-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Materials Engineering

p-ISSN: 2166-5389 e-ISSN: 2166-5400

2015; 5(4): 105-108

doi:10.5923/j.ijme.20150504.05

Cleavage Parallel to the Grain for Schizolobium amazonicum Wood Specie

Diego Henrique de Almeida1, Tiago Hendrigo de Almeida2, Eduardo Chahud3, Luiz Antônio Melgaço Nunes Branco3, André Luís Christoforo4, Francisco Antonio Rocco Lahr5

1Pitágoras Faculty, Department of Engineering, Poços de Caldas Campus, Poços de Caldas, Brazil

2Department of Materials Engineering (SMM), Engineering School of São Carlos (EESC), São Paulo University (USP), São Carlos, Brazil

3Faculty of Engineering and Architecture, FUMEC University, Belo Horizonte, Brazil

4Centre for Innovation and Technology in Composites (CITeC), Department of Civil Engineering (DECIv), Federal University of São Carlos (UFSCar), São Carlos, Brazil

5Department of Structures Engineering (SET), Engineering School of São Carlos (EESC), São Paulo University (USP), São Carlos, Brazil

Correspondence to: Diego Henrique de Almeida, Pitágoras Faculty, Department of Engineering, Poços de Caldas Campus, Poços de Caldas, Brazil.

| Email: |  |

Copyright © 2015 Scientific & Academic Publishing. All Rights Reserved.

Wood is one of the main raw materials utilized by man. It can be applied in furniture and package industries, and also in components for building construction, including structures. For all these purposes, it is necessary to know the physical and mechanical properties of wood specie being used. Brazilian Code ABNT NBR 7190:1997 (Design of Timber Structures), in its Annex B, presents methods for determining wood mechanical properties, among them the cleavage parallel to grain. This property is important because it relates to the design of bolted and nailed joints in timber structures. In this context, the present research aims to the experimental determination of cleavage strength parallel to grain strength for Schizolobium amazonicum (Paricá) wood specie recently used for structural purposes, in Brazil. With raising availability, due to the great production in planted areas, Paricá can achieve some segments in Brazilian exportation trade. Results showed that cleavage strength for Schizolobium amazonicum is lower when compared with traditional tropical essences, but sufficient for several structural applications.

Keywords: Cleavage parallel to the grain strength, Mechanical properties, Wood

Cite this paper: Diego Henrique de Almeida, Tiago Hendrigo de Almeida, Eduardo Chahud, Luiz Antônio Melgaço Nunes Branco, André Luís Christoforo, Francisco Antonio Rocco Lahr, Cleavage Parallel to the Grain for Schizolobium amazonicum Wood Specie, International Journal of Materials Engineering , Vol. 5 No. 4, 2015, pp. 105-108. doi: 10.5923/j.ijme.20150504.05.

1. Introduction

- Wood is a natural material and its species usually present different values of physical and mechanical properties, influenced by several factors, as example: tree origin and age, grain direction, moisture content [1-3]. Researches about physical and mechanical properties have been carried out aiming to provide subsidies for better use of wood in building construction, industries of furniture and packaging, among the different sectors that can pursue it as a raw material [4, 5].Wood can be be applied for structural purposes like bridges [6], roofs [7, 8], footbridges [9], frameworks [1] and some kind of packages, if their physical, strength and stiffness properties are known, for allowing the designs development according to Standard Codes, as the Brazilian ABNT NBR 7190:1997 - Design of Timber Structures [10].Annex B of Code ABNT NBR 7190:1997 [10] provides experimental procedures for determining wood physical and mechanical properties, necessary to substantiate structural design. Cleavage strength parallel to grain is a very important one, mainly for design of structural joints, for all types of structures. Brazilian procedures for determining cleavage strength are similar to the adopted by ASTM D143 [11].Although to know the values of cleavage parallel to grain strength is essential in evaluation of structural joints, it's fundamental to observe that some related problems can occur due to procedures of nailing and screwing [12-16]. Other import cracking causes to consider, as reported by several researches, are moisture content changes, mainly if occurred in short time intervals, in wood drying [1, 3, 17].In this context, the present research aims to the experimental determination of cleavage strength parallel to grain strength for Schizolobium amazonicum (so-called Paricá) wood specie recently used for structural purposes, in Brazil, With raising availability, due to the great production in planted areas, Paricá can achieve some segments in Brazilian exportation trade, aspect that valorizes this paper.

2. Material and Methods

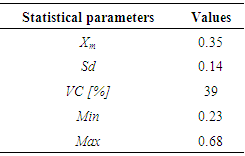

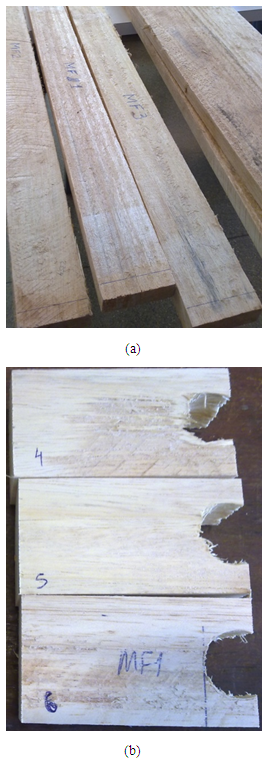

- The experimental procedures of this work were carried out in two institutions: in Wood and Timber Structures Laboratory (LaMEM), Structural Engineering Department (SET), São Carlos Engineering School (EESC), São Paulo University (USP); and in FUMEC University, Belo Horizonte, both in Brazil.For this research, lumber of Schizolobium amazonicum specie (twenty pieces), obtained from a planted forest, located Northern Region of Brazil (Paragominas, Pará State), was used.The specimens (Fig. 1) were prepared, one per piece, in standard condition of moisture content (12%), according to ABNT NBR 7190: 1997 [10]. Half of the specimens were tested in LaMEM and half in FUMEC installations.

| Figure 1. (a) Pieces of Schizolobium amazonicum Wood specie for speci- mens preparation; (b) Standard specimens for determination of cleavage strength |

| Figure 2. (a) Universal testing machine AMSLER; (b) Testing cleavage specimen |

| (1) |

3. Results

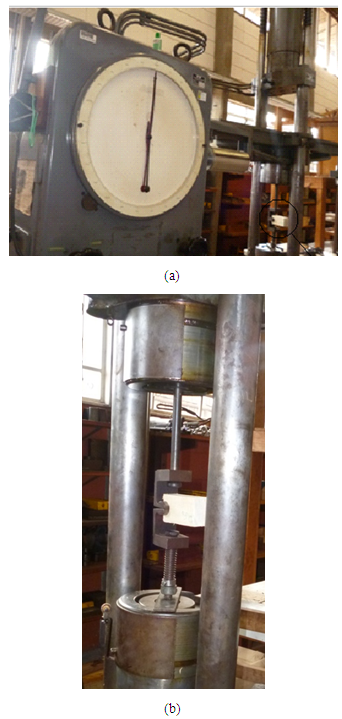

- Table 1 presents the mean values of cleavage strength (Xm), standard deviation (Sd), variation coefficient (VC) and maximum (Max) and minimum (Min) values obtained by Standard tests.

|

4. Conclusions

- Schizolobium amazonicum presents a little low average value of cleavage strength parallel to the grain, in comparison with other Brazilian wood species (of same strength class, C20).Even so, it’s possible to consider Schizolobium amazonicum sufficient for structural purposes, since proper joints calculation is carried out.

ACKNOWLEDGMENTS

- Authors would to thank to Wood and Timber Structures Laboratory (LaMEM), Structural Engineering Department (SET), São Carlos Engineering School (EESC), São Paulo University, by the materials and resources used in this research. Also, thank to CAPES, for financial supports.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML