-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Materials Engineering

p-ISSN: 2166-5389 e-ISSN: 2166-5400

2014; 4(3): 119-122

doi:10.5923/j.ijme.20140403.08

Effect of Equal Channel Angular Pressing (ECAP) on Hardness and Microstructure of Pure Aluminum

Nashith A. 1, Sanjid P. 1, Shamsudheen M. 1, Rasheeque R. 1, Ramis M. K. 1, Shebeer A. R. 1, 2

1Department of Mechanical Engineering, P. A. College of Engineering, Mangalore, India

2Research Scholar Department of Mechanical Engineering, NIT Calicut, Kerala, India

Correspondence to: Ramis M. K. , Department of Mechanical Engineering, P. A. College of Engineering, Mangalore, India.

| Email: |  |

Copyright © 2014 Scientific & Academic Publishing. All Rights Reserved.

Equal channel angular pressing (ECAP) was applied on a pure Aluminum sample and the value of hardness was investigated. It was observed that the hardness of pure aluminum have improved as a result of severe plastic deformation by ECAP. The improvement was significantly higher when compared with other conventional strengthening methods. Bulk ultra-fine grained (UFG) materials can be obtained by equal channel angular pressing (ECAP) process. Microstructure reveals that ECA pressing produces ultrafine grains. The improvement in mechanical properties is mainly attributed to both refined microstructure and high density of dislocations that may occur during ECAP. Since this method lead to an increase in hardness and tensile strength even after a single pass through the die, it is concluded that ECAP provides a simple and effective method for improving the mechanical properties of aluminum and its alloys and hence its engineering application can be broadened.

Keywords: Severe Plastic Deformation, Equal Channel Angular Pressing, Grain Refinement, Ultrafine Grains

Cite this paper: Nashith A. , Sanjid P. , Shamsudheen M. , Rasheeque R. , Ramis M. K. , Shebeer A. R. , Effect of Equal Channel Angular Pressing (ECAP) on Hardness and Microstructure of Pure Aluminum, International Journal of Materials Engineering , Vol. 4 No. 3, 2014, pp. 119-122. doi: 10.5923/j.ijme.20140403.08.

Article Outline

1. Introduction

- Materials processed by severe plastic deformation (SPD) have become an area of interest in the field of material science [1, 2]. This interest is a result of unique physical and mechanical properties enhanced by SPD methods. The different SPD methods which are under research includes, equal channel angular pressing (ECAP), high pressure torsion (HPT), multi-axial compression (MAC), accumulative roll bonding (ARB) and twist extrusion (TE) [2, 3]. The most important advantage of ECAP is that materials can be deformed to very high strain without any change in cross-sectional area ultrafine grain sizes and very large strains can be obtained, and hence receives a special attention amongst them. A major challenge for producing ultrafine-grained (UFG) materials for many structural applications need to be in bulk form and is difficult. Equal-channel angular pressing (ECAP) is one of the most promising techniques that can process bulk UFG materials large enough for structural applications [1, 4]. This method has been the subject of many studies in recent years due to its capability of producing large, fully dense samples with improved physical and mechanical properties and ultrafine (or nanometer scale) grain size [5-9]. In this technique, a metal billet is pressed through a die containing two channels, equal in cross-section intersecting at an angle.The work-piece is inserted into the top channel and pressed into the bottom channel by a plunger. During pressing, the billet undergoes severe shear deformation but retains the same cross-sectional geometry so that it is possible to repeat the pressings for a number of passes, each one refining grain size. Between each adjacent two passes, it is possible to rotate the billet around its longitudinal axis, creating different ECAP routes [10-13].The material selected for ECAP technique is Aluminum, due to its extensive use in the industries. It also yields remarkable properties like low metal density, relatively soft, durable, lightweight, ductile ability to resist corrosion. Structural components made from aluminum and its alloys are vital to the aerospace industry and are important in other areas of transportation and structural materials. Aluminum is almost always alloyed, which markedly improves its mechanical properties, especially when tempered. It is used as pure metal only when corrosion resistance or workability is more important than strength or hardness. Aluminum alloys are also the widely used material today which spans the entire range of industries. They are used in consumer products and military applications. The aircraft and aerospace industry uses aluminum alloys because it is much lighter than steel and every kilogram of weight reduction results in greater fuel savings and higher payloads. The car industry has increased its use of aluminum over the years as the price of gasoline has increased and the need to reduce vehicle weight has been of paramount importance. Today, much of aluminum’s use is to reduce the weight of the item being produced, but it has always been popular because it is easy to machine, cast, extrude, roll, etc. and many alloys are age-hardenable. Because of the widespread use of Aluminum and its alloys, it is important to enhance their mechanical properties for better application.

2. Experimental

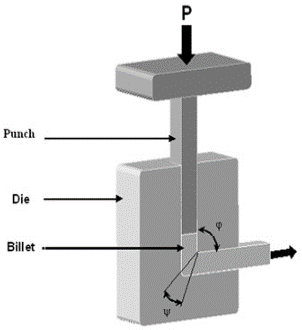

- The material used in this work is commercially available 99.6% pure aluminum. The experiments were carried out on three samples cut from an ingot and machined to a size of 11.8 x 11.8 x 65 mm. prior to the process, the samples were annealed to 450℃ and cooled slowly until the furnace temperature dropped. The experiments were carried out by using the route A (no rotation), for a single pass. The ECAP was conducted using a “three-block die” made of tool steel with an internal angle (Φ) of 900 between the vertical and horizontal channels. The angle defining the arc of curvature (ψ) at the outer point of intersection (point A in Fig. 1) was 0°. The channels had equal cross-sections. The die consisted of two side blocks and a center block. The main die geometry was machined into the center block. These three blocks were then bolted together to form a single internal channel. This design allows more convenient manufacturing and provides greater flexibility in obtaining different die geometries by changing the center block only. For multi-pass ECAP route Bc was adopted in many of the recent studies [14] because this route produces a uniform microstructure of equiaxed grains separated by high-angle grain boundaries more rapidly than other routes. Figure 2. show the schematic of ECAP and photograph of the ECAP die fitted to the hydraulic press of 25 tones capacity. Small samples were prepared for optical microscopic studies. Samples with 10 x 10 mm size and thickness 2 mm were cut from centre of pressed specimen. These samples were finely polished for taking optical images. Hardness was measured with Brinell hardness machine to obtain BHN (Brinell hardness number) and Rockwell Hardness testing machine for RHN (Rockwell Hardness Number). The hardness tests were conducted by applying the load for 15 s. Each hardness value was determined using three separate samples in the same processed condition by taking the average of seven measurements on each of them and the microstructure of all the samples were analysed using optical microscopy to find out the variation in grain refinement.

| Figure 1. Schematic diagram of ECAP |

2.1. Deformation Routes for ECAP

- Depending on billet rotation, different deformation routes are applied: 1. Route A has no rotation of the billet, 2. During Route BA, billet is rotated counterclockwise 900 on every even number of passes and clockwise 900 on every odd number of passes3. In Route BC, the billet is rotated 900 counterclockwise after every pass. This route produces a uniform microstructure of equiaxed grains separated by high-angle grain boundaries more rapidly than other routes4. In Route C, the billet is rotated at 1800 after every pass

| Figure 2. Die assembly mounted on 25 ton Hydraulic pressing machine |

3. Results and Discussions

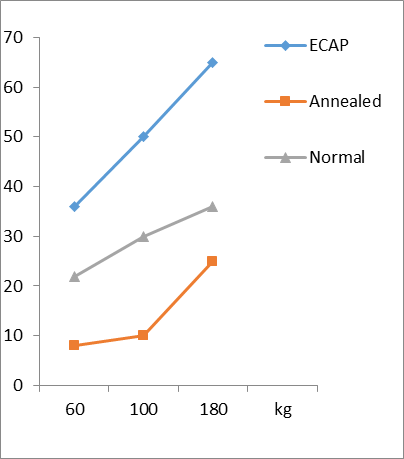

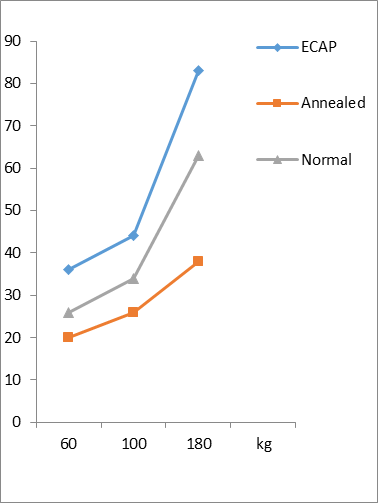

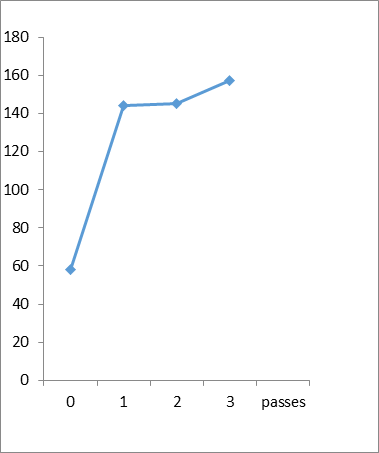

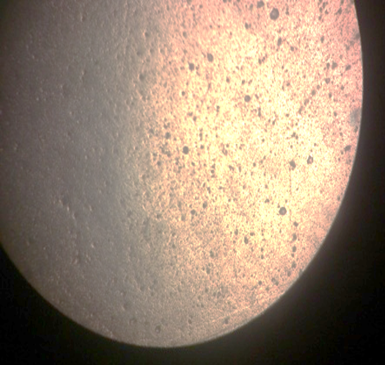

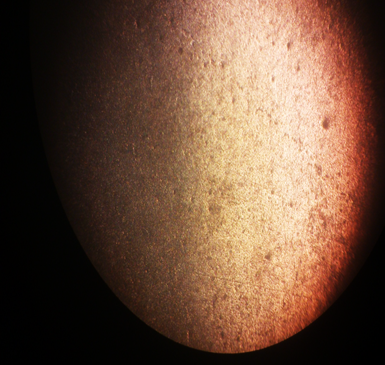

- From the graphs shown in Figure 3,4 it is clear that there is a significant increase in hardness of the material after ECAP compared to normal specimen and annealed specimen at all the three loads (60, 100, 180 kg) even after a single pass. Literature shows that such results were obtained for other materials. From the tensile test conducted for the same material by A. Sivaram and U. Chattingal [15] it was observed there is a significant increase in tensile strength of the material after ECAP as shown in Fig. 5. After annealing the tensile strength of the aluminum was found to be 58MPa which increased significantly on the first pass itself. The UTS after the second and third passes of were 145 and 157MPa, respectively. The deformation produced by ECAP leads to grain refinement [16]. The microstructures are shown in Fig. 6 and Fig. 7 shows that the deformation produced by ECAP lead to grain refinement. Grain mis-orientation measurement was not carried out in this study. However it is well known that the proportions of high-angle grain boundary increases with increase in strain. ECAP process can provide a potential way for refining grain size to 200–300 nm for the pure aluminum materials in bulk. The above optical observations have shown that the grains can be refined significantly with the increase of the deformation during ECAP. The microstructure evolution of the workpiece can be changed via different processing routes. However, the dis-locations and sub-grain boundaries in the samples cannot be detected through the optical observations [16]. Images at higher resolutions with the help of Scanning Electron Microscopy can yield the details of dis-locations and sub-grain boundaries.

| Figure 3. Load vs. RHN |

| Figure 4. Load vs. BHN |

| Figure 5. Tensile strength vs. no. of passes |

| Figure 6. Optical microscopic image of pure un-processed Aluminum |

| Figure 7. Optical microscopic image of ECA pressed Aluminum after single pass showing better grain size |

4. Conclusions

- The equal-channel angular pressing was successfully applied to the Aluminum billet using route A. Even with one ECAP pass there was significant increase in both hardness and strength. The change in hardness of the alloy with ECAP passes is almost consistent with the trend in strength, but the rate is different. The changes in properties were attributed to the strong microstructural alterations as a result of the ECAP processing. Moreover, ECAP can possibly be used as an alternate step to hot extrusion in industrial processing to break down a coarse structure. The process of grain refinement can be described as continuous dynamic recovery and recrystallization. From the viewpoint of microstructure analysis, the grain refinement process is to control the dynamic balance of the generation and annihilation of the dislocations. From the viewpoint of the macro deformation analysis, the grain refinement process is to seek proper number of the passes and the optimal processing routes. Thus it can be concluded that use of equal-channel angular pressing provides a simple and effective procedure for improving the mechanical properties of Aluminum and its alloys and can provide new capabilities in many engineering applications.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML