S. I. Durowaye1, G. I. Lawal1, M. A. Akande1, V. O. Durowaye2

1Department of Metallurgical and Materials Engineering, University of Lagos, Akoka, Lagos, Nigeria

2Department of Chemistry, International School, University of Lagos, Akoka, Lagos, Nigeria

Correspondence to: S. I. Durowaye, Department of Metallurgical and Materials Engineering, University of Lagos, Akoka, Lagos, Nigeria.

| Email: |  |

Copyright © 2014 Scientific & Academic Publishing. All Rights Reserved.

Abstract

Reinforcement of polymers by particulates plays an important role in the improvement of the mechanical and physical properties of high performance materials. Hence, the mechanical behaviour of coconut shell and palm fruit particulate polyester composites was studied in order to develop an engineering material for industrial application. Coconut shell and palm fruit particles were separately and thoroughly blended with polyester resin. 1g of catalyst and 0.5g of accelerator were added to the mixture to achieve a good homogenous interfacial interaction. Particles of the reinforcement with different weight fractions (5, 10, 15, 20, 25 and 30) wt. % were added to 95g, 90g, 85g, 80g, 75g and 70g corresponding weight of polyester resin. For the 5% weight of reinforcement, there is a corresponding 95g of polyester resin used. The samples were made by mould casting and the mechanical properties of the developed composites were evaluated. The ultimate tensile strength of 70MPa was obtained for the coconut shell particulate polyester composite, while that of palm fruit particulate polyester composite was 62.5MPa. The highest impact strength value for coconut shell particulate polyester composite was 4.76J, while that of palm fruit particulate polyester composite was 4.60J. The highest hardness value for coconut shell particulate polyester composite was 208 BHN while that of palm fruit particulate polyester composite was 182.30 BHN. To know the maximum strength that the coconut shell and palm fruit particulate polyester composites can withstand while being stretched or pulled before breaking, their weight % (reinforcement) must be kept below 10 and 20% respectively. To measure the resistance of the coconut shell and palm fruit particulate polyester composites to, indentation or penetration such as abrasion, drilling, impact and scratches, the weight % (reinforcement) must be kept at 10 and 20% respectively.

Keywords:

Mechanical properties, Polyester, Coconut shell, Palm fruit, Composite

Cite this paper: S. I. Durowaye, G. I. Lawal, M. A. Akande, V. O. Durowaye, Mechanical Properties of Particulate Coconut Shell and Palm Fruit Polyester Composites, International Journal of Materials Engineering , Vol. 4 No. 4, 2014, pp. 141-147. doi: 10.5923/j.ijme.20140404.04.

1. Introduction

From time immemorial, man has always strived to make use of available materials at his disposal to better the lots of the people around him and the society in general. These efforts had led to various research works being carried out for decades by trying to find alternatives and/or substitutes for some materials that appear to have outlived their existence. Studies on composites have shown that new materials have been discovered such as metal matrix composites, ceramic matrix composites and polymeric composites which were all found to be capable replacements in the many industrial applications, when compared to old used materials. There have been little developments in the use of natural fiber or particulates as reinforcement materials for polymeric composite. Though findings have shown that natural fillers reinforced polymeric materials provide materials engineers with a new group of materials that offer exceptional combinations of mechanical properties that make them equivalent to steel applications. There is need to make use of available materials/resources to produce composites with unusual combination of properties that no traditional materials like ceramics, polymeric materials or alloys possess. It is the applications of these materials used in the industries that are the driving force behind the discovery of new materials which has led to the designing of materials for specific applications often called composites. Generally, composite are produced when two or more materials are joined together to give combination of properties that cannot be attained otherwise [1]. According to the principle of combined action, better property combinations are fashioned by the judicious combination of two or more distinct materials. Composites of sorts include multiphase metal alloys, ceramics, and polymers. There are also a number of composites that occur in nature. For example, wood consists of strong and flexible cellulose fibers surrounded and held together by a stiffer material called lignin. Bone is a composite of the strong yet soft protein collagen and the hard, brittle mineral apatite. Also teeth and abalone shell. A composite is a multiphase material that is artificially made, as opposed to one that occurs or forms naturally [2]. In a composite, one phase is equally continuous and it is known as the matrix while the other phase is known as the reinforcement and it is distributed within the matrix. It may be in the form of fibrous or particulate. In addition, the constituent phases must be chemically dissimilar and separated by a distinct interface. Thus, most metallic alloys and many ceramics do not fit this definition because their multiple phases are formed as a consequence of natural phenomena. Most composites have been created to improve combinations of mechanical characteristics such as strength, stiffness, toughness, ambient and high-temperature [3].Polymer-matrix composite (PMCs) consists of polymer resin (a high molecular weight reinforcing plastic) as the matrix with particulate as the Polymer-matrix composite (PMCs) consists of polymer resin (a high molecular weight reinforcing plastic) as the matrix with particulate as the reinforcement medium [4]. The primary functions of the matrix are to transfer stress between the reinforcing fibres or particulate, act as a glue to hold the fibers together and protect it from mechanical and environmental damage [5]. However, fibers and particulate (reinforcement) are hydrophilic in nature, so they take in water. These materials are used in producing greater composite and larger quantities in respect to their room temperature properties, cost and ease to fabricate. Particulate composite produced have distinct properties rather than to improve strength, it contains large amounts of coarse particles that do not block slip effectively [6]. Optimizing the thermal properties of groundnut shell particle reinforced polymer composite materials have been studied. The composite specimens were prepared with varying weight percentage of groundnut shell particles in polymer matrix. The result reveals that using groundnut shell as reinforcement could develop beneficial composites and can be used for thermal applications [7]. The mechanical and thermal properties of date palm fiber and coconut shell particulate filler reinforced epoxy composite have been studied. The composite was fabricated by hand lay-up technique. The filler content in the composite is kept constant at 20 wt% while epoxy composite is reinforced with date palm fibers, coconut shell particle filler, and date palm fibers/coconut shell particle filler hybrid respectively. The results show that these fillers may yield reasonable properties and could be used for low cost applications [8]. The thermal, mechanical and morphological properties of polypropylene clay and wood flour nanocomposites were studied. The compaction of all these fillers in the matrix improves the thermal stability. The tensile modulus and strength of most of the hybrids were highly increased with increased loading of clay [9]. Treated tropical wood sawdust polypropylene polymer composite was studied in order to improve the mechanical and morphological properties. Results indicated that the mechanical properties of the chemically treated sawdust polypropylene composite were found to be higher than those of the raw ones [10]. To cope with the obvious limitations of polymers, for example, low stiffness and low strength, and to expand their applications in different engineering areas, different types of particulate fillers are often added to process polymer composites, which normally combine the advantages of their constituent phases. Reinforcement of polymers by particulates plays an important role in the improvement of the mechanical and physical properties of high performance materials. Hence, the mechanical behaviour of coconut shell and palm fruit particulate polyester composite is studied in order to develop an engineering material for industrial application.

2. Experimental Procedure

2.1. Materials

The materials used for this study are unsaturated polyester resin (matrix), methyl ethyl ketone peroxide (catalyst), cobalt Naphthanate (Accelerator), masking tape (mould release agent), coconut shell and palm fruits. They were all sourced locally in Lagos.

2.2. Equipment/Apparatus

The equipment used for this study are: Electronic weighing balance, Sets of beakers, Small containers, Hand-gloves, A petty dish, Syringe, A pair of scissors, Instron testing machine, Testometric universal testing machine, Brinell testing machine and Impact testing machine. Sieve Bowl (80 BSS).

2.3. Collection and Processing of Coconut Shell and Palm Fruit

The coconut shell was got from Sebasi Coconut Company in ancient city of Badagry, Lagos while the palm fruits were bought at Iworo market in Badagry. The coconut shell and palm fruits were dried for 5 days, cleaned thoroughly, firstly ground by manual hammering, then through hammer milling machine and finally through ball milling machine to get them into powdery particulate forms. A sieving bowl of 80 BSS (British standard size) was used to sieve the particulates so as to have homogenous reinforcement-matrix interfacial mixture.

2.4. Weighing of the Materials

The unsaturated polyester resin was weighed using an electronic weighing machine with the use of the beaker placed on the petty dish. The polyester resin was added gradually into the beaker until the weight indication observed is equal to the required polyester amount needed for that particular mixture with reinforcement particulates. The same process was repeated for other polyester amount needed for the other particulate mixture. The catalyst (methyl ethyl ketone peroxide) was weighed using the electronic machine with the use of beaker placed on the weighing machine. With the help of a syringe, the quantity of the catalyst needed was taken and poured by drops into the beaker containing the reinforcement-matrix mixture. With the indicator on the weighing machine, the pouring by drops of catalyst was stopped once 1g of catalyst is obtained. The same procedure was used for the accelerator (cobalt Naphthanate) but 0.5g was used.

2.5. Samples Production

The polyester resin matrix was weighed using an electronic weighing balance such that there is an interval of 5g between the polyester poured into the beaker for mixture with coconut shell particulate reinforcement. For the 5% weight of coconut shell particles reinforcement, there is a corresponding 95g of polyester resin poured into the beaker using electronic weighing balance after which 1g of catalyst and 0.5g of accelerator were added to the mixture to give better homogenous interfacial interactions. For 10%, 15%, 20%, 25% and 30% wt reinforcement, 90g, 85g, 80g, 75g and 70g respectively of polyester resin were used. Also the same 1g of catalyst and 0.5g, of accelerator were equally added to each mixture and stirred thoroughly after which the mixture was poured into the wooden moulds for casting. The same procedure was used for the palm fruit particles. The wooden mould cavity for impact, tensile, flexural and hardness were done separately based on their dimensions (shape, size). The dimension for flexural and hardness tests are 140mm x 50mm x 5mm, the dimension for impact test is 60mm x 10mm x 10mm while that of tensile test is 26mm x 150mm x 10mm. A total of 60 samples were produced such that there were 12 mould samples each for impact and tensile tests for coconut shell and for palm fruit totalling 48 samples while 6 mould samples were for both hardness and flexural tests for coconut shell and palm fruit totalling 12 samples. The moulds were coated with a mould release agent masking tape so as to allow it to cure and be easy to remove after curing. The process was repeated for all the mould samples to be cast and after curing, the samples were stripped from the mould. Particulate coconut shell polyester and particulate palm fruit polyester composites were developed and their mechanical properties were evaluated. The tensile testing was performed using an Instron universal testing machine. Impact testing machine was used for the impact test. The Brinell hardness testing machine was used to carry out the hardness test. Testometric universal testing machine was used for the flexural test.

3. Results and Discussion

Table 1. At 5wt % particulate for Coconut shell and Palm fruit with 95g of polyester matrix

|

| |

|

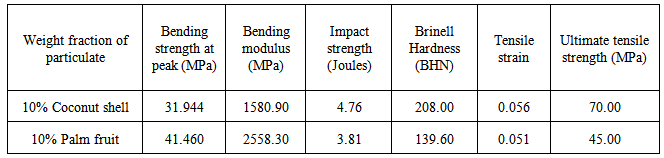

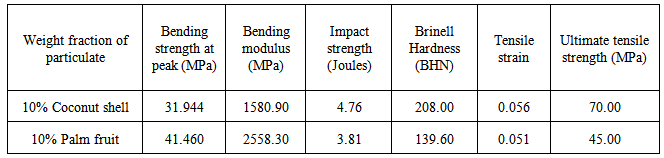

Table 2. At 10wt % particulate for Coconut shell and Palm fruit with 90g of polyester matrix

|

| |

|

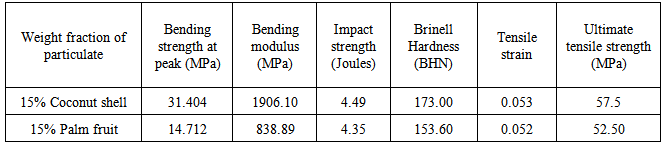

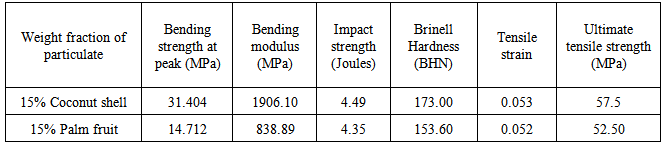

Table 3. At 15wt % particulate for Coconut shell and Palm fruit with 85g of polyester matrix

|

| |

|

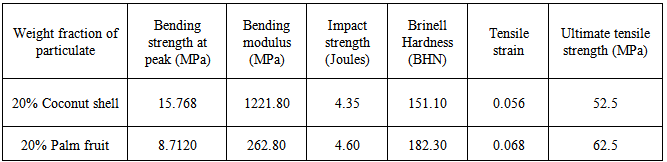

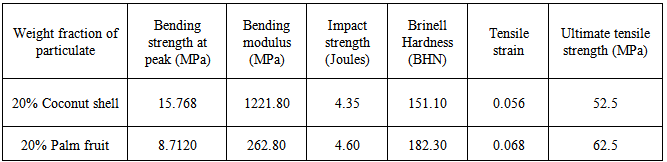

Table 4. At 20wt % particulate for Coconut shell and Palm fruit with 80g of polyester matrix

|

| |

|

Table 5. At 25wt % particulate for Coconut shell and Palm fruit with 75g of polyester matrix

|

| |

|

Table 6. At 30wt % particulate for Coconut shell and Palm fruit with 70g of polyester matrix

|

| |

|

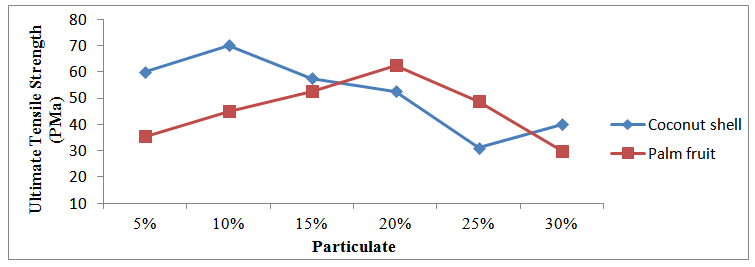

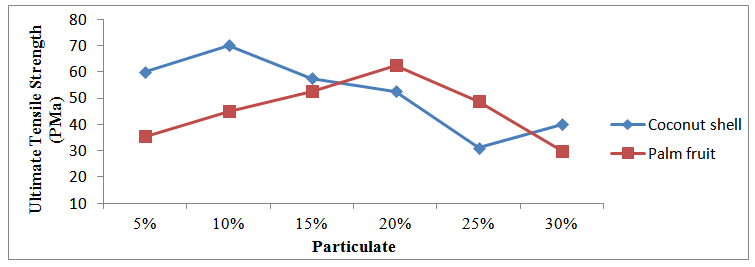

3.1. Ultimate Tensile Strength

In figure 1, the coconut shell particles reinforced polyester composite has the highest tensile strength value of 70MPa at 10wt % reinforcement. The lignin content in coconut shell particles consist of polar hydroxyl groups, benzene rings and non-polar hydrocarbon which is capable of enhancing the adhesion between the reinforcement and the matrix [11]. The palm fruit particles reinforced polyester composite recorded a progressive increase in tensile strength until it reaches a maximum value of 62.5MPa at 20wt %. This is due to the increase in surface area, good distribution and dispersion of the reinforcement in the matrix. This results into strong particles–matrix interaction which increases the ability of the particles to restrain gross deformation of the matrix. A general decrease in ultimate tensile strength is observed beyond 20wt % (palm fruit particles reinforced polyester composite) and 10wt % (coconut shell particles reinforced polyester composite). This may be due to increase in discontinuity between the particles surface and the matrix as the reinforcement concentration increases in the two composites. | Figure 1. Ultimate tensile strength of particulate polyester composite |

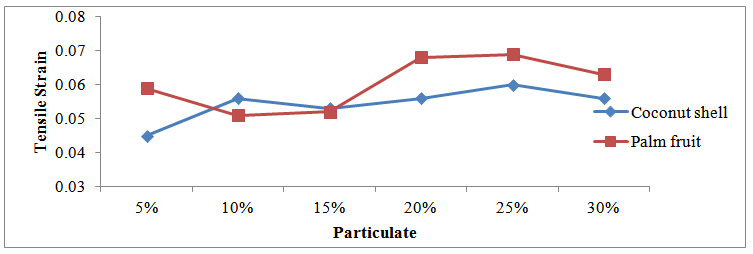

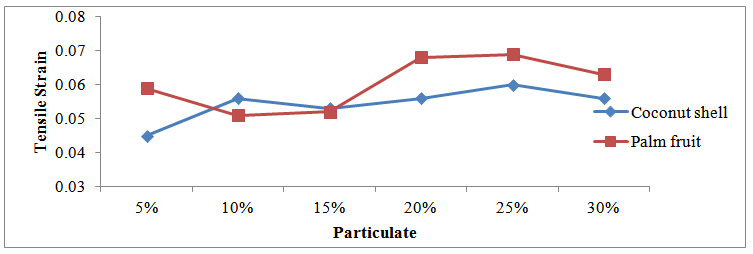

3.2. Tensile Strain

In figure 2, both composites show increasing strain (ductility) as reinforcement concentration increases. The highest strain values of 0.06 and 0.069 at 25wt % reinforcement of coconut shell and palm fruit particles respectively were obtained. Increase in reinforcement concentration above 25wt % reduces the elasticity of the matrix. This enhances rigidity and causes a decrease in tensile strength and ductility as a result of restriction in the polymer matrix movement. The ductility at break decreased upon filler addition for composites regardless the nature of the filler. At higher filler content, the domination of filler-matrix interaction can be expectable to subside and being substituted by filler-filler interaction [12]. | Figure 2. Tensile Strain of particulate polyester composite |

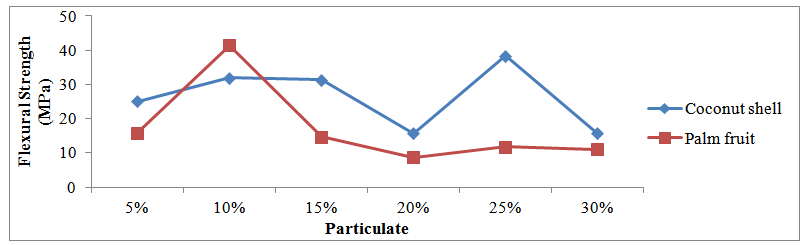

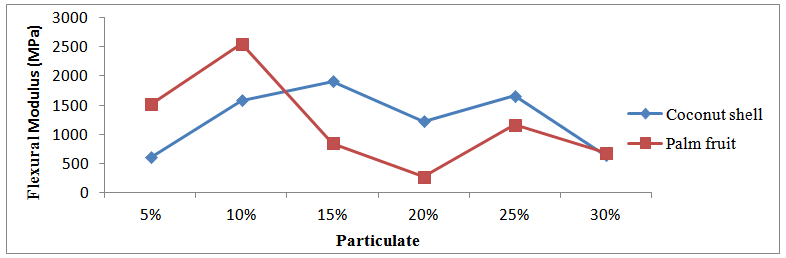

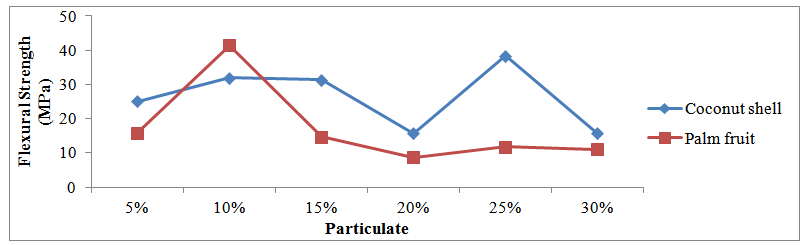

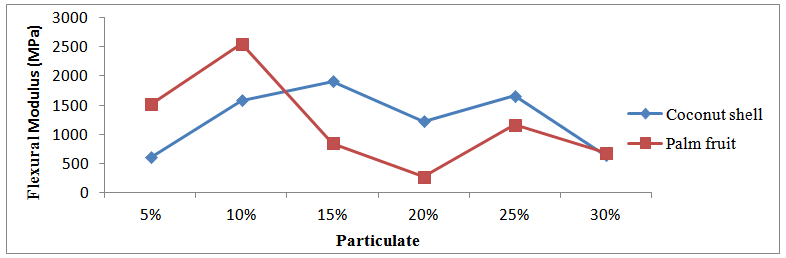

3.3. Flexural Properties

The flexural properties of composites depend critically on the microstructure of the composite and the interfacial bonding between the reinforcement and the matrix [13]. In figures 3 and 4, both flexural strength and modulus of the two composites increased with increase in reinforcement content at 10wt %. This is due to the strong interfacial adhesion/bonding between the particles and the matrix which enhances load transfer [14]. The later decrease in flexural strength and modulus is due to agglomerate formation at higher concentrations of the reinforcement of the two composites which is also observed in the tensile behaviour. | Figure 3. Flexural strength particulate polyester composite |

| Figure 4. Flexural modulus of particulate polyester composite |

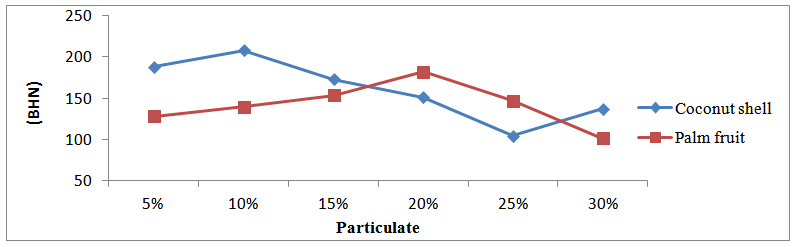

3.4. Hardness Result

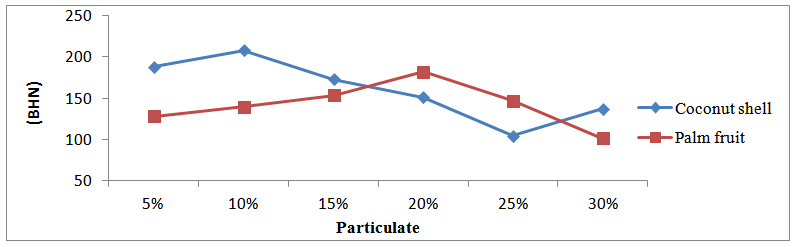

The hardness behaviour of the two composites is shown in figure 5. For coconut shell particulate polyester composite, the hardness value increases up to a maximum value of 208 BHN at 10wt %. Beyond this reinforcement value, its hardness decreases. For palm fruit particulate polyester composite, the hardness value increases up to a maximum value of 182.3 BHN at 20wt % and reduces as reinforcement increases. | Figure 5. Brinell hardness of particulate polyester composite |

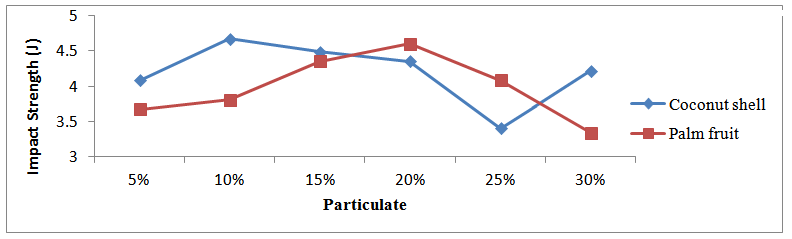

3.5. Impact Strength Result

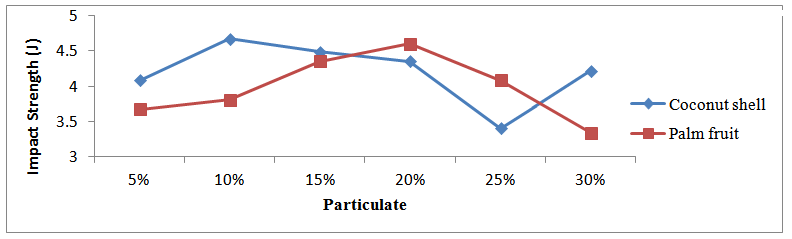

The response to impact shock of the two composites is shown in figure 6. For coconut shell particulate polyester composite, the impact strength increases up to a maximum value of 4.76J at 10wt %. Beyond this reinforcement value, its impact strength decreases. For palm fruit particulate polyester composite, the impact strength increases up to a maximum value of 4.60J at 20wt % and reduces as reinforcement increases. The increase in impact strength of the composites is due to increase in elasticity of the composite thereby increasing the deformability of the matrix [15]. As the concentration of the reinforcement increases, there is poor interfacial adhesion between the polymer matrix and the particles resulting into occurrence of micro-cracks at the point of impact which decreases the impact strength. The decrease in impact strength is due to the inability of the reinforcements to block the crack propagation resulting in reduction of the impact strength [16]. | Figure 6. Impact strength of particulate polyester composite |

4. Conclusions

To measure the ductility of the composite using coconut shell and palm fruit polyester particulate, the weight % (reinforcement) must not exceed 25%. To know the maximum strength that the coconut shell and palm fruit particulate polyester composites can withstand while being stretched or pulled before breaking, their weight % (reinforcement) must be kept below 10 and 20% respectively. To measure the resistance of the coconut shell and palm fruit particulate polyester composites to, indentation or penetration such as abrasion, drilling, impact and scratches, the weight % (reinforcement) must be kept at 10 and 20% respectively. To know the tendency of coconut shell and palm fruit particulate polyester composites to bend, there is need to keep the weight % (reinforcement) at 15 and 10% respectively. To measure the coconut shell and palm fruit particulate polyester composites’ ability to resist deformation under load, the weight % (reinforcement) at peak must be kept at 25and 10% respectively. To know the capability of the coconut shell and palm fruit particulate polyester composites to withstand sudden applied load in terms of energy, the weight % (reinforcement) should not exceed 10 and 20% respectively. In this study, coconut shell and palm fruit particles enhanced the mechanical properties of the polyester matrix composites. They are potential materials for interior applications such as gear cams, car seat, dash board, and car interior for decorative purposes or other interior parts of automobile where high strength is not considered a critical requirement.

ACKNOWLEDGEMENTS

The authors would like to thank Professor S.B. Hassan and Dr. L.O. Osoba, Department of Metallurgical and Materials Engineering, University of Lagos for their valuable assistance.

References

| [1] | Han-Seung Yang, Hyun-Joong Kim, Jungil Son, Hee-Jun Park, Bum-Jae Lee, Taek-Sung Hwang (2004): “Rice-husk flour filled polypropylene composites; mechanical and morphological study”. Elsevier Composite Structures 63 (2004) 305–312. |

| [2] | Chandramohan D. and K. Marimuthu (2011): “Drilling of natural fiber particle reinforced polymer composite material”, International Journal of Advanced Engineering Research and Studies. Vol. 1. Issue 1.October-December, 2011. Pg.134-145. E-ISSN2249 – 8974. |

| [3] | Mariana Etcheverry and Silvia E. Barbosa (2012): "Glass Fiber Reinforced Polypropylene Mechanical Properties Enhancement by Adhesion Improvement". Materials 2012, 5, 1084-1113. ISSN: 1996-1944.www.mdpi.com/journal/materials. |

| [4] | Netra L. Bhandari, Sabu Thomas, Chapal K. Das and Rameshwar Adhikari (2012): “Analysis of Morphological and Mechanical Behaviours of Bamboo Flour Reinforced Polypropylene Composites”. Nepal Journal of Science and Technology Vol. 13, No. 1 (2012) 95-100. |

| [5] | Omar Faruk, Andrzej K. Bledzki, Hans-Peter Fink, Mohini Sain (2012): “Bio-composites reinforced with natural fibers: 2000–2010”. Elsevier: Progress in Polymer Science 37 (2012)1552–1596. www.elsevier.com/locate/ppolysci. |

| [6] | Nadir Ayrilmi; Songklod Jarusombuti; Vallayuth Fueangvivat; Piyawade Bauchongkol and Robert H. White (2011): “Coir Fiber Reinforced Polypropylene Composite Panel for Automotive Interior Applications”. Fibers and Polymers 2011, Vol.12, No.7, 919-926. |

| [7] | Raju, G.U; Gaitonde, V.N and Kumarappa, S (2012): “Experimental Study on Optimization of Thermal Properties of Groundnut Shell Particle Reinforced Polymer Composites”. International Journal Emerging Science, 2(3), 433-454, September 2012. ISSN: 2222-4254. |

| [8] | Sewench N. Rafeeq; Inaam M. Abdulmajeed and Areej Riyadh Saeed (2013): “Mechanical and Thermal Properties of Date Palm Fiber and Coconut Shell Particulate Filler Reinforced Epoxy Composite”. Indian Journal of Applied Research Vol. 3 Issue. 4. April 2013. ISSN - 2249-555X. |

| [9] | Lee, S.Y; Kang, I. A; Doh, G.H; Kim, W.J; Kim, J.S; Yoon, H.G; Wu, Q. Thermal (2008): “Mechanical and morphological properties of polypropylene/clay/wood flour Nanocomposites”. International Journal of Emerging Sciences. eXPRESS Polymer Letters Vol.2, No.2 (2008) 78–87. |

| [10] | Muhammad Abdul Mun’aim Mohd Idrus; Sinin Hamdan; Muhammad Rezaur Rahman and Muhammad Ssiful Islam (2011), “Treated Tropical Wood Sawdust-Polypropylene Polymer Composite: Mechanical and Morphological Study”. Journal of Biomaterials and Nano-biotechnology, 2011, 2, 435-444. |

| [11] | Salmah, H; Marliza, M and The, P.L (2013); ‘‘Treated Coconut Shell Reinforced Unsaturated Polyester Composites’’. International Journal of Engineering & Sciences.http://www.ijens.org/Vol_13_I_02/1310202-8383-IJET-IJENS.pdf. |

| [12] | Salmah, H; Marliza, M and The, P.L (2013); ‘‘Treated Coconut Shell Reinforced Unsaturated Polyester Composites’’. International Journal of Engineering & Sciences.http://www.ijens.org/Vol_13_I_02/1310202-8383-IJET-IJENS.pdf. |

| [13] | Subita Bhagat and Pardeep Kumar Verma (2013): ‘‘Effect of Graphite Filler on Mechanical Behaviour of Epoxy Composites’’. International Journal of Engineering Technology and Advanced Engineering. www.ijetae.com (ISSN 2250-2459, ISO 900:2008 Certified Journal, Volume 3, Issue 2, February 2013). |

| [14] | Sarojini Swain 92013): ‘‘Synthesis and Characterisation of Graphene Based Unsaturated Polyester Resin Composites’’. Department of Advanced Material Process Technology Center, Crompton Greaves Ltd., Kanjur Marg, Mumbai 400042, India. Transactions on Electrical and Electronics Materials Vol. 14, No. 2, pp 53 – 58, April 25, 2013. |

| [15] | Ritesh Kaundal; Amar Patnaik; Alok Satapathy (2012): Solis Particle Erosion of short Glass Fiber Reinforced Polyester Composite’’. American Journal of Materials Science 2012, 2(2): 22-27 DOI: 5923/j.materials.20120202.05. |

| [16] | Sabu Thomas; Kuruvilla Joseph; Sant Kumar Malhorta; Koichi Goda and Meyyarappallil Sadasivan Sreekala (2012): ‘‘Polymer Composites’’. Wiley-VCH Verlag GmbH & Co. KGaA, Volume 1. |

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML