-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Materials Engineering

p-ISSN: 2166-5389 e-ISSN: 2166-5400

2015; 5(2): 17-22

doi:10.5923/j.ijme.20150502.01

Material Selection for Crusher Jaw in a Jaw Crusher Equipment

Adelana Rasaki Adetunji1, 2, Abiodun Ayodeji Abioye1, 2, Dayo Adeyemi Isadare1, 2, Kunle Joseph Akinluwade1, 2

1Department of Engineering, Prototype Engineering Development Institute (PEDI), Ilesa, [National Agency for Science and Engineering Infrastructure, NASENI] Nigeria

2Department of Materials Science and Engineering, Obafemi Awolowo University, Ile-Ife, Nigeria

Correspondence to: Kunle Joseph Akinluwade, Department of Engineering, Prototype Engineering Development Institute (PEDI), Ilesa, [National Agency for Science and Engineering Infrastructure, NASENI] Nigeria.

| Email: |  |

Copyright © 2015 Scientific & Academic Publishing. All Rights Reserved.

There have been reported cases of the crusher jaw failure due to the high level of impact, tear and shear stresses experienced by the crusher jaw during service. The purpose of this paper is to select a suitable candidate material for the design of crusher jaw that can sustain fracture by any of the three modes of failure – tear, shear and impact at low cost using CES EduPack.

Keywords: Crusher jaw, Material selection, CES EduPack, Fracture,Comminution

Cite this paper: Adelana Rasaki Adetunji, Abiodun Ayodeji Abioye, Dayo Adeyemi Isadare, Kunle Joseph Akinluwade, Material Selection for Crusher Jaw in a Jaw Crusher Equipment, International Journal of Materials Engineering , Vol. 5 No. 2, 2015, pp. 17-22. doi: 10.5923/j.ijme.20150502.01.

Article Outline

1. Introduction

- The mining and preparation of ore for extraction of the valuable minerals and production of a commercial end product of such minerals is called mineral processing or ore dressing. Apart from regulating the size of the ore, it is a process of physically separating the grains of valuable minerals from the gangue minerals, to produce an enriched portion, or concentrate, containing most of the valuable minerals, and a discard, or tailing, containing predominantly the gangue minerals (Wills and Atkinson, 1991). Mineral processing is the art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock, or gangue. It is the first process that most ores undergo after mining in order to provide a more concentrated material for the procedures of extractive metallurgy. The primary operations are comminution and concentration.The first mechanical stage in mineral processing is comminution which involves liberation of valuable minerals from the gangue. It is usually a dry operation carried out in two or three stages. The large lumps of the run mines are reduced in the primary crushing stage; this can reduce the lump of 1.5m to 10-20 cm using jaw crushers. Primary crushers are commonly designed to operate 75% of the available time, mainly because of interruptions caused by insufficient crusher feed and by mechanical delays in the crusher (Lewis, et.al, 1976). The reclaiming operations of the primary crusher products from the ore storage to the disposal of the final crusher product involves the secondary crushing process, it is usually between 0.5 and 2cm. the secondary plant consists of appropriate crushers and screens, this is one or two size reduction stages, although more than two size reduction stages may be involved in secondary crushing if the ore is extra hard or in a case to minimize the production of fines. For slippery and tough ore, the tertiary crushing stage is usually substituted by coarse grinding in rod mills.The heavy duty machines use in the first mechanical stage of comminution are mainly jaw crushers. The distinctive feature of this class of crusher is the two plates which open and shut like animal Jaws (Grieco and Grieco, 1985), this jaw is called crusher jaw. The crusher jaws are set at an acute angle such that one jaw is pivoted and the other jaw is fixed. The pivoted jaw swings around the pivot and make impact on the fixed jaw, crushing the fed lumps in the jaw crusher. Essentially, the task of selection is that of matching the choice of material to the requirements of the design (Ashby, 2005 and Charles et.al., 1997) Novel or well selected materials provide designers with excellent features. For instance, new materials offer promising perspectives in assisting automotive engineers to achieve improvement in vehicle fuel efficiency (Hemanth, et. al, 2011).They have been reported cases of the crusher jaw failure due to the high level of impact, tear and shear stresses experienced by the crusher jaw during service. The purpose of this paper is to select a suitable candidate material for the design of crusher jaw that can sustain fracture by any of the three modes of failure – tear, shear and impact at low cost using CES EduPack. The CES material and process selection software is an example of such a computer implementation (Ashby, 2005). Other analytical techniques may also be adopted for various designs (Chan and Zhou, 1994 and Dieter, 1991).

2. Methodology

- The method of Function-Objectives-Constraints used by Akinluwade et al., (2015b) was applied in this study. The essentials of the study methodology are described in the next sub-sections.

2.1. Design and Function

- An impact mechanism was designed in Pro- Engineer (Pro-E) to simulate the loading conditions of a typical jaw crusher. It was deduced that a load of 3.28 x 108 Pa may cause failure of the hammer. CES EduPack was applied to select materials for the crusher jaw using the Function-Objectives-Constraints approach. The specific function of a crusher jaw is to propagate and sustain fracture by any of three modes of failure-tear, shear and impact.

2.2. Constraints and Objective

- Constraints represent crucial non-negotiable design conditions to be met. Constraints for the design of the crusher jaw are: Contact stress must not cause damage to either surface; toughness (for pivots exposed to shock loading) not be lower than 1.3 x 108 Pa.m0.5; thermal expansion (for high frequency crushers) not beyond 10 x 10-5; hardness not lower than 4.9 x 109 Pa with yield strength not beyond 1.80 x 109 Pa and cost not beyond 10 USD/Kg. Technical constraints were deduced from dynamic simulation while cost constraint is an administrative decision. Objectives represent what the design is required to maximize, minimize or maintain in its function (Akinluwade, et al., 2014b). Accordingly, the crusher jaw is require to propagate and sustain fracture by any of three modes of failure—tear, shear and impact.

3. Result and Discussion

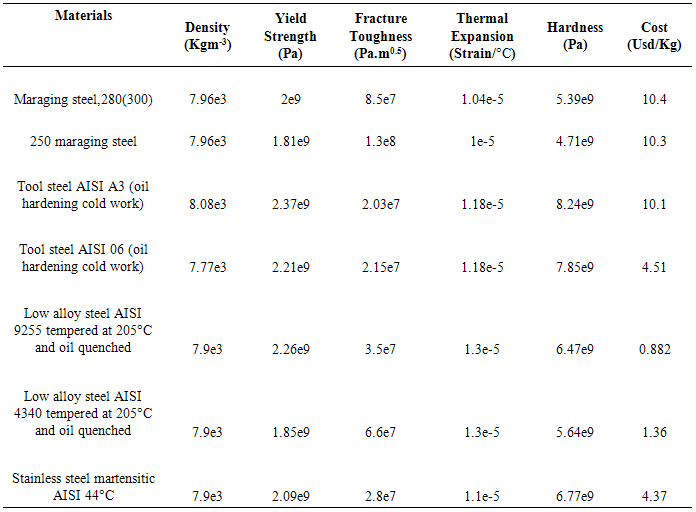

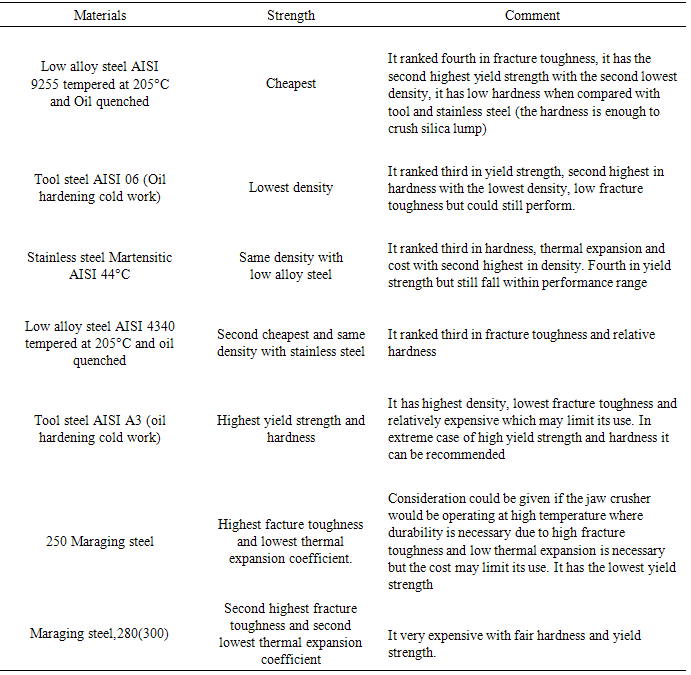

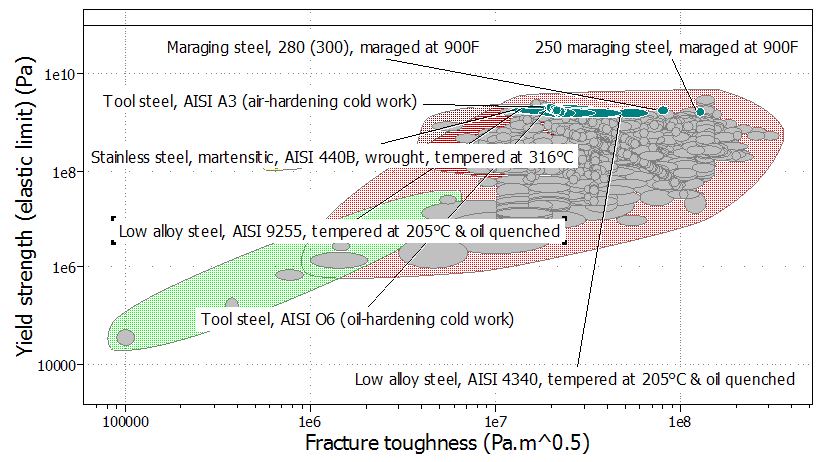

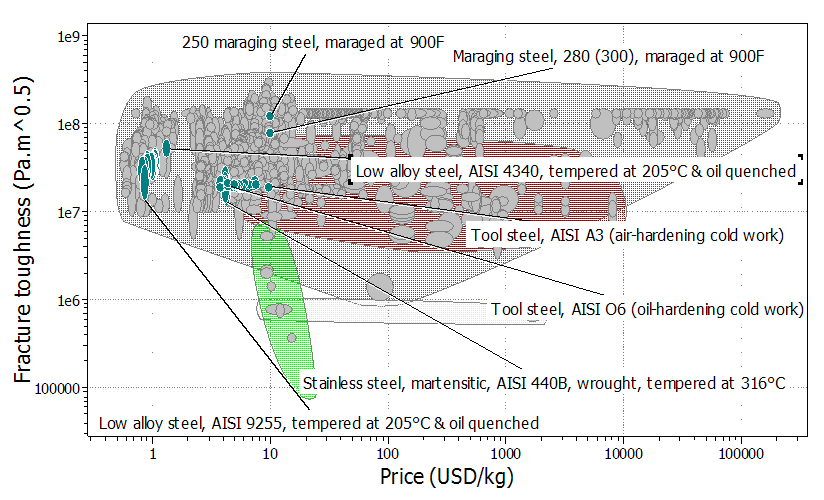

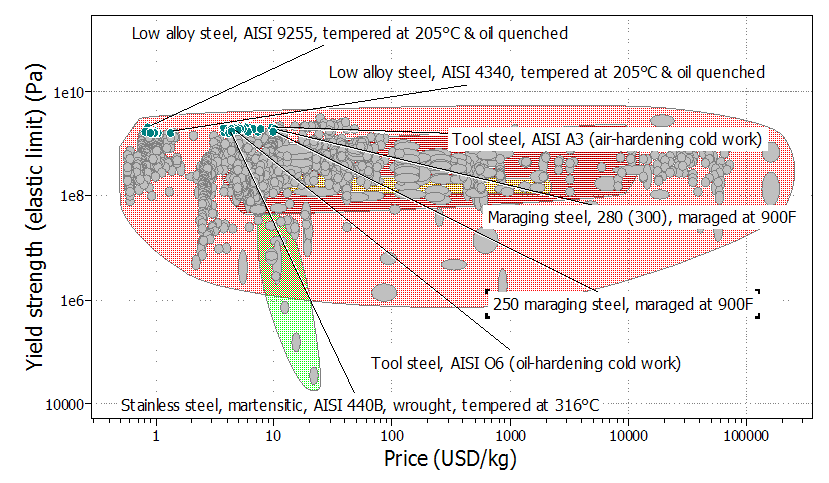

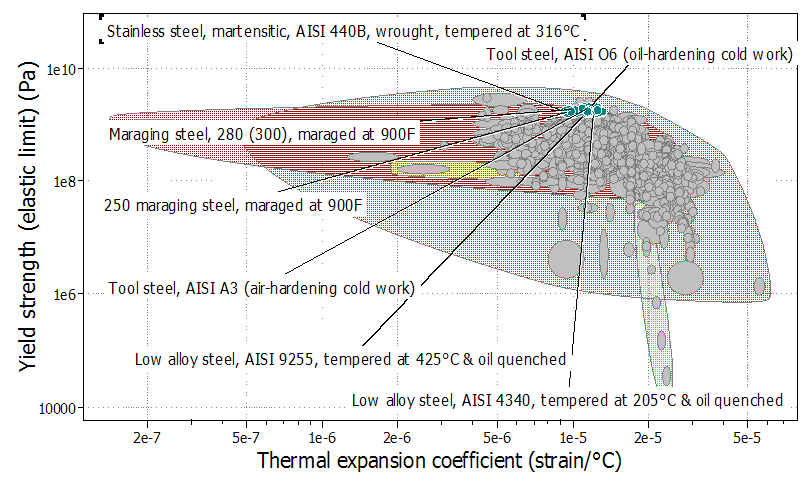

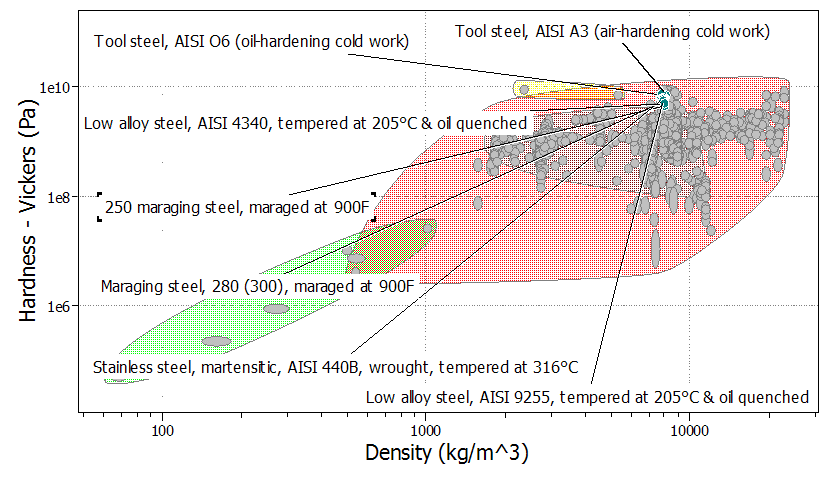

- For the purpose of this application where preference is given for impact strength, all material families other than steel were screened off. The selection collection now parades stainless steel, low alloy steel, tool steel and maraging steel. Ranking was done on the basis of Fig 1 (Yield strength as a function of fracture toughness), Fig 2 (Fracture toughness as a function of price), Fig 3 (Yield strength as a function of price), Fig 4 (Yield strength as a function of thermal expansion coefficient), Fig 5 (Hardness (Vickers) as a function of density) and Table 1 (Material properties values considered for selected candidate materials). The final material selected is Low alloy steel AISI 9255 tempered at 205C and Oil quenched, although it ranked fourth in fracture toughness, it has the second highest yield strength with the second lowest density, it has low hardness when compared with tool and stainless steel (the hardness is enough to crush silica lump) and is the cheapest. The choice of Low alloy steel AISI 9255 tempered at 205℃ and Oil quenched gives better performance while minimizing cost.

| Figure 1. Yield strength as a function of fracture toughness |

| Figure 2. Fracture toughness as a function of price |

| Figure 3. Yield strength as a function of price |

| Figure 4. Yield strength as a function of thermal expansion coefficient |

| Figure 5. Hardness (Vickers) as a function of density |

|

|

4. Conclusions

- The study concluded that Low alloy steel AISI 9255 tempered at 205C and oil quenched is the material choice that maximizes performance and minimizes cost for crusher jaw in applications whose service requirements are bounded by the stated constraints. This choice lowers production cost appreciably while also upholding performance in all essential aspects of the service environment.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML