-

Paper Information

- Next Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Materials Engineering

p-ISSN: 2166-5389 e-ISSN: 2166-5400

2014; 4(3): 83-87

doi:10.5923/j.ijme.20140403.02

Permeability of Paricá (Schizolobium amazonicum herb.) Wood Species from the Amazon Region

Laurenn Borges de Macedo 1, Diego Henrique de Almeida 1, Carlito Calil Neto 1, Luciano Donizeti Varanda 2, André Luis Christoforo 3, Carlito Calil Junior 1, Francisco Antonio Rocco Lahr 1

1Department of Structural Engineering, Engineering School of São Carlos (EESC/USP), São Carlos, 13566-590, Brazil

2Department of Material, Engineering School of São Carlos (EESC/USP), São Carlos, 13566-590, Brazil

3Centre for Innovation and Technology in Composites – CITeC, Department of Civil Engineering, Federal University of São Carlos, São Carlos, 13565-905, Brazil

Correspondence to: André Luis Christoforo , Centre for Innovation and Technology in Composites – CITeC, Department of Civil Engineering, Federal University of São Carlos, São Carlos, 13565-905, Brazil.

| Email: |  |

Copyright © 2014 Scientific & Academic Publishing. All Rights Reserved.

Paricá (Schizolobium amazonicum Herb.), is a native species from Amazon region, with very susceptible wood to xylophagous agents attacks. Therefore, to know the permeability of this species is information to define the chemical treatment suitable for the durability of this wood in use. For this study, it sawed wood from planted areas of the amazon region was used. It is possible to determine the permeability with the aid of proper equipment. The specimens, used in this research, were obtained randomly from pieces, 6 specimens for each one of the fluids tested: atmospheric air, distilled water and CCA chemical preservative. The value of atmospheric air permeability was 504.15 cm³/cm.atm.s with variation coefficient of 7.78%. For distilled water, the permeability and the variation coefficient were 10.84 cm³/cm.atm.s and 23.16%, respectively. Regarding the CCA, the permeability was 228.69 cm³/cm.atm.s and the variation coefficient 61.97%.

Keywords: Physical properties, Permeameter, treatability of wood

Cite this paper: Laurenn Borges de Macedo , Diego Henrique de Almeida , Carlito Calil Neto , Luciano Donizeti Varanda , André Luis Christoforo , Carlito Calil Junior , Francisco Antonio Rocco Lahr , Permeability of Paricá (Schizolobium amazonicum herb.) Wood Species from the Amazon Region, International Journal of Materials Engineering , Vol. 4 No. 3, 2014, pp. 83-87. doi: 10.5923/j.ijme.20140403.02.

Article Outline

1. Introduction

- Wood has been used for various purposes over the centuries for being a material with singular characteristics [1]. Every day, the development of technologies in the forest sector have enabled increase in the potential uses of this raw material due to improvements in their physical, chemical and mechanical properties. In Brazil, the Amazon region is considered a potential area of investment in the forest sector, since it offers good demand of species with large variability of properties and possibilities for several uses. However, even taking in account this favorable aspect of the region, the lack of knowledge about the properties of most species and their performance under some usage conditions is still an obstacle for the adequate application of wood.From the 80s, some government initiatives have encouraged the characterization of native species. Various works in this direction have been conducted since then and, hereupon, is verified a possible reduction in the use of consecrated species, making possible a gradual decrease of deforested areas [2, 3].The Paricá (Schizolobium amazonicum Herb.), species of the Caesalpinaceae family and originally from the northern region of Brazil, presents a straight stem with a low incidence of nodes. The wood of this species has a yellowish-white color, with good visibility of growth rings and perceptible distinction between heartwood and sapwood. According to [4], most of the biomass produced by the trees of this species is concentrated in the stem. In accordance with [5], the Paricá has a basic density varying from 0.3 g/cm3 to 0.62 g/cm3, which provides good workability of the species of wood.The low incidence of defects in wood, the high price in internal and external market and its easy processing and excellent workmanship makes Paricá a species of great potential for several uses [6]. Paricá has been employed since for matchsticks manufacturing to the production of doors, plywood, particleboard, glulam timber and concrete formwork. Paricá presents good potential for commercial plantations, agroforestry and reforestation of degraded areas because it has a rapid development and a good performance both in homogeneous cultures and in consortium [7].Due to its low extractives content, compared to other tropical species, this species can be very susceptible to attack by xylophagous agents [8]. Therefore, the study of its permeability becomes of great importance to ensure that the preservative treatment can be made properly, making it possible to prolong their durability and, consequently, increasing their usability. From a commercial viewpoint, the use of biocides, also known as wood preservatives, is the most beneficial. The preservative treatment implies an increase of the initial cost, however, due to greater durability of wood over the period of use, the cost is diluted to the point of being more advantageous compared to untreated wood [9].The permeability of the wood is determined by the facility with which certain fluid through a porous solid because of the actions of a pressure gradient, obeying Darcy's law [10, 11].Property directly related to the treatability of wood, permeability is greatly influenced by the chemical and physical composition of the material, as well, by the flow regime of the fluid used, the permeability can be in the longitudinal direction of the wood in the order of more than 1000 times higher than the same greatness as the tangential or radial direction [12]. Still according to the same author, to eliminate the influence caused by the fluid during the determination of this property can use the specific permeability. Thus, according to [13-15], the values obtained of the permeability are independent of the fluid and will only be a function of the size and number of openings of the anatomical characters of the wood structure.Because of the growing demand for the use of the species Paricá, the need of to prove greater durability of the species for structural purposes, the need of to provide greater durability of the species for structural purposes, through the chemical treatment and, the possibility of its use in the production of GLT, this study aimed to determine and compare permeability of this species of wood in relation to fluids like air, distilled water and the chromated copper arsenate chemical preservative (CCA).

2. Material and Methods

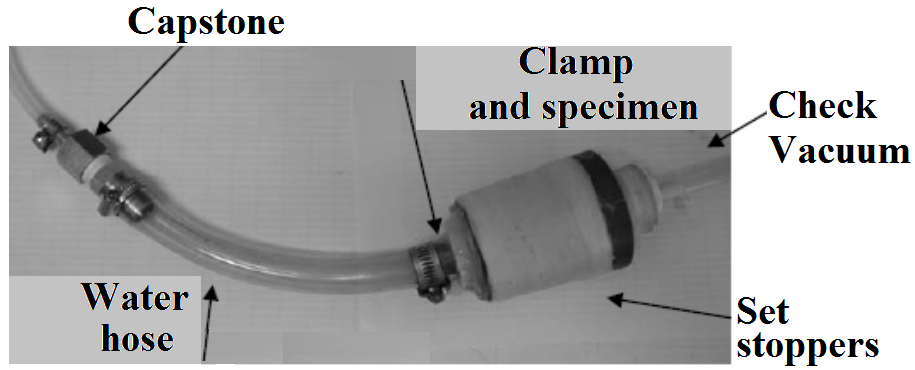

- For the present study Paricá wood obtained from the National University of Pará (UFPA), Brazil was used.The specimens were obtained from pieces in equilibrium ambient moisture with thicknesses ranging from 35 to 40 mm, width of approximately 150 mm and a length of 2.5 m, randomly chosen from a homogeneous lot. The pieces were lathed to achieve the appropriate size for testing in the Laboratory of Wood and Timber Structures (LaMEM) of School of Engineering of São Carlos (EESC) of University of São Paulo (USP) to obtain samples of cylindrical shapes. 18 specimens with longitudinal length ranging from 48.61 to 51.73 mm and the diameter 18.77 to 21.74 mm were used. 6 specimens were used to evaluate the permeability of the wood for each type of fluid analyzed. To ensure the fluid flow only in the desired longitudinal direction (parallel to the fibers of the wood), the specimens were sealed in its lateral direction with a resin based on oil castor bean. The resin was easily applied using a brush, with rectilinear motion, with the curing time of approximately 72 hours (Figure 1).

| Figure 1. The specimens sealed with a resin based on oil castor bean |

| Figure 2. Equipment for determining the air flow. Source: [11] |

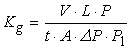

| (1) |

| Figure 3. Equipment for measuring the permeability to liquid |

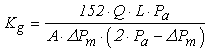

| (2) |

3. Results and Discussions

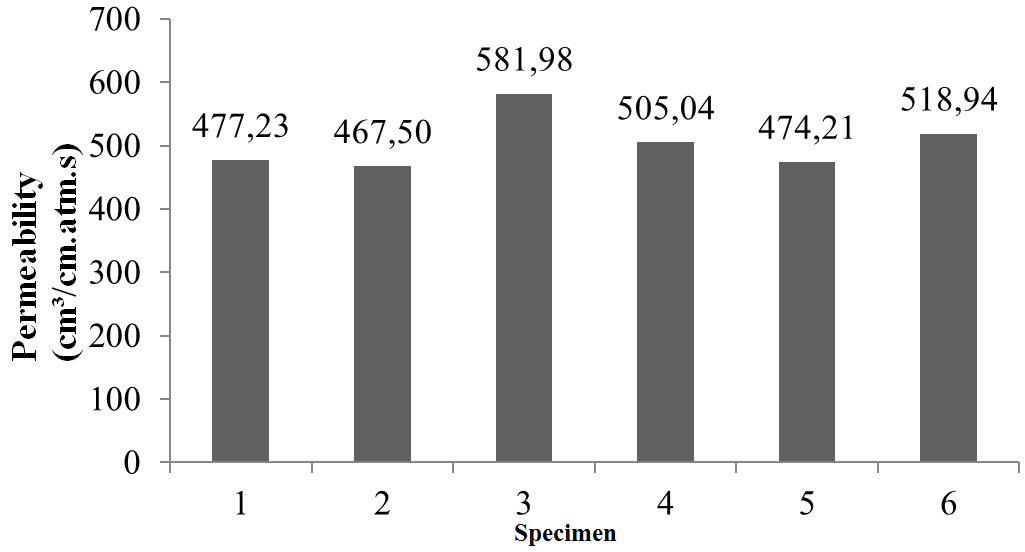

- The average value of permeability of atmospheric air in the wood Paricá was 504.15 cm³/cm.atm.s, with a coefficient of variation of 7.78%. Figure 4 illustrates the bar graph with the permeability values obtained for each specimen tested.

| Figure 4. Paricá permeability of atmospheric air |

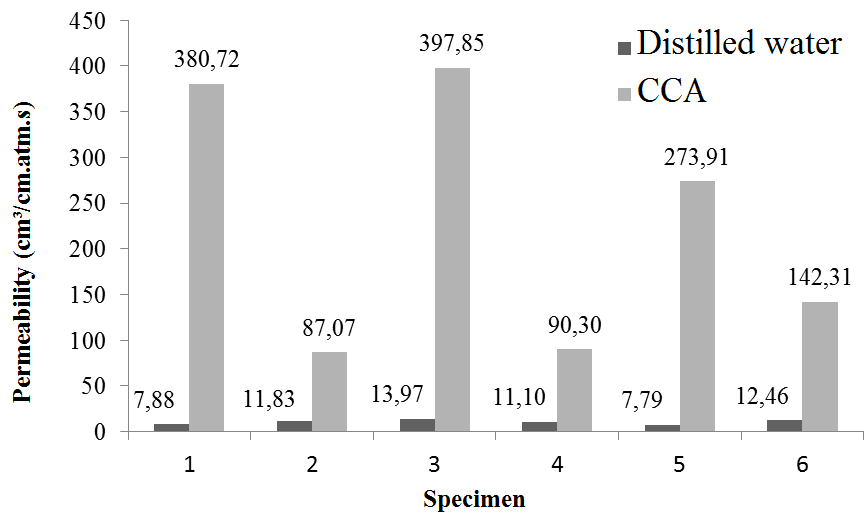

| Figure 5. Permeability to distilled water and CCA by the Paricá |

4. Conclusions

- The atmospheric air permeability was greater than the liquid permeability due to the greatest ease of displacement of the gaseous fluid. The permeability to liquid chemical preservative CCA was about ten times higher in comparison to distilled water, and, depending on viscosity, were expected approximate values. Factors that contributed to these results consisted in the removal of specimens in heartwood area of the tree and coming from regions of sapwood. Due to the good permeability to liquid and atmospheric air, the results obtained demonstrate the feasibility of using wood Paricá (Schizolobium amazonicum Herb.) for processes that the displacement of fluid through the wood is necessary, as treatments and other applications.

ACKNOWLEDGEMENTS

- The authors thank the Laboratory of Wood and Timber Structures (LaMEM) Department of Structures (SET) of School of Engineering of São Carlos (EESC), University of São Paulo (USP) by the possibility of doing this work, and also the National University of Pará (UFPA), by donating of wood used in tests.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML