-

Paper Information

- Next Paper

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Materials Engineering

p-ISSN: 2166-5389 e-ISSN: 2166-5400

2015; 5(5): 125-128

doi:10.5923/j.ijme.20150505.04

Research on Electrical Conduction Characteristic and Temperature-Dependent Characteristic of Aqueous MCF Rubber to Create High Sensitivity Sensor

Yaoyang Zheng1, Kunio Shimada2, Chikai Tei3

1Department of Mechanical Engineering, Fukushima National College of Technology, Fukushima, Japan

2Faculty of Symbiotic Systems Science, Fukushima University, Fukushima, Japan

3Faculty of Informatics and Engineering, University of Electro-Communications, Tokyo, Japan

Correspondence to: Yaoyang Zheng, Department of Mechanical Engineering, Fukushima National College of Technology, Fukushima, Japan.

| Email: |  |

Copyright © 2015 Scientific & Academic Publishing. All Rights Reserved.

Magnetic compound fluid (MCF) is a smart fluid material developed by our group’s Prof. Kunio Shimada. Thus far, we have developed a MCF rubber composite material consisting of fine metal particles and a silicon-oil rubber called “oiliness MCF rubber”. The oiliness MCF rubber conducts electricity and heat very well. As an example, we have applied this rubber to touch sensors on robot arms. Recently, in order to make higher-sensitivity sensors, we successfully developed a new material called “aqueous MCF rubber”. Although both types of MCF rubber are good electrical and heat conductors when compressed, the aqueous MCF rubber is superior. In the present paper, we compare the electrical conduction and temperature-dependent characteristics of the two types of rubber.

Keywords: MCF (Magnetic compound fluid), Oiliness MCF rubber, Aqueous MCF rubber, Electrical conduction, Sensitivity

Cite this paper: Yaoyang Zheng, Kunio Shimada, Chikai Tei, Research on Electrical Conduction Characteristic and Temperature-Dependent Characteristic of Aqueous MCF Rubber to Create High Sensitivity Sensor, International Journal of Materials Engineering , Vol. 5 No. 5, 2015, pp. 125-128. doi: 10.5923/j.ijme.20150505.04.

Article Outline

1. About MCF

- The MCF is a smart fluid material developed by Prof. Simada, a member of our study group. Thus far, we have proposed a MCF composite material consisting of fine metal particles and silicon-oil rubber. It can serve as a kind of colloidal solution as well.To make the proposed MCF rubber, metal fine particles were compounded with kerosene-based MF, mixed with silicon-oil rubber, and then dried to a solid rubber. We called the dried solid rubber the “oiliness MCF rubber”. If we dry the oiliness MCF rubber under a magnetic field, the characteristics of the MCF rubber exhibit some changes. The metal fine particles included in the MCF composite material form network-like clusters under a magnetic field, and most of the clusters are formed along the direction of the magnetic field. Therefore, the oiliness MCF rubber can conduct current flow and transfer heat well. We applied the oiliness MCF rubber to a robot arm as a touch sensor, etc. The cost of making the MCF rubber is higher, however, and it cannot measure a smaller imposition power. Thus, we developed a new MCF-conducting rubber to overcome these faults. The new rubber is aqueous MCF rubber, developed using water-based magnetic fluid and latex natural rubber. In this paper, we explain the characteristics of the aqueous MCF rubber and describe its interesting temperature-dependent characteristic.

2. The two Kinds of MCF-conducting Rubber

2.1. The Oiliness MCF Rubber

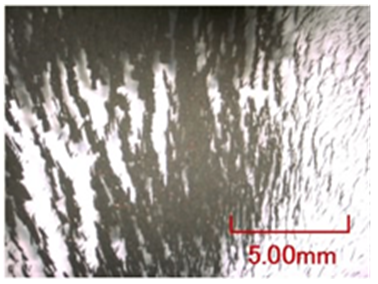

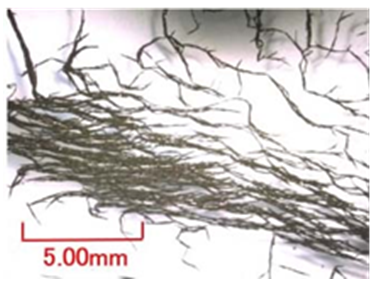

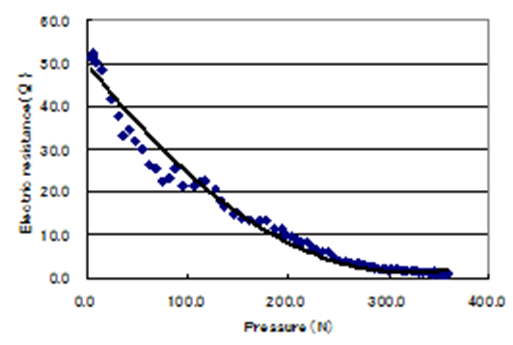

- Silicon-oil rubber compounded with MCF has many needle-shaped magnetic clusters in cases where the MCF contains iron particles, HQ with 1.2 µm diameters, and kerosene-based MF. To give the MCF rubber high conductivity, Cu particles (length 8-10 µm) and Ni particles (length 3-7 µm) were used in the MCF compounded into the silicon-oil rubber. When the MCF was compounded with HQ and Cu, the shape of the HQ was spherical, and thus the magnetic clusters of MCF in the rubber were needle-shaped, as shown in Fig. 1. In contrast, when Ni and Cu were used, the magnetic clusters of MCF in the rubber had network-like shapes (as shown in Fig. 2), because of the very twig-like shape of Cu and the remnant magnetization of Ni. The MCF rubber was dried under a magnetic field generated by two permanent magnets at about 5.44 KGauss. Because oil was in the rubber and kerosene was in the MF, we decided to call the rubber “oiliness MCF rubber”. Fig. 1 shows the conductivity (resistance) of oiliness MCF rubber and its relation to the imposition power. Electrical resistance of the oiliness rubber behaves such that it is large if the imposition power is large, but in the case of a relatively small imposition power, it is difficult to measure it for stability. Please note that the weight ratio of the materials used in the MCF oiliness rubber in Fig. 3 were Ni: 3 g, Cu: 3 g, MF: 4 g, and SH9550: 10 g; the size was 0.37 mm, a square piece 20 mm x 16 mm.

| Figure 1. Photograph of magnetic clusters of MCF (Cu at 3g, HQ at 3g, MF at 4g) |

| Figure 2. Photograph of magnetic clusters of MCF (Cu at 3g, Ni at 3g, MF at 4g) |

| Figure 3. Resistance-pressure relation of the oiliness MCF rubber |

2.2. Aqueous MCF Rubber

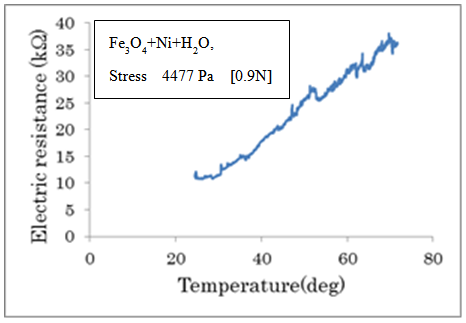

- In the same way, we mixed nickel powder (Ni123, length 3-7 μm), copper powder (MF-D2, length 8-10 μm) and MCF consisting of MF (water-based, Sigma Chemistry Co., Ltd.) into LATEX natural rubber.To manufacture the MCF rubber, we then held it between facing permanent magnets (surface Magnetic flux density about 5000 gauss) and 1-mm thick nonmagnetic plates to stiffen under a magnetic field. Because water was in both the rubber and MF, we decided to call this product “aqueous MCF rubber’. In addition, we used neither nickel powder nor copper powder. Of course, the conductive characteristics were expected to change. As for the aqueous MCF rubber and oiliness MCF rubber, a magnetic cluster exists in the magnetic field direction, because they stiffened under a magnetic field. Therefore, when they receive imposition power in the thickness direction, electrical resistance falls, having conductive characteristics. In addition, a change of the resistance was seen in the aqueous MCH rubber with a small imposition power, more so than with the oiliness MCF rubber initially. In other words, the aqueous MCH rubber is highly sensitive as a sensor; its characteristics are listed in Fig. 4. The figure shows that you can measure a smaller imposition power (Newton number) with a relatively big range.

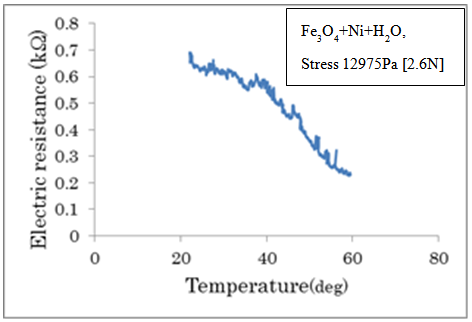

| Figure 4. Change of the electric resistance with the temperature |

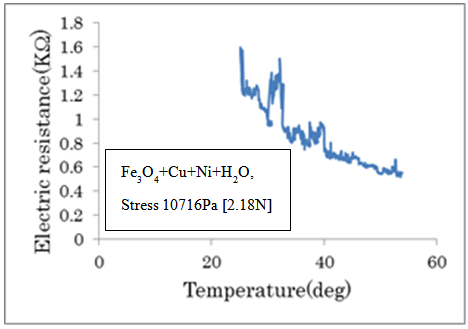

| Figure 5. Change of the electric resistance with the temperature |

| Figure 6. Change of the electric resistance with the temperature |

3. Discussion

- Aqueous MCF rubber can be made more easily and at a lower cost than conventional oiliness rubber.Experiments showed that electrical conduction has temperature-dependent characteristics in aqueous MCF rubber. Along with raised temperature, when the rubber was pressed by weak force, the electric resistance rose and showed conduction characteristics similar to metal; when pressed by strong force, the electric resistance indicated semiconduction properties.Pressing by weak force causes the electrons among the metal microparticles to move, giving the rubber conduction. However, when temperature becomes high, the violent oscillation of metal atoms interferes with free electron movements. Consequently, the resistance rises. In conditions under pressing by strong force, metal microparticles have strong coherence. Accordingly, positive holes and carrier of free electrons make current in the microworld. The carrier moves actively along with temperature elevation. Hence, resistance becomes small.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML