-

Paper Information

- Next Paper

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Materials Engineering

2012; 2(4): 50-56

doi: 10.5923/j.ijme.20120204.04

Properties of Sugar Cane Bagasse to Use in OSB

Antônio Jorge Parga Silva 1, Francisco Antonio Rocco Lahr 2, André Luis Christoforo 3, Túlio Hallak Panzera 3

1Department of Civil Construction, Federal Center of Technological Education of Maranhão, São Luis, 65030-000, Brazil

2Department of Structural Engineering, University of São Paulo (EESC/USP), São Carlos, 13566-590, Brazil

3Department of Mechanical Engineering, Federal University of São João del-Rei (UFSJ), São João del-Rei, 36307-352, Brazil

Correspondence to: André Luis Christoforo , Department of Mechanical Engineering, Federal University of São João del-Rei (UFSJ), São João del-Rei, 36307-352, Brazil.

| Email: |  |

Copyright © 2012 Scientific & Academic Publishing. All Rights Reserved.

The composites of natural fibers are products known in several parts of the world, however their utilization is relatively restrict due to the lack of information concerning their properties and structures. Lignocellulosic fibers present high length/thickness relation, which contributes to the biodegradation and continuity of the ecological cycle. Such fibers present low density and enable a lower cost in composites manufacture, playing an important role in the definition of their physical and mechanical properties. The cane bagasse is a residue derived from sugar cane, a commercially important product in Brazil, with a high concentration of fibers, high content of lignin, which is a factor of environmental impact, with future perspectives of use. The present paper aims to evaluate the density of cane bagasse as composites of long particles and their internal adhesion, as well as to verify their temperature until decomposition and suggest their possible future utilization. The requisites of this product in terms of limit values for the properties of OSB are defined by EN-300/2002 standard.

Keywords: Composites, OSB, Sugar Cane Bagasse

Article Outline

1. Introduction

- The reutilization of natural organic residues to obtain an applicable product is a very useful practice that generates many advantages in the evaluation of social areas, expanding baselines for economic applications, with a low cost product which is ecological and far less polluting, in order to create a country’s sustainable development.Alternatively to the use of organic waste for use in buildings and other compounds are distinguished OSB (Oriented Strand Board), made up of wooden panels or comparable (long, large and fine particles) agglutinated with a resin and compressed in layers.Generally, on its external layers the OSB has its flakes arranged longitudinally in relation to the length of the board, while in the intermediate layers they are arranged perpendicularly or randomly distributed, as illustrated in Figure 1.

| Figure 1. Directed layers, long particles and OSB panels in the market. Source:[1] |

2. Materials and Methods

- The material used in this evaluation was the sugar cane residue, commonly known as “bagasse” originating from the mills located near the city of São Carlos, SP, Brazil. It was evaluated as composite, which is particulate and resin composites. The resin employed was polyurethane based on mammon oil, type bi-component and the reaction time was of 25 minutes. The resin with pre-polymer I201 will be used with 1:2 feature to produce the panels, with one part of pre-polymer based on di-isocyanate and 2 parts of polyol. These resin composites were donated by KEHL Chemical Industry of São Carlos-SP. One of the resins is done by cold curing process, which can be accelerated by increasing the temperature up to 120℃ without losing its properties. Because the group of derivatives usually applies this temperature, 90℃ was chosen, thus generating less energy in the fabrication process of panels[1].

2.1. Thermogravimetry (TG) and Differential Thermal Analysis (DTA)

- A simultaneous thermal balance TG-DTA, brand NETZSCH, model STA 409 Cell (Figure 2) was employed for this analysis, with a heating rate of 10℃/min. owing to the fact that this heating ratio promotes a better resolution curve standard in nitrogen atmosphere.

| Figure 2. NETZSCH Equipment, model STA 409 Cell-Thermogravimetric analysis |

2.2. Treatment

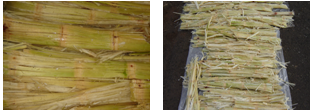

| Figure 3. Material treated in water and sun dried for preliminary drying |

2.3. Drying

- The artificial drying process is done in heater for 16 hours at 60ºC temperature, where it is checked for possible anomalies, since above this temperature there is water loss that could cause disequilibrium to its basic structural form. Immediately after treatment and drying it is prepared for particulate obtainment by cutting (Figure 4) it to mean length of 14cm.

| Figure 4. Bagasse after being dried in heater, test equipment, solid percentage and slicing of sugar cane bagasse |

2.4. Mixture Particulate Direction and Pressing

- The mixing process is relative to the degree of residue compaction and follows the standard guidelines commonly used to industrially manufacture oriented strand board (OSB). Cane bagasse offers a wide range of applications owing to its low density fiber and low cost. In the present paper for the production mixture, a mammon based oil polyurethane resin was employed at a proportion of 1:2, pre-polymer/polyol and cane-bagasse type residue in compaction proportion and intended density, respectively.Subsequent to the resin application, the long particles were placed in a particle orienter to divide the layers. Such layers are divided in external and internal layers. The external layers imperatively have the same orientation, while the internal ones can be oriented or not, as illustrated in Figure 5.

| Figure 5. Large particle orienter developed in LaMEM-SET and layers of oriented particles of cane bagasse |

| Figure 6. Long particles in Marconi MA-98/50 hydraulic press and definitive panel |

2.5. Moisture Test

- The samples with a minimum weight of 20g must be removed, their form and dimensions are not important. However, they must not possess free particles.Initially, the samples should be weighed and then placed in a heater at a temperature of (103±2) ℃ until they reach a constant mass.Afterwards, it must cool to room temperature, weighed again and the moisture ratio calculated by Equation 1:

| (1) |

2.6. Density Tests

- The square samples must be removed and the sides should measure nominally 50 mm and conditioned up to a constant mass to a relative moisture of (65±5) % and a temperature of (20±2) ℃. Constant mass is when the results of the successive weighing, performed with at least 24 h. interval, do not differ more than 0,1% in relation to the sample mass.The samples should initially be weighed and their t thickness measured at the point they meet diagonally. b1 and b2 should be measured at two points, parallel to the edge of the sample, along the lines that pass through the center of the opposing edges. Density is calculated by Equation 2:

| (2) |

2.7. Test of Swelling in Thickness

- To determine the swelling in thickness, after immersion of the panels in distilled water for 24 hours, the square format samples with edges of (50±1) mm must be removed.The thickness of the samples must be diagonally measured at the intersection before and after it is immersed in clean water with pH 7±1, at a temperature of 20±1 ℃ and must remain submerged in 25±5 mm of water for 24 hours. The thickness swelling in percentage is calculated by Equation 3:

| (3) |

2.8. Internal Adhesion

- For internal adhesion (IA) of the panels, the square shaped samples must be removed with edges measuring (50±1) mm.Metal supports are fastened on both sides of the samples, subsequently they undergo traction in opposite directions so that they sever. Internal Adhesion is calculated by Equation 4:

| (4) |

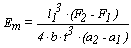

2.9. Modulus of Elasticity and Modulus of Rupture in Static Bending Tests

- To determine modulus of elasticity (Em) and modulus of rupture (Fm) in static bending tests, rectangular shaped samples must to used, with (50±1)mm midth (b). The length (l1) should be 20 times the nominal thickness plus 50mm.The specimens should be conditioned up to constant weight, under relative moisture of (65±5)% and a temperature of (20±2) ℃, considering that constant weight is obtained when the results of two successive weighing, performed with at least 24h of interval, do not differ more than 0,1% in relation to the initial sample weight.The Modulus of Elasticity in bending strength (Em) is calculated by Equation 5. Each set of samples taken from the same panel gives the mean value to Em:

| (5) |

| (6) |

3. Results

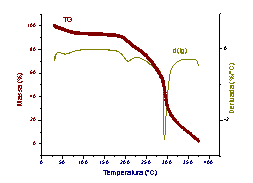

- Thermal characteristicsIn the analysis of thermal characteristics of the sugar cane bagasse is taken into consideration as well as the polyurethane mammon based resin applied.For the cane bagasse a thermogravimetric decomposition curve was set up, varying from room temperature up to 300℃, as seen in Figure 7.Suitable behavior was verified from room temperature up to 60℃, higher than this temperature there is a water loss up to 75℃, after this point the beginning of an ebullition reaction at around 100℃ is seen, afterwards water loss of decomposition near 125℃ begins, hence occurring the start of decomposition of the bagasse structure at 200℃ and from this temperature the process of total burning of the residue initiates.

| Figure 7. Thermogravimetric decomposition curve of the sugar cane bagasse |

|

|

|

|

|

4. Conclusions

- Sugar cane bagasse possesses a broad thermal baseline in its use of resins and other applications, which ranges from room temperature up to 150℃, with decomposition beginning at 200℃. Results indicate to application of cane bagasse with long particles, evidencing high, medium and low density.The values of modulus of rupture and modulus of elasticity in longitudinal direction reached the method requeriments. In transversal direction, only the modulus of rupture reached the method requeriments. Modulus of elasticity values can be incresed by a more care control of mixing process and pressing temperatures.Internal adhesion of the particulate with 10% of polyurethane mammon based resin is considered satisfactory, notwithstanding the mix process was manual.Since Brazil is the biggest worldwide producer of sugar cane residue, it is considerably favorable for this type of particulate with this kind of raw material and technique.

References

| [1] | A. J. P. Silva. “Aplicação de partículas longas e orientadas de bagaço de cana-de-açúcar na produção de painel particulado similar ao OSB”. Tese (Doutorado). Escola de Engenharia de São Carlos da Universidade de São Paulo, 2006. |

| [2] | D. Zhow. “A estudy of oriented structural board made from hybrid poplar. Phisical and mechanical properties of OSB”. Holz Als Roh Und Werkstoff, Berlin, v. 48, n. 7-8, p. 293-296, 1990. |

| [3] | S. Suzuki, K. Takeda. “Production and properties of Japanese oriented strand board I: effect of strand length and orientation on strength properties of sugi oriented strand board”. Japan Wood Science, Tokyo, v. 46, p. 289-295. 2000. |

| [4] | W. Thomas. “Poisson’s ratios of an oriented strand board”. Wood Sci Technol, 37, pp. 259–268, 2003. |

| [5] | T. Nishimura, M. P. Ansell, N. Ando. “The relationship between the arrangement of wood strands at the surface of OSB and the modulus of rupture determined by image analysis”. Wood Sci Technol, 35 (6), pp. 555–562, 2003. |

| [6] | G. Painter, H. Budman, M. Pritzker. “Prediction of oriented strand board properties from mat formation and compression operating conditions”. Part 2: MOE prediction and process optimization. Wood Sci Technol, 40 (4), pp. 291–307, 2006. |

| [7] | V. Yadama, M. P. Wolcott, L. V. Wolcott. “Elastic properties of wood-strand composites with undulating strands”. Compos Part A: Appl Sci Manuf, 37 (3), pp. 385–392, 2006. |

| [8] | M. Rebollar, R. Perez, R. Vidal. “Comparison between oriented strand boards and other wood-based panels for the manufacture of furniture”. Mater Des, 28 (3), pp. 882–888, 2008. |

| [9] | J. M. H. Jesus. “Estudo do adesivo poliuretano à base de mamona em madeira laminada colada(MLC)”. São Carlos, 2000, 106p. Tese de Doutorado – Ecla de Engenhria de São Carlos, Universidade de São Paulo. |

| [10] | L. C. R. Araújo. “Caracterização química e mecânica de poliuretanas elastoméricas baseadas em materiais oleoquímicos”. São Carlos, 1992. Dissertação de Mestrado – Instituto de Física e Química de São Carlos. Universidade de São Paulo. |

| [11] | S. Claro Neto. “Caracterizações físico-químicas de um poliuretano derivado de óleo de mamona utilizado para implantes ósseos”. São Carlos, 1997. 127p Tese de Doutorado – Instituto de Química de São Carlos, Universidade de São Paulo. |

| [12] | M. A. E. Santana, D. E. Teixeira. “Uso do bagaço de cana-de-açúcar na confecção de chapas de aglomerados”. In: Congresso Florestal Brasileiro, 7; Congresso Florestal Pan-americano, 1. Curitiba, 1993. Anais. São Paulo: SBS/SBEF, p. 667-672, 1993. |

| [13] | G. Han, Q. Wu. “Comparative properties of sugarcane rind and wood strands for structural composite manufacturing”. Forest Products Journal 54(12): p. 283-288, December/2004. |

| [14] | M. C. Mesa Valenciano. “Incorporação de resíduos agroindustriais e seus efeitos sobre as características físico-mecânicas de tijolos de solo melhorado com cimento”. Dissertação (Mestrado) – Faculdade de Engenharia Agrícola, Universidade de Campinas, Campinas, 1999. |

| [15] | J. F. M. Hernández, B. Middendorf, M. Gehrke, H. Budelmann. “Use of wastes of the sugar industry as pozzolana in lime-pozzolana binders: study of the reaction”. Cement and Concrete Research, v. 28, n. 11, p. 1525-1536, 1998. |

| [16] | L. K. Aggarwal. “Bagasse-reinforced cement composites”. Cement and Concrete Composites, v. 17, n. 2, p. 107-112, 1995. |

| [17] | C. R. Sarmiento, W. J. Freire. “Argamassa de cimento e areia combinada com fibras de bagaço de cana-de-açúcar”. Engenharia Agrícola, v. 17, n. 2, p. 1-8, 1997. |

| [18] | C. Y. Kawabata. “Aproveitamento de cinzas da queima de resíduos agroindustriais na produção de compósitos fibrosos e concreto leve para a construção rural”. Tese (Doutorado) – Faculdade de Zootecnia e Engenharia de Alimentos da Universidade de São Paulo, Pirassununga, 2008. |

| [19] | European Committee For Standardization. European Standard - EN 300. Aglomerado de partículas de madeira longas e orientadas (OSB) – Definições, classificação e especificações. Portugal, 2002. |

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-Text HTML

Full-Text HTML