| [1] | Shin, B.K., Lee, T.I., Xiong, J., Hwang, C., Noh, G., Cho, J.H. and Myoung, J.M., 2011, Bottom-up grown ZnO nanorods for an antireflective moth-eye structure on CuInGaSe2 solar cells, J. Solar Energy Materials & Solar Cells, 95, 2650-2654. |

| [2] | Ootsuka, T., Liu, Z.,. Osamura, M, Fukuzawa, Y., Kuroda, R., Suzuki, Y., Otogawa, N., Mise, T., Wang, S., Hoshino, Y., Nakayama, Y., Tanoue, H. and Makita, Y., 2005, Studies on Aluminum-doped ZnO films for transparent electrode and antireflection coating of β-FeSi2 optoelectronic devices, Thin Solid Films, 476, 30-34. |

| [3] | Szarko, J.M., Song, J.K., Blackledge, C.W., Swart, I., Leone, S.R., Li, S. and Zhao, Y., 2005, Optical injection probing of single ZnO tetrapod lasers, Chemical Physics Letters, 404, 171-176. |

| [4] | Al Asmar, R., Atanas, J.P., Ajaka, M., Zaatar, Y., Ferblantier, G., Sauvajol, J.L., Jabbour, J., Juillaget, S. and Foucaran, A., 2005, Characterization and Raman investigations on high-quality ZnO thin films fabricated by reactive electron beam evaporation technique. Journal of Crystal Growth, 279 , 394-402. |

| [5] | Barnes, T.M., Leaf, J., Hand, S., Fry, C. and Wolden, C.A., 2004. Room temperature chemical vapor deposition of c-axis ZnO. Journal of Crystal Growth, 274, 412–417. |

| [6] | Chen, S., Zhang, J., Feng, X., Wang, X., Luo, l., Shi, Y., Xue, Q., Wang, C., Zhu, J.and Zhu, Z., 2005, Nanocrystalline ZnO thin films on porous silicon/silicon substrates obtained by sol–gel technique, Applied Surface Science, 241, 384–391. |

| [7] | Ayouchi, R., Leinen, D., Martın, F., Gabas, M., Dalchiele, E. and Ramos-Barrado, J.R., 2003, Preparation and characterization of transparent ZnO thin films obtained by spray pyrolysis. Thin Solid Films, 426, 68–77. |

| [8] | Chaabouni, F., Abaab, M. and Rezig, B., 2006, Characterization of n-ZnO/p-Si films grown by magnetron sputtering, Superlattices and Microstructures, 39, 171–178. |

| [9] | Kobayashi, H., Kogetsu, Y., Ishida, T., and Nakato, Y., 1993, Increases in photovoltage of ‘‘indium tin oxide/silicon oxide/mat-textured n-silicon’’ junction solar cells by silicon preoxidation and annealing processes. J. Appl. Phys, 74, 4756. |

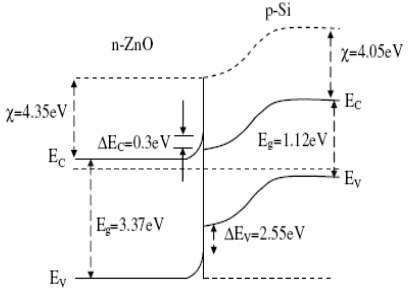

| [10] | Ajimsha, R.S., Jayaraj, M.K and Kukreja, L.M., 2008, Electrical Characteristics of n-ZnO/p-Si Heterojunction Diodes Grown by Pulsed Laser Deposition at Different Oxygen Pressures. Journal of Electronic Materials, 37, 770–775. |

| [11] | Sun, H., Zhang, Q.F and Wu, J. L, 2006, Electroluminescence from ZnO nanorods with an n-ZnO/p-Si heterojunction structure . Nanotechnology, 17, 2271–2274. |

| [12] | Baik, D.G. and Cho, S.M., 1999, Application of sol-gel derived films for ZnO/n-Si junction solar cells, Thin Solid Films, 354-227. |

| [13] | Kobayashi, H., Mori, H., Ishida, T. and Nakato, Y.J., 1995, Zinc oxide/n-Si junction solar cells produced by spray-pyrolysis method. J. Appl. Phys, 77, 1301. |

| [14] | Kishimoto, S., Yamamoto, T., Nakagawa, Y., Ikeda, K., Makino, H. and Yamada, T., 2006, Dependence of electrical and structural properties on film thickness of undoped ZnO thin films prepared by plasma-assisted electron beam deposition. Superlattices and Microstructures, 39,306–313. |

| [15] | Dong, B. Z., Fang, G. J., Wang, J. F., Guan, W. J. and Zhao, X. Z., 2007, Effect of thickness on structural, electrical, and optical properties of ZnO: Al films deposited by pulsed laser deposition. Appl. Phys., 101, 033713. |

| [16] | Du, G., Cui, Y., Xiaochuan, X., Li, X., Zhu, H., Zhang, B., Zhang, Y. and Ma, Y., 2007, Visual-infrared electroluminescence emission from ZnO/GaAs heterojunctions grown by metal-organic chemical vapor deposition. Appl. Phys. Lett., 90, 243504. |

| [17] | Dutta, M. and Basak, D., 2008. p-ZnO/n-Si heterojunction: Sol-gel fabrication, photoresponse properties, and transport mechanism. Appl. Phys. Lett., 92 , 212112. |

| [18] | Sze, S.M., 1981.Physics of Semiconductor Devices. 2nd Edn., John While and Sons |

| [19] | Ocak, Y. S., 2012. Electrical characterization of DC sputtered ZnO/p-Si heterojunction. Journal of Alloys and Compounds, 513, 130-134. |

| [20] | J.I. Pankove, Optical Processes in Semiconductors, Prentice - Hall Inc, Englewoord Cliffs, NJ, 1971. |

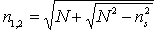

| [21] | I.S. Yahia, Farag, A.A.M., Cavas, M. and Yakuphanoglu, F., 2013, Effects of stabilizer ratio on the optical constants andoptical dispersion parameters of ZnO nano-fiber thin films. Superlattices and Microstructures, 53, 63–75. |

| [22] | Pierret R.F. Semiconductor Device Fundamentals, Addison - Wesley, 1996. |

| [23] | Singh, C.S., Agarwal, G., Durga Rao G., Chaudhary S., Singh, R., 2011, Effect of hydrogen peroxide treatment on the electrical characteristics of Au/ZnO epitaxial Schottky diode. Materials Science in Semiconductor Processing, 14, 1–4. |

| [24] | Klason, P., Rahman, M.M., Hu, Q.H., Nur, O., Turan, R. and Willander, M., 2009, Fabrication and characterization of p-Si/n-ZnO heterostructured junctions. Microelectronics Journal, 40, 706–710. |

| [25] | Zebbar, N., Kheireddine, Y., Mokeddem, K., Hafdallah, A., Kechouane, M. and Aida, M.S., 2011.Structural, optical and electrical properties of n-ZnO/p-Si heterojunction prepared by ultrasonic spray. Materials Science in Semiconductor Processing, 14,229–234. |

| [26] | Yakuphanoglu, F., Caglar, Y., Caglar, M. and Ilican, S., 2010, ZnO/p-Si heterojunction photodiode by sol–gel deposition of nanostructure n-ZnO film on p-Si substrate, Materials Science in Semiconductor Processing, 13,137–140. |

| [27] | Majumdar, S., Banerji, P., Majumdar, S. and Banerji, P., 2009, Temperature dependent electrical transport in p-ZnO/n-Si heterojunction formed by pulsed laser deposition, J. Appl. Phys. |

| [28] | Farag, A.A.M., Farooq, W.A., Yakuphanoglu, F., 2011, Characterization and performance of Schottky diode based on wide band gap semiconductor ZnO using a low-cost and simplified sol–gel spin coating technique, Microelectronic Engineering, 88, 2894–2899. |

| [29] | Nelson, J., 2003, The Physics of Solar Cells. Imperical College Press, UK. |

| [30] | Mansour, Sh. A. and Yakuphanoglu, F., 2012, Electrical - optical properties of nanofiber ZnO film grown by sol gel method and fabrication of ZnO/p-Si heterojunction. Solid State Sciences, 14, 121-126. |

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML