-

Paper Information

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Materials Engineering

p-ISSN: 2166-5389 e-ISSN: 2166-5400

2012; 2(3): 23-31

doi: 10.5923/j.ijme.20120203.03

Synergistic Effects of Micro Size Flyash Particulate and Glass Fiber on Friction and Wear of Vinylester Hybrid Composites under Dry and Water Lubricated Sliding Condition

S. R. Chauhan1, Bharti Gaur2, Kali Dass1

1Department of Mechanical Engineering National Institute of Technology Hamirpur (H.P.) India – 177005

2Department of Chemistry National Institute of Technology Hamirpur (H.P.) India - 177005

Correspondence to: Kali Dass, Department of Mechanical Engineering National Institute of Technology Hamirpur (H.P.) India – 177005.

| Email: |  |

Copyright © 2012 Scientific & Academic Publishing. All Rights Reserved.

In this paper the tribological performance of vinylester and its composites under dry and water lubricated sliding conditions has been investigated. For investigating the friction and wear tests were carried out on a pin on rotating disc under ambient conditions at normal applied loads of 10, 30 and 50N and under sliding speed of 1.6, 2.8 and 4.0 m/s. The results showed that the coefficient of friction decreases with the increase in applied normal load under both dry and water lubricated condition. The specific wear rate of GFR vinylester composite reduces significantly with the addition of fly ash particulates.

Keywords: Specific Wear Rate, Glass Vinylester Composites, Scanning Electron Microscopy

Article Outline

1. Introduction

- Researchers have shown that the friction and wear behaviours of polymers in fluid environments differ to a great extent, from those in the dry friction conditions. Theabsorption of water and plasticization of polymer surfaces influence the friction and wear of the polymeric composites. It has been investigated that fluids such as water and other the solution inhibit the formation of transfer films of fiber/ polymer debris on the counterface and the wear rates are greater than those obtained in dry conditions. Absorption of water may cause reduction in strength, modulus of elasticity, increase in the elongation and swelling of the surface layer [7-10]. In the experimental findings of the tribological characterics of glass vinylester and SiC filled glass vinylester composites it has been reported that the water into the interface of polymer/metal sliding combination reduces the coefficient of friction, but increases the wear rate of the composites[11].The investigation related to the tribological properties of polyether ether ketone (PEEK) has been reported in the studies[12-18]. The most of the investigations published were related to the friction and wear of polymers sliding against steels at dry sliding conditions. In addition, some investigations have been conducted on the friction and wear of polymers in water lubrication conditions[12-14]. The water into the interface of polymer/metal sliding combination generally reduces the coefficient of friction, but may increase the wear rate of the polymer[19]. The investigation of water lubricated tribological performance of carbon reinforced PEEK composite reported showed that the coefficient of friction under water lubricated condition is lower than that the dry condition[20]. The friction and wear phenomena also lead to a loss of mechanical efficiency. Therefore the influence of sliding speed and applied normal load on the friction and wear is extremely important[21].The ease of processing and light weight of polymer composites reinforced with woven fabric in addition to possessing good properties make them quite attractive for various industrial applications. However, woven roving fabric is a better choice since the woven rovings are cheaper as the expense of yarn preparation is eliminated. The manufacturing process such as heat treatment and finishing processes are also avoided by treating the rovings with a size and provides better reinforcing action. It has been found that woven forms of fiber reinforcement have been found to yield superior friction and wear characteristics. In recent times, E-glass fiber based composites has also found extensive application in many naval structures[22-26]. The tribological characteristics were found to depend on the type of resin, size, shape and orientation of the fibers used for the reinforcements[27]. However, many of the recent studies considered short fiber, unidirectional, bi-directional fiber reinforced polymer composites[28-31]. The study of the tribological properties of the directionally oriented warp knit glass fiber reinforced polymer composites was carried using three-different thermoset resins, i.e., vinyl-ester, epoxy and polyester as matrix materials in different directionally oriented knit structures. In these investigations it was concluded that biaxial warp knit composites and composites with epoxy resin are the best choice for tribological applications[29]. Studies conducted on the influence of normal load on the friction and wear of fly ash filled vinylester composites concluded that the matrix filled with 40% by weight of fly-ash has highest wear resistance and lowest coefficient of friction[32]. Particulate graphite and carbon fiber are preferred as fillers in tribo-composites because they impart reinforcement, conductivity, lower friction and improved wear behaviour[33]. The matrix materials play an important role as is the case for thermoset resin matrix composites which can be designed for specific applications by properly changing the polymer matrix. Therefore presently more of research work is being directed towards exploring the potential advantages of thermoset matrix for composite applications[34]. Vinylester is one of these kinds of matrix material, which has found a place in the family comprising thermoset engineering polymers due to its excellent mechanical properties with excellent chemical/corrosion resistance, even at elevated temperature. Vinylester resins were first introduced commercially in early 1960s. Today they are one of the most important thermosetting materials. Vinylester resins have been widely recognized as materials with excellent resistance to a wide variety of commonly encountered chemical environments[35]. Vinylester resins combine the best properties of epoxies and unsaturated polyesters. Vinylester resins can be easily handled at room temperature and have mechanical properties similar to epoxy resins. The chemical resistance offered by vinylester resins has shown that it is better than polyester resins, especially hydrolytic stability and at the same time they offer greater control over cure rate and reaction conditions than epoxy resins. Vinylester resins based on epoxy novaloc are used for engineering applications as the resin shows superior chemical resistance at elevated temperatures [36]. In manufacturing sectors fly ash usage by large volume could be exploited and it may prove substantially beneficial in techno-commercial and environmental terms[37]. The use of fly ash in intimately mixed hybrid composites as friction materials ideally conform to such an economy driven ideology where the amount of fillers in the composites can be in the range of 30–70% other than the binder, friction modifiers and specialty additives and fibrous reinforcements[38]. The general chemical composition of fly ash is mainly a mixture of SiO2, Al2O3, CaSO4, and un-burnt carbon. They are composed of fine sized particles with uniform physical and engineering characteristics. As the fly ash particles are typically generated above 1000oC they can be expected to provide thermally stable bulk at elevated temperatures which is a highly desirable characteristic for friction materials. In addition to these aspect the advantage in usage of fly ash as filler material, the very high specific heat (800 kJ/kg K) coupled with poor conductivity of fly ash particles could potentially facilitate the enhancement of friction material performance by imparting the capacity of excessive heat storage in the composite without allowing it to flow to the metallic back plate. In brakes systems if this event occurs it could not only damage the integrity of the pad by adversely affecting the bonding of the composite to the back plate but also could potentially heat-up the brake fluid causing erratic mechanical activation of the braking system as a whole [39–42].From the literature it has been observed that the majority of the investigations confined their discussions to various polymers and their composites under dry sliding conditions only. Therefore in this paper the influence of test speeds and applied normal loads on friction and wear behaviour of pure vinylester, GFR vinylester composites and fly ash filled GFR vinylester composites has been investigated. Friction and wear tests were carried on a steel disc using a pin-on-disc arrangement under dry and water lubricated sliding conditions.

2. Experimental Details

2.1. Preparation of Vinylester Resin and Materials Used

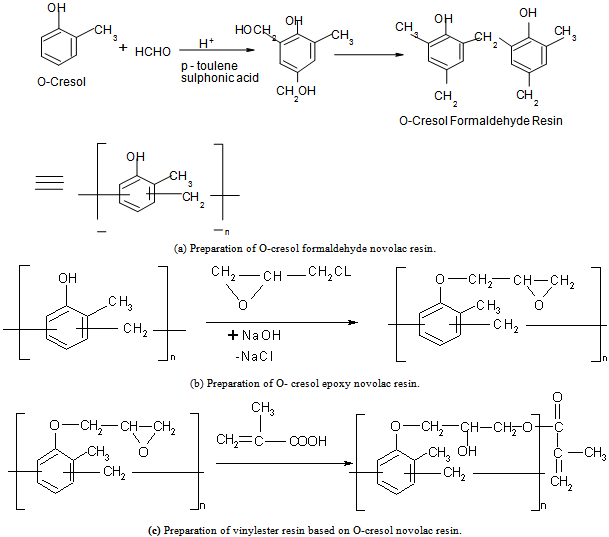

- Vinylester resins are addition products of various epoxide resins and unsaturated monocarboxylic acids, most commonly methacrylic acid. A low molecular weight co- monomer such as styrene, vinyl-toluene, or methyl methacrylate addition is common practice to dilute the vinylester oligomers to reduce the room temperature viscosity of the mixture and yield a solution with a typical viscosity in the range of 200–2000 cps. Typical reaction conditions are 120℃ for 4–5 h, and hydroquinone is commonly used as the initiator. The conversion of the reaction is 90–95%[35]. GFR composites are manufactured in the laboratory by contact molding process. The steps involved in preparation of vinylester resin from the synthesis of ortho-cresol formaldehyde novolac are shown in Figures 1(a-c). The type of resin used in this work is vinylester resin (density 1.23 g/cm3 and Modulus 2.3-4MPa) and reinforcing phase E-glass fibers (modulus 72.4GPa, density 2.54 g/cm3) were supplied by Northern Polymer Pvt. Ltd. New Delhi. Methyl ethyl ketone peroxide (MEKP-1%), Cobalt Naphthenate (1.5%) were used as catalyst and accelerator respectively. Four different types of specimens were prepared for this study. The fly ash was used as filler materials (10wt% and 20wt %) in this study.

2.2. Composite Laminates Fabrication

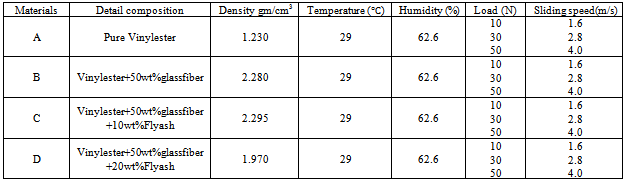

- Conventional wet hand layup technique was used for making of the glass vinylester composite laminates. The cobalt Naphthenate 1.5% was mixed thoroughly in vinylester resin and then 1% MEKP was mixed in the resins prior to reinforcement. The fiber loading (weight fraction of glass fiber in the composite) was kept 50 wt% for all the samples. The stacking procedure consists of placing the fabric one above the other with the resin mix well spread between the fabrics on a mould release sheet. A porous Teflon film was again used to complete the stack. To ensure uniform thickness of the sample, a 3mm spacer was used. The mould plates were coated with release agent in order to aid the ease of separation on curing. The similar procedure was repeated in all cases unless thickness of 3mm was obtained. A metal roller was used so that uniform thickness and compactness could be obtained. The whole assembly was placed in the compression molding machine at a pressure of 60 Kgf/cm2 and allowed to cure at room temperature for 24hrs. The laminate sheets of sizes 300×300×3 mm3 were prepared. Specimens of suitable dimensions were cut using a diamond cutter for wear testing as per ASTM standard. The other composite samples with particulate fillers of fixed weights (10 wt% and 20 wt %) percentage were fabricated by the same technique. The fillers were mixed thoroughly in the vinylester resin mechanically before the glass fiber mats were reinforced in the matrix body. Composites C and D contain fly ash particles (size 80-100 µm) in 10 wt% and 20 wt% proportions respectively. The detailed compositions along with the designation are presented in Table 1.

| Figure 1(a-c). Preparation of vinylester resin |

|

2.3. Friction and Wear Measurements

- The friction and sliding wear performance evaluation of vinylester (A) and its composites B, C and D under dry and water lubricated sliding conditions, were carried out on a pin-on-disc type friction and wear monitoring test rig (DUCOM) as per ASTM G 99. The counter body is a disc made of hardened ground steel (EN-32, hardness 72 HRC, surface roughness 0.7 μ Ra). The specimen is held stationary and the disc is rotated while a normal force is applied through a lever mechanism. During the test, friction force was measured by transducer mounted on the loading arm. The friction force readings are taken as the average of 100 readings every 40seconds for the required period. For this purpose a microprocessor controlled data acquisition system is used. A series of test were conducted with three sliding velocities of 1.6, 2.8, and 4m/s under three different normal loading of 10, 30 and 50N. Weight loss method was used for finding the specific wear. During these experiments initial and final weight of the specimens were measured. The material loss from the composite surface is measured using a precision electronic balance with accuracy + 0.01 mg.

| (1) |

2.4. Scanning Electron Microscopy

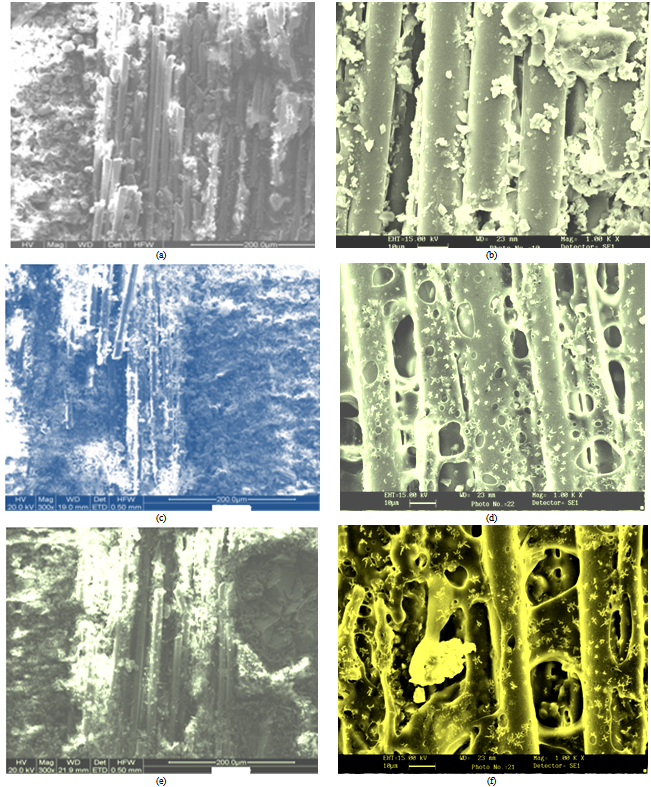

- The surfaces of the specimens were examined directly by scanning electron microscope. The composite samples were mounted on stubs with silver paste. To enhance the conductivity of the samples, a thin film of platinum was vacuum-evaporated onto them before the photomicrographs are taken.

3. Results and Discussion

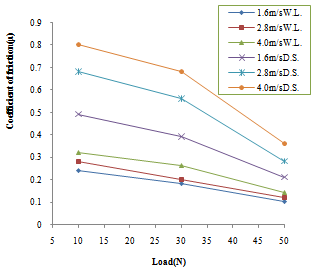

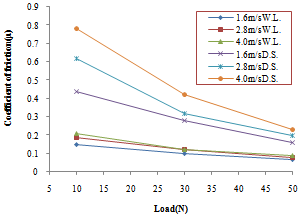

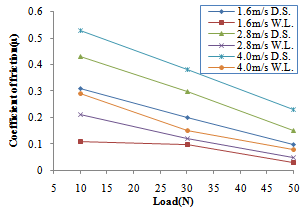

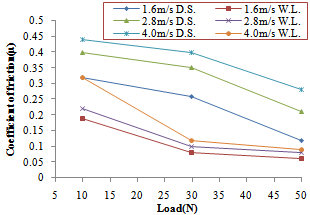

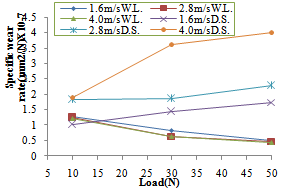

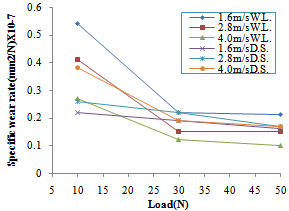

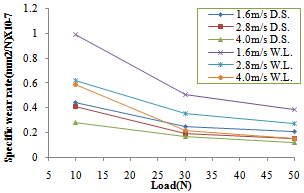

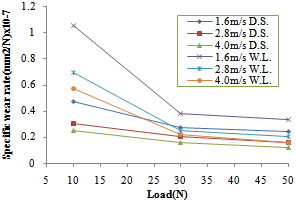

- Table 1 presents the detailed compositions of the materials taken for studies, test conditions and parameters considered for experimentation scheme. Figures 2-5 present the variation of coefficients of friction with applied normal load values (10, 30 and 50N) at different sliding speeds of (1.6, 2.8 and 4.0 m/s) under dry and water lubricated sliding conditions of pure vinylester sample A, composite samples B (vinylester+50wt% GFR), C (vinylester+50wt% GFR+Fly ash10wt%) and D (vinylester + 50wt% GFR+Fly ash 20wt %). Similarly the Figures 6-9 show the variation of specific wear rate with applied normal load values (10, 30 and 50N) at different sliding speeds of (1.6, 2.8 and 4.0 m/s) under dry sliding and water lubricated sliding conditions for pure vinylester sample A, composite samples B, C and D respectively. Figure 10 presents the SEM pictures of worn surface of composite samples B, C and D at applied normal load of 50N and sliding speed of 4.0 m/s under dry and water lubricated sliding conditions.From Figures 2-5 it is seen that coefficients of friction decreases with increase in applied normal load for pure vinylester and its composites at sliding speed of (1.6, 2.8 and 4.0m/s) both under dry and water lubricated sliding conditions. Under dry sliding conditions increasing applied normal load and sliding speed, increases the temperature at the interface.

| Figure 2. Coefficient of friction Vs applied normal load for sample-A at sliding speeds 1.6, 2.8, 4.0m/s under dry sliding conditions (D.S.) and water lubricated (W.L.) conditions |

| Figure 3. Coefficient of friction Vs applied normal load for sample-B at sliding speeds 1.6, 2.8, 4.0m/s under dry conditions (D.S) and water lubricated (W.L.) conditions |

| Figure 4. Coefficient of friction Vs applied normal load for sample-C at sliding speeds1.6, 2.8, 4.0m/s under Dry sliding conditions (D.S.) and water lubricated (W.L.) conditions |

| Figure 5. Coefficient of friction Vs applied normal load for sample-D at sliding speeds 1.6, 2.8, 4.0m/s under dry conditions (D.S.) and water lubricated (W.L) conditions |

| Figure 6. Specific wear rate Vs applied normal load for sample-A at sliding speeds 1.6,2.8,4.0m/s under dry sliding conditions (D.S.) and water lubricated (W.L.) conditions |

| Figure 7. Specific wear rate Vs applied normal load for sample-B at sliding speeds 1.6, 2.8, 4.0m/s under dry sliding conditions (D.S.) and water lubricated (W.L.) conditions |

| Figure 8. Specific wear rate Vs applied normal load for sample-C at sliding speeds 1.6, 2.8, 4.0m/s under dry sliding conditions (D.S.) and water lubricated (W.L.) conditions |

| Figure 9. Specific wear rate Vs applied normal load for sample-D at sliding speeds 1.6, 2.8, 4.0m/s under dry sliding conditions (D.S.) and water lubricated (W.L.) conditions |

5. Conclusions

- The following conclusion can be drawn from the present study1. The coefficient of friction of vinylester (V), GFR vinylester composites and fly ash filled GFR composite decreases with increase in applied normal load under dry as well as under water lubricated sliding conditions. The coefficients of friction under water lubricated sliding conditions are lower than that of dry sliding conditions.2. The reinforcement of glass fiber and fly ash filler improves the wear characteristics of vinylester both under dry and water lubricated conditions. However pure vinylester has higher specific wear rate due to small mechanical properties.3. For pure vinylester under dry sliding conditions has the highest value of specific wear rate 2.29×10−7mm2/N at load 50N and sliding speed of 2.8 m/s. However the lowest wear rate is 0.12×10−7 mm2/N for vinylester composite D under dry sliding condition. The lowest value of specific wear rates under water lubricated conditions is 0.10x10-7 mm2/N for vinylester composite specimen B. 4. Pure vinylester, E-glass fiber reinforced vinylester and fly ash filled E-glass fiber reinforced vinylester composites show that specific wear rate is little influenced by the applied normal load and sliding speed but more influenced by environmental conditions from dry to water lubricated sliding conditions.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-Text HTML

Full-Text HTML