20160603.06

EDGE Glued Panels Grading through Transversal Vibration Testing

Carlito Calil Neto1, Felipe Arroyo2, Victor Almeida De Araujo3, André Luís Christoforo2, Francisco Antonio Rocco Lahr4, Carlito Calil Junior4

1Wood and Timber Structures Laboratory (LaMEM), São Carlos Engineering School, São Paulo University - USP, Av. Trabalhador São-carlense, Centro, zip code, São Carlos, SP, Brazil

2Centre for Innovation and Technology in Composites - CITeC, Department of Civil Engineering (DECiv), Federal University of São Carlos, São Carlos, Brazil

3Research Group LIGNO of UNESP-Itapeva, Department of Forest Sciences, School of Agriculture Luiz de Queiroz of University of São Paulo (ESALQ/USP), Piracicaba, Brazil

4Department of Structures Engineering (SET), Engineering School of São Carlos (EESC), São Paulo University (USP), São Carlos, Brazil

Correspondence to: André Luís Christoforo, Centre for Innovation and Technology in Composites - CITeC, Department of Civil Engineering (DECiv), Federal University of São Carlos, São Carlos, Brazil.

| Email: |  |

Copyright © 2016 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

The Edge-Glued Panel is produced using sawn wood, i.e., lumber, with or without butt joints and edge-glued lumber. It can be composed with one layer, but the most common is with three layers (two external longitudinal and one transversal). This panel is used in Europe for furniture and forms of concrete structures. The resin applied in the gluing is based on urea-formaldehyde and phenol-formaldehyde. Due to the importance of this panel, this research aims to analyze the use of Transversal Vibration techniques for EGP grading. For this purpose, twelve EGP panels of three layers were produced and tested in order to determine the modulus of elasticity and modulus of rupture in static bending and dynamic modulus. The results showed nonexistent correlations among the dynamic modulus of elasticity with EGP density and between the modulus of rupture in static bending with the dynamic modulus, providing just a good correlation between statistic and dynamic modulus of elasticity.

Keywords: Wooden panel, Nondestructive test, Transverse vibration, Panel classification

Cite this paper: Carlito Calil Neto, Felipe Arroyo, Victor Almeida De Araujo, André Luís Christoforo, Francisco Antonio Rocco Lahr, Carlito Calil Junior, EDGE Glued Panels Grading through Transversal Vibration Testing, International Journal of Materials Engineering , Vol. 6 No. 3, 2016, pp. 97-102. doi: 10.5923/j.ijme.20160603.06.

Article Outline

1. Introduction

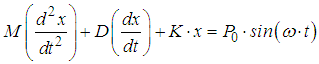

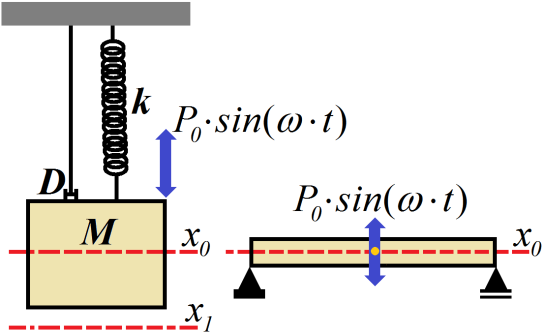

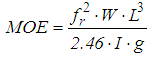

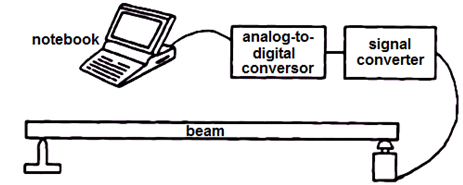

- Since 1990s, the solid wood material started to be more stable like in the panel industry and to be used in a faster and more practical manner in the furniture industry as compared to the past with the aid of the developing technology [1].The Edge-Glued Panel or EGP is formed by laterally glued lumber, with or without end-grain joints [2]. In addition to having the properties of wood, the EGPs have a more heterogeneous structure than solid wood because of the style of cutting solid laths, which come together to form panels [3]. Edge-glued panels are manufactured through the lateral gluing with synthetic adhesives of wooden lathes with width from 30 to 50 millimeters and thickness from 15 to 30 millimeters [4], i.e., they are created from narrow strips of lumber that are glued together under pressure [5]. EGP composition can contain one layer, however, the most popular solution is the three-layer panel whose two external layers are longitudinal and the central layer is transversal [2]. The application of flat edge joining’s at a 90º angle from any joining application in side-by-side of long, narrow wooden strips restrict the mechanical resistance of the raw materials in the production of edge-glued panels.In relation to its raw material, the EGP generally uses wood from planted forests, e.g., pine [6, 7], eucalypt [8, 9], etc. The adhesives applied in gluing stages are generally based on urea-formaldehyde or phenol-formaldehyde [2]. Due to EGP is not being harmful to human health and the environment, the importance of this material is increased [9].During 1998 to 2007, the Brazilian EGP production presented growth rate around 97%, which was justified by the growing produced volume from 255,000 to 503,000 m3 [10]. In contrast, [1] evaluate that the total European EGP production is reported to be approximately 2 to 2.5 million m3/year.The edge-glued panels are versatile in that they can be manufactured for specific end uses, or made as standard-sized blanks [11]. This product has been very applied in Europe for the manufacturing of furniture and concrete forms for structures [2]. Many furniture companies utilize EGPs in products such as table tops, bed or chest panels, and doors. This furniture application for EGP is also quoted by [1], [4] and [7].Key advantages of edge-glued panel production include the relatively low cost of equipment, potential use of smaller diameter stems, utilization of less valuable grades of lumber, flexibility in panel product sizes, and the opportunities to sell within established local markets [5].Nondestructive evaluation of physical properties of wood has its origin in the need to solve practical problems without destruction of the integrity of the examined object, and scientific methods became possible in the early 1900s with the development of theory of elasticity and of the instrumentation for measurement of wood properties [12]. Measurement of mechanical properties of structural composite products is an emerging technology that operates analogously to the machine grading process [13].Nondestructive techniques also enable wood maintenance through mapping of decayed areas without the need to remove parts of the structure [14].[15] list that the most common methods of nondestructive evaluation applies the technologies of x-ray, ultrasound, eddy-current, vibration analysis, acoustic emission, etc. Transverse vibrations and stress waves can be used to estimate bending stiffness [16, 17]. [18] state the nondestructive techniques are based on the use of an estimator to verify the mechanical properties of wood. Thereby, the nondestructive evaluations based on vibration and ultrasound techniques are used in scientific area to determine the physical and mechanical properties of woods [15]. These transverse vibration techniques have received considerable attention for nondestructive testing applications in wood industry [19].This method consists of a stroke application in a bi-supported wood piece, whose supports are a lamina in an extreme and a load cell in the other end piece. The piece will vibrate at its natural vibration frequency up to this vibration ceases due to the damping. The load cell captures the vibration of the beam and transfers the signal to a circuit, which amplifies and filters it, and then, this amplified signal is digitized and sent to a computer to determine the frequency of the oscillating signal [20].In the transverse vibration method, the natural vibration frequency of any material is correlated to its static bending. As a consequence, appropriate mathematical relations among these properties and the properties of static bending and elasticity can be obtained through statistical regression analysis [21].To illustrate these methods of transverse vibration (Fig. 1), an analogy can be drawn between the behavior of a vibrating beam and the vibration of a mass that is attached to a weightless spring and internal damping force [19, 22]. According to [20], this natural vibration frequency of wood will depends on: the modulus of elasticity of wood, span between the two supports, wood density, and the type of support.In the Figure 1, the mass M is supported from a rigid body by a weightless spring whose stiffness is denoted by K. Internal friction or damping is represented by the dashpot D. A forcing function equaling P0 sin ωt or zero is applied for forced or free vibration, respectively. When M is set into vibration, its equation of motion can be expressed by the following [19, 22]:

| (1) |

| Figure 1. Mass-spring dashpot vibration (left) and transversely vibrating beam (right). Adapted from [19] and [22] |

| (2) |

| Figure 2. Machine to determine Modulus of Elasticity by transverse vibration |

2. Material and Methods

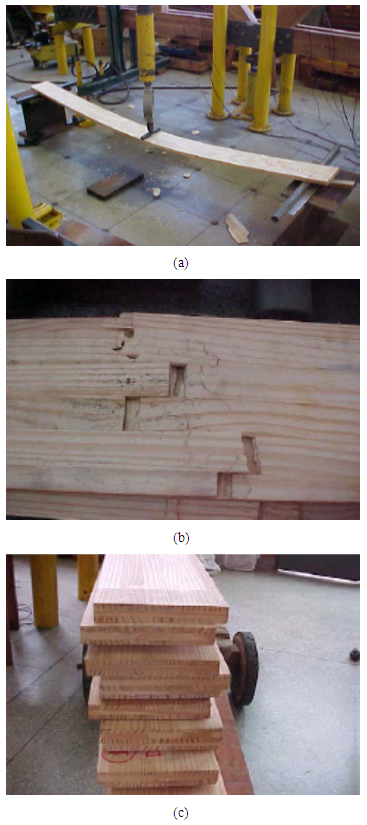

- The selected boards for this research were 12 three-layered edge-glued panels. The EGP composition is formed by two external longitudinal layers and a transverse central layer, both in Pine wood with 7-millimeter thick. Battistella industry manufactures these edge-glued panels using melamine adhesive, which are known by the commercial name IstelaPlac. These EGP boards with 150-millimeter width by 2050-millimeter length were tested in static bending in three points, to obtain the modulus of elasticity in static bending (MOE or E) and the modulus of rupture in static bending (MOR). To evaluate the validity of the utilization of the nondestructive grading method by transverse vibration (TV), the wooden pieces of EGP were classified through the Metriguard equipment for transverse vibration.In transverse vibration grading, the equipment E-Computer model 340 from Metriguard was used (Fig. 3). Before the test, the dimensions of transverse section were measured, as well as the lengths of the 12 boards. These EGP boards were tested in a 2000-millimeter span.

| Figure 3. Equipment of transverse vibration used in the tests |

| Figure 4. (a) Static bending test, (b) transverse section of pieces and (c) EGP beams |

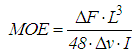

| (3) |

3. Results and Discussion

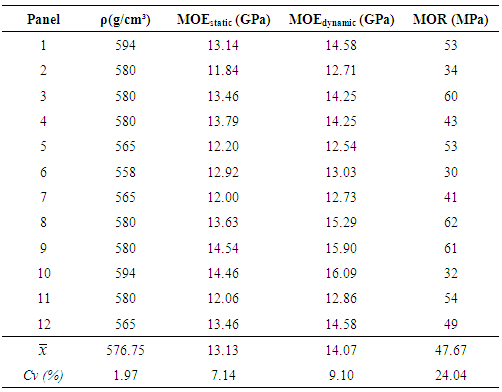

- The mean values

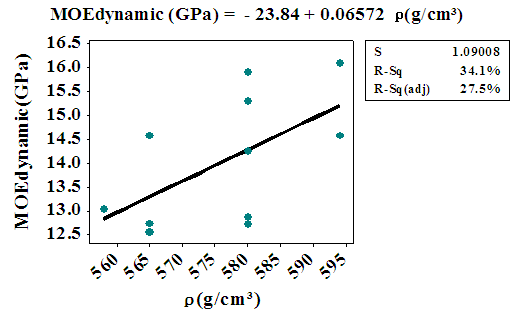

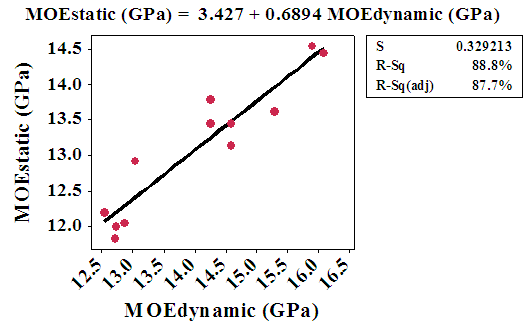

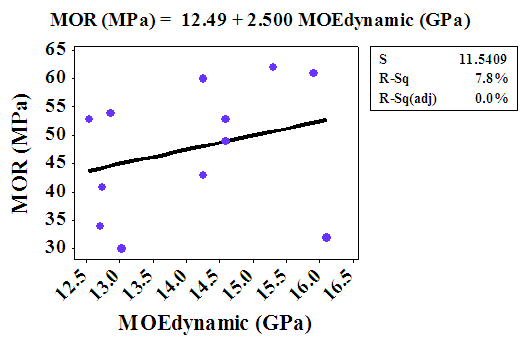

and the variation coefficient (Cv) results are presented in Table 1, and the obtained results from the linear regression models are graphically presented in Figure 5, 6 and 7 with the respective statistical analysis (equation and R2 determination coefficient).Of linear regression models tested, it is noted that the density did not appear as good estimator of the dynamic modulus of elasticity of EGP panels. The dynamic modulus of elasticity can be used to estimate the static modulus of elasticity due to the excellent value obtained for the coefficient of determination (R2=87.7%), but does not show as good estimator for the determination of the bending strength.

and the variation coefficient (Cv) results are presented in Table 1, and the obtained results from the linear regression models are graphically presented in Figure 5, 6 and 7 with the respective statistical analysis (equation and R2 determination coefficient).Of linear regression models tested, it is noted that the density did not appear as good estimator of the dynamic modulus of elasticity of EGP panels. The dynamic modulus of elasticity can be used to estimate the static modulus of elasticity due to the excellent value obtained for the coefficient of determination (R2=87.7%), but does not show as good estimator for the determination of the bending strength.

|

| Figure 5. Analysis of linear regression between MOEdynamic and density |

| Figure 6. Analysis of linear regression between MOEdynamic and MOEstatic |

| Figure 7. Analysis of linear regression between MOEdynamic and MOR |

4. Conclusions

- Through the results and analysis, it was verified that there is no correlation between the dynamic modulus of elasticity and density as well as there is no correlation between modulus of rupture and dynamic modulus of elasticity, and a good correlation between the static and dynamics modulus of elasticity.Furthermore, the average modulus of elasticity verified by the static bending tests was 13.13 GPa with the standard deviation of 0.9 GPa. For the transverse vibration method, the average modulus of elasticity was 14.07 GPa with a standard deviation 1.23 GPa. Through the transverse vibration equipment, the determination coefficient (R2) was 0.8877.Then, the transverse vibration technique is a practical and accurate method for nondestructive grading for EGP panels.

ACKNOWLEDGMENTS

- We are grateful the industry Battistella Indústria e Comércio de Madeiras for the donation of EGP boards used in the tests. The tests were realized in the Laboratory of Woods and Wooden Structures (LaMEM – Laboratório de Madeiras e Estruturas de Madeira) of University of São Paulo (USP – Universidade de São Paulo).

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML